Research Article: 2021 Vol: 24 Issue: 6S

The Manufacture of Klong-Yao Isan (Isan Folk Long Drums) of the Ban Talat Klong - Yao Isan Production Group, At Ban Wai Subdistrict, Wapi Pathum District, Mahasarakham Province

Weerayut Seekhunlio, Mahasarakham University

Sayam Chuangprakhon, Mahasarakham University

Abstract

This research article presents the results of a study on “The Manufacture of Klong - Yao Isan by The Ban Talat Klong - Yao Isan Production Group at Ban Wai, Wapi Pathum, Mahasarakham”. which is part of the research report on “A Guideline of Making Isan Long-Drums by Using a Technique of Merging Woods Instead of the Pieces of Wood.” This research was qualitative. The data was collected by document and fieldwork data. The research instruments consisted of interviews and observatories. The data were analyzed and performed under the established procedures. According to the study, it found that the method of making the Isan traditional Isan Klong Yao started with the preparation of the wood. Wood trunks with a diameter of 10-13 inches and a length of about 1 meter were used to make a 9 '', 10 '', 11 '', and 12 '' Isan Klong Yao, respectively. The wood trunks were then machined with a wood lathe forming an Isan Klong Yao. Klong Yao can be divided into three parts: the upper part is cylindrical, the drum hip, and the drum end. To rake out the wood, the trunks were cored about 1 inch thick. Then make drum grooves, drum reeds, and decorations. For making the drumhead of Klong Yao, the hides used were dried cowhides that were obtained by stretching the cow rawhide in the sun, then measured the cowhide against the drum mouth to cut to a 2-inch-long shroud. Punched a hole to the drumskin and strapped leather cords to attach the drumskin to the Klong Yao, then put the string between the leather cord holes and the steel rods under the grooves. When the drumhead is finished, put the drum in the sun to dry out the drumskin. Once the drum is dry, use a knife to scrape off all the hair and sand the surface with sandpaper. And the last step is to re-tighten the drum string to make the drumskin firmed resulting in a better sound.

Keywords

Manufacture, Klong-Yao, Mahasarakham

Introduction

Long drums are the oldest instruments of the Isan people. Long drums are beaten for entertainment, celebration, or leading the procession, so the dancers follow the rhythm of the Isan style (Srisarakham, 1978). Isan people use long drums in processions of various traditions starting from traditions that occur in villages, villagers gather to bring long drums to perform such as the Kan Lon Parade, Phra Upakut, Naga Parade, Money tree Parade, Kathin ceremony parade (Chonpairot, 1983). In addition, long drums are brought to the merit-making festival of the month or Isan people call it “Heet Sibsong”, such as the fourth month, Boon Phawet parade, Nang Songkran parade, the sixth month, Boon Bang Fai parade, the eighth month the candle parade, the tenth month, Prasat Phueng parade, or other creative activities. Long drums are musical instruments that related to the Isan people’s lifestyle. They are not only used in the ceremonies around the twelve months but also use to play for fun on different occasions. They are also used to tell the time and signal in different situations (Pinkeaw, 2009). Therefore, the long drums are the musical instrument that has an important role in the community and the long drums band compose of other instruments such as Ramana (a one-ended drum or a tambourine), bath, small cymbals, cymbals, harp, bass, keyboard, etc.

The shape of the traditional Isan long drum almost everywhere is similar, that is, the head of the drum has a long round shape and the end looks like a large clay mortar. The inside is hollowed and the long drum face size is about 8-12 inches in diameter, the tail is shorter than the head, and the tip will bloom like a trumpet. It is popularly made from jackfruit wood. At present, large jackfruit trees are in short supply. Therefore, some drum makers use Chamcha wood or mango wood as a substitute for making a long Isan drum. These materials have not different sound, but still not enough to meet the needs because the long drum, when it used for a while, may break and be difficult to repair. As for the drum cover, it is popular to use dried cowhide that has not been tanned. Once the drums are hardened and the front of the drum is finished, dry the drum skins and use a sharp knife to scrape the outer skins to be cleaned until it is suitable thickness. The sets of Isan long drums always have a Klong-Tum (tambourine or a small, short, two-headed drum) that is indispensable. This tambourine drum face has a diameter of 16 inches or more. The drum body is short approximately 12-16 inches long, covered with leather on one side. When it is hit, there is a thumping sound. This drum has many names, such as the big drum, the Ramana drum, the tambourine drum, which is used to beat with the Isan folk long drum that has a high sound. It helps to make a low bass sound and a sweet melody. Each village usually has the Isan folk long drum kept at the temple and ready to be used at any time.

Nowadays, Isan folk long drums are widely used in Isan folk musical ensembles, in schools, both primary and secondary, and university levels in the Northeast and other regions as well (Santaweesuk, 2019). Isan folk bands must have at least four Isan folk long drums and one tambourine. Moreover, a traditional Isan long drum band must use at least eight long drums, however, it depends on the size and number of musicians in each band. It was found that the widely used long drum and done by a long drum maker in Mahasarakham Province (Kamhongsa, 2019; Silapachok, 2019; Jaksen, 2019). From this issue, the researcher was interested to study how to make traditional Isan long drums of the Ban Talat Klong drum production group, Ban Wai Subdistrict, Wapi Pathum District, Mahasarakham Province. Furthermore, it is the source of the traditional style of Isan folk long drums in Mahasarakham Province, which is an area with a large number of long drum troupes (Pimprajun, 2019). It has been promoted to be a province that organizes “the Folk Long Drum Fair” every year. This is area was a source for research studies and data collection to continue the work of art and culture, and to apply for the benefit of academic circles and communities including as a guideline for making Isan folk long drums.

Research Objective

To study the methods of making Isan folk long drums of the Ban Talat long drum production group, Ban Wai Subdistrict, Wapi Pathum District, Mahasarakham Province.

Literature Review

Tammawat (1995) said that indigenous wisdom refers to the process of intellect, thinking, to seek the body of knowledge in the local community. It shows the current relationship between nature, mind, and behavior, society, organization and culture, community, economy, production technology, and finally self-reliance.

Tabtimtong (2001) studied the condition of existence of long drums troupes at Wapi Pathum District, Mahasarakham Province. It found that the Wapi Pathum Long Drum Troupe developed into three periods, the first being unformed because it started from the cheerful and fun nature of the villagers mixed with belief and faith that take long drums to the parade. In addition, they not only get entertainment, but they also received a merit. The second period is the tradition. Pinkeaw (2009) studied “The long drum band of the Luk Somphit Sitchusin, Na Nua Sub-district, Nam Som District, Udon Thani Province”. It found that there are seven styles, rhythms, and patterns of long drum playing: Lai Sarakham, Lai Hae, Lai Pong Ching, Lai Sao, Lai Sadoet, Lai Phu Thai, Lai Thai Yai, and Lai Sing. The rhythm of the long drum was brought from three patterns of Mahasarakham Province, namely Lai Sarakham, Lai Hae, and Lai Thai Yai, while the other 4 patterns and the style of playing drums are all created by themselves.

Itsaranuwat (1999) studied “the Long drums of people in Sri Somdet district, Roi Et Province”. It found that in making long drums, tools must be prepared, which are wood, saw, cowhide, ax, knife, pimple, curved steel (must), steel, lathe, sanding rasp, and rough rasp. The diameter of the drum face was about 22-24 cm and length 80-87 cm. Santaweesuk, et al., (2003) studied “Principles of basic mechanics and techniques for making Isan folk instruments.” It aimed to study the factors affecting the quality of each Isan folk instrument and analytical study the materials used to make Isan folk instruments. The study found that the basic mechanics and methods of making Isan folk instruments were found in three provinces, namely Mahasarakham Province, Kalasin Province, and Roi Et Province. It has not much different in making Isan folk musical instruments. The key factor in sound quality is the quality of the materials used, such as the quality of the wood, the quality of the leather, and the experience of the craftsman.

Karin (2017) researched “the development of the performance of a long drum band in Mahasarakham Province.” It was qualitative research. Research methodology in ethnomusicology was used for two purposes: to analyze the form of long drum performance in Mahasarakham Province, and to find concepts for the development of long drum performances in Mahasarakham Province. The researcher collected data mainly from the fieldwork from artists and experts. It was then used for descriptive analysis. The styles of long drum performances in Mahasarakham Province consist of three styles: 1. Traditional, 2 Applied, and 3 competition styles. Champadaeng (2018) studied “The Long drums in the culture of the people of Wapi Pathum District, Mahasarakham”. The results showed that the long drum played of Wapi Pathum District residents, Mahasarakham Province has been born since ancient times and has been passed down through generations. Then it became very popular when there was the long drums contest in “On-Sorn Klong Yao of Wapi people: the Good Local Products Fairs” in 1996, etc. onwards.

Sachs (1968) studied “the origins of musical instruments or percussion instruments.” It starts from the movement rhythmic body, foot-stomping, clapping hands, knee-slapping, hip stomping, and other body parts in dancing. It also includes the use of various materials from nature to make various types of percussion instruments such as shakers, percussion instruments, rams, beating instruments, and various types of drums, in which the Northeastern region, where drums can be attributed to the harp play. Macedan (1981) studied “techniques and theories in the field of musicology”. He collected data in fieldwork focusing on rural music of different localities in Southeast Asia. It is not related to the music in the various courts, techniques that are mentioned in the use of instruments. Systematic reporting of information acquired the ethnomusicological data and various technical music information.

Research Methodology

A study on “the Manufacture of Klong - Yao Isan (Isan Folk Long Drums) of The Ban Talat Klong - Yao Isan Production Group, At Ban Wai Subdistrict, Wapi Pathum District, Mahasarakham province”. The researcher used ethnomusicology qualitative by collecting data from documents, fieldwork data, observing, and interview. Then the researcher took all the data for analysis with a descriptive and analytical presentation with the following steps:

SCOPE OF RESEARCH

• Research Area: Ban Talat, Ban Wai Sub-district, Wapi Pathum District, Mahasarakham Province

• Duration In this study: the researcher spent time between May 2009 and May 2020.

• The sample population

• Knowledge group uses purposive sampling who are five academics and teachers in the educational institutions

• Group of practitioners are four representatives from Isan folk long drum makers and Long drum production group of Ban Talat, Ban Wai Sub-district, Wapi Pathum District, Mahasarakham Province,

• General people are ten representatives from the group that provides general information about traditional Isan folk long drums.

Collection of information from related documents and research focusing on the study of making traditional isan folk long drums. The study was conducted from various sources as follows:

• Office of Academic Resources of Mahasarakham University

• Online and international databases

Fieldwork data collection: The researcher has collected fieldwork data from individuals and agencies involved in various fields to connect the data from related studies, documents, and research. The researcher selected information related to the manufacture of Isan folk long drums of the long drum production group, Ban Talat, Ban Wai Subdistrict, Wapi Pathum District, Mahasarakham Province. The method of observation and interview are as follows:

• Interviews: The researcher used a structured interview in which the researcher has prepared questions and an unstructured interview that the researcher used a general conversation style and interviewed about the process, how to make traditional Isan folk long drums.

• Observation: The researcher used participant observation. The researcher observed the Isan folk drum making method as well as practice making traditional Isan long drums with craftsmen. For non-participant observation, the researcher made observations on wood selection techniques, turning, drilling, and skinning of Isan folk long drums.

• Data recording: The researcher recorded the data from the fieldwork as follows: 1) record it in a notebook and a laptop; 2) record sound with a digital computer; 3) record still images with a digital camera; and 4) record motion pictures with a digital camera.

Data Processing and Data Analysis

After the researcher has collected the data, the researcher divided the data into three parts: the first part was the preparation of the wood, the second part is woodturning and wood coring, and the third part is leather preparation and skinning of Isan folk long drums.

Data Analysis and Presentation

The researcher presents the results of the data analysis that are concisely summarized according to the objectives of the research and presents the research results by descriptive analysis.

Research Results

The researcher studied the fieldwork data by studying the process and the method of making traditional Isan folk long drums. The craftsmen used log sticks which is similar to a traditional method for making folk long drums at present. The researcher had the fieldwork at Ban Talat, Ban Wai Sub-District, Wapi Pathum District, Mahasarakham Province by interviewing and observing a group of craftsmen. The manufacture of Isan folk long drums can be divided into three parts of processes and methods as follows:

Wood Preparation

Selection of wood: The wood which is popular for making drums uses locally available wood such as jackfruit, mango, and Chamchuree. When the wood is selected, it was sawn into pieces of approximately 1 meter in length, and the diameter of the heartwood is about 10-13 inches. The wood for making long drums is used in pieces without processing.

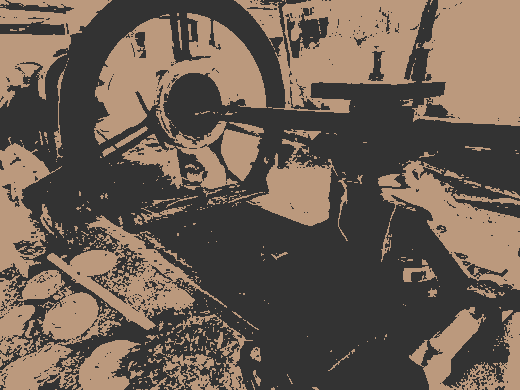

Wood Turning and Wood Coring

The craftsmen form an external long drum before turning the wood by using an ax to cut the bark out to make it easier to turn the drum body. Then they have to drill holes in the center of the log on both sides as a point of attachment of wood to the lathe in forming long drums. The length of the hole size is about 5 centimeters and the width is about 2 centimeters, which the turning devices are materials adapted from general carpentry tools such as a sharp turning knife, a grooving knife, a lathe knife for a drum waist, a pattern lathe knife. In the process of turning long drums, it requires skill to do by using a lathe with an electric motor drives the drum to spin. Then, craftsmen use a sharp turning knife lying against the support beam on the lathe and allow the ends of the knife to contact the lumber little by little throughout the lumber. After getting the logs of the desired size, craftsmen start doing the waist and the end of the drums beautifully. When it finished turning, should be sawed the header and the end of the long drum for the drilling platform in the next order.

The proportion of the long drum can be divided into three parts: 1) the upper part is cylindrical, 2) the drum waist part is turned to a depth of about 1 centimeter from the upper part to attach a steel rope to accelerate the long drum skin, and 3) the end of the drum resembles a loudspeaker and the end part has the same diameter as the top part. The length of each part depends on the diameter of the finished long drum face as follows:

• Drum diameter, length 9 inches, upper length 12 inches, length of drum waist 10 inches, and rear length 9 inches.

• Drum diameter, length 10 inches, upper length 13 inches, length of drum waist 11 inches, and rear length 10 inches.

• Drum diameter, length 11 inches, upper length 13 inches, length, length of drum waist 12 inches, and rear length 11 inches.

• Drum diameter, length 12 inches, upper 14 inches, length of drum waist 13 inches, and 12 inches rear length.

Drilling inside the drum: craftsmen take the finished long drum to the wood chisel along with the head and rear, keeping the drum body hollow and the edges approximately 1 inch thick.

Making a drum tongue from the mouth down about 2 inches, make a drum tongue by drilling it with a slope and make the mouth as thin as possible.

Decorating the drum body: craftsmen may need to fill the cracks or wood-eating insect marks by using sawdust powder mixed with glue and then applied to fill the cracks of the long drum.

Chopping grooves (throwing the rope up the front of the drum): The distance of the holes is approximately 1 inch, 29 holes. When the grooves are chopped, leave the long drum in the shade for 1-2 weeks to allow the wood to dry. The reason for not putting it in the sun, it may make the wood crack and warp.

Smoothing the drum surface by sanding with sandpaper which craftsmen have to take long drums to the lathe platform again and turn on the lathe to make the long drum spin, and use sandpaper to smooth the drum. Then craftsmen coat the primer with lacquer and let it dry. After that, they are coated with urethane to have a beautiful appearance.

Preparing the Skin and Making the Skin of Isan Folk Long Drums

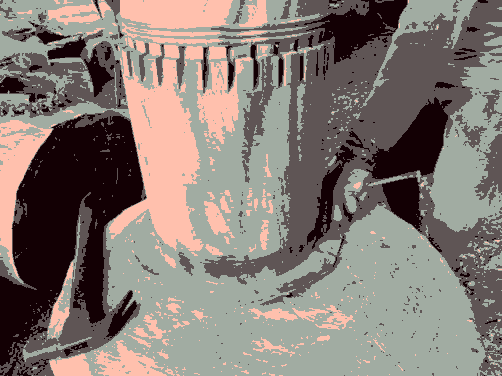

Selection of drum skins: The leather used is cowhide. If you want to get good quality, it must be 2 years old up a female cowhide, and stretched with a wooden frame. After that, they put it in the sun to dry for 2-3 days.

Cutting the drum skin: craftsmen brought the drum skin laid on a flat surface and put the Long drums on the leather. Then they use a pencil or pen to draw along the drum's mouth and cut the leather according to the outlined pattern by leaving the covering part coming down from the mouth about 2 inches.

Softening of the leather by soaking the leather in water for about 12 hours to make the soft leather and remove the cow hair, and then craftsmen beat it with wood by placing the leather on a non-hard ground. They use a hammer to pound the leather all over. After that, they bring the long drum laid on the leather, scratched with a pen again, and measure the distance of the leather drum hole.

Punching the leather according to the outlined pattern of pen marked which is measured by the number of holes in the drum ropes. The spacing of each hole is approximately 1 inch, using the chisel to drill vertically and horizontally which vertically lead the chisel to drill outside the circle line and horizontal drill about 1 inch apart from the vertical holes.

Stringing the leather drum: craftsmen use 1 nylon rope to measure around 3 circles, which is the same type as the long leather drum rope. The craftsmen stretch the string between the long leather drum string and the hole under the steel and circle around the long drum until all holes. The recommendation for stringing the rope to accelerate the sound, it must be threaded as the leather is wet so that when the leather dries, the leather of the drum will be tight enough. Stringing the rope can be done as follows.

Round 1: It will be threaded out in the hole no. 1,5,9,13,17,21,25,29

Then it will be threaded into the hole no. 4,8,12,16,20,24,28,3

Round 2: It will be threaded out in the hole no. 2,6,10,14,18,22,26

Then it will be threaded into the hole no. 5,9,13,17,21,25,29

Round 3: It will be strung out in the hole no. 3,7,11,15,19,23,27

Then it will be threaded into the hole no. 6,10,14,18,22,26,1

Stretching the skin of the long drum, the hairy side must be removed from the outside. When the drum skin is finished and brought the drums are dry in the sun. Craftsmen must remove the hair with a knife and use sanding paper to smooth the surface evenly. Then they take the drum to look at the sun by shining from the end of the drum to the drum skin. They must check which part of the drum skin is thinner. If the leather is uneven, sandpaper must be sanded until the thickness is the same, and the last step is to re-tighten the drum string to make the drumskin firmed resulting in a better sound. This is the completion of making traditional Isan long drums of the Ban Talat long drum production group, Ban Wai Sub-district, Wapi Pathum District, Mahasarakham Province.

Results Discussion

The manufacture of Isan folk long drum of the Ban Talat long drum production group, Ban Wai Sub-district, Wapi Pathum District Mahasarakham Province use locally-available wood such as jackfruit, mango, and Chamchuree. It is machined, molded, and punched into a hollow inside, so it is made with single-faced leather. It corresponds to Thanit Yoopho that mentions the long drums as follows: the drum is made with single-faced leather and it is made of real wood such as mango wood. The front part is large; the end looks slender, and then escalates into the shape of a loudspeaker. There are many sizes and some drum faces size is about 21 centimeters wide, stretching from the face of the drum reaches its rear approximately 75 centimeters (Qupho, 1967). It is consistent with the research of Ranjan Isara-Nuwat “Long drums of the people of Sri Somdet District, Roi Et Province. It found It found that in making long drums, tools must be prepared, which are wood, saw, cowhide, ax, knife, pimple, curved steel (must), steel, lathe, sanding rasp, and rough rasp. Then the craftsmen start to make the long drums as follows: The diameter of the drum face was about 22-24 cm and length 80-87 cm. Then cut into a drum puppet and bring it to the lathe to be clean. After that dig inside to make a hole and polish the surface to be smooth, paint and polish the leather sheet to drill holes and cover the drum body. The craftsmen use a knife to scrape off the cow's hair, decorate, and test the sound to make every sound the same (Itsaranuwat, 1999). The manufacture of long drums is the wisdom of invented villagers, so they can bring long drums to play in the merit tradition to connect the culture that occurs in that community very well. This is consistent with Jaruwan Thammawat's explains that the concept of local wisdom transfer refers to the process of intellect and thinking to seek the body of knowledge in the local community. It shows the current relationship between nature, mind, and behavior, society, organization and culture, community, economy, production technology, and finally self-reliance (Tammawat, 1995).

The manufacture of Isan folk long drum of the Ban Talat long drum production group, Ban Wai Sub-district, Wapi Pathum District Mahasarakham Province, has no much different methods, but it depends on the equipment of the craftsman and refinement of each craftsman from the selection of wood, woodturning, wood drilling, and the making of Isan folk long drum skins. These are consistent with the research of Piyaphan Saenthaweesuk et al. studied “Principles of basic mechanics and techniques for making Isan folk instruments.” It aimed to study the factors affecting the quality of each Isan folk instrument and analytical study the materials used to make Isan folk instruments. The study found that the basic mechanics and methods of making Isan folk instruments were found in three provinces, namely Mahasarakham Province, Kalasin Province, and Roi Et Province. It has not much different in making Isan folk musical instruments. The key factor in sound quality is the quality of the materials used, such as the quality of the wood, the quality of the leather, and the experience of the craftsman. It also gave the suggestions that it should be studied in the techniques of making Isan folk instruments to cover the entire northeastern region. It should encourage a contest to make Isan folk instruments, and it should be encouraged to have the Isan folk instrument craftsman exchange knowledge. n the making of Isan folk instruments between craftsmen in each area, resulting in the development and learning of each other (Santaweesuk et al., 2003).

In addition, the long drums produced by the Ban Talat long drum production group, Ban Wai Sub-district, Wapi Pathum District Mahasarakham Province, are used in processions in various traditions. It also found that traditional Isan long drums were used in school music activities, teaching in the curriculum of many higher education institutions, including the On-Sorn Long Drums of Wapi Pathum Fairs are held every year. There are many long drum bands in Mahasarakham Province participated and there is also a long drum contest for the Royal Cup. It is broadcast live in various online media to make people know more about Isan folk long drums. As a result, it is the dominant identity of Mahasarakham Province. It corresponds to the research results of Komkrit Karin studied “The development of long drum performances in Mahasarakham Province”. The styles of long drum performances in Mahasarakham Province consist of three styles: 1. Traditional, 2 Applied, and 3 competition styles. For the concepts of the performing development, the traditional style should be reserved, but the applied and competition styles can be developed in details of performance focusing on entertainment, beauty, harmony. There are important principles but look at the suitability of the location as well. Moreover, it focuses on the concepts of performance for the competition style (Karin, 2017). It is also consistent with the research of Sittisak Champadang, “The Long drums in the culture of the people of Wapi Pathum District, Mahasarakham”. The results showed that the long drum played of Wapi Pathum District residents; Mahasarakham Province has been born since ancient times and has been passed down through generations. Then it became very popular when there was the long drums contest in “On-Sorn Klong Yao of Wapi people: the Good Local Products Fairs” in 1996, etc. onwards. The present conditions of playing and cultural competitions affect the economy, society, and Culture in Wapi Pathum District, Mahasarakham Province (Champadaeng, 2018).

Conclusion and Recommendation

A study of “The manufacture of Isan folk long drum of the Ban Talat long drum production group, Ban Wai Sub-district, Wapi Pathum District Mahasarakham Province”, can be summarized as follows: 1) Preparation of wood: the wood that is popularly used to make drums uses locally available wood such as jackfruit, mango, and Chamchuree. It should be sawn into pieces of approximately 1 meter in length and diameter only about 10-13 inches of heartwood, which is used as a piece of wood without processing. Before turning the wood by using an ax from the bark to make it easier to form the drum 2) Woodturning and wood coring is a material adapted from general carpentry tools. After the logs of the desired size have been placed, start turning the waist and the end of the drum beautifully. When finished from turning, the long drum has been machined into a chiseling machine throughout the head and rear. The drum body is hollow and the edge is approximately 1 inch thick. The decoration of the drum body may need to be filled the cracks and insect marks. Chopping grooves (threaded holes in front of the drum) and holes distance approximately 1 inch at 29 holes. Smooth the surface of the drum by sanding with sandpaper to smooth the drum. Coat the foundation with lager and leave until dry. After that, coated with polyurethane to make it beautiful. 3) Preparing the skin and making the skin of Isan folk long drum use cowhide. If you want to get good quality, it must be 2 years old up a female cowhide, and stretched with a wooden frame. After that, put it in the sun to dry and cut the leather according to the size of the drum face. Next craftsmen make leather soft and punched holes in the leather, string to attach the drum skin to the long drum by bringing a string which is between the long leather drum string and the sloping hole under the iron. Then they strung it around the long drum until all holes are made. To stretch the skin of the long drum, the hairy side must be removed. When the skin of the drum is finished, the long drum is exposed to the sun to dry the skin. Take a knife to scrape off all the feathers and use sanding paper to rub the surface to be smooth and even, and the last step is to re-tighten the drum string to make the drumskin firmed resulting in a better sound.

Recommendations can be as follows: 1) Suggestions for utilizing the research results 1.1) Methods and processes of Isan folk long drums should be transferred to the Isan folk musical instruments craftsmen to have understanding and expertise. 1.2) There should be support for making Isan folk long drums which is the curriculum of musicology. 2) Proposals for the next research 2.1) There should be an experimental study to modify the method of sticking to the traditional Isan long drum skins. to a universal style that can adjust the sound faster and easier. 2.2) There should be a study of making folk long drums with other techniques to bring synthetic materials and can make long drums faster.

Acknowledgments

This Research Project Received Research Funding from Thailand Science Research and Innovation (TSRI). Corresponding author: Sayam Chuangprakhon, College of Music, Mahasarakham University, Thailand. E-mail: sayam.c@msu.ac.th

References

- Jarernchai, C. (1983). Isan Folk Music. (1st edition). Mahasarakham : Department of Music Srinakharinwirot University.

- Jaruwan, T. (1995). Analysis of Isan wisdom. (1st edition). Mahasarakham. Mahasarakham University.

- Khomkrich, K. (2017). The development of the performance style of the long drum band in Mahasarakham province. In the research report. The Thailand Research Fund.

- Maceda, J. (1981). A manual of a field music research with special reference to Sonthes Asia. Philippiness : College of Music, University of the Philippiness.

- Pipop, P. (2009). Som-pit Sit-chu-silp Long drums Band Na-Ngua Subdistrict, Nam-Som District, Udon Thani Province. Master of Fine Arts Thesis, Mahasarakham University.

- Piyapan, S. et al., (2003). Principles of basic mechanics and techniques of making Isan folk instruments. In the research report. Mahasarakham University.

- Pornchai, S. (1978). Isan folk Long drum. In Isan, the case of the Isan Heritage knowledge book series. (145-149). Mahasarakham : Rajabhat Mahasarakham University.

- Runjorne, I. (1999). Long drums of the people of Sri Somdet District Roi Et Province. Master of Arts Thesis, Mahasarakham University.

- Sachs, C. (1968). The history of musical instruments. New York: W.W. Norton.

- Sayam, C., & Weerayut, S. (2020). On a guideline of making isan long-drums by using a technique of merging woods instead of the pieces of wood. Bangkok : Thailand Science Research and Innovation.

- Sitthisak, C. (2018). Long drums in the culture Ways, Wapipathum district Mahasarakham province. Journal of Fine and Applied Arts Khon Kaen University, 10(1), 91-109.

- Sombat, T. (2001). The existence of the Long drums band Wapi Pathum District, Mahasarakham Province, Master of Arts Thesis, Mahasarakham University.

- Tanit, O. (1967). Thai musical instruments. (2nd edition). Bangkok: Siwaphon Publishing