Research Article: 2017 Vol: 16 Issue: 2

The Main Economic Factors of Sustainable Manufacturing within the Industrial Policy Concept of Industry 4.0

Vladislav Genrihovich Frolov, N. I. Lobachevsky State University of Nizhny Novgorod

Dmitry Igorevich Kaminchenko, N. I. Lobachevsky State University of Nizhny Novgorod

Dmitry Yuryevich Kovylkin, N. I. Lobachevsky State University of Nizhny Novgorod

Julia Alexandrovna Popova, N. I. Lobachevsky State University of Nizhny Novgorod

Angelina Alexandrovna Pavlova, N. I. Lobachevsky State University of Nizhny Novgorod

Keywords

Industrial Production Development, Industrial Policy, Industry 4.0, SWOT-Analysis, Economic Factors, Learning Factories, Customized Goods, Added Value.

Introduction

One of the most important tasks of modern Russian economy is to increase competitiveness of products of various industries. It implies the need to implement the specific steps that are connected with improving of natural, material and labor resources use efficiency, increasing labor productivity and the number of the high-performance workplaces, rapid development of Russian production and scientific and technical potential, etc. Such tasks must be carried out with regard to the emerging global trends in industrial production development. In particular, the concept of the so-called Industry 4.0 is gaining popularity. It has already proved its significance in the rise of development efficiency of various industries in different countries.

Industry 4.0 was initially developed by German Government in order to create coherent policy framework and to maintain industrial competitiveness of the country. There are related features which are used internationally: Internet of Things (IOT), Internet of Services, Industrial Internet, Advanced Manufacturing and the concept of Smart Factory. Once it is successfully implemented, the potential benefits of Industry 4.0 will relate to productivity gains, revenue growth and competitiveness. The implementation horizon is to have pilots running in 2016 and full implementation by 2025 (Smit, Kreutzer, Moeller & Arlberg, 2016)

Industry 4.0 describes the organization of production processes which are based on interacting technologies and devices: A model of future ‘smart’ factory where the computer-driven systems control physical processes and make decentralized decisions which are based on the self-organization mechanisms.

The German Government has institutionalized its commitment to Industry 4.0 by setting up a platform led by Ministries of Economy and Research that was brought together by representatives from business, science and trade unions. The platform Industry 4.0 itself has divided its main areas of focus across five different working groups up: Reference Architecture; Standardization; Research and Innovation; Networked systems security; Legal environment; and Work, Education/Training (Industry 4.0, n.d.).

In 2014 the National Technology Initiative was created in Russia. It was aimed at developing strategically important industries and shaping future and prospective markets. Nine markets such as AeroNet, AutoNet, MariNet, EnergyNet, NeuroNet, SafeNet, HealthNet, FoodNet, FinNet which are called “markets of the future” and a technological group for development of advanced production technologies-TechNet were also established (Industrial Internet of Things, 2016).

The road map called TechNet has cross-market and cross-sectoral nature in the framework of the National Technological Initiative organization. It provides technological support for future markets development and high-tech companies through development of advanced production technologies, both within the market and through cross-industry technology transfer. Therein close cooperation of the TechNet group with the prospective markets of the future (which are currently in process of development) is planned.

The purpose of the roadmap is to create new generation of productions such as “Factory of the Future”: Digital (Smart)/Smart (Virtual). The key task of TechNet is to implement projects that are aimed at developing advanced production technologies and increasing their effective use in the industry, creating distributed regional and sectoral network of future functioning factories, formatting new testing and standardization systems and at developing a system for engineers’ and other technical staff training at a new modern level.

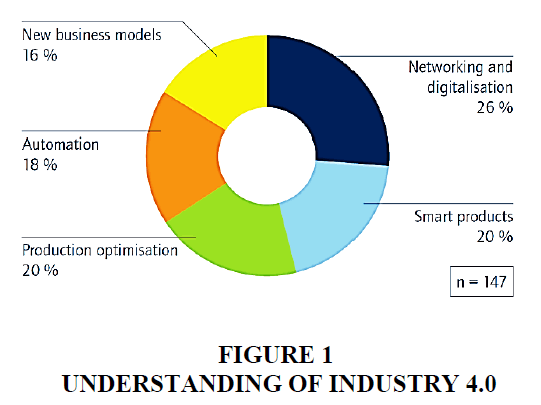

Understanding of Industry 4.0 concept is constantly evolving due to the high level of activities and constant development of new approaches, concepts and solutions from the side of businesses and research institutions. Many countries stick to a very similar position in understanding of Industry 4.0 concept, despite the differences in their specific focus. The term Industry 4.0 has also become established as a global brand. The experts from different countries primarily associate Industry 4.0 with networking and digitalization as shown on Figure 1 (Kagermann, Anderl, Gausemeier, Schuh & Wahlster, 2016).

There are no doubts that the above mentioned steps in the framework of Industry 4.0 concept can lead to solving one of the most important targets in Russia: To increase competitiveness of products in different industries. At the same time, the key issue is how to implement such events in Russian economy. For example, how exactly should the interaction of Government, business and research institutions can be organized? This question indicates the need to develop such strategies which will include the basic mechanisms of implementing the main aspects of the concept of Industry 4.0 in specific Russian economy. Moreover it is expediently to analyze the economic factors of industrial production in Russia in the framework of the Industry 4.0 concept. One of the present paper targets is to explore it.

It’s obvious, that the factors’ study which influence industrial production development is one of the most pressing and topical issues in economics. Economic, social, technological, political and other factors that have serious impact on industrial production in conditions of Industry 4.0 have been thoroughly studied in a great variety of papers written by foreign and Russian authors.

The increasing complexity of organization in the manufacturing system cannot be managed by a centralized form and decision making processes can be “shifted away from a central instance towards decentralized instances” (Smit, Kreutzer, Moeller & Arlberg, 2016). Decision making processes are “becoming increasingly complicated as a result of an enormous number of alternatives and multiple conflicting goals” (Tonelli, Demartini, Loleo & Testa, 2016.).

Smit, Kreutzer, Moeller & Arlberg analyzed general strengths and weaknesses, opportunities and threats which are related to Industry 4.0 for European manufacturers (Smit, Kreutzer, Moeller & Arlberg, 2016). Maksyutina & Golovkin studied an opportunity of the innovative growth and expansion of 3D-printing technology development in the large industrial enterprises (Maksyutina & Golovkin, 2016). Chebotarev, Chebotarev & Zhurenko explored the relevant aspects of industrial and technological policies that are related to technological restructuring of a production sector on the principles of the fourth industrial revolution (Chebotarev, Chebotarev & Zhurenko, 2016). Khusnullova & Absalyamova examines the socio-economic consequences of the Fourth Industrial Revolution (Khusnullova & Absalyamova, 2016). Automation of the decision-making process for improving of the business competitiveness allows you to build sustainable competitive advantages, strengthen the market position and increase the value of the business. This is achieved through the uniqueness of implemented innovative technologies. (Kuznetsov et al., 2017). S.R. Smirnov presents options for management development under influence of the fourth industrial revolution (Smirnov, 2016).

On the basis of analysis of available papers and documents on the designated topic it has become possible to conclude that in general authors highlight distinct factors that are the most crucial for manufacturing under Industry 4.0: Decision making process effectiveness; staff training; small and medium enterprises attitude to Industry 4.0 processes; manufacturing processes complication; new digital market models and relations emergence; production automation et al. Within the framework of this paper it has been planned to carry out in depth analysis of the key economic factors of manufacturing production under Industry 4.0 on the basis of statistical and publicly accessible data.

Our research is aimed at a detailed analysis of internal and external economic factors in the development of industrial production: Strengths, weaknesses, opportunities, threats related to Industry 4.0 in the context of Russian industrial policy. Most studies in the sphere of the industry of 4.0 are aimed at assessing of the features and effects of digital transformation of high-tech competitive manufacturing enterprises (usually European), with a high degree of automation of production and strong industry (cluster) connections. The relevance of this study is determined by the need for a systematic assessment of the economic factors of the development of Russian manufacturing enterprises within Industry 4.0, which are characterized by a strong differentiation in terms of economic status and automation.

The rest of the paper is organized as follows. Section 2 describes the use of SWOT-analysis in order to achieve the goals of the paper as well as substantiates the validity and reliability of chosen methodology. In Section 3 there is description of SWOT-analysis performance: The process of filling the main fields and SWOT-analysis matrix construction. Section 4 brings out the most significant economic factors in development of industrial production in Russia in conditions of Industry 4.0 (increased productivity and profitability of production, the rise of collaboration effectiveness between the economic entities). Section 5 includes the general conclusions about new economic opportunities and threats for Russian industrial complexes under Industry 4.0. In Section 6 the list of references is pointed out.

Methodology

SWOT-analysis is a strategic planning method that enables to identify internal and external factors of environment. SWOT-analysis is a preliminary research phase in preparation of the manufacturing development strategic plans and in the process of strategic goals elaboration in the framework of Industry 4.0. This method is versatile in the process of already established factors generalization as well as in identifying new ones. It enables examining the issue of manufacturing development, both at the level of specific economic entities and at the level of complex economic systems.

The general idea of SWOT-analysis application is to determine, how each of the possible manufacturing development ways in the framework of Industry 4.0 concept will be able to affect success of strategic processes in the Russian industrial enterprises. In present paper the following four elements of SWOT-analysis will be considered: Strengths- Resource or capacity that can be effectively used by organization in order to achieve objectives; Weaknesses: Limitation, fault or defect in organization that will keep it from achieving of objectives; Opportunities: Any favorable situation in organization’s environment; Threats: Any unfavorable situation in organization environment that is potentially damaging to its strategy. The industrial strategy for Russian manufacturing under concept Industry 4.0 will be suggested in the result of this research.

The economic factors of SWOT-analysis were identified on the base of statistical and publicly accessible data, an extensive literature review and expert questionnaire-based field method as well.

The managers of industrial enterprises and scientists of Lobachevski State University of Nizhny Novgorod were interviewed in the course of paper preparation. The interviews have included the different specific questions about the factors of Russian industrial production development under in conditions of the fourth industrial structure.

Based on the established factors the matrix of SWOT-analysis was constructed. In this matrix four thematic fields were highlighted. One field shows what kind of strengths must be used in order to get the advantages from the opportunities of environment. Other field displays how the organization will be able to overcome existing weaknesses due to the environment opportunities. One more field indicates which forces should be used in order to eliminate threats. Finally, one more field shows from which weaknesses is necessary to get rid of in order to try to prevent from imminent threat.

Through construction of the matrix strategies for industrial production development in Russia in the framework of Industry 4.0 concept were proposed. It was the important step to the establishment of the main factors for sustainable manufacturing within the framework of Industry 4.0. Such way of research goal achievement confirms the reliability of the study. In its turn, validity of SWOT-analysis use in the paper is that this methodology allows completing the concrete task of the research, connected with development of industrial production strategies in Russia in the framework of concept Industry 4.0.

Results

Strengths, weaknesses, opportunities and threats that are related to the economic aspects of manufacturing development in the framework of concept Industry 4.0 are given in the following tables (Tables 1, 2, 3 and 4).

| Table 1: Strengths Of Manufacturing Development In Russia In The Framework Of The Industry 4.0 Concept |

|

| Strengths | |

|---|---|

| S1 | Increased productivity. Productivity: With regard to the opinions of the foreign scientists productivity improvements of between 15-25% excluding material costs and 5-8% including materials costs. The greatest benefits are expected in industrial components and automotive (Russman, Lorenz, Gerbert, Waldner, Justus, Engel & Harnisch, 2015) |

| S2 | A higher level of profitability |

| S3 | Reduction of production costs |

| S4 | Industrial production growth |

| S5 | Competitiveness of industrial enterprises (high-tech products) |

| S6 | Reduction of production cycle |

| S7 | Increase of shareholder value in enterprises |

| S8 | Availability in Russia of the IOT platforms for collecting, storing and processing data, both at global and national levels (Industrial Internet of Things, 2016). |

| S9 | Time increase of uninterrupted functioning of equipment and reduce its downtime |

| S10 | End-to-end automated management of product throughout its life cycle |

| S11 | Increasing role of learning factories |

| S12 | “A new kind of intelligent, connected and agile value chain” (Erol, Jager, Hold, Ott & Sihn, 2016) |

| S13 | Production of individual and customized goods |

| S14 | Increase the productivity of collaboration between structural departments |

| S15 | Decision making process decentralization |

| S16 | 6% increase in employment during the next 10 years (Russman, Lorenz, Gerbert, Waldner, Justus, Engel & Harnisch, 2015) |

Table 1 was composed by the authors on the basis of statistical, publicly accessible data, interviews of Russian experts.

| Table 2: Weaknesses Of Manufacturing Development In Russia In The Framework Of The Industry 4.0 Concept |

|

| Weaknesses | |

|---|---|

| W1 | Employment: This is a controversial area as in the past automation and technological advances have at times led to reduction in employment, at least in the short term. Boston Consulting Group (here and after-BCG) expects a 6% increase in employment during the next 10 years but their caution is that different skills will be required and that some low-skilled workers may be displaced by machines while others such as mechanical engineers, software developers and IT experts will be in great demand (Russman, Lorenz, Gerbert, Waldner, Justus, Engel & Harnisch, 2015) |

| W2 | “High dependence on resilience of technology and networks small disruptions can have major impacts” (Smit, Kreutzer, Moeller & Arlberg, 2016) |

| W3 | Dependence on a number of factors (Technological standards, labor supply with relevant skills, investment and scientific research) |

| W4 | Significant cost of technologies development and introduction |

| W5 | Increasing complexity of decision making (Decision making processes are “becoming increasingly complicated as a result of an enormous number of alternatives and multiple conflicting goals”) (Stock & Seliger, 2016) |

| W6 | Potential loss of control over enterprise |

| W7 | Ineffective ownership structure for cooperation of industrial enterprises |

| W8 | Weak intersectoral ties between industrial enterprises |

| W9 | The low susceptibility of business structures to technological innovations |

| W10 | Insufficient development of the system of public-private partnerships in the implementation of innovative projects-the share of organizations that are received funding from the budget for these purposes is 0.8 percent (in Germany-8.8 percent, in Belgium-12.7 percent) (Smit, Kreutzer, Moeller & Arlberg, 2016) |

| W11 | The investment scale. Not a sufficient share of investment in the GDP of the Russian Federation-is about 17%. It is necessary to have more than 30 % of investment in order to achieve sustainable development of industrial enterprises (Industrial Internet of Things, 2016). |

| W12 | The wear of main production founds of industrial enterprises |

Table 2 was composed by the authors on the basis of statistical, publicly accessible data, interviews of Russian experts.

| Table 3: Opportunities Of Manufacturing Development In Russia In The Framework Of The Industry 4.0 Concept | |

| Opportunities | |

|---|---|

| O1 | The possibility of strengthening of the manufacturing industry in Russia (and the other industries) |

| O2 | An opportunity of development of new leading and breakthrough markets for goods and services |

| O3 | “Lower entry barriers for some SMEs to participate in new markets, links to new supply chains” (Smit, Kreutzer, Moeller & Arlberg, 2016) |

| O4 | “Improved customer satisfaction?new markets: Increased product customization and product variety” (Smit, Kreutzer, Moeller & Arlberg, 2016) |

| O5 | The possibility of transition to the sixth technological structure of economy (Khusnullova & Absalyamova, 2016) |

| O6 | The possibility of cooperation strengthening between industrial enterprises, research organizations in the process of achieving of synergies |

| O7 | The possibility of the enlargement of GDP rates of growth. Approximately 3% of GDP per year; This index depends on the expected increase in producer demand for improved equipment and application of data in combination with consumer demand for individual products |

Table 3 was composed by the authors on the basis of statistical, publicly accessible data, interviews of Russian experts.

| Table 4: Opportunities Of Manufacturing Development In Russia In The Framework Of The Industry 4.0 Concept | |

| Threats | |

|---|---|

| T1 | The threat of competitiveness weakening of the different Russian industrial sectors is in relation to the world leaders |

| T2 | The threat of weakening of industrial enterprises economic security |

| T3 | The threat of “vulnerability to and volatility of global value chains” (Smit, Kreutzer, Moeller & Arlberg, 2016) |

| T4 | The threat of weakening enterprises competitiveness in the Russian regions |

| T5 | The threat of an insufficient level of formation of the Industry 4.0 ecosystem in Russia, including: Difficulties with development of application services and organizational readiness of potential customers and application developers for industrial Internet platforms (Industrial Internet of Things, 2016). |

| T6 | The threat of a principled impossibility of domestic enterprises is to compete with leading international industrial corporations, both at the cost of production and order fulfillment speed (Industrial Internet of Things, 2016). |

| T7 | Non-investment character of taxation system |

| T8 | The threat of insufficient long-term financing. High interest rates on long-term loans |

| T9 | The threat of significant barriers to the spread of new technologies in the economy |

Table 4 was composed by the authors on the basis of statistical, publicly accessible data, interviews of Russian experts.

For more complete feedback from the method, we use the construction of variants and actions that are based on the intersection of the fields. To do this, we consider various combinations of environmental factors and internal properties. We consider possible pair combinations and highlight those that should be taken into account during the process of strategy elaboration (Table 5).

| Table 5: The Swot-Analysis Matrix | ||

| Opportunities (O) | Threats (T) | |

|---|---|---|

| Strengths (S) | S-O | S-T |

| Weaknesses (W) | W-O | W-T |

1. The S-O field shows what kind of strengths must be used in order to get the advantages from the opportunities of environment.

2. The W-O field displays how the organization will be able to overcome existing weaknesses due to the environment opportunities.

3. The S-T field indicates which forces should be used in order to eliminate threats.

4. The W-T field shows from which weaknesses is necessary to get rid of in order to try to prevent from imminent threat.

As a result of it, the strategies of the industrial development in Russia within the concept of “Industry 4.0" were proposed. These strategies are aimed at the implementing of planned economic effects, as well as the strategies that would reduce the impact of identified negative economic factors that will be able exert an impact on the development of priority sectors of industry:

1. S1, S2-T8. To use a higher level of profitability and labor productivity in manufacturing according to Industry 4.0 in order to stimulate long-term investments (financing);

2. S1, S2-O2. To use a higher level of profitability and labor productivity in manufacturing industries according to Industry 4.0 in order to form the new leading (breakthrough) markets for goods and services. The creation of the markets for new goods and services (robotics, electric cars, drones and others) and significant transformation of the industrial sector of the economy, just as it is currently happening in the digital media and trade sectors through introduction of the Internet technologies;

3. S5-O7. To use the increase of industrial enterprises competitiveness (high-tech products of high redistribution) under Industry 4.0 in order to ensure the rates of growth of industrial production and GDP;

4. S8-O5. To use a change in management, automation and production technologies in order to transit to the sixth technological structure;

5. S7-T8. To use the increase of the shareholder value of enterprises through introduction of Industry 4.0 technologies in order to attract long-term investments (financing);

6. S10-O6. To use interaction between elements (smart-logistics) in the value chain for possible cooperation of industrial enterprises;

7. O1-W12. To use the capability for strengthening of the positions of manufacturing industries in Russia (and of other industries) due to the Industry 4.0 technologies focused on modernization of industrial enterprises and increase of the demand for domestic products;

8. S8-O7. To use transition to the new business models: From the sale of products to the sale of services (creation of IT platforms) in order to increase the rates of industrial production;

9. S1, S2, S12-O6, O7. To use the efficiency growth of the processes in the supplier-consumer chain for transition from inflationary to deflationary development, which is based on the growth of efficiency of all participants of the manufacturing ecosystem under Industry 4.0, including end-customers;

10. S11-T2. To actively use learning factories; it will contribute to improvement of the organizational skills of modern enterprises employees and it also will reduce the risks that are associated with ensuring of the economic security of enterprises;

11. S12-O3. To develop the new type of intellectual value chain, when the communication between the various key elements is carried out by using cloud technologies; efficiency of these technologies use contributes to decrease of entry barriers for some small and medium enterprises in order to participate in new markets;

12. S13-O4. To implement production of individual and customized goods at reasonable prices; it will contribute to the growth of customer satisfaction; increased product adaptation and product variety will contribute to development of new business models that actively use Smart data technologies in order to offer new services;

13. S12, S14-T3. Rise of collaboration productivity between departments and the new type of value chain will reduce threats that are related to the vulnerability and volatility of global value chains through the introduction of individual employee motivation systems, including Smart data technologies use.

Based on the forgoing we think that industrial policy within the framework of Industry 4.0 should be formed in the balanced way, both, at the level of the interested enterprises-producers and at the level of industries, clusters, regions. At the state level, it is necessary to regulate the interests of the subjects, prioritize innovations and investments in strategically important areas and regularly monitor and analyse the implementation of a complex strategy for the development of industrial production within the framework of the concept of Industry 4.0 (the road map "TechNet"). At the level of industries, regions it is surely to organize the self-regulating associations, consortiums, regional and international technology parks, innovative clusters. At the level of the interested manufacturing enterprises, there should be a more rapid transformation of consumers' requests into a customized product through modern technologies of Industry 4.0. The result should be a consistent redistribution of financial resources and as a result, interconnected innovation development of industry structures, strengthening of the competitiveness and equability of the industrial development of different forms of ownership, including in the regional context in Russia.

Discussion

The results obtained in our study overlap with the results obtained by other researchers earlier.

Among the most important strategies for the Russian industry it is necessary to emphasize the strategies that are aimed at the stimulating long-term investments, ensuring of redistribution of financial resources between the industries, as well as strategies that are aimed at shaping of the new leading markets for goods and services (Khusnullova & Absalyamova, 2016; Sidorenko & Frolov, 2015). In this regard, among the most significant economic factors in development of industrial production in Russia under Industry 4.0 as well as earlier noted for European producers we should note increased productivity and profitability of production entities (Smit, Kreutzer, Moeller & Arlberg, 2016), the rise of collaboration effectiveness between the economic (Kagermann, Anderl, Gausemeier, Schuh & Wahlster, 2016.). Such factors as the need to develop the new type of intellectual value chain, production of individual and customized goods at reasonable costs and the use of learning factories have special meaning (Erol, Jager, Hold, Ott & Sihn, 2016.).

To our mind, it is expediently to use economic factors of industrial production development in Russia under Industry 4.0 in the framework of the National Technological Initiative “road map” TechNet. At the same time, the following internal economic factors acquire special significance for the development of Russian industry within the framework of "Industry 4.0" concept and differ from the factors identified by other authors in relation to European manufacturers: Ineffective ownership structure for cooperation of industrial enterprises; weak intersectoral ties between industrial enterprises; the low susceptibility of business structures to technological innovations; insufficient development of the system of public-private partnerships in the implementation of innovative projects; the investment scale. Not a sufficient share of investment in the GDP of the Russian Federation (Industrial Internet of Things, 2016); the wear of main production founds of industrial enterprises.

The most significant external economic factors include the following threats for the development of industrial production in Russia within the framework of Industry 4.0: Non-investment character of taxation system; the threat of insufficient long-term financing; the threat of significant barriers to the spread of new technologies in the economy.

Conclusions

The industrial sector is the basis for economic growth and the rise of productivity in Russia. The development of industry is accompanied by growth in scientific and research activities. It contributes to formation of the new knowledge bases and new industries. It also facilitates to emergence of innovations and inventions within the country. Such factors as the emergence of the knowledge products at the world level, early testing and confirmation of solutions and their rapid commercialization and introduction are able to ensure creation of the competitive national products. World industrial production is standing on the threshold of the fourth technological revolution. It is connected with the possibility of drastic modernization of production and economy. In this regard, new economic opportunities and threats for Russian industrial complexes have appeared. The lag in transition to the new principles of interaction in the “supplier-consumer” chain can be added to the lag in productivity and quality of products. It can lead to fundamental inability to compete with the leading international industrial corporations because of the costs of production and order fulfilment speed. Significant investments are needed for industrial production development in Russia in the framework of the Industry 4.0 concept and also for achieving of a high level of competitiveness in production and technologies, high-technology industries, innovations. Realization of projects Industry 4.0 on the basis of the revealed economic factors will contribute to investment stimulation and redistribution of financial resources between different branches. Focusing attention on business and cooperation with universities or research organizations is the required condition for the implementation of Industry 4.0 projects. The development of industrial production in Russia with considering of these factors will enable to effectively use the opportunities and to cope with emerging threats under Industry 4.0 principles. In this regard, it is necessary to create the distributed regional and branch network of functioning factories of the future, to form the new testing and standardization systems and to develop a system for training of engineers and technicians at a new level.

The priority research directions for our further studies (which are an integral part of the introduction of Industry 4.0 in Russia) are the following:

1. Detailed analysis of economic factors of industrial production development in accordance with the industry 4.0 concept for priority sectoral sectors at the regional level;

2. Assessment of the economic potential of manufacturing enterprises and economic effects of the implementation of Industry 4.0 at the regional level;

3. Substantiation of logistical schemes of cross-sectoral cooperation of industrial enterprises.

References

- Chebotarev, S., Chebotarev, V. & Zhurenko, D. (2016). Initiative industry 4.0: A new industrial policy. The Society and economy, 6, 43-57.

- Erol, S., Jager, A., Hold, P., Ott, K. & Sihn, W. (2016). Tangible industry 4.0: A scenario-based approach to learning for the future of production. In the Proceedings of the 6th CIRP Conference on learning factories, 13-18.

- Industrial internet of things (2016). World experience and development prospects in Russia. Assessment of the impact on the quality of life of citizens and the economic development of the country.

- J?son & Partners Consulting (2016). Retrieved May 15, 2017, from http://json.tv/ict_telecom_analytics_view/industrialnyy-promyshlennyy-internet-veschey-mirovoy-opyt-i-perspektivy-razvitiya-v-rossii-otsenka-vliyaniya-na-kachestvo-jizni-grajdan-i-ekonomicheskoe-razvitie-strany-20161128041733

- Industry 4.0 (2017). Federal ministry for economic affairs and energy. Retrieved May 15, 2017, from www.bmwi.de/Redaktion/EN/Dossier/industrie-40.html.

- Kagermann, J., Anderl, R., Gausemeier, J., Schuhm, G. & Wahlster, W. (2016). Industry 4.0 in a global context: Strategies for cooperating with international partners (acatech Study). Munich: Herbert Utz Verlag, 9.

- The fourth industrial revolution and its socio-economic impact. Fundamental and applied research of the cooperative sector, 2, 59-63.

- Khusnullova, A.R. & Absalyamova, S.G. (2016). The fourth industrial revolution and its socio-economic impact. Fundamental and applied research of the cooperative sector, 2, 59-63.

- Kuznetsov, V., Trofimov, O.V., Frolov, V.G., Sidorenko, Y.A. & Plekhova, Y.O. (2017). Creative tools of raising the competitiveness of business on the basis of intellectual technologies of decision support. Communications in Computer and Information Science, 754, 302-316.

- Maksyutina E. & Golovkin, A. (2016). Neo-industrialization of Russian economics on the basis of additive industrial technology use and human capital development. In the Proceedings of the International scientific-practical conference-Innovative Economy and Industrial Policy of the region (EcoProm 2016), 211-221.

- Sidorenko, Y. & Frolov V. (2015). Basic conditions for the formation of industrial policy: The problem of innovation and investment balance. Economy and entrepreneurship, 11(1), 142-145.

- Russman, M., Lorenz, M., Gerbert, P., Waldner, M., Justus, J., Engel, P. & Harnisch, M. (2015). Industry 4.0: The future of productivity and growth in manufacturing industries. Retrieved May 15, 2017, from http://www.zvw.de/media.media.72e472fb-1698-4a15-8858-344351c8902f.original.pdf

- Smirnov, S. (2016). Scenarios for business and management development in the fourth industrial revolution era. The history of management thought and business: Management and scenario leadership. Moscow: Lomonosov Moscow State University, 275-280.

- Smit, J., Kreutzer, S., Moeller, C. & Arlberg, M. (2016). Industry 4.0. Retrieved May 15, 2017, from www.europarl.europa.eu/RegData/etudes/STUD/2016/570007/IPOL_STU(2016)570007_EN.pdf

- Stock, T. & Seliger, G. (2016). Opportunities of sustainable manufacturing in industry 4.0. In the Proceedings of the 13th Global conference on sustainable manufacturing-Decoupling growth from resource use, 536-541.

- Tonelli, F., Demartini, M., Loleo, A. & Testa, C. (2016). A novel methodology for manufacturing firms value modeling and mapping to improve operational performance in the Industry 4.0 era. In the Proceedings of the 49th CIRP Conference on manufacturing systems, 122-127.