Research Article: 2019 Vol: 18 Issue: 6

The impact of technological transfers on innovative capacity of manufacturing entities in an emerging economy

Joy Ifeoma Enemuo, University of Nigeria

Anthony Obiora Ude, University of Nigeria

Ben Etim Udoh, University of Nigeria

Chinedu Afamefuna Obiora-Okafo, University of Nigeria

Ifeoma Joanes Onodugo, University of Nigeria

Abstract

Keywords

Technological Transfers, Innovative Capability, Manufacturing Entities, Globalization.

Introduction

Manufacturing industry as a major player in Nigeria economy is greatly affected by the various environmental conditions brought about by liberalization which include economic, social, legal, political and technological factors (Oriarewo et al., 2018). When an organization is faced with uncertain conditions, the demand for better performance increases (Kamalian et al., 2011). Usually, proponents of globalization believe that it offers greater opportunities for improved firm performance as well as economic performance especially in less developed countries (Akpan & Atan, 2015). The Nigerian manufacturing industry over the past decade has undergone swift changes due to transfers in technology, globalization and trade liberation. The entrance of more foreign companies into the manufacturing industry has brought about stiff competition (Obi-Anike et al., 2017). With this openness, come costs as it reduces the market strength of domestic firms and increases competitive pressure on them that could easily force them out of businesses. On the other hand, with these openness could come with some good benefits as it improve efficiency in operation as new technologies are brought in and higher growth rate with lowering of poverty. Hence, a vibrant manufacturing sector has been acclaimed as a sure means of boosting economic growth and raising the standard of living (Danladi et al., 2015).

The search for the effect of technological transfers and globalization on manufacturing firms has received serious attention in global circle in the past few years. One among the reasons behind this interaction, as Sajuyigbe et al. (2015) notes, is that these businesses make remarkable contributions to the economies of both developing and developed countries. Firms’ competitive advantage depends not only on its productivity but also on the quality of its product, which may be seen as a bye product of technology. Transfers of technology and knowledge suggest that greater openness yields unambiguous better manufacturing firms’ performance in terms of higher level of output or income (Agu et al., 2016). Changes in firms’ performance expect evaluation to show the extent of how the utilization of companies’ assets affects business performance. The performance of a company stands out amongst many factors of management (Vernon, 2009). Organizations are evaluated to know how well they perform. This is done by comparing them to other organizations’ in the global arena because the world has been reduced to a small village due to technological development (Chibuzo et al., 2017), as trade globalization which entails the links among enterprises, institutions as well as citizens, movement of goods and services, across national borders (Agbarha & Peter, 2017). Firm’s progress is essentially clarified by its achievements within a specific time, and the link in technology and performance of manufacturing firms in Nigeria requires a definite scholarly attention.

The trend in the Global world shows that a technological transfer is the mechanism by which trade, business and activities are carried across boundaries of a nation to another. It is believed that when technology is transferred and shared, manufacturing firms would be at advantage to have access to new and more vibrant markets, access to better technology, better supplies, higher demands/larger market, higher profits, experience more capital formation. Though there may be incidence of competitions, technological transfers enable businesses to become innovative as they meet with stiff competition, which encourage them to improve on quality of their products, access world resources, enjoy comparative advantage and absolute advantage thus become efficient and effective. On the other hand, the Nigeria manufacturing sector has not really merge into the global system as the Nigerian manufacturing sector is characterised with low capacity utilization, declining contribution to the nation’s output, dominance of substantial goods which are unable to compete internationally and as a result accommodate large inventories. This of course, have spurred up negative effects such as poverty, low level of standard of living, increased unemployment, sharp practices and other business vices. It is against the backdrop that this study seeks to examine the effect technological transfers on the innovative capacity of manufacturing firms in Nigeria.

Review of Literature

Technology Transfer, Innovative Capacity and Performance of Manufacturing Set-ups

Technological advancements have basically played a major role in forming trans-world social spaces (Adei, 2004). Technology advancement, information and communication technology are the foundation of globalization (Chibuzo et al., 2017). It enhances transportation and introduced containerization inland and sea based transportation for banding and travelling reasonably. The developing interest to support innovation process of business, particularly technological advancement is planned to keep up or improve the competitiveness (Chibuzo et al., 2017). Additionally, they aver that it is after effect of familiarity with the consequence for utilization and natural effect. This came about because of international trades which require development of new samples of products and utilization. Oslo manual OCDE (2005) notes that innovation is characterized as advancement and fundamentally new product performance which are merchandise and ventures; process, firms’ external relations, new advertising techniques, new association, business practice and working environment association. The import of technology changes the environment in which the firms operate. This apart from product improvement and cost reduction, products of firms that utilize advanced technology may command greater demand and are thus expected to have higher growth performance. While technological globalization leads to the creation of uniform technical specification and standards in the industry, it is driven by the need to create a wider market, especially for high technology goods, leading to operational compatibility of equipment form different manufacturers thus simplifying engineering design (Nolan & Zhang, 2003; Agu et al., 2016).

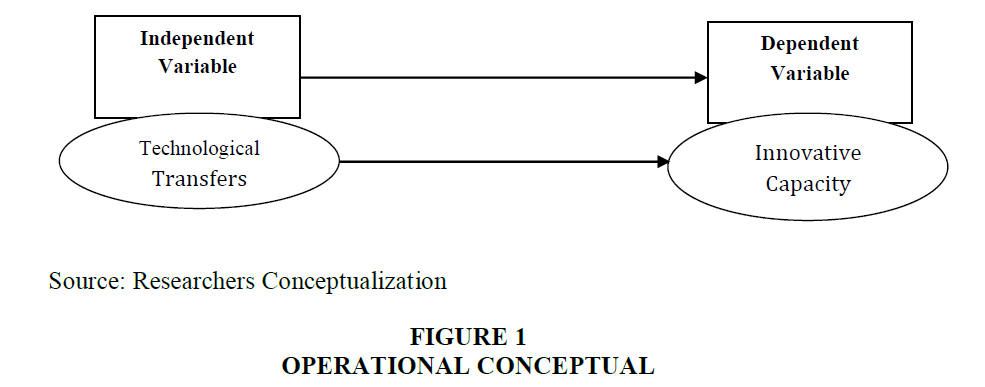

Technological transfer and developments involves new or fundamentally changed ideas and procedures, where technological oddity rises (Chibuzo et al., 2017). Franscati Manuel OCED (2002) rightly said that the innovation of aero planes, phones, computer, mobiles, satellites, internet, and other better technology made the international transfer and receiving of possible technology, thoughts and alteration of knowledge at an uncommon way and making the world smaller which make a buzz all over the world global (Roy, 2010). Information and communication is no doubt a major part or major actor for modern firms, thus are active players to drive firms to perform better. As indicated by Adei (2004), usually it is thought that every development takes place in the western world with the know-how coming into undeveloped nations because of globalization. Without it, new discoveries would remain in the nations that had innovation and nobody also would profit (Chibuzo et al., 2017). The elimination of import restriction or imported technologies either disembodied or embodied in intermediate and capital goods, reduction in tariffs has led to greater access beyond technology, machinery and inputs. The import of technology changes the environment in which the firms operate, because apart from product improvement and cost reduction, products of firms that utilize advantage technology may command greater demand and are thus expected to have higher performance (Agu et al., 2016). Hence, the study hypothesised that (Figure 1):

H1: Technological transfer has positive effect on innovative capacity in manufacturing organizations in Nigeria

Theoretical Anchor: Dependency Theory

Dependency theory is a perspective associated with Paul Prebisch & Hana Singer (Cited in Chase-Dunn, 1975). Dependency theorists argue that the way in which periphery countries integrates into the global economy and the inequality in international system has happened on the growth of the underdeveloped nations, especially the industrial based sector of these nation of which manufacturing is permanent. Dependency theory perspective on development/ performance is different from the way modernization theory and neo liberalization explains the problem of development as both theories focus on the internal problems that fuel underdevelopment. Dependency theory focuses on the external causes of underdevelopment. The theory main argument is that developed countries that represent the core of the global capitalist system have systematically impoverished underdeveloped and developing countries that account for the periphery of the global economy (Chase-Dunn, 1975).

The argument of dependency theory is heavily extracted from the Marxist theory of development. The Marxist theory argues that within a capitalist economy, there exist small groups of capitalist class whose profit is efficiently streamlined from the exploration of ma much bigger group the working class. This explains why there is a similar pattern in the relationships between countries in contemporary relationship where smaller nations (nations lacking in new technology, inadequate knowledge and low standards) are then to network with large nations rich in technology, knowledge and international standards, to being able to exploit their primary sector of the economy so as to experience sizeable industrialization especially in the manufacturing sector.

Frank (1966) argues that there are three basic historically known stages of exploitation; first stage in referred to as the mercantile capitalism which sprung forth in the 15th and 16th century which European explorers like Christopher Columbus embarked on a mission to establish trade agreements with other countries. The second stage of exploration called the era of colonialism (16th to earlier part of 20th century), European countries established feretories and dominance in large part of US, Asia and Africa. This era, colonial masters stripped off fertile lands to produce crops like rubber, sugar, tea, oil, coca, tobacco, and other raw materials needed by European imperial powers. This stage also had slave trade that is slave wave exported from West Africa to the Caribbean. The dependency theorist would also argue that so many parts of the developing countries are yet to recover from the effect of colonialism. However, Frank (1966) argues that these former colonies can never be truly independent, which is why neo colonialism is the term used to describe the present day as the third stage of exploration.

The main idea of neo-colonialism is that, even though the institutional bodies and frameworks of colonialism had collapsed, a close examination of today’s world economic system would prove that the same level of exploitation during the colonial period is still experienced in the current economic interaction between former colonies and colonial powers (Nnamdi, 2016). This could be in the form of the unfair economic practices that only serves the interest of former colonies (Onoitem, 2017). Dependency theory argues that periphery routines are subject to the exploitation, unfair trade openness terms, excessive conditionality agreements, monopolistic competition, standards and networking that arises from core countries and as a result widens the gap of socio economic disparities in periphery countries. Periphery countries remain dependent on core countries for things live loans, access to global markets, access to latest technology, access to knowledge, global networking and international standards.

Methods

The study utilized a survey design. The area of the study was South south, Nigeria comprising of six States. The population of the study involved thirteen thousand nine hundred and sixty-six (13, 966) staff of staff of nine selected manufacturing firms in the region. A sample size of five hundred and fifty four (554) was adopted using a statistical formula Trek. Data was collected using questionnaire structured on a five-point-Likert scale. Content validity was adopted in evaluating the validity of the instrument by three (3) experts of management scientists from University of Nigeria and two (2) professional management practitioners. Cronbach’s Alpha was used in testing the reliability of the instrument, and a value of 0.812 was obtained. The hypothesis of the study was tested using ordinal logistic regression technique with the Statistical Package for the Social Sciences at 5% level of significance.

Results And Discussion

Five hundred and fifty four (554) questionnaires were distributed and only five hundred and forty one (541) were correctly filled and returned representing 97.7%. While the remaining thirteen (13) filled representing 2.3% were found to be defective due to poor and wrong filling of the affected questionnaires and not returned. Table 1 shows the response of the sampled respondents on the effect of technological transfer on innovative capacity in Nigerian manufacturing organizations.

Table 1 shows questions puts forward to the manufacturing firm employees’, responses with regard the influence of technological transfer on innovative capacity in manufacturing organizations. The question items were based on 4 (four) elements of technological transfer and organizations’ ability of innovative capacity in manufacturing organizations. From the table, it was revealed that, 256 respondents representing (51.8%) and 210 respondents representing (25.5%) of manufacturing firm employees’ strongly agreed and agree that Access to new product improvement enhances innovativeness. While 19 respondents representing (3.0%) were undecided, 35 respondents representing (5.0%) and 21 respondents representing (3.7%) disagreed and strongly disagree that Access to new product improvement enhances innovativeness With reference to Creating wider market arouse the zeal for novelty, it was revealed that 220 respondents’ representing (36.5%) and 228 respondents representing (42.5%) of manufacturing firms employees strongly agreed and agree that Creating wider market arouse the zeal for novelty. While 24 respondents representing (8.0%) were undecided, 38 respondents representing (6.0%) and 31 respondents representing (7.0%) disagreed and strongly disagree.

| Table 1: Reponses Of Effect Of Technological Transfer On Innovative Capacity In Manufacturing Organizations | ||||||

| Items | SA (5) No. (%) |

A (4) No. (%) |

UD (3) No. (%) |

D (2) No. (%) |

SD (1) No. (%) |

Total |

|---|---|---|---|---|---|---|

| Access to new product improvement assist in enhancing innovativeness | 256 (51.8%) |

210 (36.5%) |

19 (3.0%) |

35 (5.0%) |

21 (3.7%) |

541 |

| Creating wider market arouse the zeal for novelty | 220 (36.5%) |

228 (42.5%) |

24 (8.0%) |

38 (6.0%) |

31 (7.0%) |

541 |

| Need for sampling information and technology enhances propensity to add value to production process | 248 (49.2%) |

222 (37.2%) |

18 (2.7%) |

31 (7.0%) |

30 (9.9%) |

541 |

| Exposure to new ideas and product refines skills and ability of employees | 255 (51.5%) |

216 (38.5%) |

10 (3.3%) |

34 (4.7%) |

26 (2.0%) |

541 |

Source: Field Survey, 2019

In relation to Need for sampling information and technology enhances propensity to adding value to production process, table 4.7 revealed that 248 of the respondents, representing (49.2%) strongly agree and 222 respondents representing (37.2%) agree that Need for sampling information and technology enhances propensity to adding value to production process, though 18 of the respondents, representing (2.7%) were undecided, 31 of the respondents, representing (7.0%) and 30 respondents, representing (9.9%) disagree and strongly disagree that Need for sampling information and technology enhances propensity to add value to production process. Furthermore, one hundred and fifty five (255) respondents, representing (51.5%) and 216 respondents, representing (38.5%) of manufacturing firms employees strongly agree and agree that Exposure to new ideas and product refines skills and ability of employees, while 10 respondents, representing (3.3%) were undecided, 34 of the respondents, representing (4.7%) and 26 respondents, representing (2.0%) disagree and strongly disagree that Exposure to new ideas and product refines skills and ability of employees

The hypothesis on the effect of technological transfer on innovative capacity in the manufacturing organization is tested below using least square regression. The response opinion in Table 1 was used to test the hypothesis.

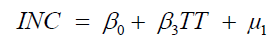

Model

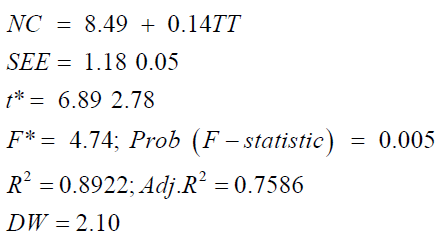

The calculated t-value for technological transfer was found to be 2.78 and also by the rule of thumb, the tabulated value is 1.96 under 95% confidence interval levels. The calculated value of technological transfer is found to be greater than the tabulated value (that is; 2.78>1.96), we thus, reject the third null hypotheses (H0). In conclusion, technological transfer has a positive and significant effect on organizations innovative capacity. Also, by examining the overall fit and significance of organizations’ innovative capacity model, it was found to have a good fit, as indicated by the high F-statistic value of 12.64 and it is significant at the 5.0 percent level. That is, the F-statistic value of 0.005 is less than 0.05. More so, the R2(R-square) value of 0.8922 shows that the model has a very good fit also. It showed that about 89.22 percent of the variation in organizations’ innovative capacity is explained by technological transfer, while the remaining 10.78 percentage unaccounted variation is captured by the error term.

The analysis of hypothesis was to find out the extent technological transfer effects organizations’ innovative capacity in selected firms in Nigeria. From Table 2 the Adjusted (R2) statistic was 0 .8922. This showed that 89.22% variance in organizations’ innovative capacity was explained by the technological transfer as an independent variable in the model. Therefore, 10.78% of the variance in organizations’ innovative capacity was accounted for by other predators not considered in the model. Taking into record the contribution of the explanatory variable to organizations’ innovative capacity in Nigeria, the beta value for technological transfer was 0.14. The beta value apparently indicated that the predictor variable of technological transfer had a positive effect on employees’ and organizations’ innovative capacity in Nigeria.

| Table 2: Regression Result On Inc And Tt | ||||

| Stepwise Regression Analyses of Technological Transfer on Outcome Variable | ||||

|---|---|---|---|---|

| Dependent Variable: innovative capacity R2 =0 .8922; F =12.64; Sig = 0.005 |

||||

| Independent Variable | Beta | t-value | Pearson Correlation(r) | Probability value |

| Technological transfer | 0.14 | 2.78 | 0.63155 | 0.005 |

Source: Authors Computation, 2019 (Eview-9.0).

The analysis of the postulated hypothesis three was to establish whether technological transfer has a significant effect on employees’ and organizations’ innovative capacity in Nigeria. The result from Table 2 revealed that the regression analysis of variance else referred to as the F-ratio computed of 12.64 was greater than F-critical of 3.00 at 5% alpha (F=12.64, p<0.05). This clearly showed that the regression model had a good fit. Therefore, there was a significant relationship between technological transfer and innovative capacity. To determine the statistically significant effect of technological transfer on innovative capacity in manufacturing organizations in Nigeria, the t-test of significance was used. From Table 2, the results indicated technological transfer had positive significant effect on innovative capacity of manufacturing organizations in Nigeria (t-computed 2.78>t-critical 1.96, t=2.78, p<0.05).

The findings of this study is in line with dependency theory which elaborated that linkages between nations (developed and developing) are to network such that those rich in technology are able to exploit their primary sector of the economy so as to experience sizeable industrialization especially in the manufacturing sector. The finding of this study agrees with some earlier studies. The current result are consistent with previous findings (Aluko et al., 2004; Sajuyigbe et al., 2015; Agu et al,. 2016; Ali et al., 2018; amongst others) which posits that due to trade globalization, Nigeria manufacturing sector are gaining experience and novelty in being better linked in technology (ICT) that has better improved their product quality.

Conclusion And Implications

The study concluded that technological transfers stimulate innovative capacity and firms’ performance in the manufacturing firms in Nigeria. Based on the findings and the conclusion of the study, the following recommendations are offered. Manufacturing organization should cultivate regular culture for knowledge transfer as this will improve swift employees’ commitment. Also there is need for manufacturing organization to create enabling environment for improved technological transfer, this will guarantee innovative capacity and stellar performance for manufacturing entities in Nigeria. The research context was limited to manufacturing entities in south-south Nigeria. It is entirely plausible that there may be significant differences in the findings if this study is replicated in other industries i.e. services industry. It will be interesting and useful for benchmarking purposes to find out if differences do exist. It is therefore recommended that this study is replicated, involving other industries for comparative analysis to be undertaken.

Limitation and Future Researches

A major limitation of the study was its restriction to south-south Nigeria. It is therefore suggested that the future study be extended to the remaining five geopolitical zones in Nigeria i.e. South East, South West, North East, North Central and North West to generalize the findings of this study. Further, the research context was limited to manufacturing firms in south-south Nigeria. It is entirely plausible that there may be significant differences in the findings if this study is replicated in other industries i.e. services industry. It will be interesting and useful for benchmarking purposes to find out if differences do exist. It is therefore important that the future study is replicated, involving other industries for comparative analysis to be undertaken.

References

- Adei, S. (2004). Impact of globalisation on management the African perspective. Management in Nigeria, 39, 40.

- Agbarha, E.K., & Peter, S.A. (2017). Globalization and economic growth in Nigeria: A cointegration approach. Journal of International Business and Economics 5(1); 105-113

- Agu, O.A., Anichebe, N.A., & Maduagwu, N.E. (2016). Impact of globalization on Nigeria manufacturing sector: A study of selected manufacturing firms in Enugu. Singaporean Journal of Business Economics and Management Studies, 5(5); 44-54

- Akpan, U.F., & Atan, J.A. (2015). The effect of globalization on selected sectors of the Nigeria economy: Agriculture, manufacturing in trade. British Journal of Economics, Management and Trade, 8(2); 144-156

- Ali, V, Obayori, E.L., & Obayori, J.B. (2018). Globalization and manufacturing sector growth in Nigeria. International Journal of Advanced Studies in Ecology, Development and Sustainability, 5(1), 54-64

- Aluko, M.A., Akinolo, G.O., & Faloke, S. (2004). Globalization and sector. A study of selected firms in Nigeria. Journal of Social Science, 9(2); 119-130

- Chase-Dunn, C. (1975). The effects of international economic dependence on development and inequality: A cross-national study. American Sociological Review, 40(6), 720-738

- Chibuzo, E.V., Onuoha, B.C., & Nwede, I.G.N. (2017). Globalization and performance of manufacturing firms in Port Harcourt. International Journal of Advanced Academic Research/Social and Management Sciences, 3(11), 1-25

- Danladi, J.D., Akomolafe, K.J., Babalola, O., & Oladipupo, A.R. (2015). Globalization and the Nigeria manufacturing sector. Journal of Law, Policy and Globalization. 41, 202-211

- Frank, A.G. (1966). The development of underdevelopment. Bastion: New England Free press.

- Kamalian, A., Yehoubi, N., & Poor, M. (2011). Emotional intelligence and corporate entrepreneurship: An empirical study. Journal of Basic and Applied Scientific Research, 1(6): 471-478

- Nnamdi, U. (2016). Navigating Nkrumah’s Theory of Neo-colonialism in the 21st century. http://www.e-ir.info/2016/01/13/navigating-nkrumahs-theory-of-neo-colonialism-in-the-21st-century

- Nolan, P., & Zhang, J. (2003). Globalization challenge for large firms from developing countries: China’s oil and aerospace industries. European Management Journal, 21(3), 285-299

- Obi-Anike, H.O., Ofobruku, S.A., & Okafor, C.N. (2017). Manpower development and employees’ performance: Qualitative assessment of small and medium scale business in Abuja Nigeria. Journal of Economics, Management and Trade, 18(3), 1-6

- OCED. (2002). Guidelines for collection and interpreting innovation Data 3rd Ed. US: OCED

- Onoitem, U.N. (2017). Globalization its impact on Nigeria’s economy and implication on national development.

- Oriarewo, G.O., Ofobruku, S.A., Agbaeze, K. & Tor, Z.A. (2018). The influence of emotional stability on employees’ performance: A review. South Asian Journal of Social Studies and Economics, 2(1); 1-8

- Roy, S.C. (2010). Challenges in scientific research and science policy in the book liberalizing research in science and technology.

- Sajuyigbe, A.S., Alabi, E. & Afolabi, A.M. (2015). Effect of globalization on the performance of small scale business in Nigeria. Paper presented at Flanatial Multi-Disciplinary Academic Conference on Africa Transformation and Development at University of Ilorin Kwara State Nigeria.

- Vernon, H. (2009). The Athenaeum. J. Francis. Retrieved from http://www.the-athenaeum.org/search.php?s=y