Research Article: 2022 Vol: 21 Issue: 1

The Impact of Supply Chain Management Practices on Supply Chain Agility - Empirical Study in Medical Sector

Raeda Jamal Saa'da, Royal Medical Services, Institute of Logistics and Management

Marwan Al-Nsour, AL-Balqa' Applied University

Awad Mohammad Altarawneh, Royal Jordanian National Defense College

Taghrid S Suifan, The University of Jordan

Rateb Sweis, The University of Jordan

Abdel Hakim O.Akhorshaideh, University of Jordan

Kholoud S.A. AL-Lozi, The University of Jordan

Citation Information: Saa'da, R.J., Al-Nsour, M., Altarawneh, A.M., Suifan, T.S., Sweis, R., O.Akhorshaideh, A.H., & AL-Lozi, K.S.A. (2021). The impact of supply chain management practices on supply chain agility - Empirical study in medical sector. Academy of Strategic Management Journal, 21(1), 1-15

Abstract

The aim of this research is to see how supply chain management strategies affect supply chain success, specifically supply chain productivity and effectiveness. The study also observes whether competitive competition has a moderating impact on the relationship between supply chain management activities and supply chain efficiency. Data for this research were collected by distributing 315 questionnaires to male and female employees in Jordanian medical sector. The hypothesized relationships were tested using hierarchical regressions. The findings show that five supply chain management practices; supplier integration, internal integration, customer integration, information sharing, and postponement have a substantial and beneficial impact on supply chain performance. The relationship between internal integration, supplier integration, and consumer integration, as well as supply chain productivity success, is moderated by competitive strength. The findings further indicate that three supply chain management activities, including internal integration, customer integration, and postponement, but not supplier integration or information sharing, have a substantial and beneficial impact on supply chain effectiveness. Information sharing and customer integration, as well as supply chain effectiveness efficiency, are moderated by competitive capability.

Keywords

Customer Integration, Information Sharing, Internal Integration, Postponement, Supplier Integration, Supply Chain Management.

Introduction

Organizational practices are generally complex and multifaceted. For the purposes of external integration, it is crucial that companies integrate with their major customers and their major suppliers. The integration must be both with suppliers and customers because if the integration is not simultaneous, then the company will not be able to have proper external integration (Mathew et al., 2013). Today, the global economy is becoming more and more competitive and as a result of this, majority of the businesses are concentrating on better customer value as compared to their competitors. Doing business in modern times is about creating processes that are more interdependent and interconnected (Dobrzykowski et al., 2014). As response to the increasing complexity and the overall uncertainty in the business environment, the businesses are now increasingly recognizing that demand for value can be increased if supply chain processes are made more interconnected and interrelated (Wisner et al., 2014). According to Mathur et al. (2018),

“Agility is the concept of management that focuses on responsiveness to dynamic and turbulent markets and customer demand supply chain agility has been identified as a strategic factor and agility of the supply chain may impact the survivability of the firm.”

Supply chain in today’s world is more interconnected than ever, because organizations today do not act in isolation and independent entities but rather supply chain aims to create value delivery systems so that companies could become more responsive and adaptive to the fast-changing times (Cohen & Roussel, 2013). According to Fawcett et al. (2012), the core competencies of organizations lie in their ability to design and as well as manage their supply chain process. This is especially true in current times because new businesses models keep emerging and forcing managers to come up with ways to provide solutions in today’s ever-changing world.

According to Sharifi et al. (2013), agility has the ability to rapidly respond to changes in market and customer demands as the bearer of competitive advantage. Despite the obvious benefits of agility, organizations are faced with challenges in implementing the measures necessary to increase their agility. Agility is now being increasingly recognized as critical characteristic by supply chain firms so as to sustain their competitiveness. According to Ganguly et al. (2019), agility is defined as the ability of a business to adapt to and react to the unexpected and unforeseen changes in the business environment.

According to Swafford et al. (2006), agility provides the capability to organization to embed the changes in the marketplace and exploit market opportunities with speed and quickness. Berteig (2005) states that there are three principles of agility which are as follows; 1) interactions and individuals are preferred over tools and processes, 2) valued goals are preferred over producing ephemera, and 3) response to changes is preferred over following a pre-defined plan.

According to Kaipia (2009), manufacturing companies have a central position in the supply chain and because of this reason improving supply chain performance is quite important for them. If the businesses want to improve their supply chain performance, they need to focus on physical flow and information flows. In healthcare sector, supply chain management is very important because of pharmaceutical products, logistics and satisfaction of patients to advance service quality compared to other sectors. In addition, changes in the medical sector have been radical in the last couple of years and many healthcare organizations are now aware of the fact that they need to adaptive and also make their supply chain functions adaptive because of ever-changing nature of the business environment. Another critical aspect is that quality of a healthcare system is directly related to the efficiency of supply chain management system and thus it is critical for healthcare systems to improve quality of their supply chain systems. The study aims to assess the impact of supply chain management practices on supply chain agility, in the context of medical industry.

Literature Review

The review of the literature was carried out according to the systematic review process defined by previous studies (Altarawneh et al., 2020; Centobelli et al., 2020; Wadesango et al., 2020).

Supply Chain Management Practices

Supply chain management may refer to a network, system, or a process that focuses on the flow of materials from one point (production) to another stage (distribution) in one direction, which involves flow of information that provides control mechanisms (Rakovska & Stratieva, 2018). As a structure, the process contains the various constituent parts, including material suppliers, production equipment, distribution activities, and consumers linked together through the ‘forward movement’ of materials and the feedback associated with flow of information. Syed (2012) defines the supply chain as a network of organizations or institutions involved through upstream and downstream linkages linked via different processes and activities that lead to the production of value in the form of final goods and services. In order to consider the network a success, the products that the final consumer gets are of high-quality and meet their tastes and preferences (Ralston et al., 2017).

Internal Integration

Additionally, the supply chain process incorporates a network of facilities that perform various functions of procurement of materials and their transformation to finished products (Parkhi, 2019). After these processes, management teams use the services of distributors in order to supply the finished products to the various outlets so that final consumers can have access to their preferred goods or services (Whitehead, 2014). Indeed, the aspect of operating responsibility associated with SCM involves the consideration of geographical location of raw materials, production process, and finished inventories using the lowest cost possible.

Suppliers Integration

Business owners throughout the world focus on the process of expanding not only in the local market but in the international arena. In this regard, irrespective of their size, all firms rely on sub-contracting suppliers in the supply chain to access raw materials and to help them facilitate the execution of orders placed by clients (Ralston et al., 2017). However, as a mechanism for increasing the quality of services provided, management teams focus on the cost, quality, and delivery approaches (Clauson et al., 2018). The issue of time management plays an essential role in SCM practices as it adds the competitive edge to the organization since customers can receive their orders in time as compared to rivals in the same industry (Scavarda et al., 2019). Based on the global scale, increased competition and approaches that organizations have adopted have caused the business to improve significantly, which has also made it difficult for other firms to enter the market.

The highly competitive levels in the current business environment characterize the complex and fierce rivalry associated with manufacturing outsourcing, shorter product life-cycles due to changing consumer preferences, and the use of new technologies. For instance, healthcare sector experiences similar challenges and have to consider the latest automation processes to increase production levels (Attia & Eldin, 2018). The consideration of such factors forces the various companies to assume more “calculated risks,” which managers should consider so as to improve the competitive edge, reduce overall costs, and improve profit levels.

Consumer Integration

Every organization focuses on cost-effective practices that enable them to compete in a healthy manner, which involves the production of goods that meet consumer needs and preferences (Mwaiseje & Mwagike, 2019). Indeed, companies consider consumers as the second most important asset after employees since without their input, firms cannot achieve the set goals and objectives (Ralston et al., 2017). Failure to consider the downside potential of the “calculated risks” can have consequences that can affect the entire supply chain’s ability to serve the final customers. Firm’s management teams that fail to consider consumer input can affect organizations’ long-term goal accomplishments, which can lead to the closure of such institutions (Hong et al., 2018). Irrespective of the competitiveness of the supply chain, executive teams in companies should consider customer feedback since it can play an essential role in improving service delivery. Institutions that adopt a higher level of SCM performance leads to improved competitive advantage, which helps such organizations to take a higher position in the market (Mathur et al., 2018). Management teams in organizations should consider the significance of continuous improvement processes within the value chain so as to increase perfection rates. As mentioned earlier, consumers often look for high-quality products with the lowest prices in the market (Saeed et al., 2018).

However, due to consumer loyalty and quality levels of specific brands, customers can consider products sold slightly above the market price. In such situations, the final product users argue that firms selling such goods may have used additional materials to improve the quality of such products (Sbai & Berrado, 2018). In this respect, the continued improvement processes that firms adopt ensure the satisfaction of all stakeholders involved in the supply chain from suppliers of raw materials to the final user or consumer. Therefore, enhancements of the supply chain help organizations to record high profit and performance levels, which replicate the mission and vision statements (Mousa & Othman, 2020).

Information Sharing

Furthermore, irrespective of the geographical location of industries or raw materials, the use of appropriate logistical processes helps in the flow of finished products from the firm through the various marketing platforms to final consumers (Narayanan et al., 2019). The main objective of SCM involves the process of achieving operational excellence through activities that maximize total revenues, minimize expenses and related costs, and making full use of all assets acquired to facilitate smooth production processes. As such, organizations that follow such procedures benefit through increased profits and market share, as well as responsiveness to consumer demand (Borges et al., 2019). Moreover, SCM allows a comprehensive incorporation of all business procedures within and outside the organization so as to enable the exchange of information, as well as movement of products, money, and services. As an operational paradigm, SCM considers an enterprise as a chain of unified entities that enables all stakeholders involved to view the perspective of the entire business (Zaid et al., 2018).

Postponement

In supply chain management, postponement is a deliberate action thorough which the final manufacturing or distribution of products or services are delayed until the receipt of customer’s order. This helps in controlling the wrong manufacturing or incorrect inventory deployment. This strategy reduces the anticipatory risk in supply chain. It can be fine-tuned so that only the generic parts shared by a firm’s various end products are warehoused and will reduce the inventory pressures throughout the company (Schwartz & Voß, 2014).

Supply Chain Performance

The challenges that investors faced linked to the supply chain led to engagements that brought manufacturers together so that they could interact with suppliers in order to upgrade the traditional supply approaches and improve the overall performance. Based on this approach, all players involved wanted to make all activities involved a unique corporate strategy so as to eliminate challenges and practices that increase costs and time wastage (Ali & Ali, 2013). Due to such engagements, wholesalers and retailers decided to integrate their logistics functions with other areas to enhance the competitive advantage over rivals in the same industry. The practice led to the merger of the traditional supporting functions of corporate strategy, which contributed to the emergence of strategic approaches to logistics and materials management. Indeed, the rise of new approaches contributed to the consideration of the process as supply chain management (SCM), which has gained significance due to its ability to improve the overall performance of organizations. Indeed, investors and other stakeholders in institutions consider SCM as a competitive strategy that brings suppliers and customers together with the desire to improve receptiveness and flexibility of all manufacturing organizations. The adoption of SCM practices involves the use of supply chain dimensions that help organizations to succeed. However, in order for the dimensions to work well, the various management teams have to make them mandatory because if the objectives linked with them are not achieved, the corporation will fail. In this regard, SCM dimension takes the multi-dimensional aspect, which makes it an appropriate tool that management teams can use to understand the supplier, internal, and consumer sides. Healthcare sector has to consider the supply aspect so as to maintain the flow of materials from one point to the next. Therefore, manufacturers play an important role in the supply chain because they produce and promote the products so that final customers or other members of the supply chain can have access to the various goods on offer.

Whitehead, et al. (2018) communicate the various propositions that explore approaches through which innovations within SCM can influence business cycle. In this respect, many organizations, including manufacturing firms consider the satisfaction of customers at the lowest cost possible as the primary concern. Management teams in organizations should work hard to enhance consumer recognition and increase revenue collection by adopting and exploring the importance of sustainable supply chains that encompass a collaborative perspective (Roldan et al., 2016). Competition among firms is no longer considered an issue in the contemporary world but rivalry between supply chains. In most firms, the aspect of SCM as a basic entity exists but management teams have not used the system to produce the desired results. Leadership teams in organizations can identify the prevailing problems in supply chains and propose solutions that may contribute to the creation of an appropriate SCM approach.

The process of restructuring internal operations and integrating procedures with suppliers and consumers with the help of web-based tools leads to cost-effective practices. (Auramo & Tanskanen, 2005) argue that some organizations have saved hundreds of millions of dollars due to the adoption and integration of web-based tools to facilitate business activities with suppliers and customers. Some firms have reported increased savings after replacing hundreds of order clerks with automated online ordering applications, which minimize intentional or unintentional mistakes. Indeed, individuals often used manual processes to process orders and include some additional information in order to benefit financially (Singh & Raghuram, 2017; Sindhwani et al., 2019). For a long period, organizations have incurred losses due to lack of structures that can address the challenges associated with manual processes in finance departments. The introduction of IT in SCM has brought benefits to organizations since all processes take place in automated online platforms where suppliers and consumers can access to perform their respective activities (Auramo et al., 2005).

Supply Chain Agility

The ability to conceptualize and understand market changes of a firm is improved through the collaboration and involvement with customers and suppliers (Zhan et al., 2018). In addition, on the basis of real customer requirements by ways of an entire methodology comprising of responsiveness and flexibility, agile firms understand and react turbulent environments by offering services and products (Zhu et al., 2018). For instance, agile practices can comprehensively be accomplished using customer integration in manufacturing companies as well as superior improvement is associated to sharing information and collaboration with customers and suppliers in demand uncertainty (Calleja et al., 2018).

On the contrary, the involvement of not all customers is shown in agile practices, but the contribution of active customers is observed with valuable information (Ciccullo et al., 2018). In addition, the involvement of society is more usual in new product procedures as well as less substantial in the development of a product during the adoption of agile practices (Inman& Green, 2018). Moreover, suppliers are viewed as strategic partners in companies practicing agile strategy (Mathu & Phetla, 2018). Furthermore, they also concentrate additionally in order to ascertain lasting associations with suppliers as well as involving them in different procedures (Green et al., 2019). In particular, the agile performance of a firm is affected by a significant factor, which is supplier involvement.

Engagement is improved by customers and suppliers in agile practices by means of understanding the needs of suppliers in the process of decision-making (Mathu & Phetla, 2018). In addition, they use the ideas as well as notions for new products of customers. Moreover, in the early stage, agile practices require the involvement of suppliers as well as the competence of agile practices in order to concern rapid responses for changing with the suitable suppliers by their implementation (Miraz et al., 2018).

Due to ineffective and unwanted operations, the manufacturing system is lean, if it is agile and is achieved with minimum waste in order to revert to the changing conditions placed upon it (Pourghahreman et al., 2018). On the other hand, leanness cannot be presumed by agility but the overall supply chain can be suited together by both approaches (Yildiz, Çankaya & Sezen, 2019). The integration of agile strategy for green supply chain management practices comprises of a long-term and a short-term phase (Zhan et al., 2018). The evaluation and execution planning of the existing state are underperformed in the short-term. On the contrary, the plan is performed as well as comprehensively integrated in the long-term (Zhu et al., 2018).

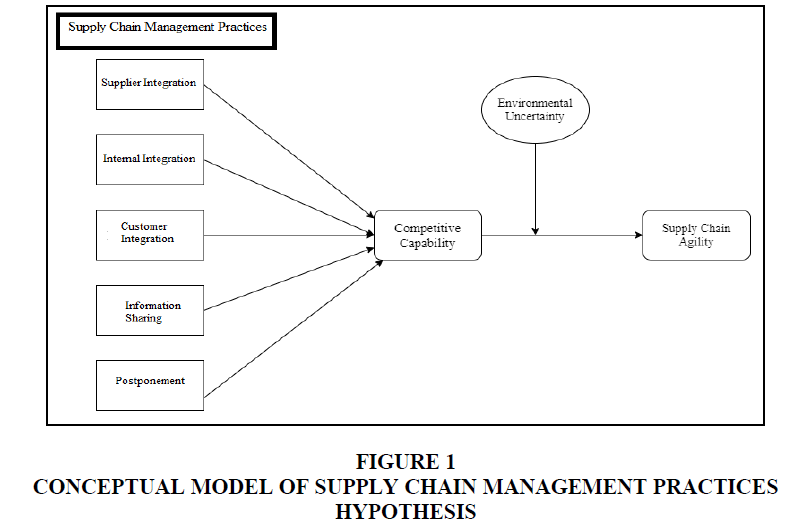

Conceptual Framework and Hypotheses

H1 Supply Chain Management Practices are positively related to Competitive Capability.

H1a Supplier Integration is positively related to Competitive Capability.

H1b Internal Integration is positively related to Competitive Capability.

H1c Customer Integration is positively related to Competitive Capability.

H1d Information Sharing is positively related to Competitive Capability.

H1e Postponment is positively related to Competitive Capability.

H2 Competitive Capability is positively related to Supply Chain Agility.

H3 Environmental Uncertainty mediate the relationship between Competitive Capability and Supply Chain Agility

Methodology

Data Collection

This paper was based on the data from a primary source using questionnaire survey. A questionnaire is defined as a set of pre-formulated questions which allows the respondents to provide their response. One of the reasons as to why this method was chosen is that questionnaire is an effective way to collect organized data, also if the researcher knows what is required and what variables to use, then questionnaire can provide an effective way to collect and analyze data. Therefore, in this study, respondents were requested to answer the questionnaire related to supply chain performance and supply chain agility practices with respect to their company. It was expected that the respondents would have the best knowledge with regard to supply chain agility, supply chain processes, supply chain structure and supply chain partners of their companies. To produce a good response rate and sound instrument, an altered questionnaire was used to observe the extent of supply chain agility application of the researched firm. The questions pertained to information such as features of supply chain agility in terms of sourcing, procurement, logistics and manufacturing and distribution from the perspective of the organization.

Sample Design and Size

The questionnaire was designed in such a way so that the respondents could rate their level of practices with regards to supply chain ability. A 5-point rating scale was used, 1 meant the lowest and 5 meant the highest. In addition, the questions were also designed to obtain information such as understanding about the level of the following practiced associated with the information flow, organizational linkage, resource sharing and supply chain infrastructure factors in their firm. The respondents were asked to indicate the level of practices followed in their organization, where 1 meant lowest level of practices and 5 meant highest level. The sample size consisted of supply and procurement officers in 36 private hospitals operating in Jordan. A total of 315 questionnaires were distributed to male and female employees from supply and procurement department of the hospitals, 307 questionnaires were returned out of them 6 questionnaires were not included in the analysis as they were incomplete. Therefore, 301 questionnaires were used in the analysis and hypotheses testing.

Data Analysis

A statistical package for social sciences (SPSS) version 25 was used for analyzing the data. Descriptive statistics including mean value, standard deviation, frequencies and percentages were calculated for demographics. In addition, factor analysis was used for reducing the number of items to manageable factor for each of the item scales. Principal component analysis was used for extracting factors with eigen values greater than 1. Varimax rotation was used for facilitating interpretation of the factor matrix. Sampling adequacy measurement tests were further investigated using the Kaiser-Meyer-Olkin (KMO) statistics for validating the use of factor analysis. Moreover, Pearson correlation analysis was used for testing the relationship between dependent variable and one or more independent variables. Lastly, multivariate regression analysis was performed for testing the hypotheses. All tests were performed at P<0.05.

Results

In construct validity, the objective is to ensure appropriate loading of the factors along with their statistical significance. Following Table 1 showed outer loading using cross loadings tabulation for the study. As per the suggestive parameters, factor loadings should be greater than 0.70 for adequate construct development. Here, all the items were loaded with greater than 0.70.

| Table 1 Cross Loadings | ||||

|---|---|---|---|---|

| SCMP | CC | EU | SCA | |

| SCMP2 | 0.732 | 0.142 | -0.061 | -0.575 |

| SCMP3 | 0.702 | 0.508 | 0.466 | -0.374 |

| SCMP4 | 0.895 | 0.716 | 0.126 | -0.467 |

| CC1 | -0.657 | -0.379 | 0.033 | 0.961 |

| CC2 | -0.310 | -0.127 | -0.131 | 0.799 |

| CC3 | -0.546 | -0.229 | 0.164 | 0.942 |

| EU1 | 0.388 | 0.433 | 0.741 | -0.202 |

| EU2 | 0.369 | 0.451 | 0.382 | -0.077 |

| EU3 | 0.577 | 0.755 | 0.236 | -0.197 |

| SCA1 | 0.517 | 0.931 | 0.373 | -0.272 |

| SCA2 | 0.621 | 0.973 | 0.049 | -0.306 |

| SCA3 | 0.640 | 0.970 | 0.143 | -0.278 |

| SCA4 | 0.452 | 0.917 | 0.049 | -0.213 |

| SCA5 | 0.675 | 0.988 | 0.111 | -0.344 |

Convergent validity measures the degree of association among the variable of measurable construct. It analyzes the variables on the basis of the concept which is supported by theoretical for inter-related statistical or not (Henseler et al., 2015). In Table 2, the outcomes provide related to analysis of composite reliability and average variance extracted (AVE) as considerations to evaluate the convergent validity. Furthermore, all the constructs showed greater composite reliability than threshold of 0.70. Finally, AVE coefficients should have greater values than 0.50 for adequate variance among the items (Fornell & Larcker, 1981b; Tabachnick et al., 2001). In this concern, all the constructs have met suggested thresholds for composite reliability and AVE. Hence, under these results, the study has appropriately gained convergent validity for all the constructs.

| Table 2 Convergent Validity | ||

|---|---|---|

| Composite Reliability | Average Variance Extracted (AVE) | |

| Supply chain management practices | 0.822 | 0.610 |

| Competitive capability | 0.982 | 0.914 |

| Environmental uncertainty | 0.897 | 0.686 |

| Supply chain agility | 0.930 | 0.816 |

Discriminant validity describes the variables differences and discrimination among research constructs which are supported by theoretical foundations is in fact unrelated (Fornell & Larcker, 1981a). There are two categories in discriminant validity which have been measured for giving widespread clarification and justification of discriminant validity comprising Fornell & Larcker (1981a) criterion and Heterotrait-Monotrait ratio (HTMT) respective to Tables 3 and 4.

| Table 3 Discriminant Validity Using Fornell-Larcker | ||||

|---|---|---|---|---|

| CM | SASS | SD | RES | |

| Supply chain management practices | 0.781 | |||

| Competitive capability | 0.614 | 0.956 | ||

| Environmental uncertainty | 0.231 | 0.158 | 0.828 | |

| Supply chain agility | -0.597 | -0.298 | 0.060 | 0.903 |

| Table 4 Discriminant Validity Using Heterotrait-Monotrait Rati (Htmt) | ||||

|---|---|---|---|---|

| CM | SASS | SD | RES | |

| Supply chain management practices | ||||

| Competitive capability | 0.720 | |||

| Environmental uncertainty | 0.456 | 0.184 | ||

| Supply chain agility | 0.732 | 0.286 | 0.270 | |

In above table, all the variables construct fulfill Fornell & Larcker (1981a) criterion as the square root of AVE for specific constructs have greater value than the comparison of others respective constructs (Fornell & Larcker, 1981a, 1981b; Henseler et al., 2015). Hence, the research outcomes of the constructs have been achieved discriminant validity.

Above table showed HTMT ratio for all the constructs in study. The Threshold for the fulfillment HTMT criterion for discriminant validity, as suggested by Henseler et al. (2015), it must be below than 0.80. In this research all the construct has been met the threshold value. All the HTMT ratio values of constructs found below than 0.80, Hence the criteria of HTMT ratio criterion have been met in discriminant validity.

Supply chain management practices (0.104, p>0.01) has positive but statistically insignificant impact on competitive capability while supply chain management practices (0.513, p<0.001) has significantly positive impact on supply chain agility. Furthermore, competitive capability (0.208, p<0.01) has significantly positive impact on supply chain agility (Table 5).

| Table 5 Hypothesis- Testing Using Path Analysis | ||||

|---|---|---|---|---|

| Estimate | S.D. | T-Stats | P Values | |

| Supply Chain Management Practices → Competitive Capability | 0.104 | 0.094 | 1.109 | 0.268 |

| Supply Chain Management Practices → Supply Chain Agility | 0.513 | 0.082 | 6.273 | 0.000 |

| Competitive Capability → Supply Chain Agility | 0.208 | 0.075 | 2.767 | 0.006 |

It has been found that the relationship between competitive capability and supply chain agility (-0.181, p>0.05) was not moderated by environmental uncertainty, and the relationship between competitive capability and supply chain agility (-0.030, p>0.715) was not moderated by environmental uncertainty. Moreover, the relationship between supplier development and supply chain resilience (0.438, p<0.001) was significantly and positively moderated by contract management. Henceforth, the relationship between supplier development and supply chain robustness (0.172, p<0.05) was significantly and positively moderated by contract management (Table 6).

| Table 6 Meditation Analysis Using Path Analysis | ||||

|---|---|---|---|---|

| Estimate | S.D. | T-Stats | P Values | |

| Competitive Capability à Supply Chain Agility | -0.181 | 0.096 | 1.876 | 0.061 |

The first phase of the regression model revealed that SCM activities as a block greatly contributed to the variance in SC efficiency level description. Considering the individual practices of SCM, five supply chain management practices; supplier integration, internal integration, customer integration, information sharing, and postponment positively and significantly affected SC efficiency. Supplier integration was found to be both negatively and positively linked to SC performance, while consumer integration was found to be negligible. The second move included incorporating competitive capability into the regression model, which culminated in a substantial increase in the variance in SC efficiency results. The incorporation of the relationships between competitive capacity and the five SCM activities resulted in yet another important improvement, meaning that the model’s predictive capacity was increased even further. The findings of the third phase revealed that competitive capability influenced the relationship between supplier integration and SC performance in a constructive and meaningful way.

The study’s results that supplier integration had a substantial positive and negative impact on SC quality can come as a surprise. Understanding the costs of such integration, on the other hand, can help to clarify this finding. Supplier acquisition entails a number of operations carried out by the client firm in order to improve the skills and competencies of the supplier. Quality management efforts, process improvement and renovation, technological reform, and other investments aimed at emerging vendors are examples of such practices. According to the findings, such practices would reduce SC performance in stable markets that are not marked by intense rivalry. The observations of present study matched those of (Swink et al., 2007; Koufteros et al., 2005), who discovered that supplier presence had a negative impact on certain output parameters. These findings contradicted those of Lee et al. (2007) and Devaraj et al. (2007), who discovered that supplier convergence improved certain output parameters. The interaction effect revealed that in environments dominated by intense rivalry, supplier integration had a substantial and positive influence on SC performance. This is a significant finding, meaning that where competitive capacity occurs, higher levels of supplier integration lead to higher levels of SC performance. In competitive markets, investments in supplier growth practices are warranted, as they are supposed to increase the consumer firm’s SC productivity results.

Internal integration was found to be the SCM practice that contributed the most to SC production. Furthermore, there was an important and positive interaction impact of competitive capability on the relationship between internal integration and SC performance. Internal integration is a critical SCM method for improving SC performance, regardless of whether markets are marked by low or intense competition, according to the findings. The findings matched those of Saeed et al. (2005) and Flynn et al. (2010), who found that internal alignment had an effect on organizational success and process reliability, respectively. The key results of exchanging information and deferring decisions on SC performance were found to be favorable and important. Competitive capacity has no moderating impact on the relationship between the two variables and SC performance. Customer convergence has no discernible impact on SC performance. Furthermore, competitive capacity had a major and negative moderating impact on the relationship between consumer integration and SC performance. That is, as competitive capacity occurs, the higher the consumer integration activities, the lower the SC performance levels. These findings were generally in line with those of Sundram et al. (2011) and Lee et al. (2007), who found that consumer convergence has little impact on SC and cost efficiency, respectively. Customer integration efforts, for example, can necessitate additional investments and resources in order to ensure timely and consistent communication with consumers. Although such contacts may be required in competitive markets, they are likely to have a negative impact on SC performance.

The findings of this study clearly support the conclusion that the supply chain integration component of consumer integration has a substantial impact on supply chain agility, but the supply chain integration dimensions of supplier and internal integration do not. These findings may appear to contradict those of Fayezi et al. (2017), who discovered a close link between supply chain incorporation and supply chain agility. (Abdallah & Nabass, 2018; Agarwal & Shankar, 2002) backed up this claim, concluding that successful supply chain integration and coordination among partners leads to more agile and scalable businesses. Both of these results support this study, which states that when agile organizations are confronted with high levels of uncertainty, their supply chain resilience increases. Internal incorporation is most successful when it comes to exploring experience and expertise in order to develop new goods (Tessarolo, 2007). This demonstrated that supply chain convergence, together with supply chain resilience and operational versatility, has an effect on a company’s exploratory activities. Given the present turbulent business climate, where recession is rampant and global commodities prices, such as oil prices, have crashed to alarming lows, it is more prudent for firms to engage in exploratory rather than exploitative activities. Companies would be forced to look beyond their usual range of market limits as a result of the numerous global challenges that have reduced their bottom lines. Exploiting their current market strategies and approaches in the hopes of extracting optimum revenue for their companies is no longer enough. Companies would have to dig deep to look beyond their normal horizons in order to diversify their industry beyond their respective sectors.

Conclusion

The results also showed that while supplier integration had a substantial and negative effect on SC performance at low levels of competitive capability, it became significant and optimistic at high levels of competitive capability. The findings of existing research on the effect of supplier convergence on success are contradictory and inconsistent. In high- competitive settings, this study adds to the SCM literature by emphasizing the value of supplier integration as a strong predictor of SC performance. The findings also revealed that at high levels of competitive capability, the effect of internal integration on SC performance became more important. By looking at the effects of individual SCM activities on SC efficacy, the research added to the SCM literature. Internal incorporation, postponement, and consumer integration were found to be the most beneficial SCM practices for SC effectiveness. Another conflicting issue in the literature was the effect of consumer convergence on SC results, which was discussed in this report. Although consumer integration has little impact on SC performance, it is critical for SC effectiveness to be maximized. The findings revealed that at high levels of strategic capacity, the effects of both consumer integration and knowledge exchange on SC efficacy were more important. In order to reach superior levels of SC effectiveness, manufacturing firms should improve the levels of application of these two activities in intensely competitive environments.

Implications

The findings of this study also show that high levels of exploratory behavior would boost supply chain resilience, as agile businesses look for innovative product technologies, new ways to satisfy consumers, and new consumer segments to invest in. These practices force the corporation to become more involved with both its vendors and consumers in order to better satisfy them. The Jordanian services and manufacturing firms must improve supply chain knowledge through the implementation of Industry 4.0 technology at the technical, logistical, and organizational levels through their respective supply chain partners in order to build a more resilient and scalable supply chain. These Jordanian services and manufacturing firms will be able to achieve rapid prototyping and development, as well as push higher levels of product and service innovation, thanks to the end-to-end convergence provided by Industry 4.0 technologies.

Limitations and Future Aspects

The data was obtained from a single informant in each manufacturing facility, which is a drawback of this study. Informants were only partly responsible for some SCM operations in some situations. More research with different informants is required so that respondents can discuss their own area of knowledge, increasing the relevance of the results. Another drawback of the study sample size is that made it unable to explore the indirect consequences of the study variables. Furthermore, use of control variables like firm scale, firm age, and industry category was avoided to prevent possible multicollinearity, which is likely to influence the outcomes when the number of variables in a regression model is increased. More research with a greater sample size is required to look at the indirect effects of the variables which provide control variables. Moreover, limitations of the evaluation approach rely on the managerial perspective of the professionals, who were working in the medical sector for assessing the significance of all elements including technology, strategy, and marketing. In addition, recognition of enablers, and agility competencies differ from one company or sector to another based on the appropriateness of specific considerations and environment of organization. Additionally, the computation of index, agility level, and weights are not easily recognized by managers. Therefore, these computations can be computerized for accelerating preciseness as well as mitigating both possibility of errors and computation time. Finally, in the system, there was inclusion of a single moderating influence. Other contextual variables can have an impact on the connection between SCM and SC results. More research is required to look at the moderating impact of other factors on the relationship between SCM activities and SC results, such as market volatility, strategic priorities, and creativity.

References

Abdallah, A.B., & Nabass, I.H. (2018). Supply chain antecedents of agile manufacturing in a developing country context: An empirical investigation. Journal of Manufacturing Technology Management, 29(6), 1042-1064.

Agarwal, A., & Shankar, R. (2002). Analyzing alternatives for improvement in supply chain performance. Work study.

Ali, S.I., & Ali, S.R. (2013). Is supply chain management important to implement in manufacturing industries of Saudi Arabia?. European Journal of Business and Management, 5(27), 58-64.

Altarawneh, M., Shafie, R., & Ishak, R. (2020). CEO characteristics: A literature review and future directions. Academy of Strategic Management Journal, 19(1), 1-10.

Berteig, M. (2005). Introduction to agile work.

Bravo, M.I.R., Moreno, A.R., & Llorens-Montes, F.J. (2016). Supply network-enabled innovations. An analysis based on dependence and complementarity of capabilities. Supply Chain Management: An International Journal.

Centobelli, P., Cerchione, R., & Ertz, M. (2020). Agile supply chain management: where did it come from and where will it go in the era of digital transformation? Industrial Marketing Management, 90, 324-345.

Ciccullo, F., Pero, M., Caridi, M., Gosling, J., & Purvis, L. (2018). Integrating the environmental and social sustainability pillars into the lean and agile supply chain management paradigms: A literature review and future research directions. Journal of Cleaner Production, 172, 2336-2350.

Cohen, S., & Roussel, J. (2013). Strategic supply chain management: The five disciplines for top performance. McGraw-Hill Education.

Green, K.W., Inman, R.A., Sower, V.E., & Zelbst, P.J. (2019). Impact of JIT, TQM and green supply chain practices on environmental sustainability. Journal of Manufacturing Technology Management.

Hair, J.F., Black, W., Babin, B., Anderson, R., & Tatham, R. (2010). Sem: An introduction. Multivariate data analysis: A global perspective, 629-686.

Hair, J.F., Hult, G.T.M., Ringle, C., & Sarstedt, M. (2016). A primer on partial least squares structural equation modeling (pls-sem): Sage Publications.

Hair, J.F., Sarstedt, M., Ringle, C.M., & Mena, J.A. (2012). An assessment of the use of partial least squares structural equation modeling in marketing research. Journal of the Academy of Marketing Science, 40(3), 414-433.

Henseler, J., Ringle, C. M., & Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. Journal of the Academy of Marketing Science, 43(1), 115-135.

Hong, J., Zhang, Y., & Ding, M. (2018). Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. Journal of Cleaner Production, 172, 3508-3519.

Huo, B., Gu, M., & Wang, Z. (2019). Green or lean? A supply chain approach to sustainable performance. Journal of Cleaner Production, 216, 152-166.

Inman, R.A., & Green, K.W. (2018). Lean and green combine to impact environmental and operational performance. International Journal of Production Research, 56(14), 4802-4818.

Kaipia, R. (2009). Coordinating material and information flows with supply chain planning. The International Journal of Logistics Management.

Koufteros, X., Vonderembse, M., & Jayaram, J. (2005). Internal and external integration for product development: The contingency effects of uncertainty, equivocality, and platform strategy. Decision Sciences, 36(1), 97-133.

Lee, C.W., Kwon, I.W.G., & Severance, D. (2007). Relationship between supply chain performance and degree of linkage among supplier, internal integration, and customer. Supply Chain Management: An International Journal.

Mathew, J., John, J. & Kumar, S. (2013). New trends in healthcare supply chain. In annals of POMS Conference Proceedings, 1-10.

Mathu, K., & Phetla, S. (2018). Supply chain collaboration and integration enhance the response of fast-moving consumer goods manufacturers and retailers to customer’s requirements. South African Journal of Business Management, 49(1), 1-8.

Mathur, B., Gupta, S., Meena, M.L., & Dangayach, G.S. (2018). Healthcare supply chain management: literature review and some issues. Journal of Advances in Management Research.

Miraz, M. H., Hasan, M. G., & Sharif, K. I. (2018). The relationship between personal and organizational in supply chain integration: Case study in Malaysia. Economic Research, 2(7), 43-48.

Mwaiseje, S.S., & Mwagike, L. (2019). Effects of agile supply chain practices on performance of healthcare sector in Tanzania: A case of selected public hospitals in dodoma city.

Narayanan, A.E., Sridharan, R., & Kumar, P.R. (2019). Analyzing the interactions among barriers of sustainable supply chain management practices: A case study. Journal of Manufacturing Technology Management.

Ritchie, J., Lewis, J., Nicholls, C.M., & Ormston, R. (Eds.). (2013). Qualitative Research Practice: A Guide for Social Science Students and Researchers. Sage.

Sbai, N., & Berrado, A. (2018). A literature review on multi-echelon inventory management: the case of pharmaceutical supply chain. In MATEC Web of Conferences, EDP Sciences.

Scavarda, A., Daú, G. L., Scavarda, L.F., & Korzenowski, A.L. (2019). A proposed healthcare supply chain management framework in the emerging economies with the sustainable lenses: The theory, the practice, and the policy. Resources, Conservation and Recycling, 141, 418-430.

Sen, D.K., Datta, S., & Mahapatra, S.S. (2018). On evaluation of supply chain’s ecosilient (g-resilient) performance index: A fuzzy embedded decision support framework. Benchmarking: An International Journal.

Sindhwani, R., Mittal, V.K., Singh, P.L., Aggarwal, A., & Gautam, N. (2019). Modelling and analysis of barriers affecting the implementation of lean green agile manufacturing system (lgams). Benchmarking: An International Journal, 26(2), 498-529.

Singh, J., & Raghuram, D.J. (2017). Evolution of supply chain management with emerging technologies. International Journal of Mechanical Engineering and Technology, 8(1).

Sundram, V.P., Ibrahim, A.R., & Govindaraju, V.G.R. (2011). Supply chain management practices in the electronics industry in Malaysia: Consequences for supply chain performance. Benchmarking: An International Journal, 18(6), 834-855.

Swink, M., Narasimhan, R., & Wang, C. (2007). Managing beyond the factory walls: effects of four types of strategic integration on manufacturing plant performance. Journal of Operations Management, 25(1), 148-164.

Syed, M.S.A.H. (2012). Supply chain management: A model for implementation for SME's in Saudi Arabia. Sheffield Hallam University (United Kingdom).

Tessarolo, P. (2007). Is integration enough for fast product development? An empirical investigation of the contextual effects of product vision. Journal of Product Innovation Management, 24(1), 69-82.

Wadesango N., Mhaka C., & Blessing, M. (2020) Literature review of the effect of corporate governance on financial performance of commercial banks in a turbulent economic environment. Academy of Strategic Management Journal, 19(3).

Whitehead, K. (2014). It’s a matter of give and take: Exploring the role of knowledge transfer in the supply chain, 1-249.

Wisner, J.D., Tan, K.C., & Leong, G.K. (2014). Principles of supply chain management: A balanced approach. Nelson Education.

Zhan, Y., Tan, K.H., Ji, G., & Tseng, M.L. (2018). Sustainable Chinese manufacturing competitiveness in the 21st century: Green and lean practices, pressure and performance. International Journal of Computer Integrated Manufacturing, 31(6), 523-536.

Zhu, Q., Shah, P., & Sarkis, J. (2018). Addition by subtraction: Integrating product deletion with lean and sustainable supply chain management. International Journal of Production Economics, 205, 201-214.