Research Article: 2022 Vol: 26 Issue: 2

The Impact of Quality Costs on Customer Value: An Applied Accounting and Financial Research in the General Directorate of Electricity Distribution in the Middle Euphrates

Atheer Ali Abdulkadhim, Madenat Alelem University College

Khawla Hamdan, University of Baghdad

Mohammed Hazim Alghazali, University of Al Mosul

Sura Naufel Bahjet, Madenat Alelem University College

Citation Information: Abdulkadhim, A.A., & Hamdan, K., Alghazali, M.H., & Bahjet, S.N. (2022). The impact of quality costs on customer value: an applied accounting and financial research in the general directorate of electricity distribution in the middle Euphrates. Academy of Accounting and Financial Studies Journal, 26(2), 1-12.

Abstract

The measurement of quality costs (Appraisal, prevention, failure) is considered of importance to customers thus research seeks to identify quality costs, their types, and customer value this and then measure the relationship between them using the SPSS statistical program on the research sample. A strong and significant correlation between (assessment costs, prevention costs, internal failure costs, and external failure costs) and (customer value).

Keyword

Quality Costs, Accounting, Finance, Appraisal Cost, Prevention Cost, Failure Cost, Customer Value.

Introduction

The political conditions and changes that our economic units have witnessed have confused their work and become lagging behind their counterparts in the region and the world, and their inability to compete, and among the reasons for their delay is the weakness of administrations and the weak use of modern administrative methods in their work. And because these costs constitute high percentages of project costs, and these costs have an impact on the company’s performance, and therefore quality is a strategic goal and a competitive advantage for most economic units that have been placed at the forefront of the objectives of the economic unit as evidence of its success, development and continuous improvement of its performance (Alwan, 2009:53). The economic units in general, and the industrial ones in particular, seek achieving competitive advantages that enables them to withstand the serious global competition challenges, to ensure its survival and continuity (Al-Jubouri, 2010:98; Hamdan & et al., 2020). The important and modern methods that contribute to achieving the cost reduction advantages and quality improvement to achieve the customer’s desires and this indicates the existence of a correlation between each of the four quality costs represented by (prevention costs, evaluation costs, internal failure costs and external failure costs) and the customer value, which will be shown in the research.

Research Methodology

Research problem

Most companies spend on quality costs (prevention and Appraisal) for the purpose of reducing the internal and external failure rate and raising the value of the customer, however, the expenditure did not achieve that goal due to the lack of follow-up to the expenditure and to ensure that the expenditure achieved the desired objectives, as the research problem is the lack of clarity in the relationship between the types of quality costs (prevention, Appraisal , failure) and the customer value of the research sample.

Research Importance

The importance of the research lie in clarifying the costs of quality with its different classifications and the value of olives and showing the relationship of each type of quality costs with the value of the customer.

Research Aims

The research aims to identify the following:

1. Quality costs and their types

2. The customer value and its relationship with the different quality costs types.

Research Hypothesis

The main hypothesis: Is there a correlation and a statistically significant effect of quality costs and the value of the customer?, a number of sub-hypotheses are branched from it:

There is a statistically significant correlation and impact relationship between quality costs (Appraisal costs, prevention costs, internal failure costs, external failure costs) and the customer's value.

Previous Studies

A study Al-Otbi & Hamdan (2014) entitled Measuring and analyzing quality costs and its impact on strategic performance in the construction sector. Where the study aimed to identify the quality in the construction sector and the characteristics of the construction sector and to measure and analyze the costs of quality in the construction sector and on one of the construction projects of the research sample, and then to show the impact of measuring and analyzing quality costs and their reflection on the perspectives of the balanced scorecard (financial, customer, internal operations, growth and learning), and the research reached a set of conclusions, the most important of which was the cost of fines incurred by the project is the highest percentage within the costs of internal failure as a result of the delay in completion within the specified dates, as it amounted to (47%), although the costs of supervising the implementation of the contract and designs represent 40% of the costs Prevention, however, did not reduce the costs of internal failure.

Study Chen (2015) entitled Customer Value and Customer Loyalty: Is Competition a Missing Link? This study aims to provide an insight into the effects of competition on customer value delivery and customer loyalty, where data were collected using a questionnaire from service employees and customers, and Anova techniques were used, Ordinary least squares, and logistic regression analysis, where the results show that competition is the supervisor of the relationship between customer value and customer loyalty from the perspective of the consumer. Also, competition is an indicator of customer loyalty from an employee's perspective. This study also found that the predictive validity of the customer-consumer model is much higher than that for employees.

Definition and Importance of Quality costs

Quality costs are defined as the costs that are related to the lack of quality of the product or service as specified in the specifications of contracts with customers and society by the economic unit (Busterfield et al., 1995: 139).

Therefore, the importance of quality costs lies in the following points:

1. Quality costs are a strong indicator to motivate the higher authorities in the application and implementation of quality costs, and these benefits are the reduction of the total costs of the product and the effective control and control of them, and as a result, an increase in the profits of the unit.

2. It is a continuous quality improvement tool, as it contributes to identifying areas of failure and weakness and sources of defects, using statistical methods (Barwari, Bashiwa, 2011:431).

3. Documenting quality costs provides a wide scope for following up the behavior of these costs, preparing for overcoming future errors, and preparing for corrective actions (Al-Jubouri, 2010:93).

4. Financial quality cost measures contribute to solving problems by comparing the costs and benefits of different quality improvement programs and identifying beginnings to reduce costs (Horngren et al., 2003:663).

5. Quality cost budgeting is developed as a tool to help management reduce total costs and evaluate performance from year to year through basic quality cost information (Garrison & Noreen, 2000:1002).Classification of Quality Costs

During the historical development of quality costs, classification there have been many attempts aimed at inventorying and categorizing the elements of quality costs since the discussion Juran (1951) of the concept of quality costs, the most prominent of which is an attempt (Feigenbaum, 1991:355-357), where he classified them into costs of prevention, Appraisal, internal failure and external failure (PAF).

From the foregoing, there are many different labels for the classification of quality costs, but they are divided into three groups: prevention, Appraisal, internal failure and external failure, which in turn is divided into internal failure and external failure. There are those who divide them into direct and indirect costs, or into visible and hidden costs and also to the costs of matching and non-conformity.

Prevention, Appraisal, Failure cost

There is an agreement among researchers, including (Croocock, 1980), (Burns 1976) and (Tim 2006), on the triple tabulation, which Juran found in his reference book Quality Control Handbook-1951, and Feigenbaum agreed with him in his book Total Quality Control-1961, As the quality costs have been classified into non-controlled costs, that is outside the control of the administration, they change inversely with the increase of that level, including (the cost of failure in its internal and external types and the remaining part of the Appraisal costs) and the other part under the control of the administration changes directly with the increase in the quality level of them (the cost of prevention and part of the cost Appraisal (Al-Jubouri, 2010:98). Below are the details of this tab:

First- Prevention cost

It can be defined as “the costs incurred by the company as a result of the efforts it exerts in the design and manufacturing, and directly to prevent non-conformity with specifications and manufacture products correctly from the first moment of production operations” (Alwan, 2009:53), and in other words as “the costs that occur to prevent the production of products does not conform to the specifications (Horngren et al., 2009:693).

This Type Includes

Quality system planning, product quality design and development costs, quality management and institutional development department (quality systems), preventive maintenance costs, information costs for quality, internal quality audits, training costs and awareness related to quality, and finally industrial safety.

Second- Appraisal Cost

As defined by Russell & Taylur, (1998) "they are the costs of measurement, examination and analysis of materials and product components" and they are "the costs that are charged to discover the individual units of production that do not match the specifications (Horngren, 2009:693). Or they are the costs associated with evaluating or reviewing and examining products or services to make them conform to quality standards and performance requirements (Olso & Partner, 2007: 28).

This type includes: Examination and qualitative assurance, engineering inspection and inspection, final examination and test costs, transformer inspection workshops, deterioration costs of inspection equipment and devices, total quality and the environment.

Third- Internal Failure Cost

It is the costs charged to defective products before they are shipped to customers (Horngren et al., 2009:693), and it is also known as all costs necessary to evaluate or dispose of the product as well as correct or replace inappropriate products or services before delivery to the customer, as well as correcting or replacing A description of the incomplete or incorrect product or service (Busterfield, 1995: 144).

This type guarantees: abnormal damage, re-examination costs.

Fourthly- External Failure Cost

The cost of external failure can be large because of its impact on the company's reputation, so the costs that are spent on these activities can be huge and can be small compared to the opportunity costs of sales that will occur in the future (Hilton et al., 2003: 268), It is defined as the costs charged to defective products after they are shipped to customers (Horgren et al., 2009:693).

This type includes: Electricity Complaints Center, Compensation and Fines, Electricity Sale losses.

Customer Value

The issue of the customer is the problem of the modern productive age, because in light of the market competition, knowledge progress and other economic developments, it has produced a new behavioral pattern for the customer. Excellence, this customer has become a very important position within the interests and priorities of the institution.

Value Concept

As defined by many prior authors such as (Berkowitz et al., 2000:364) (Arenes et al., 2008:244) and (Arenes, 2006:241) value concept cost is the Value is the ratio of interest received by the customer to the price, as defined by (Spulber, 2004: 173) (Perrealt & McCarthy, 2005: 18) it is the benefits received by the customer minus the price he pays to obtain the product.

Kotler et al. (2005:10) defined the value of the customer as the ability of the product to meet the needs of the customer. He also defined it (Hill & Jones, 2010:77). Value is the happiness and satisfaction gained from the acquisition and consumption of the product by the customer. Whereas (Hongni, 2010: 181) defined it as the satisfaction resulting from owning and using the product that meets the requirements of customers at the lowest total cost.

Customer Value Elements

Total Customer Value

It is a set of benefits that the customer obtains from the service or the commodity (kotler, 1997: P38). The benefit consists of product value, service value, personal value, and mental status value.

The value of the Product

It means the physical characteristics of the product itself and it consists of performance, reliability, conformity, durability, and aesthetics (Besanko et al., 2001: 437).

The Value of The Service

The service that is provided through the product is of increasing importance to distinguish and the areas of distinction for the service are accounts and financing, order facilities, express delivery, installation, training and consulting, after-sales services, warranty.

The value of the Personal

The organization’s personnel is an important source for achieving excellence, especially in service-oriented marketing and the high quality of personal services, where there are many characteristics enjoyed by individuals who add value through personal service, including professionalism, courteousness or courtesy, reliability or trustworthy, reliability, perseverance (Doyle, 1994; 71-72).

The value of Mental Status

Mental status is a convenient way of referring to a combination of psychological rewards that a customer receives when buying, owning, and consuming a product. And the mental position emerges through the advertising message during the mobilization (Besanko et al., 2001; p437).

Total costs to the customer

The costs incurred by the customer are divided into: (Al-Tai & Al-Abadi, 2008:80).

Cash costs: monetary costs represent the price, which is the exchange value of products and on the basis of which the value of the product that the customer will receive is determined. NS. Time cost: Some customers look at the cost of time as being higher than the cash costs, especially for customers who tend to take advantage of lost time.

1. Effort cost, which means the effort the customer makes for the purpose of acquiring the product, as this element is considered a cost paid by the customer.

2. Psychological cost: Psychological cost includes dealing with new people and the need to understand the procedures.

3. The efforts made to adapt to new things and the accompanying frustration of the customer in the event of not adding value to him when acquiring a particular product.Customer Value Hierarchy Model

The Desired Value model comprises this value hierarchical model, developed by Woodruff. Value is based on learning and focusing on Received Value, and Desired Value must be clarified (Tzokas & Saren, 1998). Assumptions, preferences, and customer evaluation conceptually customer value.

Three levels, Based on his concept of customer value. This is to be the value of the customer in a conceptual way with three levels based on his concept of customer value in Incorporated, results and goals. These three levels are combined characteristics and these levels are a model of the customer value hierarchy.

Generate value for the Customer

Customer value generation is a disciplined approach that has been used and tested by many industrial companies (Japanese automakers) and has proven its effectiveness in achieving growth and profit, because it seeks to analyze customer value from one side and from the other side perform the operational processes of the product with distinction, as it focuses on generating customer value. And the exchange of value with customers (Plaster & Alderman, 2006:3).

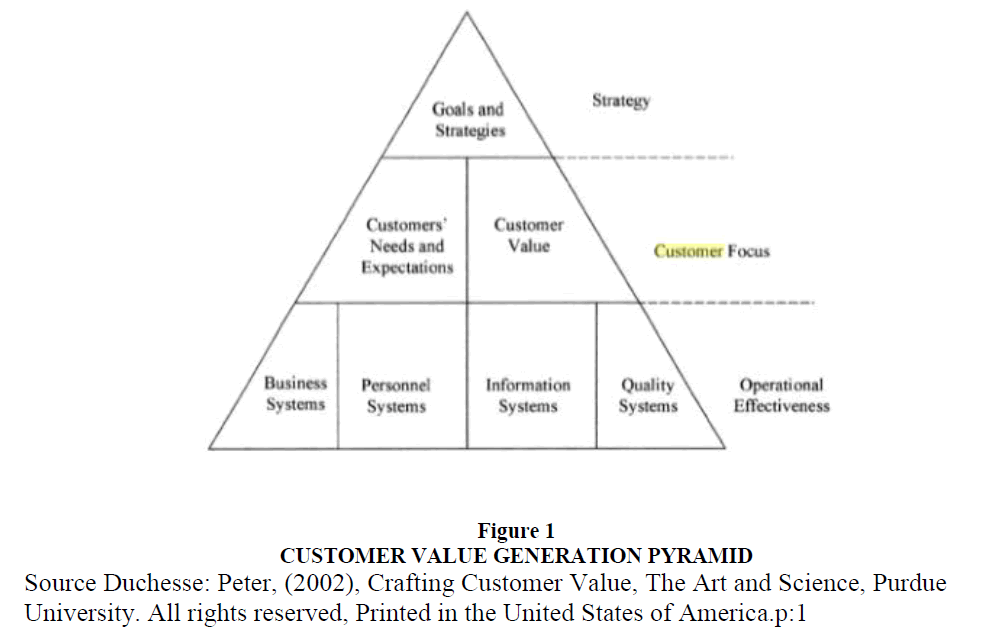

Duchessi, (2002:1-2) provides a comprehensive method for creating value for customers based on unifying the various business functions in the company around common goals and strategies, which are focusing on customer needs and expectations, understanding the basic elements of customer value, and developing plans, business, human resources, information and quality required to provide Value for customers, through a top-down process to help corporate management coordinate goals and strategies and link them to daily business activities, and manage detailed aspects such as quality, human resources and information. This method can be visualized in the form of (customer value generation pyramid) Figure 1.

Figure 1 Customer Value Generation Pyramid

Source Duchesse: Peter, (2002), Crafting Customer Value, The Art and Science, Purdue University. All rights reserved, Printed in the United States of America.p:1

An introductory overview of the General Directorate of Electricity Distribution / Middle Euphrates

The General Directorate of Electricity Distribution of the Middle Euphrates is one of the formations of the Ministry of Electricity that was created by Ministerial Order No. (128) on 10/11/2003 and issued by the Ministry of Electricity. The General Directorate supervises the distribution of electric power in these governorates, and manages all activities related to the distribution of electric power from the two voltages (11KV and 33KV), where energy is received through feeders coming out of the secondary transmission stations of the General Directorate of Electricity Transmission through the electrical network and its lines. The General Directorate takes upon itself the implementation of all works and activities related to receiving electrical energy from the General Directorate of Electrical Energy Transmission and distribution to consumers of all types throughout the Middle Euphrates region through its directorates, improving the network and collecting the sums owed by subscribers.

Quality Costs

First: Determining quality costs in the General Directorate of Electricity Distribution / Middle Euphrates: The company has a special section for financial affairs and includes a division specialized in cost accounts, but this division does not calculate quality costs, as it calculates these costs with other costs in the company The fact that the accounting guide does not contain accounts for quality costs detailed in all its sections, which are prevention, evaluation, internal failure, and external failure. Table 1 shows the elements of quality costs, the General Directorate of Electricity Distribution / Middle Euphrates, which were calculated in the published research (Hamdan et al., 2020).

| Table 1 Elements of Quality Costs, General Directorate of Electricity Distribution / Middle Euphrates | |||||

| First: the costs of prevention | Relative to quality costs | Second : - Evaluation costs | Relative to quality costs | Third : The costs of internal failure | Relative to quality costs |

| 1- Quality Planning | 0.18% | 1- Examination and qualitative assurance | 48.80% | 1- abnormal damage | 6.11% |

| 2- Product design | 0.01% | 2- Engineering inspection and inspection | 2.35% | 2- Re-examination costs | 0.30% |

| 3- Development of quality systems | 0.59% | 3- Examination and final test | 0.04% | Fourth: the costs of external failure | |

| 4- Preventive maintenance | 0.02% | 4- Transformer inspection workshops | 0.82% | ||

| 5- Information costs for quality | 0 | 5- Inspection and maintenance of midwives | 0.75% | 1- Electricity sale losses | 9.59% |

| 6- Training costs for quality | 1.26% | 6- Degradation of examination equipment | 0.81% | 2- Customer Complaint Center | 18.07% |

| 7- Quality management | 5.86% | 7- Monitor and evaluate training | 0.00% | 3- Compensation and fines | 3.10% |

| 8- Costs of internal quality audit | 0.01% | 8- Total quality and environment | 0.24% | ||

| 9- Industrial safety | 1.10% | ||||

| Total prevention costs | 9.02% | total appraisal costs | 53.81% | Total failure costs | 37.17% |

| Total components of quality costs | 100% | ||||

Customer value of the Research Sample

The customer is the main goal of any economic unit because it is the source of its financing, and in light of the modern manufacturing environment, the survival of any unit in the market depends on satisfying customers and maintaining them, so any economic unit must put customers at the forefront of its attention because it is considered its main goal, and so that it can earn Customer loyalty must have high quality products at an acceptable price, and it includes the following indicators and measures (market share, quality of manufacture, quality of the product sold, customer satisfaction, improving project quality, reducing market share risks) Table 2.

| Table 2 Customer Value Indicators General Directorate of Electricity Distribution / Middle Euphrates | |||

| Target | pointer | Measurement method | 2014 |

| Increase market share | Total customer value = market share | 5005573/8371360*100% | 59.800% |

| build quality | Product value = Percentage of damaged units | 100%*4099511/12471393 | 32.870% |

| The quality of the product sold | Personal value = Ratio of repair orders to total units sold | 91421/8371360*100% | 0.100% |

| Customer satisfaction | The value of the mental prestige = the ratio of fines to quality costs | 100%*148590518/4624982929 | 3.210% |

| Improve project quality | The value of the service provided = the ratio of idle transformers to the loads of transformers | 487/22370*100% | 2.180% |

| Reducing market share risk | Total Customer Costs = Ratio of External Failure Costs to Net Sales | 100%*140947394902/ 1473341616 | 1.045% |

Discuss and test the Hypotheses of the Study

To prove the hypotheses of the study, the following tests were used:

In testing the hypotheses about the correlation between the study variables, the researcher relied on the simple correlation coefficient (Pearson). The following tables appear, to prove the correlation hypotheses.

The main hypothesis: There is a correlation and a statistically significant effect of quality costs and the value of the customer. The hypothesis was proved according to the following table 3:

| Table 3 Shows the Proof of the First Hypothesis | ||||||||

| independent variable | dependent variable | R the amount of the relationship | relationship type | F the amount of tabin | linear regression coefficient | (T) T-value | Beta coefficient B The amount of the effect | Indication level |

| Quality costs | customer value | 0.35 | positive | 2 | 12% | 2 | 0.347 | 0 |

The results showed that there is a strong and significant correlation between quality costs and the value of the customer. The highest value (t) calculated (2) at quality costs in relation to the value of the customer, which is parallel to its tabular value under the level of significance (0.05), amounting to (2), and this is evidence of the existence of homogeneity between the variable in the sample answers, while the value of the correlation coefficient was (0.35), which is a high positive correlation if there is a strong direct relationship between (quality costs and the value of the customer). The higher the value of quality costs, the higher the value of the customer with the same increase in the amount, and the value of the variance was at a level of significance less than 0.05 = 2, and this indicates that there is a discrepancy between the sample answers, as the effect between the two variables was 0.347, and this indicates that quality costs have positive contributions to customer value.

A number of sub-hypotheses are branched from it: There is a correlation and effect with a statistical significance, quality costs (evaluation costs, prevention costs, internal failure costs, external failure costs) and the customer's value. The hypothesis was proved according to the following table 4:

| Table 4 To Prove the Sub-Hypotheses | ||||||||

| independent variable (quality costs) | dependent variable (customer value) | R the amount of the relationship | relationship type | F the amount of tabin | linear regression coefficient | (T) T-value | Beta coefficient B The amount of the effect | Indication level |

| Evaluation costs | customer value | 0.30 | positive | 690 | 9% | 2 | 0.300 | 0.00 |

| Prevention costs | 0.25 | positive | 545 | 6% | 1 | 0.253 | 0.39 | |

| The costs of internal failure | 0.94 | positive | 7.69 | 88% | 7.6 | 0.941 | 0.00 | |

| External failure costs | 0.64 | positive | 2 | 41% | 3.9 | 0.645 | 0.05 | |

Conclusions

1. The results showed that there is a strong and significant correlation between the evaluation costs and the value of the customer. The highest value (t) calculated (2) at the evaluation costs in its relationship with the value of the customer, which is parallel to its tabular value under the level of significance (0.05) and amounting to (2). This is evidence of the existence of homogeneity between the variable in the sample answers, while the value of the correlation coefficient reached (0.30), which is a positive high correlation if there is a strong direct relationship between (the evaluation costs and the value of the customer). The value of the variance was at a level of significance less than 0.05 = 690, and this indicates that there is a discrepancy between the sample answers, as the effect between the two variables was 0.300, and this indicates that evaluation costs have positive contributions to the value of the customer.

2. The results showed that there is a strong and significant correlation between the costs of prevention and the value of the customer, it amounted to less than the calculated (t) value (1) when the costs of prevention in its relationship with the value of the customer, which is parallel to its tabular value under the level of significance (0.05) and amounting to (2) This is evidence of the lack of homogeneity between the variable in the sample answers. As for the value of the correlation coefficient, it reached (0.25), which is a positive correlation if there is a strong direct relationship between (prevention costs and the value of the customer), but this relationship is not reliable, and the value of the variance is at the level of Significance greater than 0.05 = 545 and this indicates that there is no discrepancy between the sample answers that the costs of prevention have no positive contributions to the value of the customer.

3. The results showed that there is a strong and significant correlation between the costs of internal failure and the value of the customer. The highest value (t) calculated (2) at the costs of internal failure in its relationship with the value of the customer, which is parallel to its tabular value under the level of significance (0.05), which is (2) This is evidence of homogeneity between the variable in the sample answers, but the value of the correlation coefficient reached (0.94), which is a high positive correlation if there is a strong direct relationship between (the costs of internal failure and the value of the customer), the higher the value of the costs of internal failure, the higher the value of the customer With the same increase in the amount, the value of the variance was at a level of significance less than 0.05 = 7.69, and this indicates that there is a discrepancy between the sample answers, as the effect between the two variables was 0.941, and this indicates that the costs of internal failure have positive contributions to the value of the customer.

Arenes, F. (2006). Contemporary advertising, 10th ed, Irwin, McGraw – Hill.

Arenes, F., & Weigold, F.A. (2008). contemporary advertising, 11th ed, Irwin, McGraw – Hill.

Berkowitz, N., Eric, A., Hartly, W., & Rudelius, W. (2000). Marketing 6th ed, Irwin, McGraw – Hill.

Busterfield, D., & others. (2002). Total Quality Management, translated by Dr. Rashid bin Muhammad Al-Hamali, Riyadh, Saudi Arabia.

Doyle, P. (1994). “Marketing management and Strategy” By Prentice Hall Inc.

Feigenbaum, A.V. (1991). Total Quality Control, 3rd ed., McGraw-Hill Inc., New York.

Garrison, R.H., & Noreen, E. (2002). Management Accounting, translated by Muhammad Essam and Ahmed Hamed Hajjaj, Al-Marrikh Publishing House, Kingdom of Saudi Arabia.

Juran, J.M., & Frank, G. (1997). quality planning and analysis". 3rd Ed. New York: MC Graw-hill inc.

Kotler, P. (1997). Marketing management 9ed, By Prentice –Hill, Inc.

Olso, R.E., & Partner. (2007). Cost of Quality as a Driver for Continuous Improvement.

Spulber, F. (2004). Management strategy, Irwin, 2nd ed, McGraw.