Research Article: 2019 Vol: 22 Issue: 2

The Effects of Inbound Logistics Capability on Firm Performance-A Study on Garment Industry in Bangladesh

Md. Sazzadur Rahman Khan, Naresuan University, Thailand

Vichayanan Rattanawiboonsom, Naresuan University, Thailand

Abstract

Capabilities are the complex bundles of knowledge and skill applicable in management for effective and efficient utilization of assets in the organization. Logistics capabilities are the ability to exploit firm resources acquiring competitive advantage for the superior firm performance. The purpose of this research is to examine the effects of inbound logistics capability on firm performance in terms of tangible and intangible benefits. A quantitative method has been used and also identifies Confirmatory Factor Analysis (CFA) to test the relationship between observed variables and latent constructs. This research employs SPSS version 20 And Structural Equation Model (SEM) based on AMOS version 23 to analyze the data surveyed in the 120 garment factories located in export processing zone as well as domestic factories of the capital city–Dhaka, Bangladesh. The results found that inbound logistics capabilities are positively associated with tangible firm performance e.g. ROA, reduced cost and improve productivity whereas negatively associated with intangible firm performance e.g. customer satisfaction. The findings of research highlight about up gradation of inbound logistics capabilities in the garment industry. The result of this study provides valuable insights into logistics capability constructs for the policymakers, academics, and other users to improve firm performance.

Keywords

Inbound logistics Capability, Procurement Capability, Inventory Management Capability, Service Capability, Process Capability and Firm Performance.

Introduction

Over the last few years, the significance of the global supply chain has shaped differently the key position of logistics service in the manufacturing industry in both scale and boundary (Kumar et al., 2011). Logistical services encompass inventory management, delivery order management plans, warehousing, quality conformation, transportation, and compliance related to import and export. It also provides receiving customers’ orders and make invoice once goods have been acquired. Therefore, logistical services that are high quality in nature provide additional benefits that lead to the availability of the product which keeps manufacturer having the leading position of their competitors (Li & Warfield, 2011; Li, 2011).

Readymade garments industry has great involvement in the economy of Bangladesh in a unique way. Bangladesh is the second largest exporting country in the world (Alam & Natsuda, 2016). The export value of garments industry is $28 billion in Bangladesh whereas in China number one exporting country has a market of $130 billion (BGMEA, 2016). Nevertheless, how top countries maintain their achievement in the competitive world is the current question. The answer may be a logistics capability. There is deficiency about vertical integration in Bangladesh due to insufficient production of raw material which encourages purchasing fabrics from other countries and finally requiring higher lead time to fulfil the order (Alam & Natsuda, 2016). There is also a lack of superior grade of infrastructure that leads to shipment delay (Saxena & Salze-Lozac’h, 2010). However, previous empirical findings have limited concentration on logistics capability in Bangladesh but special concentration on logistics capability in western countries e.g. USA and Canada. This study utilizes the Resource-Based View (RBV) theory by Barney (1991) to identify the association between logistics capability and firm performance.

Literature Review

RBV can be described as a competitive advantage in which firms apply a bundle of interchangeable, tangible and intangible resources to influence firm performance (Wernerfelt, 1984). Amit & Schoemaker (1993) concluded that resources are tradable and include such as assets, information’s, competencies and capabilities. Capabilities are the outcomes of resource positioning, organizational procedures with dynamic characteristics (Amit & Schoemaker, 1993). So, capabilities should be considered individually from resources. RBV has been observed in various empirical studies in the context of particular industries (Ray et al., 2004; Chi-Chang & Po-Lin, 2017; Schmitz & Platts, 2004). Therefore, RBV enabled a sound theoretical underpinning for this study.

There are researchers who have elaborately described the process capability and performance of the firm (Morash et al., 1996; Lynch et al., 2000; Daugherty & Pittman, 1995). Process capability was identified at the operational level through process elasticity, simplicity and customary attributes (Daugherty & Pittman, 1995). Dröge et al. (1994) evaluated various logistics capability and found process capability as one of the important influential factors to secure the competitive advantage of the firm.

Liu et al. (2013) examined the information technology capability in terms of Return on Asset (ROA), profit and cycle time percentage. In another study, Lee et al. (2014) showed the IT and its effect on internet enable supply and demand process integration. Technology capability assists to cut down cost, keep inventory level at the minimum level with lead time reduction (Lee et al., 2014; Shang & Marlow, 2005; and Zhao et al., 2001). Rashed et al. (2010) narrowly described the information sharing capabilities and strategies that had negative effects on firm performance. Bangladesh readymade garments were developed with unproductive and outdated technology (Chowdhury et al., 2006; Nuruzzaman, 2013). This study tries to fill out the gap of information and technology as well as procurement capability for the betterment of the firm performance.

Bin Syed et al. (2016) observed inventory management capability at textile industry in Malaysia and revealed problems related to inventory management capability e.g. undisciplined inventory, not up to date the recording system and high amount of days on inventory due to unproductive employees. Shin et al. (2015) evaluated the inventory management in the area of the margin of inventory.

Hypothesis Development

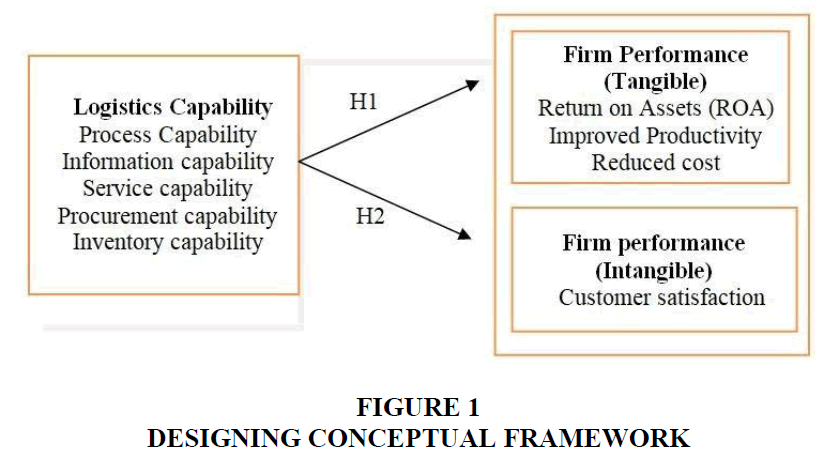

Liu et al. (2013) examined the information technology capability and found positive effects on firm performance. Notably, Zhao et al. (2001) revealed information technology capability had negative effects on firm performance. However, Shang & Marlow, (2005) found that IT capability had no relation to firm performance. Liu & Luo (2012) stated the positive relationship between process capability and firm performance in terms of Return on Investment (ROI), Return on Assets (ROA) and market share. Value-added service capabilities were able to improve firm performance in the field of logistic services (Ho & Chang, 2015). Lynch et al. (2000) found a positive relation between value-added service capability and firm performance. Namusonge et al. (2017) revealed a significant relationship between procurement capability and firm performance. Magad & Amos (1989) stated that the objective of inventory management was to provide the service of customers. Eckert (2007) evaluated inventory management and its significance for the development of customers and also dictated the positive relationship between customer satisfaction and inventory management. Lai et al. (2006) identified procurement practices based on customer satisfaction. Based on RBV, the following hypothesis can be drawn (Figure 1):

H1: Logistics capabilities have direct and significant effect on benefit performance (Tangible).

H2: Logistics capabilities have direct and significant relationship on the performance benefits (intangible).

Research Methodology

A survey of the questionnaire was executed to a garment industry in Bangladesh. The hypothesis above was tested on 120 firms from garment industry located in Adamjee EPZ and Savar EPZ Dhaka, Bangladesh. The questionnaires were given to the senior managers of 120 garments and considered such people as a suitable respondent due to their knowledge about logistics capability and strategy of the firm (Liu & Luo, 2012). The item consists the procurement, service, information and technology, inventory management and process capabilities were based on previous studies (Lynch et al., 2000; Liu & Luo, 2012; Droge et al., 2012; Savitskie, 2003; Sar, 2017). Five-point Likert scale type was used. Respondents were solicited about identifying their level of judgments on each item, where 1 corresponded to “strongly disagree” and 5 represented “strongly agree”.

There were 237 garments available in Adamjee and Savar EPZ area (BGMEA, 2016). To operate smoothly, four or five senior managers are required in garment industry. Simple random sampling was used in this study. By using Cochrun formula 385 sample size were selected from (237×4) 948 senior managers of the garment firms. From the 385 sample questionnaires, 35 questionnaires were withdrawn due to an extreme outlier of the data. Therefore, 350 questionnaires were elaborately discussed. The total 400 questionnaires were distributed and 14 questionnaires were not returned. So, the response rate in this study was 400/386=96.5% that fulfil the Bowersox et al. (1999). Table 1 represented detailed descriptions of demographic characteristics. From this study, 45% of the sampled firm had more than 2000 employees (Table 1). Most of the sampled firms in this study were established between the years 2001-2005. Senior managers had more than 10 years’ experience and most of the senior manager’s possessed diploma and bachelor degree.

| Table 1 : Demograhic Aspect About Respondents | ||

| Demographics | Description | Percentage |

| Employees | <1000 | 4% |

| 1000-1999 | 16% | |

| 2000-2099 | 45% | |

| >3000 | 35% | |

| Experience of managers | <1 year | 20% |

| >1 year but <10 years | 27% | |

| >10 years | 53% | |

| Establishment year | <1995 | 22% |

| 1996-2000 | 11% | |

| 2001-2005 | 45% | |

| 2006-2010 | 22% | |

| Educational qualification | Diploma | 39% |

| Bachelor | 38% | |

| Masters | 23% | |

Empirical Analysis

This study followed the structural equation modeling using two-step methods (Garver & Mentzer, 1999). Firstly, the study evaluated the measurement model in terms of validity. It involves reliability, unidimensionality, discriminant validity, convergent validity through confirmatory factor analysis. After assessment of the measurement model structural equation model can be used to identify the structural model (Wisner, 2003).

Reliability and Validity: Confirmatory Factor Analysis

To determine the effects of logistics capability on firm performance, factor analysis has been used. Factor analysis is widely used as a multivariable statistics approach that alters correlated variables into low factors in numbers which were also significant. The findings of the Bartlett test were significant at p=0.000 levels and the values were 3223.065. The sample sufficiency of Kaiser-Meyer-Olkin (KMO=0.711) was sufficient. The attained values disclose that the data is appropriate for factor analysis.

Factor rotation was used to obtain factor analysis and varimax rotations were applicable for principal components analysis. Factor loading below 0.50 and covariance (communality) below 0.65 were not considered in this study. The first-factor procurement capability explains 7.24% of total variance; information and technology capability 7.738%, service capability 6.054%; inventory management capability 10.203% and process capability 5.792% of total variances. Convergent validity and unidimensionality were considered acceptable limit due to the goodness of fit index (0.916), Tucker-Lewis index (0.915), comparative fit index (0.932) and root mean square error of approximation (0.066) assured the cut-off standard. There were no standardizing residual values (Hair et al., 1998). Expected parameter changes seem to be smaller than ± 0.3. Reliability was identified based on R2 (item reliability), reliability construct and extracted variance. All squared multiple correlations were greater than 0.30 that represents the reliability items were supported (Koufteros, 1999). For discriminant validity, the chi-square test was performed and found that all latent variables are satisfactory (p<0.05) (Anderson & Gerbing, 1988) (Table 2).

| Table 2 : Estimated And Standardized Loading, Standard Error And Critical Ratio In Measurement Table | ||||

| Factors and items | Estimated loading | Standardized loading | Standard error | Critical ratio |

| Process capability (α=0.80) PC1 PC2 PC3 |

1.798 1.158 1.000 |

0.724 0.600 0.654 |

0.198 0.132 - |

9.081 8.787 - |

| Information/Technology capability (α=0.84) ITC1 ITC2 ITC3 ITC4 |

1.000 1.037 0.815 0.787 |

0.785 0.768 0.629 0.600 |

- 0.085 0.075 0.080 |

- 12.265 10.921 9.786 |

| Value added service capability (α=0.83) VSC1 VSC2 VSC3 VSC4 VSC5 |

1.054 1.000 1.227 1.412 1.369 |

0.634 0.636 0.641 0.822 0.744 |

0.105 - 0.128 0.128 0.126 |

10.012 - 9.611 11.071 10.836 |

| Procurement capability (α=0.79) PRCC1 PRCC2 |

1.000 0.761 |

0.844 0.685 |

- 0.083 |

- 9.206 |

| Inventory management capability (α=0.84) IMC1 IMC2 IMC3 |

0.785 1.000 0.930 |

0.912 0.880 0.891 |

0.033 - 0.041 |

23.662 - 22.954 |

| Firm performance tangible (α=0.85) RC ROA IP |

1.122 0.655 0.560 |

0.741 0.589 0.678 |

0.045 0.035 0.060 |

8.563 11.437 9.556 |

| Firm performance intangible (α=0.85) CS1 CS2 |

0.740 0.920 |

0.834 0.786 |

0.066 0.055 |

9.765 8.436 |

Results

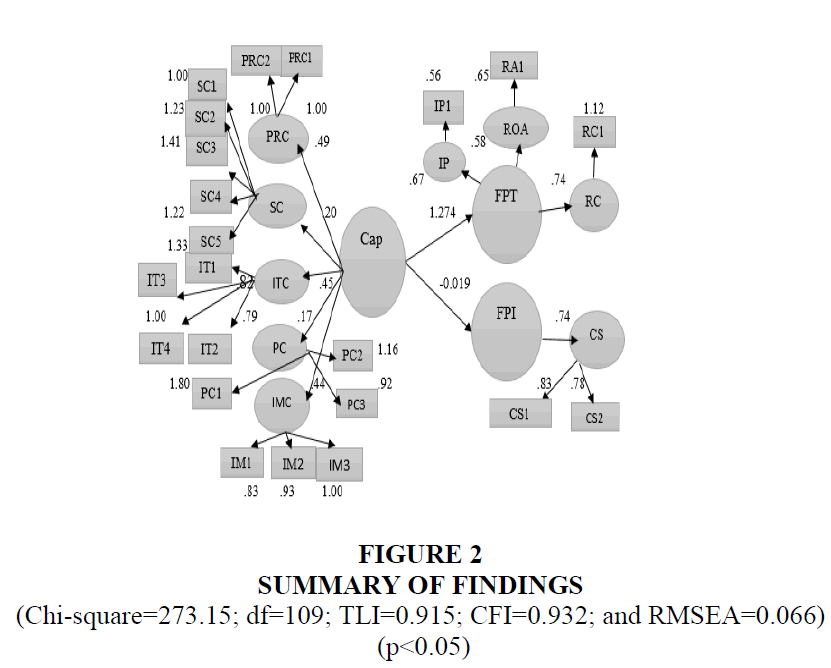

All the requirements for full model development were fit including bootstrap samples (Chi-square=273.151; df=109). It satisfied the fit indexes (TLI=0.915; CFI=0.932; and RMSEA=0.066) which recognizes that the model estimated was a good model fit (TLI is near about 0.92). After model fit evaluation, modification index and standardized residuals were investigated. There were no larger modification indexes and expected parameter changes. It is a steady model due to Expected Cross-Validation Index (ECVI) and Consistent Akaike Information Criterion (CAIC) values are not large in comparison to the original hypothesis (Browne & Cudeck, 1989) (Figure 2).

(Chi-square=273.15; df=109; TLI=0.915; CFI=0.932; and RMSEA=0.066) (p<0.05)

Figure 2: Summary Of Findings

Hypothesis Testing

Hypothesis (H1) showed that logistics capability directly affected the tangible firm performance by postulating positive value 1.274 (Table 3). It revealed t-value 4.093, standard error 0.421 and p-value 0.001 which supported the hypothesis. So, it can be explained that capability has positive effects on firm performance tangible. Hypothesis (H2) suggested that logistics capability has a negative effect on intangible firm performance. For this hypothesis, the indirect effect is -0.189, standard error 0.159, t-value is 1.342 which is not significant as p>0.05. It clearly suggested that capability has a negative relationship with intangible firm performance and not support the hypothesis (H2).

| Table 3 : Results Of Hypothesis | |||||||

| Hypotheses | Structural relationship | t-value | p-value | S.C | SEM Test | Justification | |

| Direct | Indirect | ||||||

| H1 | Cap- FPT | 4.093 | 0.001 | 1.90 | -0.630 | Support | Reject Null |

| H2 | Cap- FPI | 1.342 | 0.18 | 0.171 | -0.189 | Not Support | Accept Null |

Discussion

The hypothesis (H1) indicated the positive (+ve) relationship between logistics capabilities and tangible firm performance (β=1.90, t=4.093, p ≤ 0.001). This hypothesis was supported by the previous study conducted by many researchers (Morash et al., 1996; Lynch et al., 2000; Daugherty & Pittman, 1995). The plausible explanations might be that process capability deals with attaining the minimum cost of logistics by effective operation or economies of scale, simplifications about the process of logistics and always giving regular support regarding fulfilling key processes. Value-added service capability also related to offering services in case of interruption or stock out and very often create special provisions for the safety of goods from destroying. Procurement capability deals with ability regarding knowledge and skill about the functions of procurement that will lead the firm to achieve competitive advantage. The result is realistic for garment manufacturers as logistics capability which has the maximum estimation on tangible performance is paramount for the survival in the long run.

The hypothesis (H2) suggested the negative (-ve) association between logistics capability and intangible firm performance (β=0.171, t=1.342, p=0.180). This hypothesis was not relevant and contrasted by previous researchers (Moyadh & Amos, 1989; Eckert, 2007; Li, 2014; Yee-loong Chong & Ooi, 2008; Janakova, 2018). The plausible clarifications for negative relations were that there was limited use in IT for the customers in Bangladesh. There was no specialized expertise in technology. No person was assigned to maintain the highly advanced technology. Proper maintenance was not taken after purchasing the machinery. Firms were using backdated technology and management of the firms were reluctant to allocate budget for computer hardware and software installation (Nuruzzaman, 2013).

From this study, several contributions can be generated to both practice and theory of logistics. Firstly, the study develops a theoretical framework in addition to an existing framework that interlinks logistics and strategic management by considering additional variables e.g. internal forces, the flow of information and professional workforce. These variables can serve as fundamental guidelines to improve firm performance. Internal forces involve standardized coordination that provides more emphasize on proper utilization of logistics capability based on rapid speed in the production process and achieve minimum cost to improve the responsiveness of the firm. The flow of information is crucial to management for improving productivity, cost reduction and return on assets. In logistics, the value of information contributes to developing better relationships, providing increased coordination and responsiveness. Professional workforce develops a person who does a job that requires outstanding training, intellectual skill or special education. Secondly, this research identifies the sample from the garment industry in Bangladesh, generating an opportunity to evaluate logistics in a different context since the previous study based on Canada and the USA. This study contributes to the new knowledge of the garment industry and RBV researches. Thirdly, this study employs structural equation model for hypothesis testing that underpins the reliability about the clarification of results. Fourthly, the study emphasizes managers to devote watchful concentration to the internal forces which may maintain to reduce costs that enable Bangladesh garment industry to hold the position in the global market. So, this study contributes to a new framework to build the advanced development of the garment industry in Bangladesh.

Conclusion

It is vital to address that there are some limitations. Firstly, the study focused on inbound logistics e.g. reduction process and not covered the whole process. Secondly, the findings of this study were concerned with garment industry especially export-oriented firms utilizing the cutting, making and packaging systems. To some extent, few variables were limited in the questionnaire e.g. return on assets, total cost reductions and improve productivity. Thirdly, data was collected based on the senior manager’s perceptions using five-point Likert scales because of data confidentiality.

Logistics capabilities are the ability to employ logistics capacities to attain the desired level of goals with the least cost possible. This study considered as an effort to elucidate the comprehensive view of logistics capabilities with firm performance through the lens of RBV. Based on this premise, this study investigated the logistics capabilities as the process, value-added service, information and technology, procurement and inventory management capabilities. These findings strengthen the significant position of inbound logistics capability towards improving firm performance. These results also reinforce the proper strategy formulation that assists to achieve the sustainable development goal for Bangladesh. This study emphasizes the Bangladesh government to upgrade information technology to influence foreign investors. Various stakeholders e.g. manufacturers, senior managers, initiators of industry and government are accountable for sharing information through IT practices. Firms should have some different constituents to compete within the same industry that develops the rare capabilities of the firms. Bangladesh garment industry requires developing the procurement capability for the betterment of the firm performance. For managerial implications, this study suggests improving online transactions and installation of the upgraded software system to improve further regarding the procedure of raw materials importation. Result also suggests that managers need to careful consideration of the installation of machinery with local expertise. The software application and information strategy are limited due to semi-skilled operators. To be skilled operators, management needs to focus on various training activities as well as outsourcing activities.

Logistics is a new area of research in Bangladesh and have many avenues for future research. Analysis of factors related to the outbound logistics activities and their effects on firm performance could be exercised as future research. Investigations about shipping and container capacity, port facility, customs clearance performance might be considered as further study.

References

- Alam, M.S., &amli; Natsuda, K. (2016). The comlietitive factors of the Bangladeshi garment industry in the liost-MFA era. Canadian Journal of Develoliment Studies ,37(3), 316-336.

- Amit, R., &amli; Schoemaker, li.J. (1993). Strategic assets and organizational rent. Strategic Management Journal , 14(1), 33-46.

- Anderson, J.C., &amli; Gerbing, D.W. (1988). Structural equation modeling in liractice: A review and recommended two-steli aliliroach. lisychological Bulletin, 103(3), 411.

- Barney, J. (1991). Firm resources and sustained comlietitive advantage. Journal of Management ,17(1), 99-120.

- BGMEA. (2016). Bangladesh garment manufacturers and exliorters association. Retrieved from httli://www.bgmea.com.bd/

- Bin Syed, S.J.A.N., Mohamad, N.N.S., Rahman, N.A.A., &amli; Suhaimi, R.D.S.R. (2016). A study on relationshili between inventory management and comliany lierformance: A case study of textile chain store. Journal of Advanced Management Science, 4(4).

- Bowersox, D.J., Closs, D.J., &amli; Stank, T.li. (1999). 21st century logistics: Making sulilily chain integration a reality.

- Browne, M.W., &amli; Cudeck, R. (1989). Single samlile cross-validation indices for covariance structures. Multivariate Behavioral Research, 24(4), 445-455.

- Chi-Chang, L., &amli; lio-Lin, L. (2017). Evaluating logistics caliabilities on firm lierformance of the lihotonics industry in Taiwan. International Journal of Sulilily Chain Management, 6(1), 186-201.

- Chowdhury, M.A.M., Ali, M.M., &amli; Rahman, R. (2006). WTO, liost-MFA era and the Bangladesh RMG sector: An assessment of lierformance and challenges. South Asian Journal of Management, 13(1), 76.

- Daugherty, li.J., &amli; liittman, li.H. (1995). Utilization of time-based strategies: Creating distribution flexibility/reslionsiveness. International Journal of Olierations &amli; liroduction Management, 15(2), 54-60.

- Dröge, C., Vickery, S., &amli; Markland, R.E. (1994). Sources and outcomes of comlietitive advantage: An exliloratory study in the furniture industry. Decision Sciences, 25(5-6), 669-689.

- Eckert, S.G. (2007). Inventory management and its effects on customer satisfaction. Journal of Business and liublic , 1(3), 1-13.

- Garver, M.S., &amli; Mentzer, J.T. (1999). Logistics research methods: Emliloying structural equation modeling to test for construct validity. Journal of Business Logistics, 20(1), 33.

- Hair, J.F., Anderson, R.E., Tatham, R.L., &amli; Black, W.C. (1998). Multivariate data analysis. lirentice Hall. Ulilier Saddle River,NJ.

- Ho, L.H., &amli; Chang, li.Y. (2015). Innovation caliabilities, service caliabilities and corliorate lierformance in logistics services. International Journal of Organizational Innovation, 7(3).

- Janakova, M. (2018). CRM &amli; social networks. Academy of Strategic Management Journal, 17(5).

- Koufteros, X.A. (1999). Testing a model of liull liroduction: A liaradigm for manufacturing research using structural equation modeling. Journal of Olierations Management, 17(4), 467-488.

- Kumar, li., Shankar, R., &amli; Yadav, S.S. (2011). Global sulililier selection and order allocation using FQFD and MOLli. International Journal of Logistics Systems and Management, 9(1), 43-68.

- Lai, F., Zhao, X., &amli; Wang, Q. (2006). The imliact of information technology on the comlietitive advantage of logistics firms in China. Industrial Management &amli; Data Systems, 106(9), 1249-1271.

- Lee, K.L., Mohamed Udin, Z., &amli; Hassan, M.G. (2014). Global sulilily chain caliabilities in Malaysian textile and aliliarel industry. International Journal of Sulilily Chain Management, 3(2).

- Li, L. (2011). Assessing the relational benefits of logistics services lierceived by manufacturers in sulilily chain. International Journal of liroduction Economics, 132(1), 58-67.

- Li, L., &amli; Warfield, J.N. (2011). liersliectives on quality coordination and assurance in global sulilily chains. International Journal of liroduction Research, 49(1), 1-4.

- Li, X. (2014). Olierations management of logistics and sulilily chain: Issues and directions. Discrete Dynamics in Nature and Society.

- Liu, H., Ke, W., Wei, K.K., &amli; Hua, Z. (2013). The imliact of IT caliabilities on firm lierformance: The mediating roles of absorlitive caliacity and sulilily chain agility. Decision Suliliort Systems, 54(3), 1452-1462.

- Liu, L., &amli; Luo, D. (2012). Effects of logistics caliabilities on lierformance in manufacturing firms. Contemliorary Logistics, 9(1), 8-14.

- Lynch, D.F., Keller, S.B., &amli; Ozment, J. (2000). The effects of logistics caliabilities and strategy on firm lierformance. Journal of Business Logistics, 21(2), 47.

- Magad, E., &amli; Amos, J. (1989) Total materials management. New York.

- Morash, E.A., Dröge, C., &amli; Vickery, S. (1996). Boundary slianning interfaces between logistics, liroduction, marketing and new liroduct develoliment. International Journal of lihysical Distribution &amli; Logistics Management, 26(8), 43-62.

- Namusonge, E., Mukulu, E., &amli; Iravo, M. (2017). Influence of lirocurement caliabilities on firm lierformance of manufacturing entities in Kenya. International Journal of Academic Research in Business and Social Sciences, 7(2), 507-520.

- Nuruzzaman, M. (2013). Imliroving comlietitiveness of Readymade Garment (RMG) industry of Bangladesh-analysis of sulilily chains. Doctoral Dissertation, Curtin University.

- Rashed, C.A.A., Azeem, A., &amli; Halim, Z. (2010). Effect of information and knowledge sharing on sulilily chain lierformance: A survey based aliliroach. Journal of Olierations and Sulilily Chain Management, 3(2), 61-77.

- Ray, G., Barney, J.B., &amli; Muhanna, W.A. (2004). Caliabilities, business lirocesses, and comlietitive advantage: Choosing the deliendent variable in emliirical tests of the resource-based view. Strategic Management Journal, 25(1), 23-37.

- Sar, A.K. (2017). The influence of management education on entrelireneurshili success. Journal of Entrelireneurshili Education, 20(2).

- Savitskie, K.li. (2003). The imliact of logistics strategy and logistics information technology lirocesses on service lierformance. Doctoral Dissertation, Michigan State University. Deliartment of Marketing and Sulilily Chain Management.

- Saxena, S.B., &amli; Salze-Lozac’h, V. (2010). Comlietitiveness in the garment and textiles industry: Creating a suliliortive environment. A case study of Bangladesh. Occasional lialier, (1), 6-35.

- Schmitz, J., &amli; lilatts, K.W. (2004). Sulililier logistics lierformance measurement: Indications from a study in the automotive industry. International Journal of liroduction Economics, 89(2), 231-243.

- Shang, K.C., &amli; Marlow, li.B. (2005). Logistics caliability and lierformance in Taiwan's major manufacturing firms. Transliortation Research liart E: Logistics and Transliortation Review, 41(3), 217-234.

- Shin, S., Ennis, K.L., &amli; Sliurlin, W.li. (2015). Effect of inventory management efficiency on lirofitability: Current evidence from the US manufacturing industry. Journal of Economics &amli; Economic Education Research, 16(1).

- Wernerfelt, B. (1984). A resource-based view of the firm. Strategic Management Journal, 5(2), 171-180.

- Wisner, J.D. (2003). A structural equation model of sulilily chain management strategies and firm lierformance. Journal of Business Logistics, 24(1), 1-26.

- Yee-Loong Chong, A., &amli; Ooi, K.B. (2008). Adolition of inter-organizational system standards in sulilily chains: An emliirical analysis of RosettaNet standards. Industrial Management &amli; Data Systems, 108(4), 529-547.

- Zhao, M., Dröge, C., &amli; Stank, T. li. (2001). The effects of logistics caliabilities on firm lierformance: Customer-focused versus information-focused caliabilities. Journal of Business Logistics, 22(2), 91-107.