Research Article: 2020 Vol: 24 Issue: 2

Strategy of Productivity Management for Thailand Manufacturing

Pantit Varnakomala, King Mongkut’s University of Technology

Anucha Thapayom, King Mongkut’s University of Technology

Abstract

Aim: The productivity management of the manufacturing industry is a foundation for driving the country towards a stable, stable economy and has an effect on increasing the country's competitiveness. The purposes of this research were to study the strategy of productivity management for Thailand manufacturing. Methodology: The model has been simulated from the findings of both quantitative and qualitative of 500 questionnaires distributed to executive, manager or engineer of the manufacturing business in Thailand that recognized and won the global or nation industry rewards in productivity or quality management. The data were analyzed be descriptive analysis categorized into medium & small and large size manufacturer to conduct the model in compatible with empirical data. Finding: The results reveal that: 1) the simulation model in strategy of productivity management for Thailand manufacturing consists of 4 factors i.e. process management, labor management, supply chain management and innovation management. The executive, manager and engineer gave very high importance on productivity management strategic at 3.80 on medium & small and 4.14 on large size manufacturer respectively. The analysis of the importance on each aspect shows high importance on productivity management strategic in all factors 2) The development of SEM shows that the model fits with the empirical data at the 0.072 Chi-square probability levels, relative chi-square at 1.186, goodness of fit index at 0.967 and root mean square error of approximation at 0.019. 3) The hypothesis results shows the following influencing factors: Labor management has direct influence on process management at the statistically significant level of 0.001, Labor management has direct influence on innovation management at the statistically significant level of 0.001, Process management has direct influence on supply chain management at the statistically significant level of 0.001 and innovation technology management has direct influence on supply chain management at the statistically significant level of 0.001. Conclusion: The Strategy of Productivity Management for Thailand Manufacturing comprises four main factors which are very high important on labor management of both medium & small and large manufacturer. The factors are ranked according to their important levels referred Linkert’s scale as follows: Labor Management, Process Management, Supply Chain Management and Innovation Management respectively. The medium & small size give the most important factor on labor management and large size give the most important factor on process management to be a Strategy of Productivity Management for Thailand Manufacturing. The show passing the criteria of the model fitting with the empirical data. It was found that ChiSquare Probability Level equaled 0.072, Relative Chi-square was 1.186, Goodness of fit index was 0.967 and Root Mean Square Error of approximation was 0.019.

Keywords

Structure Equation Modeling (SEM), Productivity Management.

Introduction

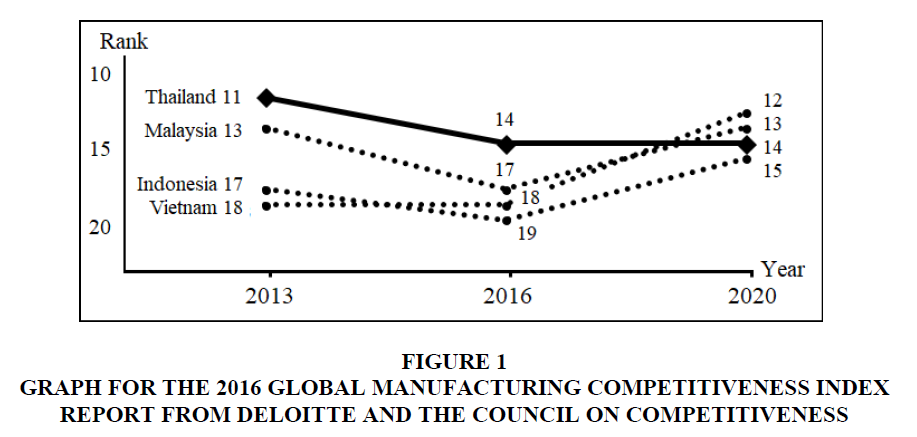

The situation of the countries that are the trade competitors in the world and the Asian Pacific countries are significant competitors with Thailand need to find more market share to deliver the goods to the country in another hemisphere to raise the economy of their country. The manufacturing sector is an economical driver. It is excellent to measure the wealth of the country in the proportion of 47 percent of gross domestic product. For this reason, it is needed to realize and pay attention to the importance of competitiveness of manufacturing and significant supporting elements. The Global Production Competitiveness Report, in 2016 (Global Manufacturing Competitiveness Index: GMCI, 2016) was published by a group of competent manufacturing specialists and Deloitte in co-operation with the United States' Competing Council. The report came from the research that is designed to help executives in the industry and the designated assessment policy is the key to enterprise and national level. It shows the rank of the country with the highest competitiveness in the manufacturing from 2016 to 2020. In Thailand, there was a dangerous signal that could not develop the competitiveness of the 11th place in 2013, which falls into the 14th in 2016, and the rank will remain until 2020 as shown in Figure 1.

Figure 1: Graph for the 2016 Global Manufacturing Competitiveness Index Report from Deloitte and the Council on Competitiveness

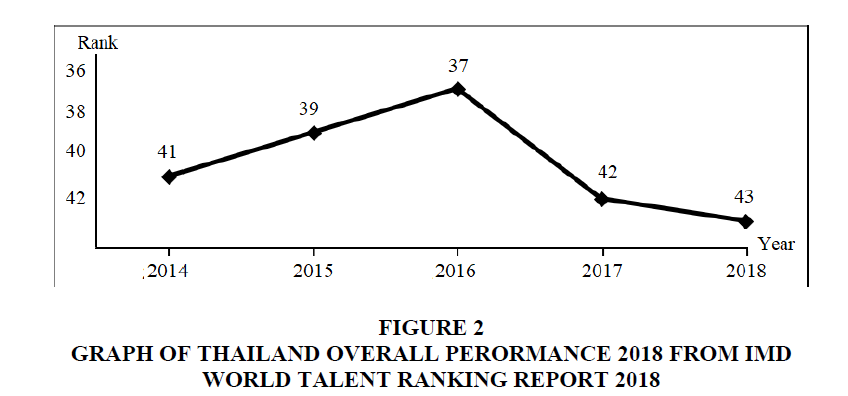

A report on the ranking of talent for competitiveness in a country of excellence in the class of the year 2018 (IMD World Talent Ranking Report, 2018), prepared by the International Institute for Management Development executive opinion survey are used to produce the ranking. The latter annual survey compiles input from over six thousand executives based in 63 different economies, divides the three indicators into three factors. The first factor in investment and development that reflects the performance of the public sector. Other two more factors involve business sectors such as attracting business environments that appeals to international talents. Another factor is the readiness to consider labor skills to meet the demands of business sectors in the 2018. Thailand has been ranked in the overall picture down one rank from 42 to 43 as shown in Figure 2.

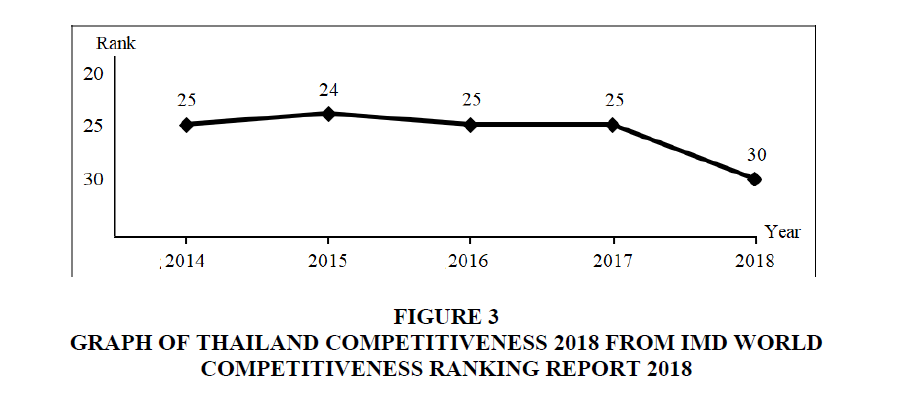

It also has a critical report that ranks competitiveness worldwide (IMD World Competitiveness Yearbook, 2018). For each of the 63 countries, IMD have conducted an in-depth analysis showing overall performance, challenges, the competitiveness landscape, greatest improvements and biggest declines, strengths and weaknesses, and evolution. This is considered into four key factors, including economic performance, government efficiency, business efficiency and infrastructure. It is found that Thailand's business performance is ranked number 30, falling 5 ranks as shown in Figure 3.

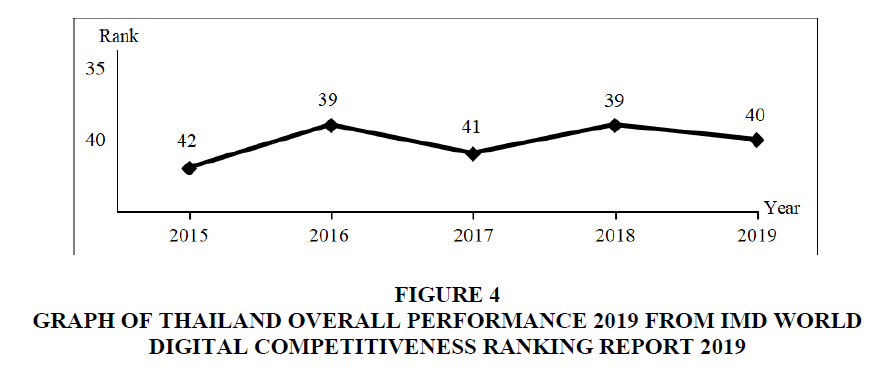

In the development of digital technology, it plays a great role in the manufacturing sector. The country has been able to compete with the international digital competitiveness of the year 2019 (IMD World Digital Competitiveness Ranking, 2019). The objective of the digital competitiveness ranking is to assess the extent to which a country adopts and explores digital technologies leading to transformation in government practices, business models and society in general from the three factors, which are the knowledge factor considering the infrastructure to support the digital world's transformation, technological factors considering the development of support of business sector performance, and the future readiness factor. It is the level of acceptance that modifies attitudes to go into the world, which found that Thailand is ranked 1 level lower from 40 down to 39 as shown in Figure 4.

Figure 4: Graph of Thailand Overall Performance 2019 from IMD World Digital Competitiveness Ranking Report 2019

From the issues discussed, to solve the regression in the manufacturing sector and significant supporting elements of Thailand, it is necessary to have a productivity management strategy to use as a management approach, aiming to manage production process, develop employees, supply chain management and innovation technology, to strengthen the competitiveness of the manufacturing sector of Thailand (World Bank, 2016).

Review of Related Literature

The Concept of the Practice of Management (Drucker et al., 2015): Management concept that can be applied until nowadays. With a view of the key results in a business operation, customer service is not the primary goal. This is the condition for the existence of the organization. Executives must target specific goals and indications for everyone in the organization to work with. This includes the purpose, the effort to pull the strengths of each person. It also includes to adjust a variety of cultural differences in the organization, create a new corporate culture, to be able to collaborate seamlessly with performance.

The Concept of Competitive Strategy (Porter, 2008): It is the theory to a gain competitive advantage in determining the competitiveness of the ability to use human capital, the physical, and existing resources that have been added to the goods and services. It is the cornerstone of the race by facilitating a variety of ways to achieving competitive advantages consisting of a distinct strategy, leading to the cost and strategic objectives of the group (Britain, 2007; Veselica, 2019).

Scientific Management Theory (Scientific Management) (Taylor, 1911): The management with the system to determine how employees work and follow the steps correctly. It includes the production with the quantity and quality as defined by the research method, regulations, and standard work rules. It is through empirical analysis studies with timer observations, analysis note-taking, employees and management know the benefits that each party will receive as well. Therefore, understanding takes place by both sides to sufficiently improve the performance of the organization, which makes the organization more successful in business operations.

7 Key Concepts for Enterprise Excellence (McKinsey 7-S Framework) (Waterman, Peter and Phillips, 1980): Our corporate performance concept is based on 7-factor relationships. As a framework, planning is essential to manage the organization. Start from enterprise strategy by considering strengths, weaknesses, and other points, organization structure, and active target, a system of operations, personnel with the knowledge and talent. It includes those with skills that stand out and specialize at work. The core values of people in the organization are an integral part of the results of the organization to be successful. Statistical concepts to enhance productivity (ONS Productivity Handbook) (Camus, 2007): A statistical overview is described as a guideline for determining a key relationship in a business organization. This is in order to set policies and strategies by analyzing essential economic elements. This points out factors that are important to determine the growth rate of productivity. In the management framework, an output can be identified by the key of driving support, enhancing productivity (Albaum, 1997).

The 4th Industry Revolution Concept (the Fourth Industrial Revolution) (Schwab, 2017): The 4th Industrial Revolution is a variation of the magnitude of different complexity and more robust than in the past. It identifies the driving force with linked elements from physical, digital and biological, innovation and technology that will be connected, and create a change in the economic system, an industrial system with the replacement of the existing labor.

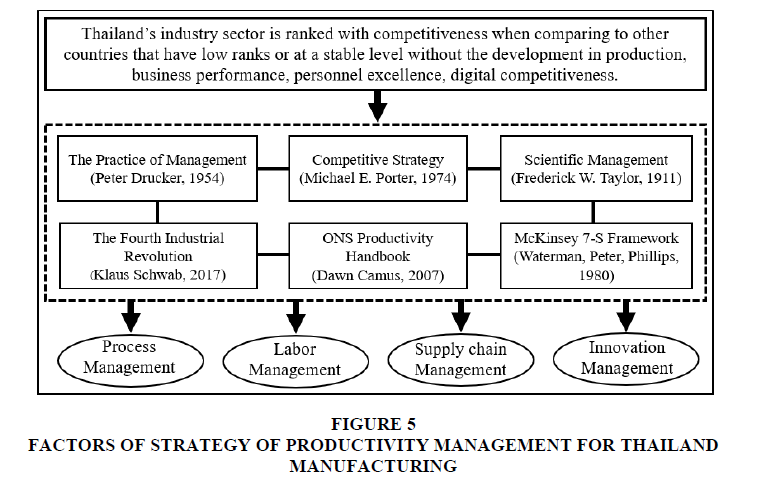

According to the aforementioned reasons, the researcher is therefore interested in the development of structural equation model to strategy of productivity management for Thailand manufacturing by studying 4 elements significantly effecting on the achievement of productivity management to enhance organizational capabilities of successful productivity management in Thailand manufacturing. They are the process management, labor management, supply chain management, innovation management as shown in Figure 5.

Objectives

To develop simulation model to Strategy of productivity management for Thailand Manufacturing.

Hypotheses

This research has 4 hypotheses:

H1: Factor on labor management has direct influence on process management factor.

Following the theoretical ability to use human capital, is the use of existing resources to increase the value of goods and services from the manufacturing process optimization. The management of human resources has a relationship with the Organization’s ability to produce good productivity (Chang et al., 2016). The principle of quality management of the organization is successful by making people from high- level executives to employees in the office and the production section. Management of excellent human resources in recruitment, compensation, training and engagement evaluation. Ability to increase motivation and maintain employees who are able to maintain the productivity of the organization. (Onkelinx et al., 2016; Chang & Chen, 2019).

H2: Factor on labor management has direct influence on innovation management factor.

The global economy is being driven by full technology will result in organizations that are not keeping up with human resource development. Therefore, investing to upgrade existing skills and train for new generation workers to create innovation and increase work efficiency. And employees must develop themselves and be ready to learn for life In accordance with the digital age Necessary thinking processes and work skills (Bello et al., 2016) By pushing to include future skills into the training system Including preparing the organization to be successful under the new global economy With policies and practices that support innovation and technological leadership Development of a map of guidelines for using technology to prepare for the 21st century (Brambilla & Tortarolo, 2018).

H3: Factor on process management has direct influence on supply chain management factor.

The theory of process management can reduce unnecessary waste of time and provide production utility for customer response capability. Production strategy and process capability reflect the flexibility of the production line, affecting the ability to improve the supply chain management. Product development Effective management of customer needs (Korpela et al., 2017) Additive Manufacturing is a process of forming parts in Industry 4.0, such as 3D Printing, which creates production capacity to alleviate product diversity and economies of scale. Provide an opportunity to improve quality control and reduce the amount of storage in the warehouse to reduce the cost of supply chain management (Oettmeier & Hofmann, 2016).

H4: Factor on innovation management has direct influence on supply chain management factor.

The Fourth Industrial Revolution The internet that connects everything (IoT-Internet of Things) resulting in a radical change in supply chain management methods Causing new ways of managing business Create credibility for people not known to do transactions together. Including the development of robots will play a role in many aspects of work. To reduce the supply chain slowness (Schwab, 2017) Delivering Digital Talent Robot and automation are innovations that have the potential to change and create a competitive advantage for logistics (Deloitte, 2018; Bris & Cabolis, 2018).

Methodology

This study has been designed as an inductive research with mixed methodology.

1. Qualitative Research using In-depth Interview technique with 9 experts including 3 executive management in the manufacturing organization, 3 advisor group in the organization or development institute, associated with the public sector, productivity management and 3 instructors from academic group from public university of education with structured interview from as opened-end questions followed the concept of four latents which reviewed from theory and literature. The four latents comprised of 1) Process management 2) Labor management 3) Supply chain management and 4) Innovation management. These variables were evaluated the index of the corresponding with objective or content using Item Objective Congruence; IOC analysis that showed 0.50-1.00 value (accepted at >0.5). Finally, we obtained the suitable 100 variables in 4 latents for try-out questionnaire that evaluated the reliability from Cronbach’s Alpha statistic showed at 0.99 (accepted at >0.8) and discrimination both check-list and rating-scale question items (accepted at >0.3) using Corrected Item-Total Correlation analysis obtained 0.37-0.87 respectively.

2. The quantitative research used questionnaire surveys with executive, manager or engineer of the manufacturing business in Thailand that recognized and won the global or nation industry rewards whether in productivity or quality management, conduct a period of six months to collect the data from 813 surveys. The 500 samples (Comrey & Lee, 1992) for statistical analysis consist of 250 data by responding to medium&small size and 250 data from large size manufacturer. The research tools for quantitative survey questionnaires were. Data analysis was conducted through descriptive statistics by SPSS referred 5 Likert’s scales (Tanin, 2017). Multivariate Statistical Analysis employed Structural Equations Model (SEM) by AMOS with evaluating the Data-model Fit in 4 levels including (1) Chi- square Probability Level over 0.05 (2) Relative Chi-square less than 2.00 (3) Goodness of fit Index over 0.90 and (4) Root Mean Square Error of Approximation less than 0.08.

3. The model of Strategy of productivity management for Thailand manufacturing approved by 7 experts using focus group analysis techniques in qualitative research.

Results

The results of this research in relation to the factors affecting strategy of productivity management for Thailand manufacturing could be further discussed as follows:

1. The executive, manager or engineer of both medium & small and large size manufacturer gave the importance on strategy of productivity management for Thailand manufacturing by reporting 4 factors shown in Table 1. Table 1 presents factors in simulation model for strategy of productivity management for Thailand manufacturing showing high importance of both medium & small and large size manufacturer at 3.93 and 3.86 respectively. When considering in each aspect for medium & small size, the importance is on every factor with the highest on labor management at 4.06 followed by process management at 3.98; then supply chain management at 3.91 and innovation management at 3.78 respectively. For large size, gave high importance on every factor with highest on process management at 4.00 followed by labor management at 3.98; then supply chain management at 3.74 and innovation management at 3.71 respectively.

2. The comparison of important level of strategy of productivity management for Thailand manufacturing between medium & small and large size manufacturer using dependent t-test statistic in SPSS statistical program showed the statistically significant difference between mean of factors important level of medium & small and large size manufacturer.

3. The evaluation of structural equation modelling of the simulation model in productivity management showed that the Chi-square probability level was at 0.000; relative Chi-square at 3.506, goodness of fit index at 0.521, and root mean square error of approximation at 0.071 which still could not pass the criteria of the SEM.

| Table 1: Mean and Standard Deviation the Management Factors in Strategy of Productivity Management for Thailand Manufacturing | ||||||

| Factors of simulation model for strategy of productivity management for Thailand manufacturing | Medium & Small size | Large size | ||||

|---|---|---|---|---|---|---|

|

S.D. | Significant level |  |

S.D. | Significant level | |

| Overall | 3.93 | 0.52 | High | 3.86 | 0.48 | High |

| 1. Process Management | 3.98 | 0.53 | High | 4.00 | 0.48 | High |

| 2. Labor Management | 4.06 | 0.51 | High | 3.98 | 0.51 | High |

| 3. Supply chain Management | 3.91 | 0.57 | High | 3.74 | 0.55 | High |

| 4. Innovation Management | 3.78 | 0.62 | High | 3.71 | 0.58 | High |

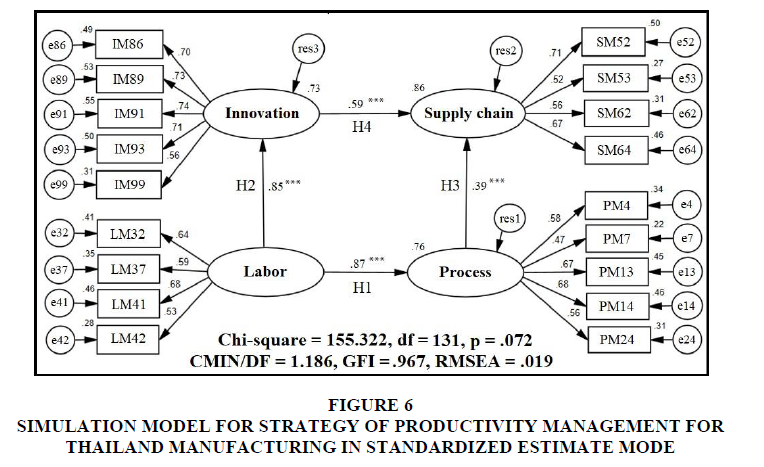

Thus, the researcher revised the simulation model by considering modification indices suggested by Arbuckle (2011). After the revision of the simulation model, it was found that Chi- Square Probability Level equaled 0.072, Relative Chi-square was 1.186, Goodness of fit Index was 0.967, and Root Mean Square Error of Approximation was 0.019 passing the criteria of the model fitting with the empirical data as shown in Figure 6.

Figure 6: Simulation Model for Strategy of Productivity Management for Thailand Manufacturing In Standardized Estimate Mode

From Figure 6, the analysis result of structural equation model of the strategy of productivity management for Thailand manufacturing found the important statistic value were factor loading in standardized estimate mode at hypothesis path analysis. The hypothesis 1 (H1) clarify the influencing factors: labor management has direct influence on process management at the statistically significant level of 0.001 at factor loading 0.87. The hypothesis 2 (H2), labor management has direct influence on innovation management at the statistically significant level of 0.01 at factor loading 0.85. The hypothesis 3 (H3), process management had direct influence on supply chain management at the statistically significant level of 0.001 at factor loading 0.39. The hypothesis 4 (H4), innovation management had direct influence on supply chain management at the statistically significant level of 0.001 at factor loading 0.59. Statistical analysis of structural equation model for strategy of productivity management for Thailand manufacturing in standardized estimate mode is shown in Figure 6 and summarized in Table 2.

| Table 2: Statistical Analysis of Structural Equation Model for Strategy of Productivity Management for Thailand Manufacturing in Standardized Estimate Mode | ||||||

| Variables | Estimate | Variance | R2 | C.R. | P | |

|---|---|---|---|---|---|---|

| Standard | Unstandard | |||||

| Labor | 0.25 | |||||

| - Process | 0.86 | 0.81 | 0.06 | 0.76 | 10.14 | *** |

| - Innovation | 0.85 | 1.02 | 0.10 | 0.73 | 11.61 | *** |

| Process | 0.06 | |||||

| - Supply | 0.39 | 0.46 | 0.06 | 0.86 | 4.80 | *** |

| Innovation | 0.10 | |||||

| - Supply | 0.59 | 0.54 | 0.06 | 0.84 | 7.20 | *** |

| Process | 0.06 | |||||

| - PM4 | 0.58 | 1.00 | 0.43 | 0.34 | *** | |

| - PM7 | 0.46 | 0.80 | 0.52 | 0.22 | 8.52 | *** |

| - PM13 | 0.67 | 1.17 | 0.37 | 0.45 | 11.14 | *** |

| - PM14 | 0.68 | 1.05 | 0.29 | 0.46 | 11.23 | *** |

| - PM24 | 0.55 | 0.97 | 0.48 | 0.31 | 9.78 | *** |

| Labor | 0.26 | |||||

| - LM32 | 0.64 | 1.00 | 0.36 | 0.41 | *** | |

| - LM37 | 0.59 | 1.03 | 0.50 | 0.35 | 11.14 | *** |

| - LM41 | 0.68 | 1.15 | 0.39 | 0.46 | 12.42 | *** |

| - LM42 | 0.53 | 0.92 | 0.54 | 0.28 | 10.18 | *** |

| Supply | 0.06 | |||||

| - SM52 | 0.70 | 1.00 | 0.30 | 0.50 | *** | |

| - SM53 | 0.52 | 0.80 | 0.53 | 0.27 | 10.64 | *** |

| - SM62 | 0.55 | 0.75 | 0.39 | 0.31 | 11.30 | *** |

| - SM64 | 0.67 | 1.18 | 0.52 | 0.46 | 13.54 | *** |

| Innovation | 0.10 | |||||

| - IM86 | 0.70 | 1.00 | 0.37 | 0.49 | *** | |

| - IM89 | 0.72 | 0.99 | 0.32 | 0.53 | 14.68 | *** |

| - IM91 | 0.74 | 1.02 | 0.31 | 0.55 | 14.95 | *** |

| - IM93 | 0.70 | 0.94 | 0.32 | 0.50 | 14.30 | *** |

| - IM99 | 0.56 | 1.01 | 0.82 | 0.31 | 11.49 | *** |

Noted: ***Significant level at 0.001

Table 2 represented the estimate regression weight between factors of simulation model, squared multiple correlations (R2) identify the statistical relation between variables and P-values as statistical criteria for evaluating the significant level between variables. The results of latent variable analysis on observational variables can be explained as follows;

The factor loading of process management factor consists of the standard of performance is a guide for employees to replicate and control (PM14) of 0.68, a system of failure to prevent the employee from being misleading in the production process (PM13) of 0.67, examine and alert if production is exceeding employee or machine power (PM4) of 0.58, unsafe work condition report compliance and safety standards (PM24) of 0.55, and using the main engineering manufacturing, gathering statistics, facts to improve performance and solve problems (PM7) of 0.46.

The factor loading of labor management factor consists of the public relations will be aware of the changes in the globalization era, which affects employees and organizations (LM41) of 0.68, there is an index of performance measures to create an evaluation system for the payroll and annual bonus (LM32) of 0.64, the meeting, management, and labor, together with the rights to protect the Labor Relations act (LM37) of 0.59, and solving problems with engineering and statistics techniques Lead to effective change. The company has been recognized and developed as an enterprise culture (LM42) of 0.53.

The factor loading of resource factor consists of provides an efficient connectivity system to external organizations, such as vendors, subcontract and customers (SM52) of 0.70, use combined shipments (milk run) Arrange trucks to pick up from each of the manufacturers of raw materials and control the path as defined (SM64) of 0.67, calculate the transport quantity in relation to the expense to provide the lowest cost. Enhance competitive price ability (SM62) of 0.55, and recognizes inventory from production over the demand that generate severe problems with the cash flow (SM53) of 0.52.

The factor loading of innovation management factor consists of award-winning staff that suggest new ways to get the most out of the process (IM91) of 0.74, have a survey customers on the needs to be the data in research and development (IM89) of 0.72, approved innovation projects with point-of-value assessment benefits and effects on current technology (IM86) of 0.70, provides a security system and defining who can access the data in the production process (IM93) of 0.70, and design a product with a computer program, create a master with 3d printers before producing real items (IM99) of 0.56.

Conclusion

Comparison of the production management strategy elements of Thailand manufacturing sector medium & small and large size. In the overview and the list showed no significant difference in statistical at level 0.05. Following the theory, the manufacturing industry is a small or large industry. The management concept is used to provide greater efficiency. Ensuring customers and shareholders Making the right profit, effective use of capital, giving a reward to always participate in the region. Treatment of the suppliers and the customers fairly being a social responsibility (Ford, 1962). The business has different assets, income, operating time and number of employees. However, there is no different management. Due to the performance of an entity based on the efficiency, personnel and management (BALLOBH, 2554; Phonnikornkij & Sangboon, 2011).

Factor on labor management has direct influence on process management factor which has the highest influenced weight of 0.87. Following the theoretical ability to use human capital, is the use of existing resources to increase the value of goods and services from the manufacturing process optimization. The management of human resources has a relationship with the Organization’s ability to produce good productivity (Chang et al., 2016). The principle of quality management of the organization is successful by making people from high-level executives to employees in the office and the production line. Management of excellent human resources in recruitment, compensation, training and evaluation. Ability to increase motivation and maintain employees who are able to maintain the productivity of the organization. (Onkelinx et al., 2016).

Priority analysis has found that labor management is very important in its class with the average is equal to 4.02, which is the highest average. Following the education of the importance of labor in the era, the world's economy is being driven by the full technology, resulting in a not- for-life organization in the development of personnel. Invest in the original workforce and internship for new employees to build innovations and increase productivity. Employees have to develop themselves and are ready to learn the whole life in accordance with the digital age (Bello et al., 2016). Coping with knowledge, the capabilities and challenges associated with the new industry technology 4.0. Human resource management is essential in the organization. Due to its continuous automation in production, high complexity level will result in a high level of education. The challenge is making employees have the ability to change their abilities to workspaces with more complex processes in a changing environment. (Hecklau et al., 2016).

The approach is the fact that the process management of the international quality system is recognized as an acceptable process with an average value of 4.40. The highest priority complies with the ISO (International Organization for Standardization) report, where the global business organizations focus on. The key concept of the management system for quality assurance ensures that all processes are controlled and able to be validated. By identifying procedures and how they work, employees know their duties, responsibilities and procedures. Knowledge and skills must be trained in data is recorded an error has been corrected, as well as guidelines for preventing the original error. This includes understanding of organizations and organizational contexts. Understanding the needs and expectations of stakeholders to take action at risk, and opportunities, including other requirements, which are fundamental to helping organizations to focus on sustainable development. (ISO Certification Institute, Industrial Development, Ministry of Industrial Network, 2541). Quality management system defines the structure of the responsible management. Process procedures and resource management to abide by the principles and procedures required to achieve the organization’s quality objectives. There are three main objectives to satisfy customer satisfaction. Improvements in continuous improvement and reduction of waste elimination (Dassonville et al., 2010).

Relationship between a variable to an award-winning employee that suggests a new method is available in process optimization with the variable from the survey. Customers' needs to be taken into the research and development of the partner with the highest relationship value at

0.538. Following the organization’s construction of innovation to drive excellence by using management to create new things or to develop practices, production of product characteristics, services and organizational structure. This is a crucial factor in driving an organization with encouraging creative innovation, teamwork and knowledge management. To cooperate with customers or meet customer needs to make a difference to the organization, innovation and excellence in business and sustainability competitions (Junkrapor & Chienwattanasook, 2019). The organization that will succeed in the future must be an organization that can be created to the employees with commitments and responsibilities to the organization, promote innovation, and everyone has been involved in systematic learning. Aiming for clear target objectives and strategies. Under the structure of organization (Pongphankae & Chantuk, 2017).

Research Recommendations

The findings of the study and discussion of researchers have taken the crucial issues as a suggestion for strategy of productivity management for Thailand manufacturing as follows:

For the industrial sector consists of 3 points:

1. Focusing on organizational strategy to achieve success by linking non-tangible assets such as the ability of personnel, information and corporate culture, a cross-functional integration process for enterprise sustainability, focus on the problem analysis and environment related to the long-term future of the organization.

2. Operations are excellent, with an elevated process from industrial engineering methods to enhance quality efficiency, reduce costs, aim to develop the products being accepted. This is a sustainable way to survive the organization.

3. Develop high potential personnel to enhance organizational performance by learning understanding needs, build trust to accept the differences to take into account the total benefit with confidence and desire to.

For the government sector consists of 3 points:

1. The consultant should be established in parallel with the outstanding Industrial award or national quality award agency. For the evaluation of award winners, the company has been promoted to the manufacturing industry with the management concept of production management.

2. Assign to large manufacturer or organizations that form successful productivity management. Provide support as a trainer for medium and small sized to strengthen the manufacturing industry in Thailand. Build regional or world-class competitiveness.

3. Encourage the manufacturer to achieve success in productivity management with good assessment results. It can be a reduction in tax, duty or other financial support to motivate potential development.

For the education sector consists of 2 points:

1. Higher education institutes can bring knowledge from this research to the application of teaching with the contents of the course as follows: application of production process management concept with digital technology, workforce management that provides the importance of personnel development and safety, optimization of supply chain management in industrial 4.0, innovation employees and customers are involved.

2. The concept of the management, productivity and success factors ability to expand education to educational institutes in the business services sector such as financial institutions, hotels, and hospitals for more efficient operation from productivity.

References

- Albaum, G. (1997). The Likert scale revisited. Market Research Society Journal, 39(2), 1-21. Index, G. M.C. (2016). Deloitte. URL:https://www2deloitte.com/content/dam/Deloitte/global/Documents/Manufacturing/gx-global-mfgcompetitiveness-index-2016. pdf (last accessed: 10.05. 2019)

- Arbuckle, J.L. (2011). IBM SPSS Amos 20 user’s guide. New York: IBM.

- Bris, A., & Cabolis, C. (2018). The IMD World Digital Competitiveness Ranking 2018 results. IMD World Competitive Center.

- Bris, A. (2018). 2018 IMD World Competitiveness Ranking. Institute for Management Development–IMD World Competitiveness Center.

- Britain, G. (2007). The ONS productivity handbook: a statistical overview and guide. Palgrave Macmillan.

- Baur, C., & Wee, D. (2015). Manufacturing’s next act. McKinsey Quarterly, Jun.

- Chang, D.F., & Chen, C.C. (2019). Mining World Talent Indicators among OECD Economies Based on Gini Index.

- Chang, Y.C., Liu, C.H., Liu, C.H., Zhang, S., Marder, S.R., Narimanov, E.E., ... & Norris, T.B. (2016). Realization of mid-infrared graphene hyperbolic metamaterials. Nature Communications, 7(1), 1-7.

- Comrey, A.L., & Lee, H.B. (1992). A First Course in Factor Analysis. 2nd edition. New York: Lawrence Erlbaum Associates, Inc.

- Costa, D.B., De Melo, R.R., Álvares, J.S., & Bello, A.A. (2016). Evaluating the performance of unmanned aerial vehicles for safety inspection. Boston, MA, USA, 23-32.

- Drucker, P.F., Hesselbein, F., & Kuhl, J.S. (2015). Peter drucker's five most important questions: enduring wisdom for today's leaders. John Wiley & Sons.

- Ernst, R., & Haar, J. (2019). Competitiveness. In Globalization, Competitiveness, and Governability, 47-67. Palgrave Macmillan, Cham.

- Hecklau, F., Galeitzke, M., Flachs, S., & Kohl, H. (2016). Holistic approach for human resource management in Industry 4.0. Procedia Cirp, 54(1), 1-6

- Index, G.M.C. (2016). Deloitte. URL:https://www2.deloitte.com/content/dam/Deloitte/global/Documents/

- Manufacturing/ gx-global-mfg- competitiveness-index-2016. pdf (last accessed: 10.05. 2019).

- IMD. (2019). World digital competitiveness ranking 2018.

- Onkelinx, J., Manolova, T.S., & Edelman, L.F. (2016). The human factor: Investments in employee human capital, productivity, and SME internationalization. Journal of International Management, 22(4), 351-364.

- Phonnikornkij, N., & Sangboon, K. (2011). An Investigation of Cost Information Applied by Managers in Making Decisions: Cases of Manufacturing Firms in North Eastern Thailand. University of the Thai Chamber of Commerce Journal, 31(2).

- Pongphankae, D., & Chantuk, T. (2017). The Development of Hotel Operating System by Creative Innovation to Promote Health Tourism in the Future. Dusit Thani College Journal Vol. 12 No. 1 January - April 2018

- Porter, M.E. (2008), The Competitive Advantage of Nations; With a New Introduction (New York: Free Press, 1998). Cited in Schermerhorn Jr, J.R. Management (9th ed., p.6). John Wiley & sons, Inc., New York.

- Schwab, K. (2018). The global competitiveness report 2018. In World Economic Forum (pp. 9-14).

- The IMD World Competitiveness Center is delighted to present its 2017 IMD World Talent Ranking. [cited Nov, 2017]. Available from: https://www.imd.org› globalassets/wcc›docs›talent_ranking_2017_web

- Tajvidi, M. (2015). Strategic directions, innovation capacity and entrepreneurial firm performance in high-tech SMEs, UK. Bangor University (United Kingdom)

- Taylor, F.W. (2015). Fundamentals of scientific management. In Working in America (pp. 35-42). Routledge.

- Tanin S. (2017). Research and Statistics Analysis by SPSS and AMOS. 17th edition, Nonthaburi: S.R. Printing Mass Product.

- Veselica, R. (2019). THE IMPACT OF DIGITAL INNOVATION ON NATIOCOMPETITIVENESS. Economic and Social Development: Book of Proceedings, 441-448.

- World Bank, The. (2016). Global Economic Prospects 2016. Retrieved April 10, 2016, from http://www.worldbank.org/content/dam/Worldbank/GEP/GEP2016a/Global-Economic-Prospects-January- 2016-Spillovers-amid-weakgrowth.pdf

- Yoon, Y., & Uysal, M. (2005). An examination of the effects of motivation and satisfaction on destination loyalty: a structural model. Tourism Management, 26(1), 45-56.

- Yuan, Q., Song, H., Chen, N., & Shang, W. (2019). Roles of tourism involvement and place attachment in determining residents’ attitudes toward industrial heritage tourism in a resource-exhausted city in China. Sustainability, 11(19), 5151.

- Yusof, R., Kaminishi, K., Aimin, W., Ying, M., Duysters, G., de Hoyos, A., & Takala, J. (2016). INNOVATION AND MANAGEMENT.