Research Article: 2021 Vol: 25 Issue: 1S

Sensitivity-Based Adaptive Management in Impowering Quality Cococraft Craftsmen

Dumasari Dumasari, Muhammadiyah Purwokerto University

Budi Dharmawan, Jenderal Soedirman University

Sulistyani Budiningsih, Muhammadiyah Purwokerto University

Imam Santosa, Jenderal Soedirman University

Keywords

Adaptive Management, Empowerment, Income, Craftsmen, Sensitivity.

Abstract

The development of sensitivity-based adaptive management is an important element in mobilizing the active participation of craftsmen in empowerment. This research was conducted deliberately in the cococraft center of Purbalingga Regency, Central Java Province, Indonesia. This research uses applied methods. The results showed the differences in the level of sensitivity in the pre-production, production, and post-production stages of quality cococrafts. The difference in the sensitivity level causes the craftsmen's ability to be different in adaptive management. This research proved the difference in sensitivity levels that were three adaptive management patterns found in cococraft craftsmen. The management were practically critical adaptive characteristics, non-practical critical adaptive characteristics, and non-critically and non-practically adaptive characteristics. Respondents with the first pattern were sensitive to the safety and availability of raw materials, continuity of production, product quality, technology adoption, and marketing guarantees. The improvement of cococraft product quality was higher than seventy-five percent in respondents with adaptive management of the first pattern. The increase in income earned by respondents with critical adaptive management patterns practically reached more than eighty percent. Respondents who apply adaptive management of the second and third patterns are still more concerned with quantity than product quality.

Introduction

Community empowerment is a dynamic process with a strategic function to increase the community's capacity and capability to develop local resources' potential. Empowerment serves to improve the quality of human resources (Aminah et al., 2015). The empowerment process needs to be done participatory and continuously (Dumasari et al., 2020). Active community participation is demanded at the implementation stage and in planning, monitoring, evaluation, and reconsideration. Thus, empowered citizens have a sense of belonging, need, and responsibility for the empowerment program. Active participation is the key to successful empowerment, including farmers and craftsmen (Chaudhuri, 2016; Khan et al., 2018; Rashid et al., 2016; Suartha et al., 2014; Wright & Annes, 2016).

Empowering farmers or craftsmen on-farm and off-farm based on local resources can significantly increase economic independence. The empowerment of craftsmen has increased product quality, raised prices, expanded markets, strengthened bargaining positions, and increased income (Dumasari et al., 2019; Hidayat & Fatmahwaty, 2014; Fengfan, 2017; Pugersari et al., 2013). However, various internal and external factors influence the smoothness of the empowerment process. The results of empowerment are often not evenly distributed to all target audiences. In the initial stage of empowering the micro coco craft business, only a small proportion (<25 percent) of the craftsmen could increase the production of quality coco crafts. Cococraft is a handicraft product with various distinctive designs and motifs that are processed from wood waste and coconut shells. The applied motion of production technology for raw material selection, cutting, splitting, slicing, and motif designs and refinement occur rapidly. Meanwhile, the majority (> 75 percent) of the new craftsmen behaved as observers with a wait-and-see attitude.

Innovators and early adopters, business owners, and pioneers in craftsmen groups are more viable business capital, solid collaborative networks, able to use information technology and online social media. Besides, they can communicate and socialize well with various parties are characteristics of craftsmen who smoothly adopt technology in empowerment (suppliers of raw materials, traders, consumer customers, market managers, local governments, researchers as sources of innovation, and other craftsmen). Meanwhile, other craftsmen who are late or laggard adopters have low business resources, solid collaborative networks, limited access to information technology and online social media, and no social contact.

The difference in the quality of human resources (craftsmen) can be seen in the determinants of active participation speed during participatory empowerment (Aminah et al., 2015; Dumasari et al., 2020; Rashid et al., 2016; Santosa & Edy Priyono, 2012). In essence, craftsmen who are slow to participate in empowerment have the awareness and interest in increasing productivity, creativity, and innovativeness. However, the management of the cococraft micro-business has not been carried out sensitively. Adaptive management based on sensitivity is still weak. According to Biber (2013), adaptive management has an essential function as a driving force for actively participating in empowerment.

Innovators and early adopters, business owners, pioneers in craftsmen groups, more viable business capital, solid collaborative networks, able to use information technology and online social media, and able to communicate and socialize well with various parties are all characteristics of craftsmen who smoothly adopt technology in empowerment (suppliers of raw materials, traders, consumer customers, market managers, local governments, researchers as sources of innovation, and other craftsmen). Meanwhile, late and laggard adopters have minimal business resources, strong collaborative networks, limited access to information technology and online social media, and little social contact.

The coco craft craftsman continues to learn from the good and bad experiences that raise profit or loss. The various forms of change that could become a problem were then studied and recorded by the craftsmen. Over a while, the sequence of experiences naturally amplifies the sensitivity. The risks that arise from each change are also recognized, recognized, identified, and categorized to determine the impact severity. Sensitivity can be used as material for risk analysis on autonomous farming by farmers and craftsmen (Datta & Bhattacharyya, 2016; Sari & Solfema, 2019).

The results of the utilization of sensitivity are valuable for decision-making and actions that are considered to be able to prevent and control disruptions in pre-production, production processes, and post-production. The risk analysis of change is also carried out sensitively by farmers by assessing the progress of farming, productivity, environmental performance, production inputs, contribution to nutrition, and family income (Estrada-Carmona et al., 2020). Sari (2019) argued that embroidery craftsmen are also sensitive to productivity and creativity in maintaining product quality to sell well in the market. In line with that statement, Zawadzka & Kurdyś-Kujawska (2015) state that the power of sensitivity can indicate a behavioral orientation to decide when it is appropriate for a person to take immediate action to develop diversification of livelihoods.

Craftsmen's entrepreneurship is also determined by their sensitivity. Craftsmen are cautious and diligent in their decisions and actions due to an instinct that is sensitive to different risks. When craftsmen are in the process of converting unique technical technologies, they show sensitivity. The craftsmen evaluated the practical and economic advantages, trial ability, complexity, observability, compatibility, and cost as soon as the coconut wood waste splitting machine technology was implemented. Craftsmen, innovators, and early adopters conduct immediate evaluations reactively and sensitively. If the test results display a good value for all of the observed metrics, the technology is unquestionably implemented. The importance of sensitivity in the assessment process cannot be overstated.

Craftsmen with heightened awareness are better prepared to make decisions and take action. Since the threats had been analyzed, bold decisions were made. Sensitivity is an individual trait. However, in certain circumstances, such as when confronted with price shifts, vigilance will shift to a collective nature. As a result, sensitivity often contributes to a proclivity.

The level of sensitivity of each craftsman is different. However, sensitivity can be managed through the learning process to identify changes and risks and arrange priority scales of problem-solving. Symptoms, form, and timing of changes were diagnosed as the cause of problems in coco craft microbusiness. The power of sensitivity can be honed and adjusted by adaptive management. This means that craftsmen who have developed adaptive management are more ready and quick to manage their sensitivity in dealing with various changes. Adaptive management is one of the strategic needs in supporting the empowerment of farmers and craftsmen (Dumasari et al., 2020).

Adaptive management in agricultural enterprises is concerned with decision-making processes related to land management planning, selection of raw materials, technology, marketing, and production waste processing. The adaptive agricultural management model has a precision at the farm level that influences the size and shape of the decision scale when determining activities that have a profitability value (Li et al., 2017). The precision management model shows that a threefold increase in the farmer's net profit per planting season. The development of adaptive management is vital for managing natural resources for on-farm and off-farm and can reduce uncertainty (Rist et al., 2013). Besides that, the development of adaptive management always requires a trained sensitivity power in mapping changes and risks.

The implementation of this study was inspired by the crucial role of sensitivity in inspiring craftsmen. The analysis of the strength of sensitivity of craftsmen during empowerment in the pre-production, production, and post-production stages is the subject of the theme. Since research findings that show sensitivity are still uncommon, the chosen study is urgent and crucial. The strength of sensitivity is also not seen as a supporting and promoting element of community empowerment, especially among coco craft artisans. Given the fluctuating and evolving existence of agricultural businesses, the aspect of sensitivity plays an important role.

Research Method

The research location was determined purposively in Purbalingga Wetan District, Purbalingga Regency, and Central Java Province, Indonesia. The research location is the coco craft industrial center, namely handicrafts made from coconut waste. The products of coco craft production are being marketed to several cities in Indonesia such as Yogyakarta, Bali, Semarang, Jakarta, Bandung, Central Kalimantan, East Kalimantan, Lampung, Bengkulu, and others. So far, the marketed cococraft product does not pay attention to quality, so that the price is difficult to increase. Although the cococraft market segment is broad, the income of craftsmen has been slow to increase. This problem is due to the craftsmen's inaction in applying technology at the stage of pre-production, production process, and the post-production process. Only a small number of skilled craftsmen used raw material identification cutting, slicing, shaving, and polishing techniques, as well as material modification. The gap in technology adoption among craftsmen tends to be due to differences in the application of sensitivity-based adaptive management. Therefore, the research location was considered to have problems that are relevant to the chosen theme.

This research employed the applied methods that combine qualitative and quantitative approaches where the qualitative part is dominant (Creswell, 1994). The applied research was conducted by providing sensitivity-based adaptive management techniques to 64 craftsmen selected. Determination of respondents using a purposive sampling technique before starting the treatment, a pre-evaluation of the respondent's interests, knowledge, and skills regarding adaptive management techniques, sensitivity level conditions, decision-making processes, and actions taken when facing changes are carried out.

In terms of sensitivity-based adaptive management strategies, all respondents received the same treatment. It is believed that all respondents are involved in using sensitivity-based adaptive management when the treatment is administered. Technology transition therapy is carried out during the empowerment process by implementing adaptive management strategies to improve the quantity and quality of coco craft goods. Identifying raw materials, polishing processes, and raw material alteration are the three types of technology used on the respondents. Expert judgment and students as co-facilitators were also included in this study's empowerment phase.

Throughout the empowerment activity, evaluation research was performed. The evaluation focuses on determining the state of the craftsmen and their sensitivity to improvements in the technology in use. Attitudes to change, reaction speed when knowing the symptoms of change, ability to identify change symptoms, knowledge of change risks, speed of response to change, speed of decision making, decision orientation, critical power, speed of taking action, and changes in the quantity of production volume—the achievement of increasing production volume are some of the condition evaluation indicators and sensitivity levels.

The types of data collected in this study are primary and secondary data. Primary data collection techniques used was in-depth interviews, participant observation, focus group discussions, and consultative interviews. Types of secondary data were collected through content analysis on various documents in relevant reports and articles.

Qualitative data collection of research was processed directly through a sequence of activities: data entry, data editing, classification of similar data, data reduction, theme tracing, linking between data with relevant themes, and data presentation. The series of processing and analysis activities were carried out in the field (ongoing analysis). Data processing and analysis time took place at the same time as data collection. The qualitative data were analyzed using an Interactive Model of Analysis (Miles & Huberman, 1991). Quantitative data were analyzed using simple, non-parametric statistics such as mean values, frequency distribution, tabulations, percentage values, and histogram graphs.

Results and Discussion

Adaptive management based on sensitivity will assist craftsmen in making more informed decisions. The craftsmen who are the respondents vary significantly in their sensitivity to the possibility of transition. This study demonstrates the need for the adaptive management concept to be developed in order to support the empowerment of artisans in the production of high-quality cococrafts.

Sensitivity includes the craftsmen's capital in managing and developing the cococraft micro-business to make it more profitable. The sensitivity of farmers and craftsmen to their products' strategic marketing is valuable (Jerome, 2017; Koppmair et al., 2017). Fluctuations in the price of on-farm and off-farm agricultural products also require the sensitivity of farmers and craftsmen from their own time to avoid being trapped by falling prices that are detrimental. (Chellattan Veettil et al., 2011). Timler (2020) stated that the sensitivity of farmers is also high towards types of plants that produce nutrient-rich food. The sensitivity of farmers is essential to anticipate consumer tastes. For craftsmen who produce cococrafts in Purbalingga Wetan, Central Java Province, Indonesia is very sensitive to production technology, product designs, and motifs that match the market trends (Dumasari et al., 2017; Khan et al., 2018). Thus, it can be stated that sensitivity is something of social energy in empowerment. Farmers and craftsmen have sensitivity to the security of raw materials as one of the leading production inputs. The high sensitivity to production input turns out to function as energy, affecting the quantity and quality of agricultural business production (Khoshroo et al., 2018).

Coconut waste, especially coconut wood, shell, and sticks, is used as a raw material for cococraft. Coconut wood is sourced from scraps left over from furniture manufacturing and building construction. Some people get it from the waste from cutting down old coconuts that aren't growing anymore. The shells came from coconut milk squeeze manufacturing waste, coconut fruit that was weakened and dropped before picking, and gouging for copre as a coconut oil ingredient. The stick is made from dried old coconut tree leaves that have fallen to the ground. The three types of coconut waste used in cococraft production are the primary raw materials.

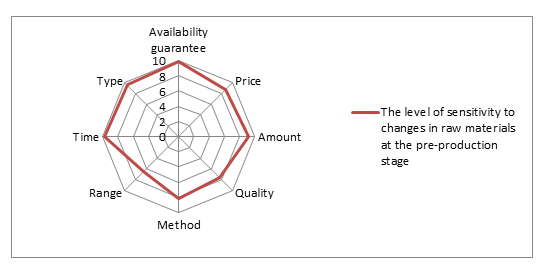

The demand for raw materials will raise as consumer demand for cococraft products rises. Similarly, as the marketing area for cococraft goods grew larger, so did the amount of raw materials used by respondents. Respondents are concerned about the supply and protection of raw materials. At the pre-production stage of raw material preparation, respondents' sensitivity to aspects of availability, price, volume or quantity, quality, process, distance, time, and form is on average high (8.46). If there are signs of disruptions in the supply of raw materials, respondents become extremely responsive. Traders who supply raw materials to which they have subscribed normally transmit these symptoms. When faced with a shortage of raw materials, the respondent contacts fellow craftsmen directly to borrow a number of raw materials, which will be returned once supply is assured. Another choice is to place an immediate order for coconut waste from suppliers of other raw materials. Five traders bring cococraft raw materials from various regions to Purbalingga Wetan, ready to meet demand from craftsmen. Figure 1 depicts variations in respondents' levels of sensitivity as the pre-production stage progresses.

Craftsmen are often acutely aware of the importance of purchasing raw materials on time. Every week, a new order is placed. Individually and jointly, orders are placed. Cococraft raw materials were purchased earlier or before stocks were depleted, according to respondents.

Respondents are concerned about ordering delays. As a result, each respondent keeps raw material reserves in the workshop as stock. Raw material types are one of the things that respondents are particularly sensitive. When it came to ordering coconut waste, respondents used a variety of criteria. The type of variety, size, age, color, texture, and integrity of the shell and coconut wood are among the various criteria listed. The price of coconut waste from local varieties is higher than the others due to its older age (> 10 years), transparent color, and sharp and intact texture.

The respondents' level of sensitivity is high when faced with signs of changes in the amount of coconut waste decreasing. Before starting production, the craftsmen frequently check the amount of raw materials stored as reserves. The raw material stock is then put to use in the manufacturing process. There are no respondents who deny that raw material scarcity is an issue. The artisans often insist on using the correct amount of raw material for cococraft production. Craftsmen with high sensitivity are more likely to accept price increases in raw materials if the increase is within a 1-5 percent tolerance range. The price of coconut wood is more volatile than the price of the shell. The price increased because it is more difficult to procure coconut wood waste during the rainy season.

The high degree of sensitivity of respondents to determining how to procure cococraft raw materials falls into the high group. When traders who supplied raw materials were difficult to reach, respondents' concerns were raised. To avoid problems with the complicated process of supplying raw materials, the majority of respondents (> 50%) purchased coconut waste via collectivity relations. The chairman of the Manunggal Karya Craftsmen Community, an innovator craftsman, was suspected of acting as a middleman in the purchase of raw materials. This approach is used to make cococraft raw materials more available, affordable, and timely.

Respondents are sensitive if there are symptoms of disturbance to the availability of coconut waste from an area of origin due to limitations or scarcity due to the reduced volume of furniture production waste and building construction materials. Respondents have several alternative solutions if the availability of coconut waste is not fulfilled from an area. The respondent's action was quick to immediately contact the farmer who provided coconut waste from another village. Respondents made immediate decisions to ensure that the cococraft production process did not stop. A commitment drives decisions and actions over ordering raw materials due to scarce availability to serving the market and consumer demands. Sufficient availability of raw materials is one of the essential conditions maintained by respondents. All respondents have a high sensitivity to the problem of availability and adequacy of cococraft raw materials. Respondents were anxious when there was a threat of scarcity of raw materials. This situation was closely related to concerns about the disruption of the cococraft production process.

The problem of quality changes and distance of the area of origin of the raw materials was only responded to with moderate sensitivity by the craftsmen. All respondents still do not take the quality of raw materials seriously. Most craftsmen (87.5 percent) felt that coconut waste raw materials of any quality could be processed into various designs and cococraft motifs. The number of respondents who began to pay attention to raw materials' quality was small (12.5 percent). The distance that must be traveled by traders who supply raw materials in finding and collecting coconut waste, especially coconut shells and coconut wood, does not get any significant sensitivity from respondents. The most important thing that is sensitive to respondents is that raw materials' availability is guaranteed on time without a long waiting process. The types and quantities of materials are according to needs and affordable prices.

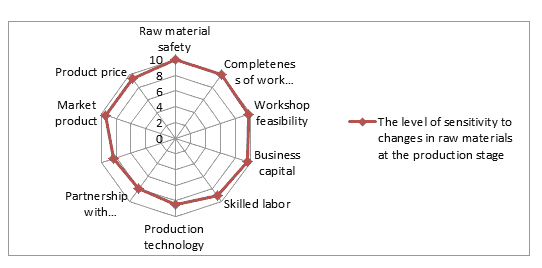

The sensitivity of respondents to changes in several things during the average production process is high. The availability of working tools and raw materials gets the highest sensitivity level. Respondents assumed that if the working tools were not available or damaged, the cococraft production process would stop. Therefore, the appropriate equipment for work tools is always adequately maintained by the respondents. When the working equipment starts to wear out, the craftsmen immediately buy a new one. Types of work tools are adjusted to the level of technology applied by the respondent. All respondents already have manual and mechanical electric work tools. The use of both is adjusted to the ability of technology adoption, economic level, the complexity of the design of the cococraft product motif, and the volume of products ordered by consumers and various market segments.

Changes concerning the feasibility of workshops have received high sensitivity from respondents. A proper workshop is one of the needs that cannot be postponed in managing micro cococraft businesses, due to high sensitivity to workshops in the end motivated respondents to prepare it permanently. Some respondents have a workshop located in the yard area. Some make some parts of the space in their residence functioned as workshops. Other respondents chose the workshops' location together in a coconut waste industry building prepared by the Regional Government of Purbalingga Regency. The building's location is in the Purbalingga Wetan sports field so that it is broad and makes it easy for cococraft production activities.

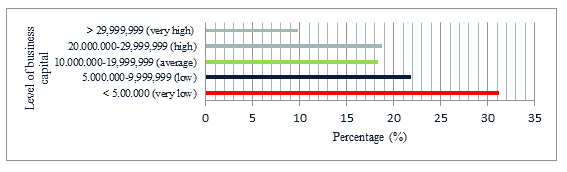

Business capital conditions vary. Only a very small number (9.78 percent) of the number of respondents have very high business capital (> 29,999,999). The number of respondents with high business capital (IDR. 20,000,000-IDR. 29,999,999) is also small (18.75 percent). Of course, this situation raises the high sensitivity of all respondents. Respondents always try to adjust the amount of venture capital with the cococraft production process, especially in terms of volume, design form, and product motives. The average business capital is owned by themselves. The amount of business capital owned by the respondents averaged Rp. 11,875,000. The highest working capital is IDR 45,000,000, and the lowest is IDR 3,000,000. The gap in business capital results in differences in the adoption of production technology. As a consequence, the quantity and quality of cococraft products produced by respondents also differed. Product prices are also not the same. The income received by craftsmen is volatile. The distribution of working capital among craftsmen is shown in Figure 2.

Changes in market segments and the feasibility of cococraft prices are sensitive for all respondents because they involve income generation. Despite the high sensitivity of the craftsmen towards market segments and price feasibility, the respondent's attitude is calmer when facing changes in both circumstances. Collective product marketing encourages respondents' confidence about the assurance that the cococraft market is always safe. It is just that the respondents have accepted the slow price increase. The respondent never bargained with the market or customers. Cococraft craftsmen already have a reasonable price which is agreed upon as a standard. The highest and lowest price for each type of product design and motif is applied to maintain price fairness. The price standard is made on a wholesale system without distinguishing quality because product marketing has not used a sorting and grading process.

The problem of skilled labor is one of the essential things that determines the production process. Respondents find it challenging to increase the quantity and quality of cococrafts when skilled labor is not available. High respondent sensitivity to the problem of changing the workforce. The experience that respondents often experience is that skilled wage workers leave them behind to move to other jobs, such as motorcycle taxi drivers, freight forwarders, construction workers, seasonal mobile traders, and workers in sweet orange orchards. All respondents need a loyal skilled workforce. Kernet craftsmen's loyalty depends on the kindness of the business owner craftsmen in providing decent wages and psychological attention, for instance, respecting and giving time off for wage workers.

The production technology used by craftsmen is adjusted to the workforce's skill level and the business capital they have. The application of cococraft production technology also depends on raw materials, equipment, and workshops. Respondents who are older (> 70 years) choose and decide to use manual production technology. The courage to buy and use mechanical equipment that is all-electric. Elderly craftsmen are frankly unable to use electric wood cutting machines for fear of misusing them so that they endanger personal safety. The level of sensitivity of respondents at the cococraft production process is shown in Figure 3.

The situation regarding cooperation with a partnership pattern also received high sensitivity from the respondents. Respondents' sensitivity is high towards partnership cooperation aimed at smoothing and expanding the market segment, supplying raw materials, developing technology facilities, developing equipment, and workshops.

Sensitivity at the production stage serves as a barrier sign that directs and warns respondents in making decisions carefully and prudently. Various experiences in managing cococraft microbusinesses have become the basis for reference levels of sensitivity. The respondent's behavior in facing changes at the stage of the production process is determined by sensitivity.

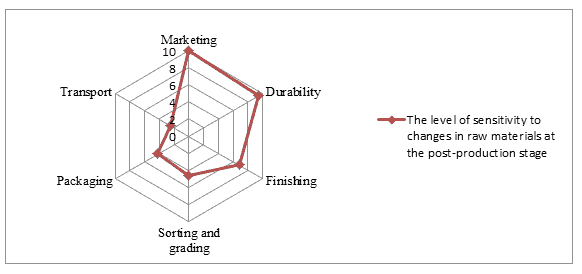

In comparison to the pre-production and production stages, the sensitivity to changes in the post-production stage is only mild. Only the marketing problem and the cococraft product's longevity were the most sensitive topics for respondents. The craftsmen's actions were instantly influenced by the decision to sell the cococraft. Following manufacturing, the correct action is to deposit the product in a particular quantity with the craftsman, the business liaison. Some sell their goods directly to shops or kiosks who have signed up to receive them. Just a small percentage of respondents sell their goods directly to customers. Because of the shorter marketing time, the marketing system is thought to be more realistic. Techniques for collective marketing are much more realistic and available. Craftsmen prefer direct marketing methods because payments are faster and easier to process. Despite the fact that the price paid is less than if you were to sell yourself.

Craftsmen worry about the durability of cococraft products when they wait to be marketed. The average waiting time is two days. If it is more than two days, the respondent keeps the cococraft in a closed and dry room. The layout is arranged in one box for one type of design and motif so that it is mixed and does not overlap. Also, do not try to avoid the product in a humid place and exposed to water. The durability of the cococraft is often impaired by the appearance of a layer of white patches on the product's surface. Of course, the non-durable cococraft is then separated as an affiran product. If there are more affiran products, it will be detrimental to the craftsmen.

The level of sensitivity of respondents is in the medium category for the finishing process. Not all craftsmen have done the cococraft finishing process. As many as 25 percent of respondents did not finish the cococraft at all. There is 40.62 percent who only sometimes do the finishing process well. Not carrying out the finishing process is due to the lack of time to fulfill the promised cococraft order. Respondents felt that the finishing process would take longer to produce. Under these circumstances, most respondents (65.62 percent) were still not optimally producing quality cococrafts. Only 34, 38 percent of respondents have produced quality cococrafts. The finishing process is one of the techniques that can improve the quality of cococraft products.

Respondents have a low sensitivity to post-production activities regarding sorting and grading, packaging, and product transportation to the market. Craftsmen pay less attention to these three post-production activities. According to respondents, the cococraft products produced are still in demand even without sorting and grading. Respondents also stated that cococrafts are sold in bulk, so they do not need a packaging technique. Respondents considered that the problem of transporting the product to the market was the responsibility of the craftsman who acted as the intermediary. Therefore, the respondent's sensitivity is low towards the three post-harvest activities. The state of the sensitivity level of respondents at the post-production stage is detailed in Figure 4.

The respondent's adaptive management ability is categorized into three patterns based on the diversity of sensitivity levels. The first adaptive management pattern has a distinctive characteristic of showing craftsmen's existence as innovators and early adopters. Only a small number of respondents (18.75 percent) have used adaptive management techniques with practical critical adaptive characteristics. Those respondents are always responsive and immediately adjust to changes in the pre-production, production, and post-production stages. Actions taken are more of a preventive nature in controlling the risk of change. A critical attitude is shown from the immediately given reaction every time a symptom of change appears in the availability and safety of raw materials and the marketing network for cococraft products. Decisions were taken immediately to avoid the risk of scarcity of raw materials, production bottlenecks, and slowness in the marketing of cococraft products. Decisions are practical in nature because they are immediately applied by taking into account the risk of loss.

Respondents with critical and practical adaptive management techniques are the innovator adopters. The scale of the business being managed was more significant than the others. The improvement of the quality of the cococraft in these craftsmen reached >75 percent. Cococraft products access quality in functional benefits, designs, motifs, textures, durability, surface smoothness, neatness, the harmony of form, and artistic beauty. Efforts to empower craftsmen with a practical critical adaptive management system can increase income up to >80 percent through the ability to maintain safety in pre-production, production, and post-production in terms of quantity, quality, price feasibility, and market security cococraft products.

The second pattern of addictive management is adaptive and critical but non-practical or impractical. The second pattern was found in the majority (62.5 percent) of respondents. Respondents with this criterion already can adapt to various changes in the pre-production, production, and post-production stages—critical response when facing symptoms of availability and safety of raw materials and the marketing of cococraft products. The process of decision-making and action is often delayed. The delay was because the respondents were hesitant and tended to wait for others—slow decisions and actions. However, respondents have tried to adopt a cautious attitude that is oriented towards preventive and curative actions. When changes are judged to pose a negligible risk, they are left alone. Respondents take action when the risk is severe and threatens the continuity of cococraft production. Respondents produce cococrafts to pursue quantity, not quality targets. After implementing adaptive management with the second pattern, the empowerment results show increased income between 50-90 percent.

Respondents who apply adaptive management with the third pattern are few (18.75 percent). The third pattern has the characteristics of adaptive respondents but not critical and non-practical or impractical in adjusting conditions to changes in the pre-production, production, and post-production stages. Respondents are aware that they need to make adjustments to circumstances and actions with changes. However, respondents are slow to give and react even though the symptoms of change have been recognized. The attitude of the respondents tends to be calm and to continue producing. Decision-making and action to prevent risk are very slow. When risks arise, then there are actions. The respondent was able to solve problems with the help of other craftsmen. The production quantity target is more concerned with the respondents with the third pattern. After participating in empowerment through the application of raw material identification techniques, polishing techniques, and material modification techniques, it is known that respondents experienced an increase in income <50 percent.

Any empowerment of quality cococraft craftsmen should consider the critical role of enhancing sensitivity. Craftsmen who can use sensitivity-based adaptive management are more engaged in empowerment, which is accomplished by the use of raw material recognition techniques, polishing techniques, and raw material alteration techniques. Craftsmen may use the three technologies to increase the quality of their cococraft goods. An adaptive management design based on sensitivity is needed (Yasuoka, 2020). The sensitivity of the craftsmen is inextricably linked to adaptive management. The ability of craftsmen to enhance designs with a touch of natural artistic value is crucial to improving the quality of handicraft goods (Hidayat & Fatmahwaty, 2014). Change can trigger a wide range of issues, which craftsmen must be aware of. However, the craftsman must be responsive to different factors that trigger changes and risks (Dibyendu Bikash Datta, 2016). The opportunity to use empathy to one's benefit makes it easier for craftsmen to participate in empowerment.

Conclusion and Recommendations

The most important aspect of adaptive management is sensitivity, which is used to enable craftsmen to produce high-quality cococrafts. Craftsmen's sensitivity levels at pre-production, production, and post-production stages serve as a reference for categorizing adaptive management trends. Adaptive management patterns in craftsmen are first identified by realistic essential and adaptive management patterns. This community of artisans is considered an innovator and early adopter, as shown by their active involvement in the empowerment process. The first trend has a limited number of respondents. Cococraft's efficiency was improved, resulting in a rise in income of more than 80%. Adaptive, critical, and impractical are the characteristics of the craftsmen who use the second pattern of adaptive management. The second pattern is used by the majority of respondents. Increase in income of 50-80% after empowerment. A few respondents carry out the implementation of the third pattern of adaptive management. Adaptive, uncritical, and impractical is the third trend. After engaging in empowerment, participants' income increased by 50%.

Acknowledgement

We are grateful to the Directorate of Research and Social Services (DRPM/ BRIN), Ministry of Research and Technology/National Research and Innovation Agency of the Republic of Indonesia, for this research.

References

- Chaudhuri, A. (2016). Understanding “empowerment.” Journal of Development Policy and Practice, I(2), 121–141.

- Aminah, S., Sumardjo, Lubis, D.P., & Susanto, D. (2015). Factors affecting peasants’ empowerment in west Halmahera district – A case study from Indonesia. Journal of Agriculture and Rural Development in the Tropics and Subtropics, 116(1), 11–25.

- Arshad, M.A., Kalimullah, Khan, S., & Shahid, Z. (2020). High performance organisation: The only way to sustain public sector organisations. International Journal of Public Sector Performance Management, 6(6), 806-816.

- Biber, E. (2013). Adaptive management and the future of environmental law. Akron Law Review, 46(4), 933–962.

- Chellattan, V.P., Speelman, S., Frija, A., Buysse, J., Mondelaers, K., & Van, H.G. (2011). Price sensitivity of farmer preferences for irrigation water–pricing method: Evidence from a choice model analysis in Krishna River Basin, India. Journal of Water Resources Planning and Management, 137(2), 205–214.

- Creswell. (1994). Research design qualitative and quantitative approaches. In Thousand Oaks, Sage Publication, London.

- Datta, D.B., Bhattacharyya, S. (2016). Analysis on problems and prospects of Indian handicraft sector. Asian Journal of Management, 7(1),

- Dumasari, D., Darmawan, W., Iqbal, A., Dharmawan, B., & Santosa, I. (2019). Development of production creativity among craftsmen by identifying techniques for characterizing coconut waste. International Journal on Advanced Science, Engineering and Information Technology, 9(2), 717–723.

- Dumasari, D., Budiningsih, S., Darmawan, W., & Santosa, I. (2017). Various determinant factors of production technology adoption in creative souvenir micro enterprise. Journal of Arts and Humanities, 6(10), 01.

- Dumasari, D.W., Ismangil, D.B., & Santosa, I. (2020). Empowerment of subsistence craftsmen through the adoption of environmentally friendly cocodust production technology. International Journal on Advanced Science, Engineering and Information Technology, 10(2), 691–702.

- Estrada-Carmona, N., Raneri, J.E., Alvarez, S., Timler, C., Chatterjee, S.A., Ditzler, L., … & Groot, J.C.J. (2020). A model-based exploration of farm-household livelihood and nutrition indicators to guide nutrition-sensitive agriculture interventions. Food Security, 12(1), 59–81.

- Hidayat, J., & Fatmahwaty, F. (2014). The art and sustainable aspects of natural dyeing in kanawida hand drawn batik (green batik). IPTEK Journal of Proceedings Series, 0(1), 136–143.

- Jerome, S. (2017). A study on agricultural marketing strategies and challenges faced by the ponmalai santhai (local market) farmers in Tiruchirappalli. International Journal of Economics and Management Studies, 4(9), 15–20.

- Ju, F.H.Y. (2017). Traditional tie-dye handicraft and modern design concept combined. Journal of Arts & Humanities, 06(08), 12–15.

- Khan, R.Y., Huang, J., Ren, K., Wahab, Z.U., & Meer, S. (2018). Creativity and richness craft: Admirable traditional carve wooden art as recognition of Pakistani heritage. Journal of Arts and Humanities, 7(9), 53–69.

- Khoshroo, A., Emrouznejad, A., Ghaffarizadeh, A., Kasraei, M., & Omid, M. (2018). Sensitivity analysis of energy inputs in crop production using artificial neural networks. Journal of Cleaner Production, 197, 992–998.

- Koppmair, S., Kassie, M., & Qaim, M. (2017). Farm production, market access and dietary diversity in Malawi. Public Health Nutrition, 20(2), 325–335.

- Li, G., Messina, J.P., Peter, B.G., & Snapp, S.S. (2017). Mapping land suitability for agriculture in Malawi. Land Degradation and Development, 28(7).

- Miles, M.B., & Huberman, A.M., (1991). Designing qualitative research.

- Pugersari, D., Syarief, A., & Larasati, D. (2013). Experimental development of commercially valuable functional products made from young coconut shells with softening techniques. ITB Journal of Visual Art and Design, 5(1), 74–91.

- Rashid, S.M.M., Islam, M.R., & Quamruzzaman, M. (2016). Which factor contributes most to empower farmers through e-agriculture in Bangladesh? SpringerPlus, 5(1), 1–14.

- Rist, L., Campbell, B.M., & Frost, P. (2013). Adaptive management: Where are we now? Environmental Conservation, 40(1), 5–18.

- Santosa, I., & Edy, P.R.E. (2012). Dissemination of village community empowerment models through agro-tourism management. Pulpit, 28(2), 181–190.

- Sari, T.M., & Solfema. (2019). Description of craftsmen’s creativities in developing sulaman bayangan crafts in Nagari Barung-Barung Balantai. Indonesian Journal of Contemporary Education, 1, 55–58.

- Suartha, I.D.G., Wedastra, M.S., & Artika, I.B.E. (2014). Model empowerment of rural poor farmer women through agribusiness base entrepreneurship development in the regency of West Lombok. International Journal of Geology, Agriculture and Environment Sciences, 2, 2–5.

- Timler, C., Alvarez, S., DeClerck, F., Remans, R., Raneri, J., Estrada Carmona, N., … & Groot, J.C.J. (2020). Exploring solution spaces for nutrition-sensitive agriculture in Kenya and Vietnam. Agricultural Systems, 180.

- Wright, W., & Annes, A. (2016). Farm women and the empowerment potential in value-added agriculture. Rural Sociology, 81(4), 545–571.

- Yasuoka, M. (2020). Designing knowledge management system for supporting craftsmen’s collaboration beyond temporal boundaries. Proceedings of the 53rd Hawaii International Conference on System Sciences, 3, 4880–4889.

- Zawadzka, D., & Kurdyś-Kujawska, A. (2015). Diversification of income sources and their significance in the risk management of farms. Zeszyty Naukowe Uniwersytetu Szczecińskiego Finanse, Rynki Finansowe, Ubezpieczenia, 74(1), 619–628.