Case Reports: 2024 Vol: 30 Issue: 1S

Problems Faced By the Company Regarding Supply Chain and Process Flow

Hafiz Bilal Shafiq, Superior University, Lahore

Muhammad Rafiq, Superior University, Lahore

Citation Information: Shafiq, H. B. & Rafiq. M (2024). Problems faced by the company regarding supply chain and process flow. Journal of the International Academy for Case Studies, 30(S1), 1-6.

Introduction

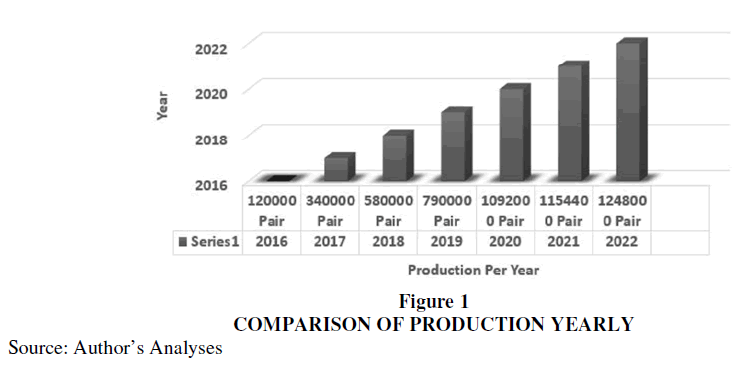

Mr. Saqib Manazir (GM Supply Chain) joined the company at the time when company was going through a very difficult time. The company was in the early stages of its growth due to which the company was facing a lot of challenges. Due to the poor supply chain network, many orders could not be placed on time due to which reputation of the company was greatly affected in the international market. Inventory Management was also worst as material shortage disturb the timely dispatch of order as well as overstocking of materials increase the carrying cost very much which ultimately hit the profit margin of the company Mr. Saqib’s selection proved to be a breath of fresh air for the company. Saqib developed a strong supply chain policy and implement in the company that showed excellent results. These measures proved to be very beneficial for the company and company start growing very speedily. After 6 years, now company is standing on a stable position due to long term strategic policy and is growing steadily. Now company is the 2nd largest shoe exporting company of Pakistan.

Shafi Lifestyle Pvt. Limited (SLS)

Shafi lifestyle is the 2nd largest Shoe exporting company of Pakistan. It is located at Bhullar Road near Gajjumatta Lahore. It deals with 90% of Leather products i.e. Long Boots, Shoes, Sneakers, Slippers, Sandals and others. With the production capacity of 4000 pairs per day its monthly production capacity touches the round figure of 100000 pair per month and 120000 pairs per Annum.

Volumetrically it’s a huge company with 2000 of workers. It has many customers from worldwide. Shafi lifestyle export its products to Germany, Austria, Africa, Holland, UK and USA.

Product Range of Shafi Lifestyle PVT Limited

For Men’s Boots, Sneakers, Formal Shoes, Party Wear, Casual shoes (Figure 1)

For Women’s Long Booties, Chelsea, Lace Up, Loafers, Sandals, Slippers, Sneakers Etc. (Figure 2)

For Kids Sneakers, Boots, Loafers (Figure 3)

Shafi Lifestyle base primarily based on three pillars including effective sales and marketing, quality commitment of product and timely delivery of product Sales and Marketing is the major element of any company and play vital role in the growth of the company. Effective sales and marketing strategy makes Shafi lifestyle to achieving millstones.

Quality is the core value on the basis of which company grow and make its reputation in the market. Shafi Lifestyle never compromise quality and set a good reputation in the market. Timely delivery is as necessary as quality in export-based companies. Timely delivered order can open doors of multiple orders in near future.

As leather is the major component in shoes and also the expensive one and need in huge quantity for production. To fulfil the requirement of leather factory relay on more than 5 tanneries.

Hafeez Shafi Tanneries, MST (Muhammad Shafi Tanneries, Siddiq Leathers, export from Turkey and Netherlands. Other materials purchase from local as well as from international market

Problems Faced by The Company Regarding Supply Chain and Product Flow

Mr. Saqib Manazir joined Shafi Lifestyle in 2015 as a General Manager Supply Chain. As on the initial stages company had to face too much challenges regarding supply chain and product flow. There was no mechanism of maintain supply chain. At the time of production most of the time faced material shortage, as leather and different ornaments import from China and other countries and take time to develop specific order, many of orders rejected by customer. Shafi Lifestyle was in big trouble. If material available on time due to shortage of Labor some orders were also late and company had to face penalty due to late shipment. Unskilled labor was also a big problem as it contributed a lot in wasting expensive raw material while production It was the time when company need a well-educated and experienced person who can handle the difficulties and get the company out of the maelstrom.

Supply Chain, Inventory Management, Lack of Skilled Labor, Insufficient manufacturing Capacity, Delay in Shipping, Low Staffing, Over Stocking/ Low Stocking, Waste Ratio

Mr. Saqib Manazir personally visited every section of the production and every department observed issues, shortcomings and made checklists of it. Mr. Saqib called a meeting with high officials and director of the company. He raised the issues he observed and took the high officials into confidence to take some bold decisions.

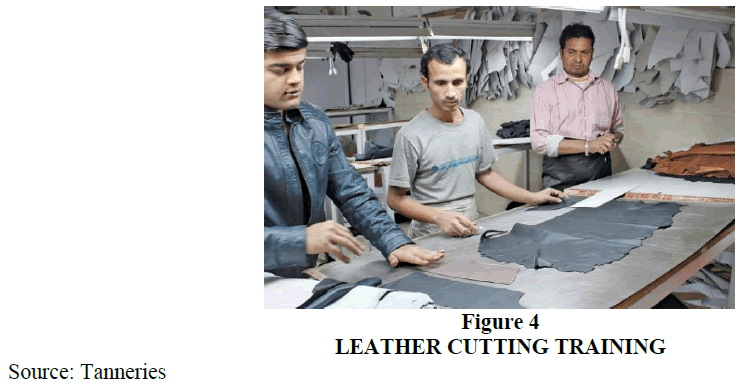

Issue of Insufficient Manufacturing Capacity to deal with the issue of insufficient manufacturing capacity Mr. Saqib open hiring of labor (Skilled and unskilled). He arranged multiple training programs for unskilled labor through the available skilled labor to enhance the production capacity of company. At the same time purchased necessary that involved in shoe manufacturing. This practice showed huge increase of production capacity six months later. (Figure 4). Issue of Low Staffing in Supply Chain network in supply chain network staff hired for efficient planning, cost managing and purchasing of Raw Materials from Local and international markets. Cost Management and Control Several cost cutting techniques applied to reduce the Waste Ratio trainings provided to the cutters to use raw material efficiently to reduce the amount of waste produced during the cutting process. Good results observed within one month of the training. (Figure 5). Procurement of Materials for procurement of materials from local vendors or from international markets, made an action plan. As order received from customer planning team send demand to procurement for purchasing specific and accurate materials for production of specific. Mr. Saqib also bound the vendors to provide the materials in lead time. Training of Planning Department Planning department also provided with the training for Material Requirement Plan, Master Production schedule that helped the department to enhance the potential capability. Delay in Shipping Delay in Shipping was also an issue due to low production, it’s also a huge issue in export sector as much penalty can be faced by the towards company in terms of Dollars.

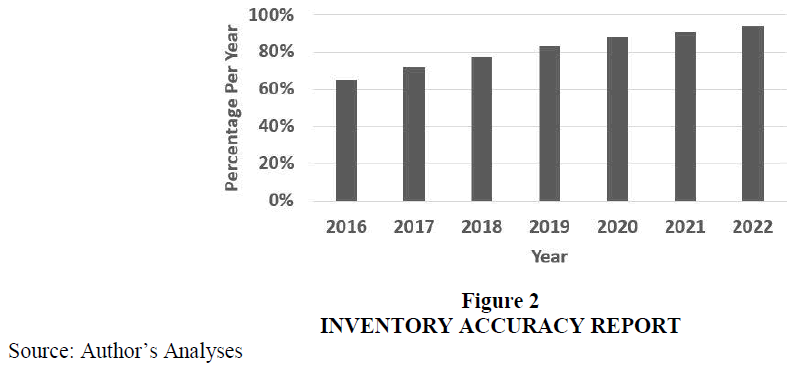

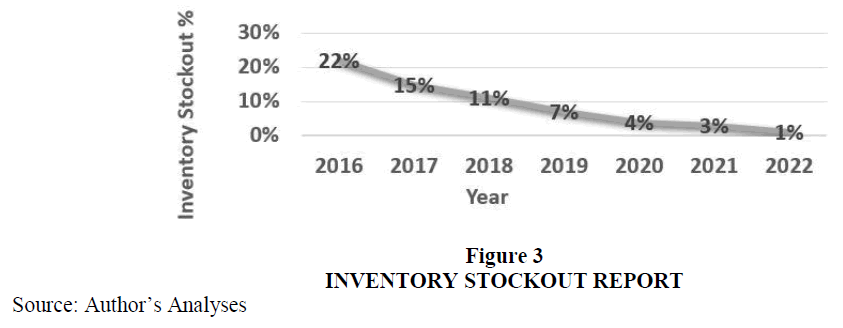

Inventory Stock out and Over Stocking Inventory Stock out and Over stocking was also a major issue of the company that time (Figure 6) At the time of production, some inventory lacks and some were over stock. Inaccurate quantities were the issue due to which profit margin also reduced and cost of stock increased. (Figure 7). Inventory Management to resolve the issue here MR GM applied a technique named as ABC Analysis. He divided the inventory into three major categories (Table 1).

| Table 1 Types Of Inventory | ||

| Category Of Material | Percentage of Item in Inventory | Percentage of Value |

| Class A Material (Regular Leather and Ornaments) |

20% | 80% |

| Class B Material (Seasonal Leather and seasonal Fur Material) |

30% | 15% |

| Class C Material (Very Rare leather and ornaments) |

50% | 5% |

Class A describes those leather and ornaments which are 20% of the total inventory but contribution in sales is 80% of that particular product.

Class B describe those Seasonal Leather and seasonal Fur Material which are 30% of the total inventory but contribution in sales is 15% of that particular product.

Class C describe those leathers which are 5% of the total inventory but contribution in sales is 5% of that particular product.

By this classification it was decided by MR GM that for class C items make to order production strategy will be used to avoid over inventory.

Demand Forecast Method also applied to avoid from the over inventory or lack of inventory. It comprised of both Qualitative methods & Quantitative methods.

Qualitative Method MR GM used DELPHI Method

A questionnaire prepared by MR GM and get opinion from the high officials of the company. Sales team directly involved in forecasting as they were the big cheese of that particular task.

Quantitative Method Quantitative methods also applied which gave benefit of estimated approach for future ordering.

In quantitative method three statistical method applied for forecasting, Simple Moving Average, Weighted Moving average, Exponential smoothing average, Forecasting technique became fruitful in making the inventory stocks in control.

Few differences also observed in actual demand and forecasted demand.

Mr. GM applied Mean Absolute deviation and mean absolute percentage Error by these measures MR Saqib Restrict the forecast inside the acceptable limits.

Conclusion

In conclusion, Under the strong leadership of Mr. Saqib Manazir company overcome the challenges and attain a huge growth in the past 7 years. Everyone played its part in achieving the goals. In export sector supply chain is very essential and crucial department as it can make the company to touch the heights of success or vice versa. Policies and practices performed in Shafi Lifestyle made it possible to achieve the goals strategically. Results also showed that application of the solutions not only resolve the supply chain hurdles but also made it possible to become the 2nd largest shoe export company of Pakistan. Furthermore, to attain more success in future technology should must adopt by the company in manufacturing as it’s very necessary to remain in the game and also must be considered the skilled labor as an asset of the company, as they play a vital role in growth of company and also 30% of the success or failure of the company depend upon the labor.

Received: 25-Jan-2024, Manuscript No. JIACS-24-14421; Editor assigned: 27-Jan-2024, Pre QC No. JIACS-24-14421 (PQ); Reviewed: 14-Feb-2024, QC No. JIACS-24-14421; Revised: 22-Feb-2024, Manuscript No. JIACS-24-14421 (R); Published: 05-Mar-2024