Research Article: 2023 Vol: 29 Issue: 3S

Problems and Prospects of Jute Industry in Assam: A case study in Assam Cooperative Jute Mill

Sampurna Khound, Darrang College

Citation Information: Khound, S. (2023). Problems and prospects of jute industry in Assam: A case study in Assam cooperative jute mill. Academy of Entrepreneurship Journal, 29(S3), 1-9.

Abstract

Jute is the natural fiber also known as the golden fiber and is the second most important fiber in India after cotton. The increased concern of protection of nature in recent days creates more opportunities and prospects in natural fiber sector. India is the largest producer of jute. West Bengal, Assam and Bihar are the major jute growing state in the country. But with the increased use of synthetic fiber, jute industry lost its glory. Therefore the main goal of the study is to find out economic and social benefits of jute and also the environmental benefit which as a whole contributes towards achieving sustainable development. To carry out the study research question has been set up according to the objective of the study. Results has been formulated on the basis of review of literature, secondary data and primary data collected through interview. Assam Co-operative Jute Mill at Silghat in Nagaon district is a full-fledge jute mill in Assam and produce variety of jute products. The mill provides huge employment opportunity and there are different category of officials and workers working in the mill. The local jute growers also getting benefit from it. Farmer’s social sustainability depends on the successful cultivation of jute.

Keywords

Jute, Golden Fiber, Sustainable Development, Environmental benefit.

Introduction

In the context of global awareness for environmental concerns, jute and allied fibres, as eco-friendly packaging materials, are again in the centre stage as against synthetic fibres, which are pollutant by nature as claimed by the environmentalists (Chapke, 2013). Food and Agriculture Organization (FAO) has declared year 2009 as the International Year for Natural Fibres considering, particularly, their environmental significance. Jute is a commercial fibre crop, which plays a significant role in the economy. Thus, raw jute farming, industry and trade support livelihood to 14 million and apart from this jute industry also contributes to the export earning of the country. Jute is mainly cultivated by the marginal and small farmers and it is a source of income generation for them.

Jute the golden fibre of India and is the 2nd most important fibre after cotton. India is ranked in 1st position in jute production and accounting for about 62.2 percent of world production and 59.3 per cent of the total area in the World (Rajpoot & Shalini Saxena, 2019). In India Jute is cultivated on 0.71 million hectares with an annual production of 9.98 million bales. West Bengal, Assam and Bihar are the major jute growing states in the country, which accounts for about 98 percent of the country’s jute area and production (State of Indian Agriculture, 2016-2017). The suitable climate for growing Jute (warm and humid climate) is during the monsoon season. Jute is a crop of humid tropical climates. For better growth, a mean maximum and minimum temperature of 34 ˚C and 15 ˚C and a mean relative humidity of 65% are required. Assam is the second largest producer of jute in India. Assam alone produces 1.6 million bales of jute. The main jute producing districts of Assam are Nagaon, Goalpara, Barpeta and Darrang district. Assam Co-operative Jute Mill full-fledge jute mill was a major producer of jute products in Assam. The mill provides huge employment opportunity and also benefit to local farmers. Though the mill has gone through financial depression due to imbalance in income and expenditure, but it has managed to grow with continuous struggle and effort.

Objectives:

1. To analyse the economic and social prospects of jute in terms of sustainability.

2. To evaluate the performance of the Assam Cooperative Jute Mill Ltd.

Research Question:

1. What are the factors responsible for the poor performance of jute mill?

Methodology

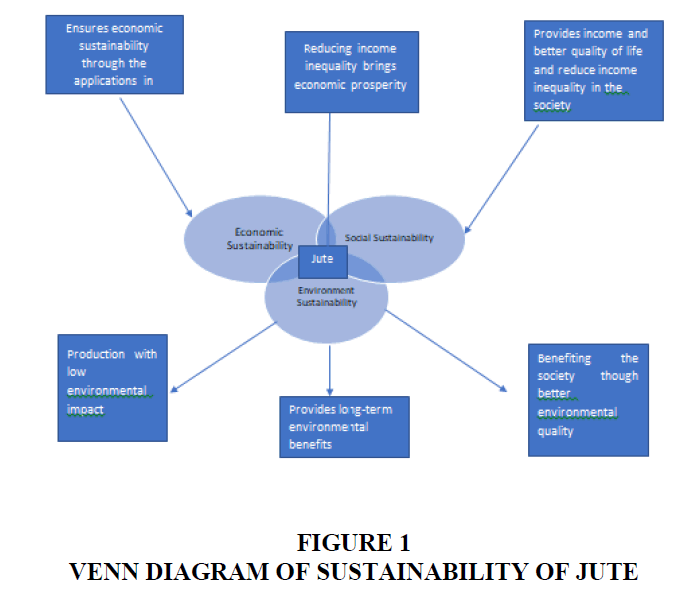

The study is based on both primary and secondary data. To study the economic prospects of jute secondary data has been collected from various annual report of ACJML and statistical handbook of Assam. For the primary data to study the social prospects of jute focused group discussion method has been adopted among the jute growers of Nagaon district. Environmental benefits of jute have been analysed on the basis of existing literature. Literature has been reviewed and analysed on the basis of the objectives of the study. Venn diagram is used to show the interconnection among the different sectors. Data has been presented in tabular method and bar diagram is also used to show the responses of the employee.

Economic and social prospects of jute production:

With the emergence of global environmental concern against nondegradable plastic, jute has received immense importance. In our own country, due to the growing environmental concerns, state and the central government started making laws and banning the use of certain kinds of non-degradable plastics. By now most of the state govts have banned the use of plastics. This has given a boost to the demand of jute by the jute industry Jahan (2019).

The following table shows the area, production and average yield per hector in Assam shows in Table 1.

| Table 1 Area, Production and Average Yield of Jute | |||

| Year | Area (in Hect.) | Production (in Tonnes) | Average yield (in Kg/Hect.) |

| 2016-17 | 75140 | 802747 | 1923 |

| 2017-18 | 69926 | 841150 | 2165 |

| 2018-19 | 65789 | 761571 | 2084 |

| 2019-20 | 64247 | 791512 | 2218 |

| 2020-21 | 62879 | 773883 | 2215 |

It has been seen from the table that there is a fluctuation in the production of jute because of the dependence on rain fall and its fluctuation during the rainy seasons.

The huge negative effects of plastic in the environment makes people conscious over the use of plastic. Many countries reduce the use of plastic commodities especially the plastic bags. If the usage of plastic bags reduces, the alternative biodegradable and environment-friendly products would be jute bags. Here lies a good economic prospect of jute. Jute has played an important role in the economy of assam. The jute industry is an agro-based industry, labour intensive industry and export-oriented industry. Jute is completely biodegradable and mix with soil within two to three months (Islam & Ahmed, 2012). Jute is not only biodegradable but it grows very fast and grow in crop rotation, so it does not occupy land for a long time and it also add fertilizer to the next crop (Islam, 2013). The environmental scientists have established that one acre of jute plants absorbs nearly 6 MT of CO2 from the atmosphere in its maturity period of 120 days and it releases 4.4 MT of oxygen in the same period. This is several times more than the normal trees (Kumar, 2017). Along with the traditional usage, jute can contribute in the production of value-added products like paper, pulp, composites, textiles and so on. Jute products can also reduce the usage of some traditional materials, for example: “wood”, that can save environment from deforestation and “plastic”, that can reduce negative impact in the environment Das, P. (2011) shows in Table 2.

| Table 2 Effects of Jute on Environment | |

| Effects on environment | Analysis |

| Air purification | Jute plant inhale carbon dioxide and exhale oxygen that result air purification. Jute composite is applied in the automobile sector and vehicle to reduce CO2 emission. |

| Preservation of forest | Natural fibres have a great role to save indigenous forests as the composites made from the fibre are good alternative of woods and timber. Along with the use of jute as a paper pulp and domestic fuel, jute composites are great alternative sources of wood. |

| Fertility of land | The fertility of land is increased with the rotten leaves and roots from jute plants. During the plantation of jute, farmers generally use cow dung which is a natural fertilizer. So, jute plantation is done naturally without making any harm to the soil |

| Biological efficiency | Jute holds strong biological efficiency quality. Jute is very fast-growing plants and to become mature it takes only four to five months. The productivity of jute is better than wood. Considering the qualities of usage, availability, production, consumption and price, jute is the most important natural and vegetable fiber after cotton. |

| Biodegradable | Polyethylene bags are not biodegradable but jute made bags are biodegradable and not harmful for the soil. |

The following Venn diagram illustrate the interconnection among economic, social and environment sector to attain sustainable development.

In assam a large section of people engaged in agriculture sector. Jute is a labour-intensive crop. Quite a large number of farmers engaged in jute cultivation and it helps to uplift their social status along with the financial issue. Increased in the jute fiber production provides advantage to the farmers. The monetary gain depends on the market price of the fiber which was highly fluctuating due to lack of regularized market. Assam cooperative jute mill provides employment opportunities to the local people. The local farmers from Nagaon district are also benefiting from the mill shows in Figure 1.

Performance of Assam Cooperative Jute Mill Ltd:

Assam Co-operative Jute Mill is situated on the south bank of the river Brahmaputra at Silghat in the Nagaon district of Assam, located at about a distance of 8 Km. from Jakhalabandha. This is the only jute mill in the country in co-operative society of Assam registered in the year 1959 under Assam Co-operative Society Act. In 1970 the mill started its commercial production. In 1971-72, the mill produced 729 tonnes of jute product. After running in an uneven pace about 14 years the mill had to close for 22 months in March 1984 for acute financial crisis and other infrastructural problems. Again, the mill was reopened on 1st January 1986, under the terms of the historic Assam Accord with the financial assistance from Central Government as well as State Government. The mill is implementing the scheme for renovation/modernization and expansion in the form of diversification from its own resources for which capacity has increased from 20 MT to 23 MT per day and later on to 29 Mt per day. The mill has been marketing its major products i.e. gunny bags through Jute Commissioner’s requisition order and the rest products such as, Hessian cloth, Multi Fold yarn, Laminated Jute Cloth etc. are sold directly to the customers of local and outside of the state.

Employment Profile: The Mill Management has been conducted several in house and outside training to employees and awareness programme including local farmers during the year. There are different category of officials and workers working in ACJML at present. The casual workers are working in weekly basis. Badli (Replacement) workers are those who work in place of others. The following table shows the different category of workers and their numbers at present shows in Table 3.

| Table 3 The Category Wise Numbers of Employment Working in the Mill | ||

| S.no. | Categories | Number of employment |

| 1 | Officers & staff | 45 |

| 2 | Security Staff | 15 |

| 3 | Permanent Workers | 515 |

| 4 | Semi-Permanent Workers | 133 |

| 5 | Badli Workers | 110 |

| 6 | Casual Workers | 105 |

| Total | 923 | |

Production and Capacity Utilization:

The mill has given stress on diversified and value added products like-hessian cloth, M.F. Yarn and bleached, dyed and laminated hessian cloth. The commercial production of laminated hessian cloth is started from 31st March 2013 and sold in the local market. The following table shows the quality-wise production and sale turnover from 2013-14 to 2020-21 shows in Table 4.

| Table 4 The Quality-Wise Production and Sale Turnover from 2013-14 to 2020-21 | ||||||

| Financial Year | Production and sale | Sacking | M.F. Yarn | Hessian | Laminated Cloth | Total |

| 2013-14 | Production in MT | 5294.3573 | 300.4200 | 323.0090 | 140.6270 | 6058.4133 |

| Sold in MT | 5164.3487 | 309.5800 | 324.3019 | 124.2357 | 5922.4663 | |

| Value in Lakh | 3358.93 | 125.95 | 215.99 | 110.55 | 3811.42 | |

| 2014-15 | Production in MT | 5592.8030 | 251.4390 | 206.8600 | 115.9770 | 6167.0790 |

| Sold in MT | 5845.6938 | 243.9200 | 215.0962 | 143.0930 | 6447.8030 | |

| Value in Lakh | 4112.54 | 103.22 | 145.87 | 148.91 | 4510.54 | |

| 2015-16 | Production in MT | 5536.1074 | 111.2000 | 284.8382 | 141.2899 | 6073.4355 |

| Sold in MT | 5099.8471 | 96.6600 | 259.4951 | 129.9391 | 5585.9413 | |

| Value in Lakh | 3798.00 | 56.54 | 240.81 | 148.80 | 4244.15 | |

| 2016-17 | Production in MT | 5273.3464 | 124.548 | 257.0607 | 111.4074 | 5766.3625 |

| Sold in MT | 5539.323 | 144.888 | 300.9228 | 96.7002 | 6081.834 | |

| Value in Lakh | 4696.53 | 97.39 | 272.67 | 137.87 | 5204.46 | |

| 2017-18 | Production in MT | 5508.8451 | 398.1430 | 302.3213 | 96.8030 | 6302.1128 |

| Sold in MT | 5518.6276 | 377.3000 | 282.9982 | 101.4210 | 6280.3468 | |

| Value in lakh | 3847.99 | 200.96 | 251.51 | 131.87 | 44438.40 | |

| 2018-19 | Production in MT | 5841.9173 | 4.8200 | 158.8548 | 40.1421 | 6045.7342 |

| Sold in MT | 5928.4148 | 19.8800 | 170.0806 | 43.1498 | 6161.5248 | |

| Value in Lakh | 4751.16 | 16.57 | 170.78 | 59.54 | 4998.05 | |

| 2019-20 | Production in MT | 5770.837 | 88.013 | 5858.850 | ||

| Sold in MT | 5657.430 | 130.138 | 5797.568 | |||

| Value in Lakh | 4706.337 | 247.702 | 4958.039 | |||

| 2020-21 | Production in MT | 3978.378 | 79.834 | 4058.212 | ||

| Sold in MT | 3935.748 | 224.323 | 4160.08 | |||

| Value in lakh | 4006.09 | 210.85 | 4216.98 | |||

In 2013-2014 total finished goods produced 6058.4133 M.T. in 302 working days and average man-days are 39.54 per M.T. The capacity utilization of factory was 80.24 per cent against 25 M.T. per day on Sacking/Hessian production. In the year 2014-2015 total finished good production increase to 6167.0790 M.T. and again it reduced to 5766.3625 M.T. in the year 2016-2017. The capacity utilization of the factory was 78.88 per cent in 2014-2015 and increase to 79.23 per cent in 2015-2016. In the year 2016-2017 capacity utilization of the factory was 75.22 per cent. From the year 2019-20 production of MF Yarn and Laminated cloth has been stopped because these two products required huge amount of raw materials but the profit margin was low. In the year 2020-21 production was low due to the impact of covid-19.

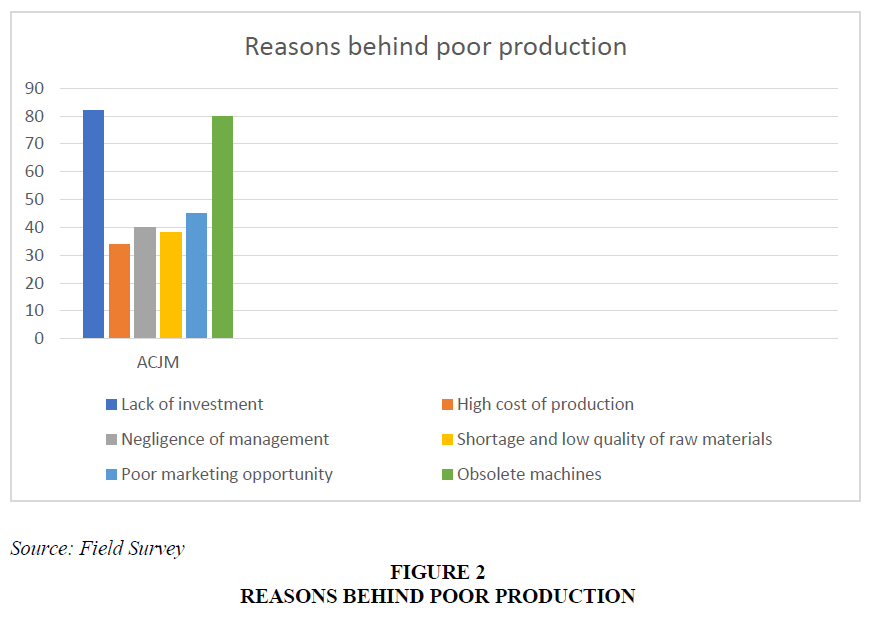

Status of production provides an overall scenario of any industrial unit. As Assam is a rich state in terms of natural resources so raw materials are available. Nagaon district of Assam which mainly focus on raw jute production is a major supplier of raw material to the ACJM. Due to the climatic condition quantity and quality varies from time to time. There are many reasons which have identified as the reasons for low rate of production are lack of investment, negligence of management, poor marketing opportunity, tough competition, high cost of production, shortage of raw materials and obsolete machines. The managerial section of all category of industry have identified mainly two reasons for low production- lack of investment and obsolete machine. The fig given below shows the responses for poor production in the three industrial units shows in Figure 2.

Current Ratio Analysis

There are so many parameters are used to identify the sick units. Among these the most valuable parameter is current ratio analysis which has been incorporated in the definition of sick units referred by Reserved Bank of India (RBI). According to RBI sick unit is “one which incur loss for the current year as well as, ratios, such as current ratio is less than 1:1 and worsening debt equity ratio” shows in Table 5.

| Table 5 Current Ratio of the ACJM | |||||||

| Name of the industrial unit | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 |

| ACJM | 1:4.2 | 1:4.6 | 1:4.06 | 1:2.3 | 1:2.6 | 1:2.5 | 1:2.4 |

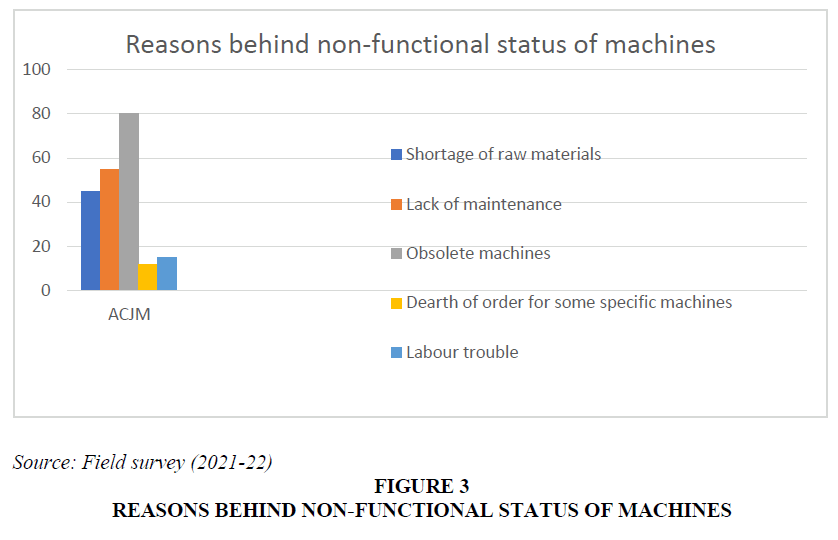

Status of machines and equipment

Condition of machines and equipment are very important factor for the smooth functioning of the industrial unit. Without good status of machines, the production becomes insufficient. The quality and quantity of production depend on the condition of the machines. In the study, it has been found that the mill is suffering from different crucial problems related to bad conditions of machines as well as insufficiency of equipment shows in Figure 3.

Responses of the employee about the poor performance of the mill:

In the study it has been found that the industrial unit is suffering from labour unrest, financial crisis, paucity of order and lack of upgradation and modernization. The following table shows the responses of the employee shows in Table 6.

| Table 6 Responses from the Employee About the Causes of Industrial Sickness | |

| Cause of sickness | % of response at ACJM |

| Lack of proper management | 42% |

| Poor implementation | 72% |

| Marketing problems | 35% |

| Non-availability and high cost of raw materials | 46% |

| Shortfall of working capital | 58% |

| Labour trouble | 76% |

| Technical/ Operational problem | 75% |

| Other Causes | 28% |

In the study it has been found that management system of the industrial unit is poor. About 42% works response that there is a lack of requisite personnel, expertise skills and adequate information and reporting system. If the top management of a company exhibiting the following defects such as-

➢ Unbalanced top management team

➢ Non-participating top management

➢ Lack of requisite personnel

➢ Insufficient knowledge for the industry concerned

These defects leads to the danger of making those decisions that often leads to sickness. Delay in receiving financial assistance also contributes to poor implementation of projects. Assam Cooperative Jute Mill has started another project in 2021 funded by NCDC (National Cooperative Development Cooperation) through Assam government. It has been observed that there are a number of terms and conditions laid down at various stages in the processing of loan which delay the project. Mostly the factors that contribute to technical problems are as follows-

➢ Inefficient operation of plant and machinery on account of frequent breakdowns.

➢ Poor maintenance and replacement of components and parts.

➢ Obsolete technology.

➢ Under-utilization of technology.

➢ Under-utilization of capacity.

➢ Shortage of power

The status of plant and equipment in a factory and its technical efficiency is a critical factor in determining the efficiency of an industrial unit. The respondent under study have said that machines and equipment are obsolete as a result production cost increased.

Conclusion

The global awareness for the environmental protection creates the opportunity of exploring Jute. As from the above study we have seen that although jute has great advantage of being natural, eco-friendly and biodegradable fibre, but its high cost in comparison to other synthetic materials as well as the lack of efficiency create a huge threat to the industry. The economic and social prospect of jute has been analysed. The study has depicted how jute can be linked with sustainable factors and contribute to sustainable development. The ACJM has the potential to grow with the upgradation of machines and equipment. Lack of investment is one of the major causes and due to which they are not able to perform well. It has been proved that jute has potential and this “Golden Fibre” has bright sustainable future if the issues are taken care of jointly by the jute industry and the government.

References

Chapke, R.R. (2013). Role of jute cultivation in farmer's livelihood. Indian Research Journal of Extension Education, 13(1), 132-135.

Das, P. (2011). Productivity and efficiency in the jute industry. Economic and Political Weekly, 74-76.

Islam, M.M. (2013). Jute of bangladesh: It's contribution to environment and challenges. The Reflector, Reflecting the issues and development in societies and states. Publisher: Md. Eanyet Ullah, 366, 08-10.

Islam, M., & Ahmed, S. (2012). The impacts of jute on environment. An analytical review on Bangladesh. Journal of Environment and Earth Science, 2(5), 24-31.

Jahan, A. (2019). The environmental and economic prospects of jute with a connection to social factors for achieving sustainable development.

Kumar, R. (2017). Indian jute industry and its future. International Journal of Business and General Management (IJBGM), 6(4), 21-32.

Rajpoot, S., & Shalini Saxena, S.S. (2019). Jute crope production estimation in major states of India. a comperative study of last 6 years FASAL ans DES estimates. The International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences, 129-136.

Received: 06-Feb-2023, Manuscript No. AEJ-23-13158; Editor assigned: 09-Feb-2023, PreQC No. AEJ-23-13158(PQ); Reviewed: 20-Feb-2023, QC No. AEJ-23-13158; Revised: 22-Feb-2023, Manuscript No. AEJ-23-13158(R); Published: 25-Feb-2023