Review Article: 2024 Vol: 28 Issue: 6S

Prediction of Green Logistics Blockages for Indian Automobile Companies by Exploration of the Fuzzy Degree of Similarity EngineExploitation of the New Fuzzy Degree of Similarity Approach towards Logistics Blockages Evaluation: Case Study of Automobile Companies

Neelkanth Dhone, Indian Institute of Management, Nagpur

Citation Information: Dhone, N. (2024). “Prediction of green logistics blockages for indian automobile companies by exploration of the fuzzy degree of similarity engineexploitation of the new fuzzy degree of similarity approach towards logistics blockages evaluation: case study of automobile companies.". Academy of Marketing Studies Journal, 28(S6), 1-11.

Abstract

Various traditional Supply Chain Management (SCM) policies, decision software, and tools are edited and developed in industrial circuits. It is observed that the Green SCM strategy is recently highly viral across the industrial circuits to well simulate the industrial supply-production cycle productive cum effectively. In GSCM, Green Logistics (GLs) is a momentous research topic. The GLs blockages are found to spark current to preserve the best Green SCM performance across Indian automobile companies. It is monitored that Indian automobile companies, whose compliance GSCM strategies are yet searching the GLs blockage Decision support system (DSS), consisting of GLs blockage model coupled with an empirical optimization engine to identify the significant GLs blockages for escalating the future GLs performance. The authors organized the systemic literature on Logistics (GLs) and its MCDM method's implications on the GLS model to fulfill the research gaps. The author recognized the ten blockages for framing a GLS model. In perspective to simulate the GLs model, and proposed a fuzzy-degree of similarity optimization engine with a new concept of positive ideal solution (considered as the novelty of work). The simulation of DSS is based on the feedback of vague information from the expert panel or industrial professionals vs. 10 significant blockages in terms of the fuzzy set corresponding to linguistic variables. The research aims to facilitate all Indian automobile companies with DSS and help them identify and scrutinize the weak and robust blockages (in the model).

Keywords

Fuzzy set, Green Logistic (GL), blockages, Levers, Degree of similarity optimization engine.

Introduction

The traditional Supply Chain Management (SCM) segments need to be updated from the brain of global researchers because many research documents are edited and floated over traditional SCM. The research works are sufficient in the curriculum of conventional SCM policies, decision software, tools, hypotheses, and decision support systems. Recently, the traditional SCM has been substituted by its strategies such as lean, green, agile, and resilient SCM, where all said SCM strategies, excluding green SCM strategy, are edited for the following dimensions such as policies, decision software, tools, hypotheses, and decision support systems. Consequently, the Green SCM strategy becomes highly viral across the industrial circuits to simulate the industrial supply-production cycle well. GSCM is the environmental thoughts derived, classically from the Eco Production Unit (EPU) and identified as ‘green’ in the 1990s. GSCM is famous for eliminating pollution, global warming, and other challenges. GSCM spotlights reducing pollution by eliminating unwanted practices such as reduction of waste and increasing business opportunities at an international standard. GSCM operations help industries remove the seven wastes: over-processing, waiting, overproduction, over-motion, defects, transportation, and inventory. In the curriculum of GSCM, GLs management becomes a focal point for current researchers and is clutched by many researchers as a sizzling research area.

Logistics is the transportation and inbounded and outbounded distribution of goods and materials from origin to destination. As a result, GLs (Green Logistics) are defined as systems that aid in conducting inbounded and outbounded distribution/logistic activities in GSCM by maintaining clean and polluted surroundings. GLs are adopted as a channel to drive out undesirable pollution, i.e., fossil fuel, danger particles, toxic gasses, etc, in logistics/distribution indices. GL blockage identification and further improvement aid the Indian automobile parts production and supplier companies in winning competitive advantages such as gaining a reputation and ethical image in the market and reducing miscellaneous costs. It is monitored that Indian automobile parts production and supplier companies must balance green logistics operations to maintain green performance. This is only possible if the suppliers’ companies can improve their GLs blockages. Sufficient research works are concluded regarding alternative or choice evaluation, benchmarking, and selection problems in GLs. Still, an insufficient quantity of research work has been published about the identification of GL blockages to improve the GSCM performance of Indian automobile companies. This is accepted as a direction of future study. It is so difficult to scrutinize the weak and robust GL blockages that the MCDM approach needs to be supported.

Multi-criteria decision-making (MCDM) approaches are designed to ascertain the best and weak factors under any strategies of SCM by addressing the conflicted attitude of factors. The features of MCDM exist to find the best solution under conflicting factors subjected to no-constrained boundary conditions. Therefore, it is included with the mathematical programming method to lead the optimization and decision evaluation problems. However, it has been perceived that the two chief difficulties, such as the scale problems and trade-off, make the MCDM model so complicated and complex. The trade-off means finding the final optimal solution via mathematical programming under multiple objectives subjected to weighted vs. single objectives. MCDM assists us in categorizing and scrutinizing the weak and strong GL blockages by providing performance evaluation, benchmarking, and measurement (PM) tools. PM is the feedback of information vs. GSCM-GLs blockages (in response to the customer’s expectations). The PM quantifies the weak and robust GLs blockages using PM methods and engine. A few technical engines and techniques have been published in the context of GSCM to identify GSCM-GL blockages but have not tackled the GL problem. Moreover, all published works are obsolete; therefore, there is a need to construct or identify a novel technical engine or technique to the extent of MCDM performance evaluation. To search for that, the author has conducted post-literacy surveys to develop and propose a GSCM-GLs blockage model and the MCDM engine to solve the GSCM-GLs blockage model.

Literature Survey

The conducted literature review in the context of the MCDM GL model and the MCDM technique or engine for finding weak and strong blockages are briefly discussed below.

The authors developed a hybrid method for electing green vendors. Economic and environmental parameters, which correspond to cost, quality, service, and environmental performance, are prioritized to control environmental pollution (Zafar et al., 2019). The authors applied a fuzzy Analytic Hierarchy Process (F-AHP) to evaluate the weights vs criteria. An Additive Ratio Evaluation (ARE) method is applied to assess the green suppliers (Mavi et al., 2015). A green supplier evaluation problem is solved by a model constituted by using economic and environmental parameters. A numerical example is displayed using the MCDM fuzzy technique to verify the feasibility as well as the advantage of the model (Yu et al., 2018). The authors applied a fuzzy data envelope analysis (FDEA) model incorporating only green supplier evaluation parameters to solve the problem (Yu et al., 2017). Implements a fuzzy set theory and TOPSIS and GRA technique for benchmarking the green supplier. An empirical case study of a Food processing Company reveals an application of research work (Banaeian et al., 2016). The authors implemented the DEMATEL method to determine the weights vs multiple indices. A green vendor evaluation problem is demonstrated to validate the method (Sun et al., 2006).

The research focused on establishing a supplier evaluation technique with the grey set to identify the best green suppliers (Huang,et al. 2023). A trapezoidal interval-valued fuzzy set is implemented with the approach TOPSIS (Technique for Order Preference Similarity to Ideal Solution) for benchmarking the green vendors. A survey case study is demonstrated to validate the model (Ingenbleek & Krampe, 2023). The research work focused on green supplier performance measurement problems. The suppliers are rated based on fuzzy grey relational analysis methods. Case research is illustrated to depict the actual application of the projected method (Harju et al. 2023).

The authors predicted the interaction between the key barriers, influencing the accomplishment of green road projects. The experienced professionals were invited for interviews in the study vs. evaluated 33 practical SCM blockages. The results depicted the incremental cost, development of innovative technologies, lack of standards, regulations, public awareness, green evaluation, and protection behavior, and critical interactive SCM blockages that influence the accomplishment of green roadway projects. The authors audited initiatives to allocate supplier resources to achieve customer satisfaction. A framework is built, incorporating a few initiatives to decide on assigning the suppliers. The model was audited using the moderated regression mathematical technique on availing 102 vendor companies. The findings revealed that a few supply chain management initiatives influence vendors’ allocation (Ingenbleek et al., C (2023). The authors audited procurement digitalization to reduce the uncertainty associated with Supply Chain Management and how procurement digitalization is related to mitigating the SCM risk and increasing SCM resilience (SCRES). The survey data was collected from 147 Finnish firms and simulated using the partial least square path technique. It has been identified that data analytics, procurement process digitalization, and data sharing work as drivers for procurement digitalization and the elimination of SCM risk management (SCRES). The authors built a multi-level structure criteria model focused on the alliance between the challenges confirming the transplant supply chain systems. Eleven complex variables were recognized by a literature review and analyzed using Delphi-interpretive structural modeling. The findings showed a lack of information systems and essential skills are barriers against transplant supply chain systems (Harju et al., 2023).

The authors presented an extended framework for project system SC (PSSC) to attain the many objectives of the Architecture, Construction & Engg, and Operations Maintenance (AECOM) value supply chain. Moreover, the many related objectives are also addressed in reviewing the emerging theme of 4th I. Revolution (4.0, I.R) techniques in AECO and also to recognize the lacunae in PSC (Bhattacharya et al., A. (2022). The authors mapped and authenticated the data of entrepreneurship career mapping the primary constructs by employing the social cognitive career development principles. Further, the authors used the same data to examine the dependent hypotheses utilizing the four-step straight co-regression analysis. Eventually, it is concluded that an entrepreneurial career solicits familiarity with SCM practices (Osorio et al., 2022). The authors evaluated the two sixty-three surveys from UK respondents of grocery stores during the COVID-19 pandemic to recognize the food SCM blockages. The research revealed that SCM traceability and data sharing related to consumers positively manage and control the visibility of the market, while visibility affects the acceptance of sustainability (Sharma et al., 2022; Dubois & Prade 1983); (Chen & Chen 2006; Chen & Chen 2009).

After passing through the literature review, the authors identify a few momentous GLs blockages to be considered for developing the MCDM-GLs model in the context of Indian Automobile companies under GSCM; in addition to that, the author determined a novel fuzzy technique to simulate the same model. Therefore, the research framework guided the author's search to finalize Research Objectives (ROs).

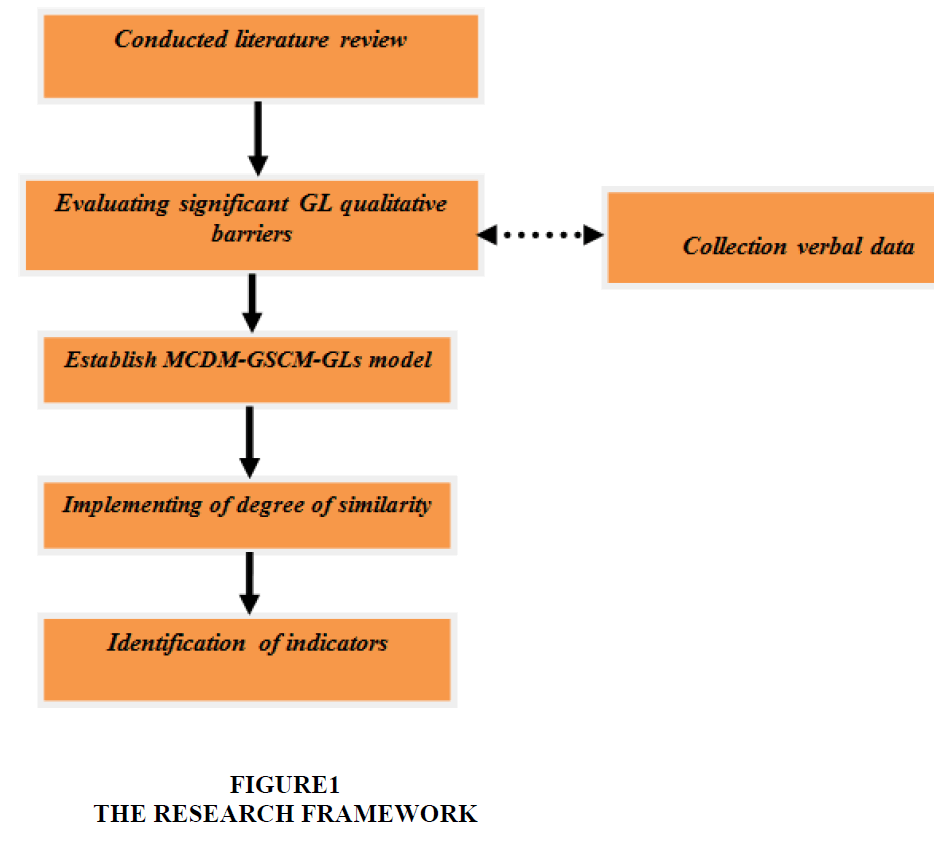

Research Framework (RF)

The research framework depicted the style and steps adopted by the author to shape the Research Objectives (ROs).

Step 1- To Build the MCDM-GSCM-GLs Blockages Model

Conducted a literature survey in GSCM and logistics initiatives to conclude that only the qualitative GSCM-GL blockages were considered due to (1) as most GLs models were based on quantitative data. (2). Scrutinized only significant qualitative Green Logistics Blockages based on a high population of GLs in most of the published research documents.

Step 2- To invent MCDM techniques to solve the MCDM-GSCM-GLs blockages model:

It identified that a revised ranking method was used, and other methods required the two sets of fuzzy data. Therefore, a technique with a degree of similarity embedded with a fuzzy set and a new positive/negative ideal solution is used to identify the weak and strong GSCM-GLs blockages Figures 1 & 2.

Research Objectives (ROs)

Therefore, the discussed above research framework directed the author to conclude and furnish the Research Objectives (ROs), which are shown below.

1. First aim: To identify the significant GSCM-GLs blockage to be considered for developing the model.

2. Second aim: To propose the technique of degree of similarity along with fuzzy and new negative/positive ideal solutions to identify the current and future GSCM-GLs blockage.

3. Third aim: To develop a green logistic barriers-based decision support system and aid the suppliers/production firms to identify the weak and robust GSCM-GLs blockage in the future.

Fuzzy-Degree of Similarity Soft Computing Technique

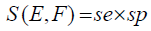

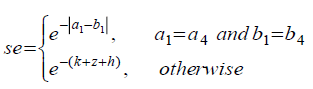

The proposed Fuzzy-degree of similarity soft computing technique is executed to map the similarly between Fuzzy Numbers (FNs) sets. The fuzzy degree of similarity technique is amalgamated with a positive/negative ideal solution (in the case of only beneficial GSCM-GL blockages) to calculate preference for the ranks of GSCM-GL blockage. Assume that a technique for the degree of similarity is measured among two fuzzy sets between E and F, as discussed below.

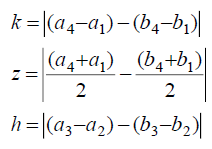

(1)

(1)

Where,

Where is the radial deference, is the centric deference, and is the point deference among and F, respectively?

and,

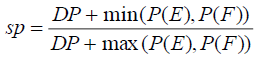

(2)

(2)

Where,

Where, and are the circumstance of and . , is an value to eliminate zero in the numerator as well as the denominator,

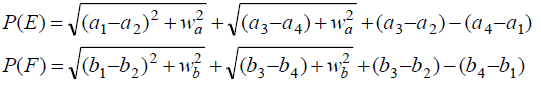

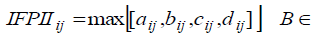

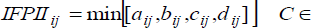

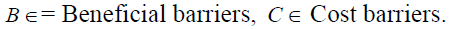

The evaluation of positive as well as negative ideal solutions by defining FPII sets:

(3)

(3)

(4)

(4)

Scenario Analysis-A Case Study

An empirical case study of an Indian automobile firm situated in the North side of India is assumed to exhibit the application of the qualitative MCDM-GSCM-GLs model. The company supplies the different types of parts. This company wishes to identify the weak and robust GSCM-GLs blockages using the subjective feedback of its own company professionals. The authors propose a built GSCM-GLs blockage model, as illustrated in Table 1. The next procedure is compliance to compute the decision.

| Table 1 Shortlisted MCDM-GSCM-GLS Blockages | ||

| Goal | GSCM-GLs Blockages | Attitudes |

| Identification of GSCM-GLs blockages weak and strong barriers | Green Transportation Inside The Company (BL-1) | (+) |

| Green Outside Shipping (BL-2) | (+) | |

| Green Service Vs Complain (BL-3) | (+) | |

| Green Material Procurement (BL-4) | (+) | |

| Green Logistic 3rd Party Evaluation (BL-5) | (+) | |

| Eco Friendly Conveyance Utilization (BL-6) | (+) | |

| Eco Friendly Product Transfer Line (BL-7) | (+) | |

| Eco Packing For Logistic (BL-8) | (+) | |

| Green Logistic Policy (BL-9) | (+) | |

| Green Logistic Idea Innovation (BL-10) | (+) | |

Stage 1: In the first stage, a team, including the seven professionals, is assisted by linguistic variables, revealed in Table 2, to evaluate priorities vs. GL blockages.

| Table 2 Nine-Member Linguistic Terms (Sahu et al., 2013) | |

| Priorities Defined | Fuzzy value representation |

| DLDefinitely low | Fuzzy (0.0, 0.0, 0.0, 0.0; 1.0) |

| VLVery low | Fuzzy (0.0, 0.0, 0.02, 0.07; 1.0) |

| LLow | Fuzzy (0.04, 0.10, 0.18, 0.23; 1.0) |

| MLMore or less low | Fuzzy (0.17, 0.22, 0.36, 0.42; 1.0) |

| MMiddle | Fuzzy (0.32, 0.41, 0.58, 0.65; 1.0) |

| MHMore or less high | Fuzzy (0.58, 0.63, 0.80, 0.86; 1.0) |

| HHigh | Fuzzy (0.72, 0.78, 0.92, 0.97; 1.0) |

| VHVery high | Fuzzy (0.93, 0.98, 1.0, 1.0; 1.0) |

| DHDefinitely high | Fuzzy (1.0, 1.0, 1.0, 1.0; 1.0) |

Stage 2: The fuzzy priorities vs GSCM-GLs blockages are shown in Table. 3, which are subsequently aggregated by references (Sahoo et al. 2013) and (Sahoo et al. 2014), is shown in Table. 4.

| Table 3 Subjective Information of Experts vs GSCM-GLS Blockages | ||||||||

| Category | GL barriers | P1 | P2 | P3 | P4 | P5 | P6 | P7 |

| Qualitative category | Green Transportation Inside The Company (BL-1) | PM | PMH | PM | PMH | PVH | PVH | PML |

| Green Outside Shipping (BL-2) | PMH | PM | PM | PMH | PVH | PVH | PML | |

| Green Service Vs Complain (BL-3) | PM | PMH | PM | PMH | PVH | PVH | PML | |

| Green Material Procurement (BL-4) | PM | PMH | PM | PM | PMH | PML | PVH | |

| Green Logistic 3rd Party Evaluation (BL-5) | PM | PMH | PM | PM | PMH | PML | PVH | |

| Eco Friendly Conveyance Utilization (BL-6) | PM | PMH | PM | PM | PMH | PML | PVH | |

| Eco Friendly Product Transfer Line (BL-7) | PVH | PVH | PAH | PM | PMH | PML | PVH | |

| Eco Packing For Logistic (BL-8) | PAH | PVH | PVH | PM | PMH | PML | PVH | |

| Green Logistic Policy (BL-9) | PVH | PVH | PAH | PM | PMH | PML | PVH | |

| Green Logistic Idea Innovation (BL-10) | PVH | PVH | PAH | PM | PMH | PML | PVH | |

| Table 4 Aggregated Fuzzy Sets, Positive Ideal Solution, Crisp Sores and Ranks | ||||

| GLs Blockages | Aggregated fuzzy set | Positive ideal solution | Crisp sores(Sp) | Ranks |

| Green Transportation Inside The Company (BL-1) | [0.796,0.851,0.930,0.955,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9919 | 3.0 |

| Green Outside Shipping (BL-2) | [0.796,0.851,0.930,0.955,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9919 | 3.0 |

| Green Service Vs Complain (BL-3) | [0.796,0.851,0.930,0.955,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9791 | 4.0 |

| Green Material Procurement (BL-4) | [0.767,0.805,0.905,0.940,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9951 | 2.0 |

| Green Logistic 3rd Party Evaluation (BL-5) | [0.767,0.805,0.905,0.940,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9951 | 2.0 |

| Eco Friendly Conveyance Utilization (BL-6) | [0.767,0.805,0.905,0.940,1.000] | [0.857,0.890,0.952,0.973,1.000] | 0.9951 | 2.0 |

| Eco Friendly Product Transfer Line (BL-7) | [0.857,0.890,0.952,0.973,1.000] | [0.857,0.890,0.952,0.973,1.000] | 1.0047 | 1.0 |

| Eco Packing For Logistic (BL-8) | [0.857,0.890,0.952,0.973,1.000] | [0.857,0.890,0.952,0.973,1.000] | 1.0047 | 1.0 |

| Green Logistic Policy (BL-9) | [0.857,0.890,0.952,0.973,1.000] | [0.857,0.890,0.952,0.973,1.000] | 1.0047 | 1.0 |

| Green Logistic Idea Innovation (BL-10) | [0.857,0.890,0.952,0.973,1.000] | [0.857,0.890,0.952,0.973,1.000] | 1.0047 | 1.0 |

Stage 3: Next, the positive ideal solution values corresponding to each GL barrier is evaluated based on attitudes of GSCM-GLs blockages by employing Equ.3, is shown in Table. 4.

Stage 4: The technique of degree of similarity is computed among the two fuzzy sets by using Equa. 2, and the crisp values corresponding to GL barriers are shown in Table 5.

| Table 5 Ranking Orders and Action Required/Improvement Over GSCM-GLS Blockages | ||

| GL barriers | Ranks | Action required/improvement |

| Green Transportation Inside the Company (BL-1) | 3.0 | Yes |

| Green Outside Shipping (BL-2) | 3.0 | Yes |

| Green Service Vs Complain (BL-3) | 4.0 | Yes |

| Green Material Procurement (BL-4) | 2.0 | Yes |

| Green Logistic 3rd Party Evaluation (BL-5) | 2.0 | Yes |

| Eco Friendly Conveyance Utilization (BL-6) | 2.0 | Yes |

| Eco Friendly Product Transfer Line (BL-7) | 1.0 | No |

| Eco Packing For Logistic (BL-8) | 1.0 | No |

| Green Logistic Policy (BL-9) | 1.0 | No |

| Green Logistic Idea Innovation (BL-10) | 1.0 | No |

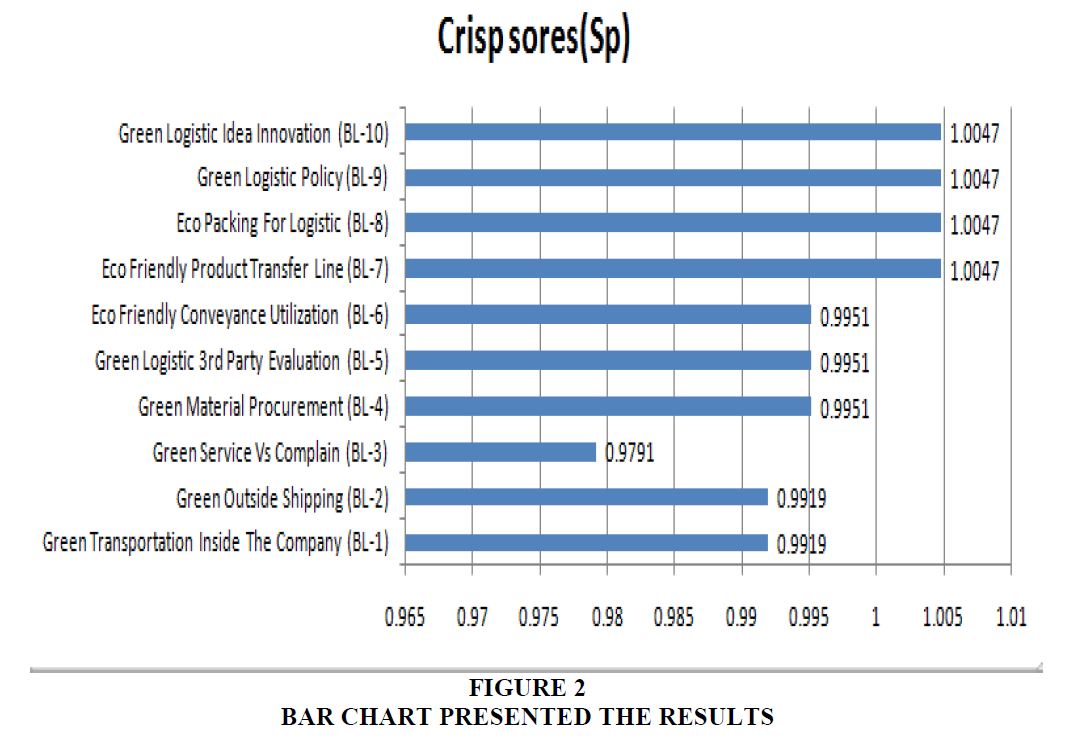

Stage 5: The results illustrate the identification of weak and robust GSCM-GLs blockages.

Results and Discussion

The fuzzy degree of similarity engine is implicated over the GSCM-GLs blockages model (consisting of GSCM-GLs blockages). The results depicted that Eco packing for logistics, Green logistic policy, Green logistic idea innovation, and Eco-friendly product transfer line don’t require improvement as the score comes (1.0047) under a fuzzy degree of similarity-1 (meet ideal solution). In contrast, the residue of GSCM-GLs blockages, i.e., green transportation inside the company, Green outside shipping, green service vs complains, green material procurement, Green logistic 3rd party evaluation and Eco-friendly conveyance utilization are weak and need to be improved for escalating the future GSCM-GLs blockages performance. The results are shown in Bar Chart 1.

Conclusion

GSCM-GLs blockages benchmarking and identification area under GSCM forum has found high momentum over years due to voiding and reducing environmental pollution issues in automobile production processes. The GSCM-GLs blockages are integrated under new rules and regulations of green practices. The objective of GLs is to focus on environmental concerns in logistic activities to compensate for the customer’s quotations. In the presented research, the soft computing method with GSCM-GL blockages aids Indian automobile parts suppliers identify weak and strong GSCM-GL blockages and significant GSCM-GL blockages. The proposed degrees of similarity technique with fuzzy and new positive ideal solutions also assist the suppliers in addressing the future green GSCM-GLs blockage identification problems.

The conclusion stated that four (4) GSCM-GLs blockages, such as Eco packing for logistics, Green logistic policy, Green logistic idea innovation, and Eco-friendly product transfer line don’t require improvement as a score comes (1.0047) under a fuzzy degree of similarity-1 (meet ideal solution), whereas, rest of GSCM-GLs blockages, i.e., Green transportation inside the company, Green outside shipping, Green service vs. complain, Green material procurement, Green logistic 3rd party evaluation and Eco-friendly conveyance utilization are line up with 0.999 score, not meet ideal solution limit. Therefore, those are recommended as weak and need to be improved to escalate the future GSCM-GLs blockage performance. Implication- The research encompasses the value for the social community and also for identifying the best green garden location alternative amongst other competitors if the model structure can be altered and integrated into future industrial garden location-based blockages. The research doesn’t target multi-linear programming and is concerned with limitations. However, the research signals solving the same problems in other interdisciplinary areas. Novelty- The method realized the concept of positive and negative ideal solutions with the technique of a degree similar to making the work novel in mythological terms. Economical work is fit from an economic point of view as don’t need any specific software.

References

Banaeian, N., Mobli, H., Fahimnia, B., Nielsen, I. E., & Omid, M. (2018). Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Computers & Operations Research, 89, 337-347.

Indexed at, Google Scholar, Cross Ref

Bhattacharya, S., & Chatterjee, A. (2022). Digital project driven supply chains: a new paradigm. Supply Chain Management: An International Journal, 27(2), 283-294.

Indexed at, Google Scholar, Cross Ref

Chen, S. M., & Chen, J. H. (2006). A new method for ranking generalized fuzzy numbers for handling fuzzy risk analysis problems. In 9th Joint International Conference on Information Sciences (JCIS-06). Atlantis Press.

Indexed at, Google Scholar, Cross Ref

Chen, S. M., & Chen, J. H. (2009). Fuzzy risk analysis based on ranking generalized fuzzy numbers with different heights and different spreads. Expert systems with applications, 36(3), 6833-6842.

Indexed at, Google Scholar, Cross Ref

Dubois, D., & Prade, H. (1983). Ranking fuzzy numbers in the setting of possibility theory. Information sciences, 30(3), 183-224.

Indexed at, Google Scholar, Cross Ref

Harju, A., Hallikas, J., Immonen, M., & Lintukangas, K. (2023). The impact of procurement digitalization on supply chain resilience: empirical evidence from Finland. Supply Chain Management: An International Journal, 28(7), 62-76.

Indexed at, Google Scholar, Cross Ref

Huang, N., Du, Q., Zou, P.X., & Huang, Y. (2023). Analysis of key factors influencing green highway project development focusing on network interaction and project success: evidence from China. Engineering, Construction and Architectural Management, 30(8), 3203-3223.

Ingenbleek, P.T., & Krampe, C. (2023). Sustainability in the supply chain–understanding suppliers’ resource allocation for sustainability issues. Supply Chain Management: An International Journal, 28(7), 28-42.

Mavi, R. K. (2015). Green supplier selection: a fuzzy AHP and fuzzy ARAS approach. International Journal of Services and Operations Management, 22(2), 165-188.

Indexed at, Google Scholar, Cross Ref

Osorio Tinoco, F., Bayon, M. C., & Murillo Vargas, G. (2022). Entrepreneurial career choice intentions among secondary students in Colombia: the role of entrepreneurial exposure. International Journal of Emerging Markets, 17(1), 277-298.

Indexed at, Google Scholar, Cross Ref

Sahu, A. K., Datta, S., & Mahapatra, S. S. (2013). Green supply chain performance benchmarking using integrated IVFN-TOPSIS methodology. International Journal of Process Management and Benchmarking, 3(4), 511-551.

Indexed at, Google Scholar, Cross Ref

Sharma, M., Alkatheeri, H., Jabeen, F., & Sehrawat, R. (2022). Impact of COVID-19 pandemic on perishable food supply chain management: a contingent Resource-Based View (RBV) perspective. The International Journal of Logistics Management, 33(3), 796-817.

Sun, H., Dang, Y., & Mao, W. (2018). A decision-making method with grey multi-source heterogeneous data and its application in green supplier selection. International Journal of Environmental Research and Public Health, 15(3), 446.

Indexed at, Google Scholar, Cross Ref

Yu, F., Yang, Y., & Chang, D. (2018). Carbon footprint based green supplier selection under dynamic environment. Journal of cleaner production, 170, 880-889.

Indexed at, Google Scholar, Cross Ref

Yu, M. C., & Su, M. H. (2017). Using fuzzy DEA for green suppliers selection considering carbon footprints. Sustainability, 9(4), 495.

Indexed at, Google Scholar, Cross Ref

Zafar, A., Zafar, M., Sarwar, A., Raza, H., & Khan, M. T. (2019). A fuzzy AHP method for green supplier selection and evaluation. In Proceedings of the twelfth international conference on management science and engineering management (pp. 1355-1366). Springer International Publishing.

Received: 29-Jan-2024, Manuscript No. AMSJ-24-14591; Editor assigned: 30-Jan-2024, PreQC No. AMSJ-24-14591(PQ); Reviewed: 29-May-2024, QC No. AMSJ-24-14591; Revised: 26-Jun-2024, Manuscript No. AMSJ-24-14591(R); Published: 06-Aug-2024