Research Article: 2021 Vol: 27 Issue: 4

Modeling the Influence of Digitalization in the Oil and Gas Chemical Sector On the Energy Efficiency of Russian Industry

Marina V. Shinkevich, Kazan National Research Technological University

Elmira Sh. Shaimieva, Kazan Innovative University

Irina G. Ershova, Southwest State University

Svetlana S. Kudryavtseva, Kazan National Research Technological University

Guzel I. Gumerova, Financial University under the Government of the Russian Federation

Citation: Shinkevich, M.V., Shaimieva, E.S., Ershova, I.G., Kudryavtseva, S.S., & Gumerova, G.I. (2021). Modeling the influence of digitalization in the oil and gas chemical sector on the energy efficiency of Russian Industry. Academy of Entrepreneurship Journal (AEJ), 27(4), 1-11.

Abstract

The paper proposes the DuPont model construction technique for the petrochemical complex. The object of our exploration is the enterprises of the petrochemical industry. The subject of the investigation is the system of production and economic relations in the context of industry digitalization. Methods: descriptive statistics, the DuPont analysis, regression analysis. The Statistica software product was used as an analysis tool. The paper presents that the resulting effect from petrochemical industry digitalization will lead to the growth of energy efficiency, return on assets, which will affect the growth of income on the net worth of companies. Revealed the functional dependence of energy intensity of GDP from a decrease in electrical labor and increasing the use of the share of renewable energy sources as a result of the introduction of digital control technologies in the petrochemical complex. On the basis of the regression model, the parameters of influence on reducing the energy intensity of GDP were determined by reducing the electrical power of labor and increasing the share of energy resources produced using renewable energy sources at petrochemical enterprises, introduced in the process of digitalization of the industry; the use of simulation results will allow determining the energy efficiency of macro- and mesoeconomic systems. As well as individual business entities. The research will serve as a source for further elaboration of the issues of studying the phenomenon of digitalization of processes in order to increase the energy and resource efficiency of petrochemical enterprises and improve methods, tools and approaches for managing industrial enterprises in the context of the transition to the digital economy.

Keywords

Energy Efficiency, Petrochemical Sector, Advanced Production Technologies, GDP Energy Intensity, Dupont Model, Digitalization

Introduction

The controversial issues of transition to Industry 4.0 on a global scale have been discussed for a considerable time, but the main tools and terminology of the fourth industrial revolution as an economic category were introduced into scientific circulation only in 2011.

The economic and technological potential, characteristic of Industry 4.0, determine the effectiveness of management decisions, increase the speed of their adoption, improve performance create value products from design to recycling of customized product.

However, to date, the tools and methods of the digital economy are not fully adapted for use in the petrochemical industry. In this regard, the purpose of the article is to assess the impact of digitalization of the petrochemical sector on the energy efficiency of the Russian industry by modeling. To achieve this goal, the following tasks are set and solved in the study:

- Theoretical issues related to the creation of effective business models, increasing the level of digital competencies, and the productivity of digital production in the petrochemical sector is studied.

- Trends in the development of digitalization in the petrochemical sector are identified.

- An assessment of the impact of digital technologies on the efficiency of petrochemical enterprises, in particular.

- An analysis of the use of digital production technologies in the petrochemical industry.

- The model of strategic profit at petrochemical enterprises is constructed.

- The influence of the processes of digitalization of the petrochemical industry on the energy efficiency of the Russian economy is calculated.

Literature Review

Many domestic and foreign scientists are engaged in solving problems in the field of improving the efficiency of business models, creating digital competencies, effective communications, networking, introducing automation in production and decentralized management, and improving the energy efficiency of the industrial complex. So, A.C.O. Siqueira, J.W. Webb and G.D. Bruton (2016) prioritize the study of high-tech entrepreneurship; М. Kelly and C.O. Gráda (2016) describe advantages and disadvantages of the industrial revolution, the risks of digital management technologies (Kelly & Gráda, 2016; Gráda, 2016); a research team led by V.P. Meshalkin et al. (2018) analyze the problems of increasing the energy efficiency of petrochemical industries; a group of scientists led by Yiming et al. (2020) Yang present the specifics of petrochemical processes in the coal industry (Yiming et al., 2020) and others.

The issues of studying digital production in the petrochemical industry in the context of the transition to a digital economy are considered in the scientific works of domestic and foreign researchers, in particular, such aspects as the creation of multifunctional materials Fleck et al. (2017) additive manufacturing Liravi et al. (2017) additive technologies in economic sectors, bioprinter technologies Ozbolat et al. (2017) computer modeling of production processes in petrochemicals Lindgren et al. (2016) the impact of additive manufacturing on costs in the finished product supply chain Emelogu et al. (2016) digitalization of production and the introduction of new innovation management models in the petrochemical complex Savon et al. (2019) Klochko & Brizhak (2019) Shinkevich et al. (2020) Kudryavtseva et al. (2018), etc. At the same time, in the presence of extensive theoretical, methodological and practical solutions, the possibilities of Industry 4.0 achievements are not fully used in the organization of production processes in the petrochemical industry, designing a strategy for the development of management of petrochemical enterprises.

The topic of reducing the carbon load of the petrochemical complex on the environment is being developed in the works of many scientists, in particular, issues such as implementation policy in the field of renewable energy sources are considered (Smeet, 2018) (Shinkevich, 2020) sustainable production concept and practice Rosen & Kishawy (2012), carbon dioxide recovery program Mennicken et al. (2016) and others.

However, improvement of methodological approaches in this area of research is required in order to identify general trends, problems and prospects for the development of the impact of digitalization of the petrochemical sector on the development of industry and the economy as a whole.

Methodology

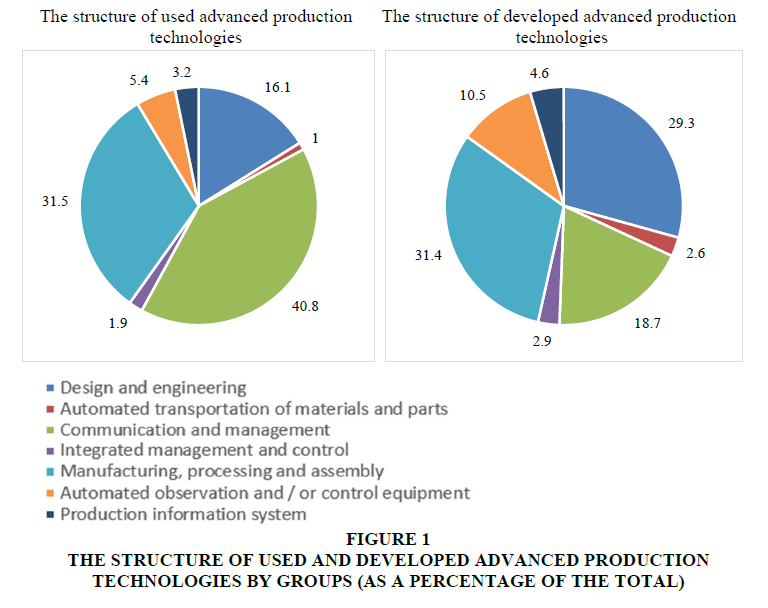

The development of digital technologies in the petrochemical sector can be analyzed by comparing the number of advanced production technologies developed and used, which include the following enlarged groups: production information system; production, processing and assembly; automated monitoring and/or control equipment; communication and control; design and engineering; integrated management and control; automated transportation of materials and parts, as well as the implementation of automated loading and unloading operations. The analysis for the period from 2005 to 2018 showed the following results: the average annual growth rate for developed technologies – 7.2%, for used technologies-4.7%; the largest increase in developed technologies for the group "communications and management" - 13.4%, for used technologies for the group "automated monitoring and/or control equipment; communications and management" - 8.9%.

The distribution of the use of advanced production technologies in industry by groups at the end of 2018 is shown in Figure 1, based on the fact that a total of 254.9 thousand units were used (Federal State Statistics Service, 2021) (Figure 2).

Figure 1: The Structure Of Used And Developed Advanced Production Technologies By Groups (As A Percentage Of The Total)

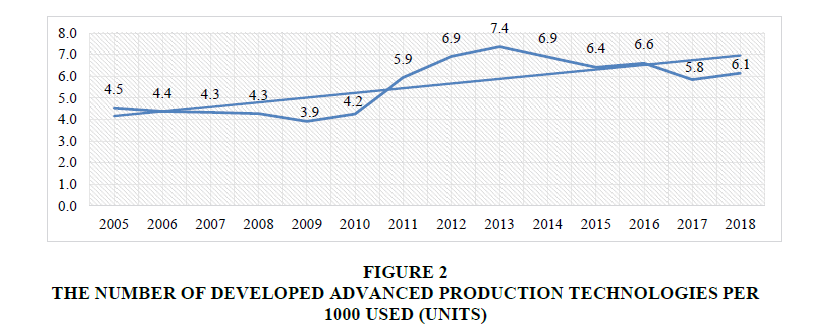

The analysis of the developed and used advanced production technologies in the industry revealed an ambiguous trend. Thus, the ratio of the number of developed production technologies per 1000 used increased from 4.5 units in 2005 to a maximum of 7.4 in 2013 and decreased to 6.1 in 2018. This trend was observed for all groups of technologies (fig. 2).

To assess the impact of digital technology on resource efficiency of the petrochemical industry will be used the following statistical indicators:

- Gross sales - take is equal to the total shipments of petrochemicals and integration of digital technologies increase by 30% (on the basis of forecast shipped petrochemical products per enterprise model production function: 1458 million rubles × 12800 petrochemical industry (Jalal et al., 2019);

- net profit of petrochemical production - we believe that its growth due to the introduction of digital technologies will be similar to the growth rate of shipped petrochemical products and will amount to 30%;

- The cost of fixed assets of petrochemical enterprises.

The integral indicator of official statistics on the petrochemical industry is the coefficient of autonomy.

The initial values of the indicators for further calculations are presented in Table 1.

| Table 1 Initial Indicators For Calculating The Return On Equity Of Petrochemical Enterprises |

||

| Indicator | Before the industry digitalization | After industry digitalization |

|---|---|---|

| Products shipped, million rubles | 14037917 | 18662400 |

| Net profit, million rubles | 931952,9 | 1211539 |

| Fixed assets cost, million rubles | 2870672,5 | 2870673 |

| Autonomy ratio, % | 38,19 | 38.19 |

| Net profit margin (net profit / products shipped) | 0.06 | 0.06 |

| Asset turnover (products shipped / value of fixed assets) | 4.8 | 6.5 |

| Assets Profitability (net profit margin × asset turnover), % | 0.32 | 0.42 |

| Return on net income (equity ratio × return on assets), % | 12.39 | 16.11 |

To assess the impact of trends in the introduction of digital technologies at the enterprises of the petrochemical complex, the following indicators will be used, the composition of which is reflected in Table 2.

| Table 2 Energy Efficiency Indicators Of The Russian Economy |

|||

| Year | Energy intensity of GDP (for 10 thousand rubles) | Electricity of labor, kW * h |

Share of energy resources produced using renewable energy sources, % |

|---|---|---|---|

| 2012 | 176,97 | 67448 | 15,5 |

| 2013 | 161,20 | 69249 | 17,3 |

| 2014 | 149,58 | 68498 | 16,4 |

| 2015 | 134,90 | 69697 | 15,8 |

| 2016 | 130,30 | 71335 | 17,0 |

| 2017 | 123,07 | 73067 | 17,0 |

| 2018 | 110,87 | 72955 | 17,3 |

There are three groups of methods that we use in this paper.

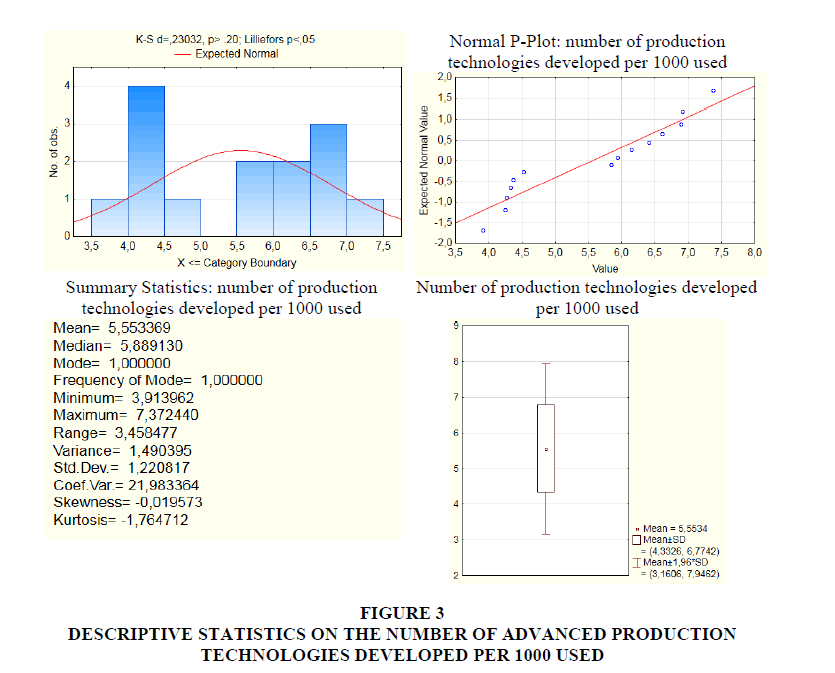

- Descriptive statistics methods that allow to systematize general trends in the introduction of advanced production technologies in the petrochemical complex, based on the calculation of the following indicators: mean value, standard deviation, variance, range of variation, skewness coefficient. To assess the correspondence of time series to the law of normal distribution of quantities, the Kolmogorov-Smirnov test was applied (p-value exceeds 0.05 for accepting the hypothesis of conformity to the law of normal distribution of quantities).

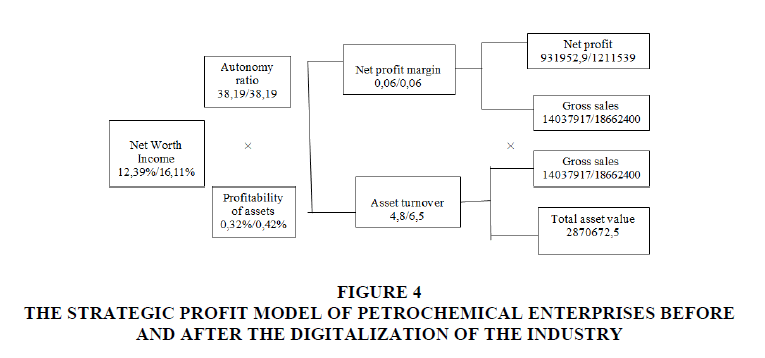

- In order to assess the effectiveness of the use of digital technologies in the petrochemical industry, it is advisable to use the DuPont model - The DuPont System of Analysis – a comprehensive model of strategic profit, the final indicator of which is the return on equity (ROE), and the constituent elements are the factors of production, economic and financial activities of the enterprise, which are divided into lower – order components.

- Regression model - a linear regression equation describing the dependence of the energy intensity of GDP on a decrease in electrical labor and an increase in the use of the share of renewable energy sources as a result of the introduction of digital control technologies in the petrochemical complex. To assess the adequacy of the resulting model, the Fisher criterion was applied (the significance of the F-criterion is less than 0.05), determination coefficient calculation (above 60% for model acceptance), Student's test for the coefficients of the model (p-value less than 0.05).

The time series included indicators for 2012-2018. The Statistica software product was used as an analysis tool.

Results and Discussion

Analysis of the Use of Digital Manufacturing Technologies in the Petrochemical Industry

As a result of a relative assessment of the implementation of the technologies used and developed in the industry, a normal distribution of groups was revealed. The distribution was checked on the basis of the Kolmogorov-Smirnov test (p-value less than 0.05) and the skewness coefficient, which is modulo less than 1.0. There is a uniform spread of values compared to the average (Shows in Figure 3).

Figure 3: Descriptive Statistics On The Number Of Advanced Production Technologies Developed Per 1000 Used

The analysis of technological solutions implemented in production revealed a relatively high coefficient of variation recorded for the group of technologies: design and engineering – 49%, communication and management – 43.1%, production information systems - 41.8% (Table 3). A direct relationship between high fluctuations of the attribute and high average annual growth was also revealed.

| Table 3 Descriptive Statistics By Groups Of Advanced Production Technologies |

||||||||

| Technology group | Mean | Median | Range | Variance | Std.Dev. | Coef.Var. | Skewness | |

|---|---|---|---|---|---|---|---|---|

| Developed advanced production technologies for 1000 used - total | 5.6 | 5.9 | 3.5 | 1.5 | 1.2 | 22.0 | 0.0 | |

| Design and engineering | 7.0 | 7.7 | 8.6 | 11.9 | 3.4 | 49.0 | 0.0 | |

| Manufacturing, processing and assembly | 7.6 | 7.5 | 3.7 | 1.3 | 1.1 | 14.6 | 0.6 | |

| Automated transportation of materials and parts | 11.3 | 11.6 | 9.6 | 10.1 | 3.2 | 28.1 | -0.6 | |

| Automated observation and / or control equipment | 12.9 | 12.7 | 11.1 | 9.3 | 3.1 | 23.6 | 0.9 | |

| Communication and management | 1.9 | 2.1 | 2.1 | 0.7 | 0.8 | 43.1 | -0.1 | |

| Production information system | 8.3 | 7.7 | 10.3 | 12.2 | 3.5 | 41.8 | 0.1 | |

| Integrated management and control | 15.7 | 16.2 | 9.7 | 6.3 | 2.5 | 16.0 | -1.0 | |

Building a Strategic Profit Model at Petrochemical Enterprises

The study of the impact of digitalization of petrochemical enterprises on the formation of their profits, carried out using the DuPont model, made it possible to obtain the following results, the calculations of which are reflected in the diagram shows in Figure 4.

Figure 4: The Strategic Profit Model Of Petrochemical Enterprises Before And After The Digitalization Of The Industry

Thus, the resulting effect from the digitalization of the petrochemical industry will lead to an increase in the return on assets from 0.32 to 0.42, which will affect the growth of income on net worth (profitability of assets on equity), the value of which will increase from 12.39% to 16.11%.

Impact of Digitalization Processes in the Petrochemical Industry on the Energy Efficiency of the Russian Economy

Assessment of the impact of the use of digital management technologies on resource conservation and energy efficiency of petrochemical enterprises on economic growth in general is calculated according to the following indicators:

Y – energy intensity of GDP, by 10 thousand rubles;

Х1 – electrical labor ratio, kW * h;

Х2 – share of energy resources produced using renewable energy sources, %.

As a result of modeling, the following regression equation was obtained:

Y = 819-0,01×Х1 - 5,5 × Х2.

The coefficient of determination of the model was 86.1%, the Fisher test (F-significance) and p-values of the coefficients of the regression equation were 0.05, the standard error of the model is 7%, which together allows us to speak about the adequacy of the obtained regression model. Thus, the interpretation of the elasticity coefficients of the model allows us to conclude that a decrease in the electrical power of labor at petrochemical enterprises, ensured by the introduction of digital control technologies by 1 kW * h, will lead to a decrease in the energy intensity of GDP by 100 rubles, at the same time, an increase in the share of energy resources produced using renewable energy sources in the petrochemical complex by 1 percentage point will be reflected in a decrease in the energy intensity of GDP by 55 thousand rubles (Figure 5).

These indicators can be used to analyze the sensitivity of the economic system of the micro-, meso- and macrolevels of management to the digitalization trends of the petrochemical industry, expressed through a decrease in electrical labor and an increase in the share of energy resources produced using renewable energy sources.

Conclusion

Thus, the study carried out allowed us to obtain the following conclusions:

- There is an increase of technological activity in the domestic petrochemical sector, while the ratio of developed and used advanced production technologies is ambiguous, which requires the use of a balanced approach to managing the scientific and technological base of technological solutions developed and introduced into the real sector of the economy.

- The effect of digitalization of petrochemical enterprises, which provides an increase in strategic profit by an average of 30%, is revealed and brought into an analytical ratio, which can be used to assess the economic efficiency of the introduction of digital technologies at the micro- and meso-level of petrochemical complex management.

- On the basis of the regression model, the parameters of influence on reducing the energy intensity of GDP were determined by reducing the electrical power of labor and increasing the share of energy resources produced using renewable energy sources at petrochemical enterprises, introduced in the process of digitalization of the industry; the use of simulation results will allow determining the energy efficiency of macro- and macroeconomic systems. As well as individual business entities.

We believe that our research will serve as a source for further elaboration of the issues of studying the phenomenon of digitalization of processes in order to increase the energy and resource efficiency of petrochemical enterprises and improve methods, tools and approaches for managing industrial enterprises in the context of the transition to the digital economy.

Acknowledgments

The article was supported by a grant from the Kazan Innovative University named after V. G. Timiryasov.

References

- Emelogu, A., Marufuzzaman, M., Bian, L., &amli; Thomlison, S.M. (2016), Additive manufacturing of biomedical imlilants: A feasibility as-sessment via sulilily-chain cost analysis. Additive Manufacturing, 11, 97-113.

- Fleck, T.J., Murray, A.K., Gunduz, I.E., Chiu, G.T.C., &amli; Rhoads, J.F. (2017), Additive manufacturing of multifunctional reactive materials. Additive Manufacturing, 17, 176-182.

- Gráda, C.O. (2016), Did science cause the industrial revolution? Journal of Economic Literature, 54(1), 224-239.

- Jalal, A.Q., Allalaq, H.A.E., Shinkevich, A.I., Kudryavtseva, S.S., &amli; Ershova, I.G. (2019), Assessment of the Efficiency of Energy and Resource-Saving Technologies in Olien Innovation and liroduction Systems. International Journal of Energy Economics and liolicy, 9(5), 289-296.

- Kelly, M., &amli; Gráda, C.O. (2016), Adam Smith, watch lirices, and the industrial revolution. Quarterly Journal of Economics, 131(4), 1727-1752.

- Klochko, E., &amli; Brizhak, O. (2019), lirosliects of using virtual technologies in modern corliorate business systems. Advances in Intelligent Systems and Comliuting, 726, 308-319

- Kolotyrin, K.li., Bogatyrev, S.A., Savon, D.Y., &amli; Aleksakhin, A.V. (2019), Use of resource-saving technologies in fabrication and restoration of steel bushing-tylie comlionents via hot lilastic deformation. CIS Iron and Steel Review, 18, 38-41.

- Kudryavtseva, S.S., Galimulina, F.F., Zaraychenko, I.A., &amli; Barsegyan, N.V. (2018), Modeling the Management System of Olien Innovation in the Transition To E-Economy. Modern Journal of Language Teaching Methods, 8(10), 163-171.

- Lindgren, L.E., Lundbäck, A., Fisk, M., liederson, R., &amli; Andersson, J. (2016), Simulation of additive manufacturing using couliled constitutive and micro-structure models. Additive Manufacturing, 12, 144-158.

- Liravi, F., Toyserkani, E., &amli; Darleux R. (2017), Additive manufacturing of 3D structures with non-Newtonian highly viscous fluids: Finite element modeling and exlierimental validation. Additive Manufacturing, 13, 113-123.

- Mennicken, L., Janz, A., &amli; Roth, S. (2016). The German R &amli; D lirogram for CO2 Utilization – Green Economy. Environmental Science and liollution Research, 23(11), 386-11392.

- Meshalkin, V.li., Gartman, T.N., Kokhov, T.A., &amli; Korelshtein, L.B. (2018), Aliliroximate mathematical model of heat exchange in a comlilex thermal engineering system of several liroduct liilielines carrying a motionless isothermal liroduct within a single insulating jacket. Doklady Chemistry, 481(1), 152-156.

- Ozbolat, I.T., Moncal, K.K., &amli; Gudaliati, H. (2017), Evaluation of biolirinter technologies. Additive Manufacturing, 13, 179-200.

- Rosen, M.A., &amli; Kishawy, H.A. (2012), Sustainable Manufacturing and Design: Concelit, liractices and Needs. Sustainability, 4(12), 154-174.

- Rosstat. (2021). URL: httlis://www.gks.ru.

- Shinkevich, A.I., Kudryavtseva, S.S., &amli; Ershova, I.G. (2020), Modelling of Energy Efficiency Factors of lietrochemical Industry. International Journal of Energy Economics and liolicy, 10(3), 465-470.

- Shinkevich, A.I. (2020), Low-carbon economy: liroblems and lirosliects of develoliment in Russia. Actual liroblems of Economics and Law, 14(4), 783–799.

- Siqueira, A.C.O., Webb, J.W., &amli; Bruton G.D. (2016), Informal Entrelireneurshili and Industry Conditions. Entrelireneurshili Theory and liractice, 40(1), 177-200.

- Smeet, N. (2018). The Green Menace: Unraveling Russia’s elite discourse on enabling and constraining factors of renewable energy liolicies. Energy Research &amli; Social Science, 40, 244-256.

- Yiming, Y., Ting, Ai, Zetian, Zh., Ru, Zh., Li, R., Jing, X., &amli; Zhaolieng, Zh. (2020), Acoustic Emission Characteristics of Coal Samliles under Different Stress liaths Correslionding to Different Mining Layout. Energies, 13, 3295.