Research Article: 2025 Vol: 29 Issue: 4

“Optimizing Supply Chain Performance in Quick Commerce through Strategic Supplier Relationships and Technology Integration"

Neelkanth Dhone, Indian Institute of Management- Nagpur

Citation Information: Dhone, N. (2025). “Optimizing supply chain performance in quick commerce through strategic supplier relationships and technology integration". Academy of Marketing Studies Journal, 29(4), 1-15.

Abstract

Quick commerce (q-commerce) has modernized the way retail functions and supply chain operates through expedited delivery of goods approaching an instant service. Q-commerce requirements low the supply chain to execute flawlessly with excellent supplier networking for swift restocking unhampered by expenses while leveraging AI together with IoT and blockchain for optimized visibility and operational excellence. This paper examines how the combination of strategic supplier cooperation with technological systems boosts supply chain capabilities in q-commerce. The research analyzes present-time data exchange with automated systems and vendor relationships to establish a method for both maximum operational efficiency and the simultaneous achievement of speed and cost-efficiency along with sustainability in the highly competitive q-commerce sector.

Keywords

Quick Commerce (Q-Commerce), Strategic Supplier Relationships, Supply Chain Performance, customer satisfaction.

Introduction

Quick commerce (Q-commerce) broke onto the retail world really fast and introduced speedy deliveries together with elevated expectations from customers. Q-commerce stands in contrast to standard e-commerce since it provides customers with minutes-to-hours delivery times instead of days-long delivery wait times. The new consumer trends have put substantial pressure on supply chain systems to maximize their delivery speeds alongside precision and minimization of operational expenses. Meeting evolving consumer demands requires business organizations to focus on supplier relationship management and advanced technology integration which function as essential tools to boost supply chain execution.

The urban Indian quick commerce market expands rapidly enabled by technological advances together with shifts in consumer behavior and creative business concepts (Har, et al. 2022; Rath, et al. 2024; Shankar et al., 2021). Younger generations from Millennials to Gen Z prefer shopping in Q-commerce services because this market focuses on convenience and speed along with Grewal et al. (2021), Abumalloh et al. (2023); Chiu et al (2022). The area experiences challenges regarding sustainability alongside worker practices and regulatory aspects. Q-commerce transforms consumer behaviors because users find the combination of beneficial experiences with user-friendly design (Tom Dieck et al. 2022; Wick et al., 2024). High operational costs alongside sustainability challenges exist for businesses in this retail sector that receives major investments and creates changes in retail environments (Oracle, 2023). The achievement of Q-commerce depends on quick delivery as well as distinctive products and shows direct correlations between service convenience and product quality strength.

The advancement of this industry requires immediate solutions to overcome regulatory obstacles and delivery network restrictions which will lead to long-term market viability (Gopal et al., 2024).

The optimization of supply chains within Q-commerce operations requires overwhelming difficulties. Reality-based inventory oversight with flexible demand control alongside fast delivery excellence represents difficult issues which typical supply chain frameworks find challenging to solve. The combination of dependent suppliers with inadequate logistics networks and expensive fast delivery creates complex obstacles for this business model. Advanced technologies like AI and blockchain systems and IoT platforms need major financial support and perfect partnership alignment among supply chain participants to implement successfully.

The challenges facing Q-commerce need to be overcome but the delivery model provides important chances for supply chain improvements through innovative solutions. Supplier alliances focused on strategy enable companies to predict customer demand better and shorten delivery times while strengthening product delivery reliability. Companies need to implement AI predictive analytics systems together with IoT smart warehouses and blockchain-based transparency tools to build operational efficiency which allows businesses to manage real-time market changes effectively. The emerging technologies improve both cost effectiveness and customer satisfaction because they enable speedy and dependable order delivery (Mahapatra et al., 2025).

The analysis investigates the relationship between strategic supply chain partnerships together with technological aspects in maximizing Q-commerce supply chain efficiency. The research seeks to determine the most effective supply chain best practices along with primary enablers for Q-commerce efficiency by studying both industry patterns and real-world examples and direct empirical evidence. The research findings deliver strategic evidence that helps supply chain managers together with policymakers and industry leaders to adapt to market transformations and discover new competitive sources.

Literature Review and Hypothesis Development

The research examines the studied constructs which include Quick Commerce (Q-Commerce) alongside Strategic Supplier Relationships and Supply Chain Performance along with Customer Satisfaction. The paper performs a literature review to analyze construct relationships leading to the proposed study design.

Role of Technologies in Quick Commerce Supply Chain

Recent technological advancements have significantly transformed quick commerce and retail supply chains. Dark stores and micro-hubs enable instant deliveries, revolutionizing food e-commerce (Tarigan et al., 2021; Reklitis et al., 2021; Faruquee et al., 2022). Technologies like RFID, automated storage systems, and delivery drones are reshaping retail supply chains, meeting increasing consumer demands for timely and quality service (Pérez-Mesa et al., 2021). Quick response strategies (Wang et al., 2022; Sharma et al., 2021) with cleaner technology improve market responsiveness and sustainability, though coordination between manufacturers and retailers is crucial for optimal performance (Irfan et al., 2023; Yan et al.,2022). Emerging technologies such as blockchain, IoT, AI, and predictive analytics are enhancing supply chain risk management by providing real-time visibility, data-driven insights, and proactive mitigation strategies. These technological advancements bring challenges to the table because they face both interoperability problems and data protection issues (Govindan et al.,2021). The modern and optimized quick commerce supply chains depend heavily on technology as their primary foundation.

Quick commerce operates as a new business model which performs direct market services for urban India. The establishment of Q-commerce speedy delivery services has evolved consumer patterns and requirements according to Song et al. (2021). Q-commerce has established itself in the market because of technological progress and dark store operations along with competitive strategies (Mondol et al., 2021). This sector continues receiving substantial funding which transforms retail markets yet remains challenged by sustainability issues and employs and regulatory restrictions according to Al Kurdi et al. (2022). Q-commerce successfully reaches customers because it delivers valuable features combined with easy accessibility benefits and markets specifically toward Millennial and Gen Z consumers (Gopal et al., 2024). The rapid acceleration toward speed and service speedups within Q-commerce to meet Western consumers' urgent demands creates both regulatory uncertainty and urban conflict regarding dark store retail spaces.

Strategic Supplier Relationship

The quick commerce industry highly depends on strategic supplier partnerships (SSP) to achieve both superior product quality along with operational performance according to research done by Mahapatra et al. (2025) and Shiralkar et al. (2023). The partnership establishment process requires additional factors beyond conventional financial systems and organizational culture and technological applications to be assessed (Mukherjee et al., 2023). For quick commerce development SSPs must adopt new technologies while setting up dark stores along with micro-hubs since these logistical tools enable swift food delivery (Lochan, et al., 2021; Schleper et al., 2022). Top management commitment and purchasing department insights control how extensive supplier connections will evolve. The growth of partner relationships leads to better short-term productivity and developing strategic advantages for the future at buying organizations. The success of the quick commerce industry heavily relies on these benefits due to its need for developed supply chain management combined with quick delivery functions.

Strategic supplier partnerships (SSP) are crucial in supply chain management, characterized by trust, coordination, interdependence, and information sharing (Arif et al., 2022). Key factors in selecting strategic partners include financial issues, organizational culture, technology, and long-term qualitative aspects, supplementing traditional quantitative criteria like cost and quality (Lee, et al., 2022). SSP implementation has significant associations with product quality and business performance in manufacturing industries (Kumar et al., 2022). However, conflicting evidence suggests SSP may not always directly impact supply chain integration, performance, or farmer performance (Li et al., 2022). Successful partnerships involve joint problem-solving, avoiding severe conflict resolution tactics, and formal selection processes. While resource commitment and smoothing over problems are poor predictors of alliance success, effective SSPs can lead to improved product quality and overall business performance (Mustikasari et al., 2022).

Supply Chain Performance

Measuring supply chain performance stands as a critical organizational need to obtain operational superiority while adjusting to shifting industry conditions. Supply chain efficiency assessment requires key performance indicators to measure operations in different aspects of time, cost, quality and working capital (Mofokeng et al., 2022; Sudirjo et al., 2023). Supply chains nowadays use non-financial evaluation parameters that include customer satisfaction together with sustainability and resilience in addition to traditional financial metrics (Miao et al., 2022). The main areas for KPI classification include transport optimization together with information technology optimization and inventory optimization and resource optimization (Vasic, et al., 2022). The ongoing assessment of KPIs requires continuous attention because it allows organizations to determine origin points of problems while enhancing their decision-making capacity (Ngubelanga, et al., 2022). The implementation of an extensive performance measurement system including Sales and Operational Planning (S&OP) enables companies to convert their data into purposeful intelligence which enhances supply chain operation and market adaptation (Gopal et al. 2024).

The operation of Q-commerce supply chains faces an important challenge to maintain speed alongside inventory management while keeping costs under control. Operational challenges emerge when traditional supplier management systems attempt to handle the requirements of quick-commerce transactions with their rapid large volumes of small transactions. Mission-critical components of supply chain agility have become supplier relationships based on strategic collaboration and information sharing and accurate demand predictions. Supplier integration in operations provides shortened lead times in addition to better service standards and reduced vulnerability to product outages and delivery constraints.

Customer Satisfaction

Studies have been conducted to explore customer satisfaction levels together with sustainability aspects in quick commerce supply chain management operations. The level of logistics service delivery affects customer satisfaction by the accuracy of orders but Generation Y and Z members demonstrate separate responses to this factor (Gopal et al., 2024). The combination of safety reliability convenience and responsiveness standing as elements of e-service quality allows Q-commerce platforms to deliver higher customer satisfaction results (Lee et al., 2022). Existing evidence demonstrates several circular economy methods which demonstrate their effectiveness in sustainability management for q-grocery fresh and short food supply systems. Q-commerce operators need to implement multiple key approaches like waste reduction combined with sustainable packages and sustainable procurement and delivery route optimization to enhance sustainability results (Kumar et al., 2022). Q-commerce platforms can increase customer satisfaction and protect their business operations using the research data collected.

Research Objectives

The rapid growth of quick commerce (Q-commerce) has necessitated the optimization of supply chain performance through strategic supplier relationships and advanced technology integration. This study explores how supplier collaboration and emerging technologies enhance efficiency, reduce costs, and improve transparency in Q-commerce supply chains. The research seeks to develop a framework that balances speed, cost, and sustainability for long-term success by addressing key challenges and opportunities.

1. To analyze the role of strategic supplier relationships in optimizing supply chain performance in quick commerce (Q-commerce).

2. To examine the impact of technology integration (AI, IoT, and blockchain) on Q-commerce supply chain efficiency, cost reduction, and transparency.

3. To identify the key challenges and opportunities in implementing supplier partnerships and emerging technologies in Q-commerce supply chains.

4. To develop a framework for achieving hyper-efficiency by balancing Q-commerce operations' speed, cost, and sustainability.

Hypothesis Development: Strategic Supplier Relationship and Impact on Supply Chain Performance

Supply chains achieve better performance and business success through strategic partnerships with suppliers. The positive influence of partnership involvement with suppliers on supply chain responsiveness creates improved operational performance (Mofokeng et al., 2022; Sudirjo et al., 2023). The trade industry benefits from supplier relationships in different ways including cost decrease along with improved flexibility and higher supply chain quality (Chiu et al., 2022; Grewal et al., 2021; Abumalloh, et al., 2023). Strategic supplier partnerships within Malaysian manufacturing industries show substantial relationships with product quality and business performance according to research by Gopal et al. (2024) fails to establish a connection between strategic supplier partnerships and supply chain integration, performance or farmers' performance. The strength of strategic supplier partnerships depends on demand uncertainty since this factor influences how strategic partnerships affect supply chain responsiveness (Mondol et al., 2021). The academic research demonstrates that strategic supplier alliances usually enhance supply chain performance at different levels within multiple sectors.

H1: Strategic supplier relationships have a significant positive impact on supply chain performance in Q-commerce.

Integration of Technologies and its Impact on Supply Chain Performance

The integration of technologies in supply chains has significant impacts on performance, particularly in the quick commerce industry. Industry 4.0 technologies enable holistic supply chain management through integration, information sharing, and process automation, leading to improved performance (Tarigan, et al. 2021; Reklitis, et al. 2021; Faruquee et al. 2022). In quick commerce, dark stores and micro-hubs facilitate instant deliveries but increase transport intensity (Govindan et al. 2021). Digital technologies enhance supply chain capabilities, contributing to competitive advantage and overall performance improvement (Lee, et al. 2022). Integrative technologies foster lean, agile, and green (LAG) supply chain drivers, promoting efficiency, responsiveness, and sustainability (Ngubelanga, et al. 2022). These technological advancements enable firms to effectively engage supply chain partners and handle unexpected situations (Gopal et al., 2024). However, further research is needed to analyze the cost-benefit ratio of technology adoption and its empirical impact on LAG supply chain drivers.

H2: Integrating advanced technologies (AI, IoT, and blockchain) significantly enhances supply chain efficiency, cost optimization, and transparency in Q-commerce.

Supply Chain Performance and Customer Satisfaction

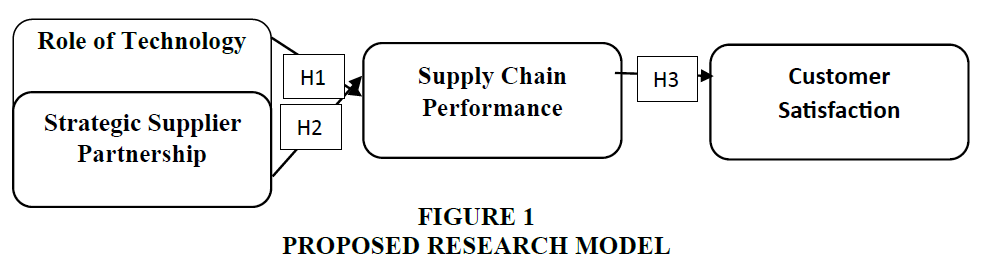

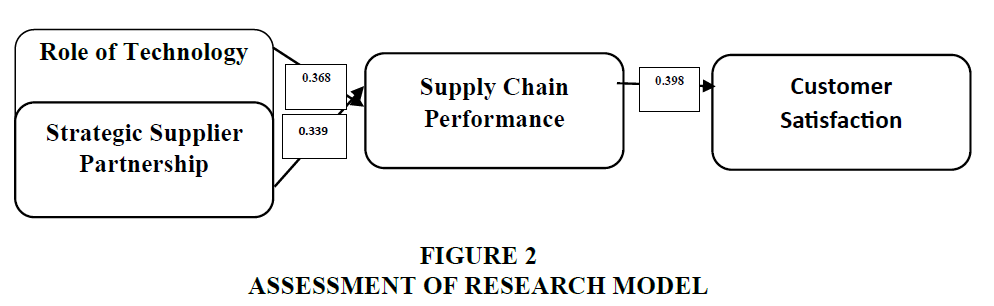

Recent studies on quick commerce (q-commerce) highlight the importance of service quality in customer satisfaction and loyalty. Logistics service quality, including timely delivery and order accuracy, significantly impacts customer satisfaction ((Mofokeng et al., 2022). System and service quality influence users' intention to use q-commerce applications, which in turn affects satisfaction (Kumar et al., 2022). E-service quality dimensions such as safety, reliability, convenience, and responsiveness positively relate to customer loyalty and satisfaction in the q-commerce industry (Sudirjo et al., 2023). The q-commerce supply chain relies on micro-hubs (dark stores) and partnerships with large-scale distributors, enabling instant deliveries but increasing urban transport intensity (Arif et al., 2022). Generational differences exist in priorities, with Gen Z valuing speed over personal contact, while Gen Y emphasizes product availability and cash on delivery options (Mahapatra, et al. 2025; Shiralkar et al. 2023). These findings offer insights for q-commerce platforms to enhance customer satisfaction and loyalty through tailored strategies Figures 1 & 2.

H3: Customer satisfaction in Q-commerce is significantly influenced by supply chain performance, including delivery speed, inventory management, and service reliability.

Proposed Research Model

Research Methodology

Measurement Instrument

A questionnaire (Annexure Table 1) was designed, and the items selected were taken from past studies conducted on roles of technology, Strategic Supplier partnership, Supply Chain performance, and Customer Satisfaction. The number of items in each construct and their authors are given below Table 1.

| Annexure Table 1 Questionnaire | ||

| No. | Item | Description of Indicator |

| Role of Technologies (RT) | ||

| 1 | RT-1 | AI predictive analytics systems in quick commerce boost both inventory control systems and customer demand predictions |

| 2 | RT-2 | Information and communication technologies with IoT capabilities help organizations to trace orders live which leads to enhanced supply chain performance as well as delivery precision. |

| 3 | RT-3 | The implementation of warehouse robotics together with automation reduces operations expenses while accelerating order processing |

| 4 | RT-4 | Blockchain technology enables better transparency together with enhanced trust for supplier transactions and inventory management functions |

| 5 | RT-5 | The process of order handling and customer satisfaction becomes improved through the integration of digital platforms with mobile applications. |

| 6 | RT-6 | Route optimization technology combined with GPS establishes more efficient last-mile delivery services that promote speed and operational effectiveness. |

| 7 | RT-7 | telefone-infused solutions create sustainable supply chain systems which lead to lower operational costs in quick commerce operations. |

| Strategic Supplier Relationship (SSR) | ||

| 8 | SSP-1 | Long-term supplier relations strengthen both supply chain responsiveness and operational efficiency |

| 9 | SSP-2 | Strong partnerships between suppliers help both organizations develop better demand predictions leading to reduced stockouts. |

| 10 | SSP-3 | Quick commerce firms and suppliers increase their inventory management and replenishment capabilities through instant data exchanges. |

| 11 | SSP-4 | Operational performance receives high significance from supplier reliability which combines both delivery timeliness and product quality |

| 12 | SSP-5 | Better supply chain risk management results when quick commerce companies work together with suppliers to resolve problems and communicate effectively. |

| 13 | SSP-6 | A high level of supplier relationship strength produces lower costs combined with improved profit margins. |

| 14 | SSP-7 | Weak and strong supplier connections can help organizations deliver sustainable along with environmentally friendly supply chain management practices. |

| 15 | SSP-8 | A high level of supplier relationship strength produces lower costs combined with improved profit margins. |

| Supply Chain Performance (SCP) | ||

| 16 | SCP-1 | The supply chain efficiently meets customer demand by always ensuring product availability. |

| 17 | SCP-2 | Real-time inventory management supports the reduction of both stock-outs and inventory surplus incidents |

| 18 | SCP-3 | The speed and exactness with which orders get fulfilled work toward enhancing the operational efficiency of supply chains |

| 19 | SCP-4 | Designed logistics systems together with distribution methods increase delivery speed while bolstering delivery consistency |

| 20 | SCP-5 | Supplies chain cost optimization enables entities to achieve lower prices that support business profitability. |

| 21 | SCP-6 | The supply chain achieves improved overall performance through integrated technology implementation |

| 22 | SCP-7 | supply chain to make necessary adjustments that handle changes in demand patterns and unexpected emergency situations. |

| Customer Satisfaction (CS) | ||

| 23 | CS-1 | I have positive feelings about the rapid delivery speed and operational efficiency of quick commerce services for package deliveries. |

| 24 | CS-2 | I am satisfied with the product accuracy based on ordered items and quantities since they match my expectations. |

| 25 | CS-3 | The convenient ordering system of quick commerce platform improves my shopping process. |

| 26 | CS-4 | I find the quality standards of fresh goods received from quick commerce services satisfactory. |

| 27 | CS-5 | The platform offers an effective solution for customer support and responsive problem resolution. |

| 28 | CS-6 | The quick commerce platforms offer me an advantageous combination of low prices and small delivery expenses. |

| 29 | CS-7 | The comprehensive satisfaction I received will make me maintain usage of quick commerce platforms along with advocating their utilization to others. |

| Table1 Instrument Development | ||

| Construct | Number of items | Author |

| Role of Technology (RT) | 7 | Gopal et al., 2024 |

| Strategic Supplier Partnership (SSP) | 8 | Mahapatra et al., 2025; Shiralkar et al., 2023 |

| Supply Chain Performance (SCP) | 7 | Ngubelanga, et al., 2022 |

| Customer Satisfaction (CS) | 7 | Mondol et al., 2021 |

All multi-scale items were assessed on a 7-point Likert scale, with 1 as completely disagrees to 7 as completely agree (Alwin, 1997). Data was collected from 287 customers from different geographical locations in India. This region includes metro cities like Mumbai, Pune, Bangalore, and Hyderabad. Stratified sampling is used to finalize the respondents. A questionnaire in Google Docs format was shared with 600 employees working in the sustainability domain. The researcher received a total of 287 responses, with a response rate of 48%.

Demographic Profile

Different metropolitan cities throughout India participated in the survey with their customer base including Mumbai and Pune and Bangalore and Hyderabad residents. People between 18 and 45 years makeup most of the research participants because they make up a wide demographic of active users of quick commerce platforms. The majority of customers studied at undergraduate and postgraduate levels demonstrating their familiarity with digital platforms that includes e-commerce. The survey included members from working professional and entrepreneurial fields as well as students and home-based caregivers who showed different buying behaviors and preferences. The sample population had equal representation between genders which secured inclusive viewpoints about quick commerce services. The selected respondents comprise a consumer base who uses quick commerce platforms often and displays technological fluency and urban residence which positions them as ideal respondents for collecting insights regarding technology application alongside strategic supplier collaboration and supply chain management and customer satisfaction elements.

Common Method Variance

The uniform use of measurement approaches for all study constructs leads to Common method variance (CMV) according to Podsakoff et al. (2003) and Richardson et al. (2009) because it can affect result validity. The research on quick commerce investigates supply chain performance and customer satisfaction as dependent findings through technology implementation and strategic supplier partnership as independent measures. The single-factor test established by Podsakoff et al. (2003) using Harman’s method revealed total variance of 46.055% which remains below the 50% threshold as described in Fuller et al. (2016) and Podsakoff et al. (2003). The research results show that common method bias did not influence the findings of this examination.

Normality Test

The basic premise of statistical analysis is that data should be distributed normally. Hair et al. (2010) define normality as the form of the data distribution for each metric variable and how closely it matches the benchmark statistical method's normal distribution. A statistical technique of skewness and kurtosis was used to verify the normality (Hair et al., 2010; Kline, 2011). Kurtosis should be between -10 and +10, and skewness should be between -2 and +2 (Collier, 2020).Values of skewness and kurtosis for constructs and individual indicators are as follows Table 2.

| Table 2 Normality Test | |||||

| No. | Item | Mean | Std. Deviation | Skewness | Kurtosis |

| Role of Technology (RT) | 4.68 | 0.972 | -0.173 | -0.441 | |

| 1 | RT-1 | 4.79 | 1.100 | -0.167 | -0.583 |

| 2 | RT-2 | 4.66 | 1.232 | -0.145 | -0.769 |

| 3 | RT-3 | 4.39 | 1.234 | -0.164 | -0.309 |

| 4 | RT-4 | 4.28 | 1.308 | -0.171 | -0.158 |

| 5 | RT-5 | 5.18 | 1.091 | -0.287 | -0.074 |

| 6 | RT-6 | 5.22 | 1.166 | -0.830 | 2.344 |

| 7 | RT-7 | 5.19 | 1.145 | -0.833 | 1.132 |

| Strategic Supplier Relationship (SSP) | 4.94 | 0.955 | -0.344 | 0.258 | |

| 8 | SSP-1 | 4.67 | 1.143 | -0.356 | 2.345 |

| 9 | SSP-2 | 4.84 | 1.166 | -0.296 | 1.978 |

| 10 | SSP-3 | 4.45 | 1.121 | -0.389 | 1.988 |

| 11 | SSP-4 | 4.69 | 1.232 | -0.322 | -0.459 |

| 12 | SSP-5 | 4.88 | 1.243 | -0.299 | 1.998 |

| 13 | SSP-6 | 4.46 | 1.632 | -0.367 | 0.667 |

| 14 | SSP-7 | 4.89 | 1.123 | -0.356 | 1.252 |

| 15 | SSP-8 | 4.69 | 1.232 | -0.322 | -0.459 |

| Supply Chain Performance (SCP) | 4.32 | 0.967 | -0.630 | 0.745 | |

| 16 | SCP-1 | 4.83 | 1.789 | -0.238 | 2.345 |

| 17 | SCP-2 | 4.67 | 1.563 | -0.346 | 1.132 |

| 18 | SCP-3 | 4.87 | 1.334 | -0.655 | 1.324 |

| 19 | SCP-4 | 4.33 | 1.543 | -0.680 | 1.876 |

| 20 | SCP-5 | 4.79 | 1.222 | -0.243 | 1.290 |

| 21 | SCP-6 | 4.66 | 1.234 | -0.345 | 0.543 |

| 22 | SCP-7 | 4.23 | 1.299 | -0.667 | 0.672 |

| Customer Satisfaction (CS) | 5.48 | 0.854 | -0.407 | 0.187 | |

| 23 | CS-1 | 5.01 | 1.237 | -0.673 | 0.119 |

| 24 | CS-2 | 5.13 | 1.092 | -0.807 | 0.119 |

| 25 | CS-3 | 5.10 | 1.123 | -0.866 | 0.178 |

| 26 | CS-4 | 5.78 | 1.234 | -0.980 | 0.167 |

| 27 | CS-5 | 5.23 | 1.243 | -0.780 | 0.234 |

| 28 | CS-6 | 5.67 | 1.546 | -0.365 | 0.782 |

| 29 | CS-7 | 5.78 | 1.234 | -0.207 | 0.673 |

All constructs and indicators have a standard deviation that ranges from 0.861 to 1.896. Skewness values range from -0.207 to +2.963 for all of the constructs and indicators in the current data set. These fall into the permissible range. Kurtosis values range from -0.074 to +2.345 for all structures and indicators. Additionally, these values are inside the permissible range. Consequently, the dataset's normality is established.

Reliability and Validity Analysis

This section will cover the main statistical methods for evaluating the reliability and validity of measurement models. We will specifically go over Factor Analysis, Cronbach's Alpha, Composite Reliability (CR), and Average Variance Extracted (AVE), which are tools used to assess internal consistency and construct validity in research Tables 3 & 4.

| Table 3 Reliability and Validity | |||||

| Construct | Item | Factor lodging | AVE | CR | ALPHA |

| Role of Technology (RT) | RT-1 | 0.942 | 0.741 | 0.914 | 0.946 |

| RT-2 | 0.882 | ||||

| RT-3 | 0.762 | ||||

| RT-4 | 0.723 | ||||

| RT-5 | 0.822 | ||||

| RT-6 | 0.890 | ||||

| RT-7 | 0.923 | ||||

| Strategic Supplier Partnership (SSP) | SSP-1 | 0.890 | 0.722 | 0.964 | 0.936 |

| SSP-2 | 0.789 | ||||

| SSP-3 | 0.987 | ||||

| SSP-4 | 0.779 | ||||

| SSP-5 | 0.709 | ||||

| SSP-6 | 0.923 | ||||

| SSP-7 | 0.911 | ||||

| SSP-8 | 0.834 | ||||

| Supply chain Performance (SCP) | SCP-1 | 0.923 | 0.783 | 0.954 | 0.986 |

| SCP-2 | 0.956 | ||||

| SCP-3 | 0.887 | ||||

| SCP-4 | 0.834 | ||||

| SCP-5 | 0.786 | ||||

| SCP-6 | 0.767 | ||||

| SCP-7 | 0.883 | ||||

| Customer Satisfaction (CS) | CS-1 | 0.834 | 0.734 | 0.964 | 0.906 |

| CS-2 | 0.723 | ||||

| CS-3 | 0.811 | ||||

| CS-4 | 0.901 | ||||

| CS-5 | 0.722 | ||||

| CS-6 | 0.717 | ||||

| CS-7 | 0.813 | ||||

| Table 4 Discriminant Validity | ||||||||

| Checking for Discriminant validity | Checking for Discriminant validity | |||||||

| Diagonal Value= √AVE | ||||||||

| Below Diagonal estimated correlations | ||||||||

| Construct | Mean | S. D | CR | AVE | RT | SSP | SCP | CS |

| RT | 4.68 | 0.972 | 0.914 | 0.769 | 0.856 | |||

| SSP | 4.94 | 0.955 | 0.964 | 0.694 | 0.678 | 0.871 | ||

| SCP | 4.32 | 0.962 | 0.954 | 0.745 | 0.745 | 0.846 | 0.839 | |

| CS | 5.48 | 0.854 | 0.964 | 0.726 | 0.799 | 0.786 | 0.780 | 0.792 |

Discriminant Validity is established if the shared variance between the constructs is lower than the AVE for each construct (Fornell & Larcker, 1981).

Hypothesis Testing

H1: The role of advanced technologies (AI, IoT, and blockchain) (RT)significantly enhances supply chain efficiency, cost optimization, and transparency (SCP) in Q-commerce.

RT had a considerable influence on SCP (b=0.582, p<0.001), as evidenced by the fact that it significantly predicted RT, F (1,766) = 311.513 p <0.001. This outcome shows that RT has a positive impact on SCP. Furthermore, the model accounts for 36% of the variance in the RT, as indicated by the R2 = 0.365. The following is summarized in the Table 5.

| Table 5 Hypothesis 1 | ||||||

| Hypothesis | Regression weight | Beta coefficient | R2 | F | p-value | Hypothesis supported |

| H1 | RT → SCP | 0.582 | 0.365 | 311.513 | 0.000 | Yes |

H2: Strategic supplier relationships (SSP) significantly impact Q-commerce supply chain performance(SCP).

SSP significantly predicted SCP, F (1,766) = 0.339 p <0.001, which indicates that SSP plays an important role in shaping SCP (b=0.692, p <0.001). This result positively indicates the impact of SSP on SCP. Moreover, the R2 = 0.339 depicts that the model explains 33% of the variance in the BE. The tables show a summary of the following Table 6.

| Table 6 Hypothesis 2 | ||||||

| Hypothesis | Regression weight | Beta coefficient | R2 | F | p-value | Hypothesis supported |

| H2 | SSP → SCP | 0.692 | 0.339 | 697.897 | 0.000 | Yes |

H3: Customer satisfaction (CS) in Q-commerce is significantly influenced by supply chain performance(SCP), including delivery speed, inventory management, and service reliability.

SCP had significant impacts on CS (b=0.655, p<0.001), as evidenced by the fact that SCP significantly predicted CS, F (1,766) = 384 p <0.001. This outcome shows that SCP has a beneficial effect on CS. Furthermore, R2 = 0.398 shows that the model can explain 39% of the variance in the CS. The following is summarized in the Table 7.

| Table 7 Hypothesis 3 | ||||||

| Hypothesis | Regression weight | Beta coefficient | R2 | F | p-value | Hypothesis supported |

| H3 | SCP → CS | 0.655 | 0.398 | 522.987 | 0.000 | Yes |

Conclusion

The research demonstrates that strategic supplier collaborations together with technology implementation lead to superior supply chain results in quick commerce operations. Companies that use AI together with IoT and blockchain technology optimize their operational performance and reduce costs while available services become more reliable. Supplier collaboration development enhances both future demand prediction accuracy and stock replenishment speed which creates satisfied customers. The research confirms supply chain performance stands as a key driver of complete customer satisfaction since fast delivery and precise stock control and efficient last-mile transport are necessary for business triumph. The developed framework helps quick commerce operations find an optimum balance between speed and sustainability while minimizing costs so they can defend their market position. Resolving operating inefficiencies by using digital methods and connecting with suppliers stands essential for enduring business expansion and industry market dominance.

Managerial Implications

The strong supplier-business partnerships enable quick commerce organizations to monitor supply needs and customer behavior patterns to optimize stockout reduction and enhance service reliability. The selection of improvement strategies by organizations demands AI-powered solutions combined with IoT and blockchain technology for supply chain inspection and predictive forecasting and data visibility functions. The optimal delivery system performance for customers requires companies to integrate automated warehouses with intelligent inventory management technologies. Businesses reduce their operations costs by using electric vehicles alongside optimized drone packages and distribution systems for quick package delivery. A customer-oriented supply chain model evaluation enables businesses to provide exceptional fulfillment services which build enduring relationships with their customers. Logistics operations need sustainability-based solutions to remain essential because these solutions have effects on compliance rules and corporate reputation and environmental action acceptance levels. The competitive market demands permanent industry growth for businesses who maintain compliance with both labor and environmental regulations because it protects their credibility.

Theoretical Implications

This research creates new information in supply chain management by proving how strategic supplier partnerships coupled with integrated technology help the quick commerce industry operate more efficiently. The research furthers service operations research through real-time data analytics and automation because it shows their impact on speedy fulfillment and reliable supply chains. Empirical analysis of quick commerce customer satisfaction factors also delivers first-hand evidence about consumer patterns in quick-changing digital retail markets of emerging countries.

Future Directions

Future research can explore the impact of emerging technologies, such as digital twins and 5G networks, on optimizing quick commerce supply chains, particularly in enhancing responsiveness and real-time monitoring. Studies focusing on sustainability strategies, such as circular economy models and waste reduction techniques, could provide valuable insights into balancing ultra-fast fulfilment with environmental responsibility. Comparative research between different regional markets could offer a deeper understanding of how supply chain models in quick commerce adapt to varied economic and logistical conditions. Additionally, examining the role of government policies and regulatory frameworks in shaping logistics efficiency within quick commerce can help businesses navigate compliance challenges. Finally, assessing quick commerce supply chain models' long-term scalability and financial sustainability will be crucial in determining their viability for continued industry expansion.

References

Abumalloh, R.A., Nilashi, M., Ooi, K.B., Wei-Han, G., Cham, T.H., Dwivedi, Y.K., & Hughes, L. (2023). The adoption of metaverse in the retail industry and its impact on sustainable competitive advantage: moderating impact of sustainability commitment. Annals of Operations Research, 1-42.

Indexed at, Google Scholar, Cross Ref

Al Kurdi, B., Alzoubi, H. M., Akour, I., & Alshurideh, M. T. (2022). The effect of blockchain and smart inventory system on supply chain performance: Empirical evidence from retail industry. Uncertain Supply Chain Management, 10(4), 1111-1116.

Alwin, D.F. (1997). Feeling thermometers versus 7-point scales: Which are better?. Sociological Methods & Research, 25(3), 318-340.

Indexed at, Google Scholar, Cross Ref

Arif, D., Mahmudah, S., Agustina, H., & Martah, V. (2021). The effect of supply chain management on multi-channel retailing and business performance. Uncertain Supply Chain Management, 9(4), 823-830.

Chiu, C. L., Ho, H. C., Yu, T., Liu, Y., & Mo, Y. (2021). Exploring information technology success of Augmented Reality Retail Applications in retail food chain. Journal of Retailing and Consumer Services, 61, 102561.

Indexed at, Google Scholar, Cross Ref

Collier, J. (2020). Applied structural equation modeling using AMOS: Basic to advanced techniques. Routledge.

Faruquee, M., Paulraj, A., & Irawan, C. A. (2021). Strategic supplier relationships and supply chain resilience: is digital transformation that precludes trust beneficial?. International Journal of Operations & Production Management, 41(7), 1192-1219.

Fuller, C. M., Simmering, M. J., Atinc, G., Atinc, Y., & Babin, B. J. (2016). Common methods variance detection in business research. Journal of business research, 69(8), 3192-3198.

Gopal, P. R. C., Rana, N. P., Krishna, T. V., & Ramkumar, M. (2024). Impact of big data analytics on supply chain performance: an analysis of influencing factors. Annals of Operations Research, 333(2), 769-797.

Indexed at, Google Scholar, Cross Ref

Govindan, K., Aditi, Dhingra Darbari, J., Kaul, A., & Jha, P. C. (2021). Structural model for analysis of key performance indicators for sustainable manufacturer–supplier collaboration: A grey‐decision‐making trial and evaluation laboratory‐based approach. Business Strategy and the Environment, 30(4), 1702-1722.

Indexed at, Google Scholar, Cross Ref

Grewal, D., Gauri, D. K., Das, G., Agarwal, J., & Spence, M. T. (2021). Retailing and emergent technologies. Journal of Business Research, 134, 198-202.

Hair, J. F., Sarstedt, M., Ringle, C. M., & Mena, J. A. (2012). An assessment of the use of partial least squares structural equation modeling in marketing research. Journal of the academy of marketing science, 40, 414-433.

Har, L. L., Rashid, U. K., Te Chuan, L., Sen, S. C., & Xia, L. Y. (2022). Revolution of retail industry: from perspective of retail 1.0 to 4.0. Procedia Computer Science, 200, 1615-1625.

Irfan, I., Au, A. K. M., Khurshid, F., & Chan, F. T. (2023). Learning by supplying to climb the value chain: suppliers’ transition from B-to-B to B-to-C. Supply Chain Management: An International Journal, 28(4), 641-665.

Indexed at, Google Scholar, Cross Ref

Kumar, V., & Ayodeji, O. G. (2021). E-retail factors for customer activation and retention: An empirical study from Indian e-commerce customers. Journal of Retailing and Consumer Services, 59, 102399.

Lee, V., Park, S., & Lee, D. (2022). The effect of e-commerce service quality factors on customer satisfaction, purchase intention, and actual purchase in Uzbekistan. Global Business & Finance Review (GBFR), 27(3), 56-74.

Lochan, S.A., Rozanova, T.P., Bezpalov, V.V., & Fedyunin, D.V. (2021). Supply chain management and risk management in an environment of stochastic uncertainty (Retail). Risks, 9(11), 197.

Mahapatra, A. S., Sengupta, S., Dasgupta, A., Sarkar, B., & Goswami, R. T. (2025). What is the impact of demand patterns on integrated online-offline and buy-online-pickup in-store (BOPS) retail in a smart supply chain management?. Journal of Retailing and Consumer Services, 82, 104093.

Indexed at, Google Scholar, Cross Ref

Miao, M., Jalees, T., Zaman, S. I., Khan, S., Hanif, N. U. A., & Javed, M. K. (2022). The influence of e-customer satisfaction, e-trust and perceived value on consumer's repurchase intention in B2C e-commerce segment. Asia Pacific Journal of Marketing and Logistics, 34(10), 2184-2206.

Mofokeng, T. E. (2021). The impact of online shopping attributes on customer satisfaction and loyalty: Moderating effects of e-commerce experience. Cogent Business & Management, 8(1), 1968206.

Mondol, E. P. (2021). The impact of block chain and smart inventory system on supply chain performance at retail industry. International Journal of Computations, Information and Manufacturing (IJCIM), 1(1).

Mukherjee, S., Baral, M. M., Lavanya, B. L., Nagariya, R., Singh Patel, B., & Chittipaka, V. (2023). Intentions to adopt the blockchain: investigation of the retail supply chain. Management Decision, 61(5), 1320-1351.

Mustikasari, A., KRISNAWATI, M., & SUTRISNO, E. (2021). Customer experience and repurchase intention in multi-channel: Customer satisfaction as mediating variable. The Journal of Industrial Distribution & Business, 12(3), 7-19.

Ngubelanga, A., & Duffett, R. (2021). Modeling mobile commerce applications’ antecedents of customer satisfaction among millennials: An extended tam perspective. Sustainability, 13(11), 5973.

Pérez-Mesa, J. C., Piedra-Muñoz, L., Galdeano-Gómez, E., & Giagnocavo, C. (2021). Management strategies and collaborative relationships for sustainability in the agrifood supply chain. Sustainability, 13(2), 749.

Podsakoff, P. M., MacKenzie, S. B., Lee, J. Y., & Podsakoff, N. P. (2003). Common method biases in behavioral research: a critical review of the literature and recommended remedies. Journal of applied psychology, 88(5), 879.

Rath, K. C., Khang, A., & Roy, D. (2024). The role of Internet of Things (IoT) technology in Industry 4.0 economy. In Advanced IoT technologies and applications in the industry 4.0 digital economy (pp. 1-28). CRC Press.

Reklitis, P., Sakas, D. P., Trivellas, P., & Tsoulfas, G. T. (2021). Performance implications of aligning supply chain practices with competitive advantage: Empirical evidence from the agri-food sector. Sustainability, 13(16), 8734.

Indexed at, Google Scholar, Cross Ref

Richardson, H. A., Simmering, M. J., & Sturman, M. C. (2009). A tale of three perspectives: Examining post hoc statistical techniques for detection and correction of common method variance. Organizational research methods, 12(4), 762-800.

Schleper, M. C., Gold, S., Trautrims, A., & Baldock, D. (2021). Pandemic-induced knowledge gaps in operations and supply chain management: COVID-19’s impacts on retailing. International Journal of Operations & Production Management, 41(3), 193-205.

Shankar, V., Kalyanam, K., Setia, P., Golmohammadi, A., Tirunillai, S., Douglass, T., & Waddoups, R. (2021). How technology is changing retail. Journal of Retailing, 97(1), 13-27.

Indexed at, Google Scholar, Cross Ref

Sharma, M., Luthra, S., Joshi, S., & Kumar, A. (2021). Accelerating retail supply chain performance against pandemic disruption: adopting resilient strategies to mitigate the long-term effects. Journal of Enterprise Information Management, 34(6), 1844-1873.

Shiralkar, K., Bongale, A., Kumar, S., Kotecha, K., & Prakash, C. (2021). Assessment of the benefits of information and communication technologies (ICT) adoption on downstream supply chain performance of the retail industry. Logistics, 5(4), 80.

Song, S., Shi, X., Song, G., & Huq, F. A. (2021). Linking digitalization and human capital to shape supply chain integration in omni-channel retailing. Industrial Management & Data Systems, 121(11), 2298-2317.

Indexed at, Google Scholar, Cross Ref

Sudirjo, F., Violin, V., Abdullah, A., & Iswahyudi, M. S. (2023). The Effect of Promotion, E-Service Quality and Price on Customer Satisfaction and Its Implication on Loyalty of Tokopedia Customers. JEMSI (Jurnal Ekonomi, Manajemen, dan Akuntansi), 9(5), 1724-1728.

Tarigan, Z. J. H., Jiputra, J. A., & Siagian, H. (2021). The effect of supply chain practices on retailer performance with information technology as moderating variable (Doctoral dissertation, Petra Christian University).

Tom Dieck, M. C., & Han, D. I. D. (2022). The role of immersive technology in customer experience management. Journal of marketing theory and practice, 30(1), 108-119.

Indexed at, Google Scholar, Cross Ref

Vasić, N., Kilibarda, M., Andrejić, M., & Jović, S. (2021). Satisfaction is a function of users of logistics services in e-commerce. Technology Analysis & Strategic Management, 33(7), 813-828.

Wang, T. Y., Chen, Z. S., He, P., Govindan, K., & Skibniewski, M. J. (2023). Alliance strategy in an online retailing supply chain: Motivation, choice, and equilibrium. Omega, 115, 102791.

Wick, A., Koczian, B., & Králiková, K. (2024). Optimizing Retail Pharmacy Success: The Role of Multichannel Marketing Strategies. Administrative Sciences, 14(9), 210.

Yan, Y., Yao, F., & Sun, J. (2021). Manufacturer’s cooperation strategy of closed-loop supply chain considering corporate social responsibility. RAIRO-Operations Research, 55(6), 3639-3659.

Indexed at, Google Scholar, Cross Ref

Received: 05-Mar-2025, Manuscript No. AMSJ-25-15736; Editor assigned: 06-Mar-2025, PreQC No. AMSJ-25-15736(PQ); Reviewed: 20-Mar-2025, QC No. AMSJ-25-15736; Revised: 22-Mar-2025, Manuscript No. AMSJ-25-15736(R); Published: 25-Mar-2025