Research Article: 2024 Vol: 30 Issue: 4

ISO 9001 Implementation: Boosting Sustainable Performance in Manufacturing MSMEs

V.Vivek, G.R.Damodaran Academy of Management

K.A.Guhaselvi, G.R.Damodaran Academy of Management

K.Chandrasekar, Alagappa Unviersity

Citation Information: Vivek, V., Guhaselvi , K A., Chandrasekar, K (2024). Iso 9001 Implementation: Boosting Sustainable Performance In Manufacturing Msmes. Academy of Entrepreneurship Journal, 30(4), 1-13.

Abstract

This study utilized valid constructs to measure the ISO9001 effectiveness and sustainability performance of the manufacturing MSMEs of India and to test the influence of ISO 9001 on sustainable performance. Exploratory factor analysis and first and second-order confirmatory factor analysis verify reliability and validity. Structural equation modeling investigates the statistical influence of ISO 9001 effectiveness on sustainable performance. – Results of the study revealed two reliable and variable constructs: ISO 9001 effectiveness and sustainability performance. Structural equation modeling results signify that the effective implementation of ISO 9001 has a more significant influence on the sustainable performance of the manufacturing MSMEs.

Keywords

Keywords - ISO 9001, ISO effectiveness, Sustainable development, Confirmatory factor analysis, Sustainable performance, India, Manufacturing industry, MSME.

Introduction

ISO 9001 is the International Standard for Quality Management Systems(Pallawala et al., 2019). It was initially published in 1987 by the International Organization for Standardisation (ISO) and is now one of the most widely used management tools(Carlsson & Carlsson, 1996; Lee et al., 2009). ISO 9001 assists companies of any size find more effective ways to assure quality while pushing firms to think creatively about surpassing consumer expectations(Biazzo & Bernardi, 2003; L. M. Fonseca & Domingues, 2017). The advantages of ISO 9001 in manufacturing include identifying, recording, and developing systems that fulfill customer needs such as dimensions and operational standards and predicted production efficiency(Midor & Wilkowski, 2021; Poksinska et al., 2006).

ISO 9001 standards provide much-needed certainty on internationally recognized best practices throughout the organization by including quality management, environmental performance, information security, food safety, risk management, and health and safety(Arumugam et al., 2008; Heras-Saizarbitoria et al., 2011; Kebede Adem & Virdi, 2021; Levine & Toffel, 2010; Magd, 2006; Manders et al., 2016). ISO 9001 effectiveness directly contributes to product quality and operational performance (Mangula, 2013; Stylidis et al., 2014).

Micro, Small, and Medium Enterprises (MSMEs) are known for their contributions to economic growth and sustainable development(Upadhyay et al., 2011). MSME addresses the issues of widespread poverty, unemployment, backwardness, and a poor standard of living while increasing the country's per capita and GDP. Stakeholders, customers, suppliers, the government, and regulations all play a part in boosting competitiveness, which substantially impacts MSMEs incorporate quality management activities into their firm management system to boost their chances of competing in both national and international markets(Sharma & Kharub, 2015). The economic and human resource base of MSMEs aids them in adopting quality management approaches, requiring them to constantly update and develop their knowledge and abilities about new technologies to maintain high competitiveness(Hurley, 2018; Sánchez-Infante Hernández et al., 2020).

Sustainability isn't just for huge businesses. Small businesses find it much more challenging to incorporate sustainability into their company operations(Coppola & Ianuario, 2015; M. P. Singh & Roy, 2019). Sustainable development in MSMEs is a concept and practice of these firms conducting their operations socially responsible to local and global social, environmental, and economic challenges (Amrina & Yusof, 2011a; Khurana et al., 2019; Silva et al., 2021).

As defined by ISO 9001, the Quality Management System primarily supports the United Nations' Sustainable Development Goals(Ilkay & Aslan, 2012; Kim et al., 2012). QMS is a philosophy comprised of ideas, processes, and tools that encompass values or principles such as customer focus, continuous improvement, and fact-based decision-making(L. M. Fonseca & Domingues, 2017; Lewis et al., 2005). Adopting the ISO 9001 standards would provide a solid basis for the certified organization's sustainable development efforts(Sampaio et al., 2009). ISO 9001 promotes industrial success by fostering partnerships with all members of an organization's supply chain(Mei Feng et al., 2008) (Tarí et al., 2012). It facilitates creativity while keeping long-term goals in mind and ensures responsible consumption by reducing waste and improving quality. ISO 9001 certification positively impacts all organizations (Tarí et al., 2012; Yahia-Berrouiguet et al., 2015). QMS elements are positively related to the performance factors of the Indian organizations(V. Singh et al., 2018). QMS practices significantly enhance financial, social, and environmentally sustainable performance (Ali & Johl, 2022; Dick et al., 2008).

This study attempts to give a solid solution to the issue by carefully examining how ISO 9001 effectiveness affects the sustainable performance of manufacturing MSMEs(Gotzamani et al., 2007; Padma et al., 2008; Siltori et al., 2021). This study expands on previous research by drawing on quality and strategy theory literature to better understand how organizations with successful ISO 9001 quality standards improve their sustainable performance. The concepts of "ISO 9001 effectiveness" and "sustainable performance" were established to assess ways to accomplish and influence the MSME's sustainable performance. The primary component that emerges from examining current empirical data is ISO 9001's contribution to sustainable performance. Subsequently, businesses can establish solid foundations for QMS to lead to sustainable development. This research adds novel and practical insights to the literature through structural equation modeling (SEM).

Following the downfall due to the pandemic(P. Sahoo & Ashwani, 2020), strategic cost resilience is the new cost mantra for small businesses. This study is essential for companies and researchers to understand how implementing effective ISO 9001 will influence the firms' sustainable performance(Dick et al., 2008).

The following sections of the study examine ISO 9001 effectiveness and sustainable performance. The next part is the formulation of Research models and hypotheses. In the following section, we'll discuss the research methods, the creation of the survey instrument, and the selection of a sample. This research paper concludes with discussions of the study's findings, implications, and future research avenues.

Theoretical background and conceptual foundation

ISO 9001 Effectiveness

The International Organization for Standardization (ISO) establishes performance criteria and specifies the processes required to meet quality management requirements and increase the effectiveness and efficiency of the QMS(Das et al., 2008; Kumar et al., 2018; Priede, 2012). ISO defines effectiveness, and ISO 9001 significantly impacts the quality of products and services and how well they run their businesses. (E. L. Psomas et al., 2013) Table 1.

| Table 1 ISO 9001 Effectiveness Variables and Supporting Literature | |||

| Dimension | Variable | Supporting literature | |

| Customer satisfaction | V1 | Managers and supervisors provide information and encourage activities that increase customer satisfaction. | (Kakeš & Fazlović, 2016)(Kim et al., 2011)(Sadikoglu & Zehir, 2010)(P. J. Singh, 2008) (P. J. Singh et al., 2006) (Kafetzopoulos et al., 2015a)(E. L. Psomas et al., 2013) |

| V2 | Identification of and focus on meeting customer needs and requirements. | ||

| V3 | We carry out customer satisfaction surveys. | ||

| V4 | Complaints and suggestions are Monitored to increase the level of satisfaction. | ||

| Continuous improvement | V5 | We are developing an organizational structure to support the continuous improvement of the quality management system. | (Sohal & Terziovski, 2000)(P. J. Singh et al., 2006)(L. M. Fonseca & Domingues, 2018)(Murmura et al., 2016)(Rojas et al., 2018)(Evangelos Psomas & Antony, 2014)(Gilroy et al., 2008) |

| V6 | We continuously monitor, review and improve The processes and products | ||

| V7 | We determine the Improvement areas of the system's quality management and develop an effective business plan for continuous quality improvement. | ||

| V8 | We set goals for all employees, and employee performance is continuously improved. | ||

| Prevention of non-conformities | V9 | The products conformance to specifications. | (Evangelos Psomas & Antony, 2014)(E. L. Psomas, 2013)(E. L. Psomas, 2013)(Kafetzopoulos et al., 2015b) |

| V10 | Product and process optimization According to audit findings, the product meets all applicable requirements. | ||

| V11 | Reduced non-conformity problems through quality processing, storage, packaging, and delivery | ||

| V12 | Continuous control of products and processes throughout the production steps. | ||

There was a lot of research done to determine how well ISO worked in both service and manufacturing businesses. (Sfreddo et al., 2021). Relevant literature shows that the ISO 9001 standard attempts to achieve customer satisfaction via satisfying customer needs, continuous improvement, and the prevention of nonconformities in goods and services(Evangelos Psomas & Pantouvakis, 2015). According to the study by (Martin, 2017), employee involvement and customer satisfaction affect ISO 9001 implementation and operational performance

Sustainable performance indicators

Sustainability is a crucial consideration for any business. Sustainability fosters an understanding of the link between industrial progress, innovation, the economy, and ecological problems(Lopes de Sousa Jabbour et al., 2020; Ramesh, 2019; M. P. Singh & Roy, 2019). As a result, sustainability uses three components: economic, sociological, and environmental(Bhattacharya, 2012; Veleva et al., 2001). Sustainable development in the manufacturing sector assesses organizations' efforts to decrease waste, achieve zero emissions, and construct management systems that take into account(Abid et al., 2021; Pacheco, 2020; Prashar, 2019; Vancheswaran & Gautam, 2009) Table 2.

| Table 2 Sustainable Performance Variables and Supporting Literature | |||

| Dimension | Variable | Supporting literature | |

| Environmental Performance | V13 | There is a decrease in emissions and pollution. | (Putri et al., 2020)(Chattopadhyay et al., 2016)(M. P. Singh et al., 2016)(Tjahjadi et al., 2020)(Cristofaro & Caterini, 2020) |

| V14 | Optimum utilization of all resources | ||

| V15 | Ther is a reduction in waste in all forms | ||

| Economic Performance | V16 | The quality of the product is high, and we maintain the standard requested by the customer | (Radyanto & Hayati, 2020)(D. Singh, 2019) (Ravikumar et al., 2016)(Sánchez-Infante Hernández et al., 2020)(Rossi, 2014) |

| V17 | We can monitor and control all direct and indirect costs | ||

| V18 | We have an improvement in the Supply-chain and delivery | ||

| V19 | There is flexibility in the production process | ||

| Social Performance | V20 | Employees are delighted | (Biswas & Singh, 2020) (Hernández-Perlines & Sánchez-Infantes, 2016) (Sangwan et al., 2012)(Kodrat et al., 2019) |

| V21 | Committed and initiative suppliers | ||

The performance measures are indicators based on the triple bottom line of sustainability. The performance evaluation process kicks off an organization's future performance by establishing a performance objective and a continuous improvement plan. Sustainable PerformanceIndicators can be a powerful tool in addressing the sustainability of businesses(Keeble et al., 2003)(Khan et al., 2019)

(Curkovic & Sroufe, 2011) ISO registration can leverage the competitive advantage and bring improvement in different levels of integration towards sustainability. (Hahn, 2013) ISO aims to guide all types of organizations to contribute toward sustainable development. (MacDonald, 2005) ISO is a strategic plan and has become a widespread administrative tool for corporate responses to sustainability.

(Burke & Gaughran, 2007) ISO is a foundation for sustainability management. Sustainability issues in manufacturing firms are growing exponentially. Sustainability is now shifting considerations from environmental considerations to social, ethical, and economic responsibilities, which develops a framework for sustainability management. Some studies discussed the influence of QMS and environment management on enterprise performance (Pawliczek & Piszczur, 2012). However, there is an increase in stakeholder pressure. Organizations face challenges integrating three dimensions of sustainable development into their management system (Bastas & Liyanage, 2018).

(Jabbour et al., 2014) Studies have tried to test new models to develop a relationship between quality management, environmental management, adoption of green supply chain management, and green performance, which was novel. No simultaneous connection has been identified and tested in the literature.

ISO certification has a proven influence on environment dimensions, and it varies according to the size of the company, type of activity, and location. ISO certified companies contribute at different levels toward sustainable development(L. Fonseca et al., 2021)

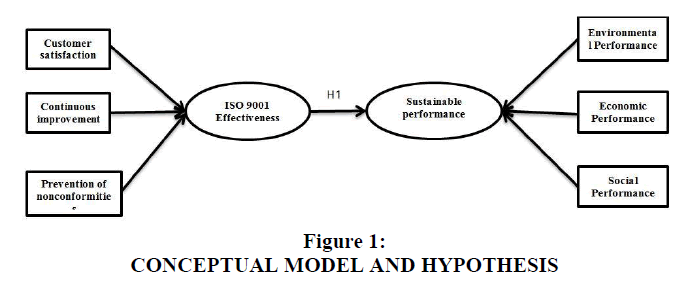

Based on the discussion on the lack of empirical evidence, our conceptual model aims to analyze the influence of ISO 9001 on the sustainable performance of manufacturing MSMEs. Figure 1 shows the conceptual model

H1: ISO 9001 effectiveness has a positive effect on the sustainable performance of manufacturing MSMEs.

Methodology

Questionnaire Development

ISO9001-certified MSMEs in India were studied to see whether the hypothesis mentioned above was correct. Preliminary surveys include literature study results and subsequent revisions from the recommendations of academics and experts in the field. Further, the questionnaire was improved based on the pilot study. The final version of the questionnaire consists of ISO 9001 effectiveness (Customer satisfaction, continuous improvement, prevention of nonconformities) and sustainable performance (Environmental, social and economic performance) as identified in the literature. Using a five-point Likert scale, respondents indicate their degree of agreement.

Sampling and data collection

One thousand Indian manufacturing MSMEs were picked randomly from the registered Udyog Aadhar-certified ISO 9001-certified manufacturing MSMEs in the country (Online registration of MSMEs. The questionnaire was delivered to the owners of the businesses through email, with two follow-up emails sent three and six weeks later. (Baruch & Holtom, 2008). Finally, 216 completed surveys were received, yielding a response rate of 21.6 percent, as determined by (Hair, 2011; Tabachnick et al., 2007) and large enough for multivariate analysis. Sample size is acceptable compared to the response rate of earlier studies carried out in the field(Heras-Saizarbitoria & Boiral, 2013; Martínez-Costa et al., 2009; Sampaio et al., 2009). Several non-responding companies responded that non-responsive bias is not a cause of concern in this study(Asch et al., 1997).

Data analysis

The latent content of ISO 9001 efficiency and sustainable performance are extracted using exploratory factor analysis (EFA). The principal component factor extraction and varimax rotation method were used (Kafetzopoulos et al., 2015b; Evangelos Psomas & Antony, 2015). Scales in EFA are refined by using first-order Confirmatory Factor Analysis(CFA) to determine the measures related to ISO 9001 and Sustainable performance. A second-order CFA validates ISO 9001 effectiveness and Sustainable performance (Galetto et al., 2017; Gunasekaran & Spalanzani, 2012; Maheswari et al., 2018; E. L. Psomas et al., 2010). Finally, the influence of ISO 9001 effectiveness on sustainable performance is assessed through Structural Equation Modelling (SEM)(Bastas & Liyanage, 2018; Kebede Adem & Virdi, 2020)

Result

The company profiles

Responses from ISO 9001 certified manufacturing MSMEs indicate that 107(49.5%) respondents were micro (up to ₹5 crore turnover), 83(38.4%) respondents were small (₹5 to ₹75 crore turnover), and 26(12.1%) of respondents belong to medium enterprises(₹75 to ₹250 Crore turnover). The manufacturing companies participating in the present study are private companies belong to several sectors, manufacturing of food products 11(5%) , textiles 7(3.2%), leather and related products 10(4.6%), furniture 13(6%), paper and paper products12(5.5%), rubber10(4.6%), plastics 26(12%), metals 42(19.4%), machienery8(3.7%), electronic equipments 29(13.4%) ,transport equipments17(7.8%) and others 31(14.3%). All the responding companies were certified with ISO 9001. 70% of the companies were in operation for more than 5 years, and 73% of the business managers were graduates.

EFA

Exploratory Factor analysis measures variables of ISO 9001 effectiveness identified in the literature (KMO= 0.912, Cumulative variance = 76.34%) (Table 3). Three latent constructs were derived and labeled: continuous improvement, customer satisfaction, and prevention of nonconformities(Evangelos Psomas & Antony, 2015).

| Table 3 Exploratory Factor Analysis of ISO9001 Effectiveness | |||

| variables | Customer satisfaction | Continuous improvement | Prevention of non-conformities |

| Factor loadings | |||

| V1 | 0.857 | ||

| V2 | 0.846 | ||

| V3 | 0.821 | ||

| V4 | 0.778 | ||

| V5 | 0.872 | ||

| V6 | 0.796 | ||

| V7 | 0.727 | ||

| V8 | 0.704 | ||

| V9 | 0.832 | ||

| V10 | 0.804 | ||

| V11 | 0.791 | ||

| V12 | 0.737 | ||

| Eigen Value | 4.816 | 2.124 | 1.168 |

| KMO | 0.912 | Cumulative variance % | 76.34 |

The sustainability performance measures identified in the literature are the measured variables of EFA (KMO= 0.873, Cumulative variance = 76.62%) (Table 4). Factors are refined into three latent constructs: Environmental performance, Economic performance, and social performance(Amrina & Yusof, 2011b; Ojo et al., 2020).

| Table 4 Exploratory Factor Analysis of Sustainable Performance | |||

| variables | Environmental performance | Economic performance | Social performance |

| Factor loadings | |||

| V13 | 0.846 | ||

| V14 | 0.792 | ||

| V15 | 0.786 | ||

| V16 | 0.857 | ||

| V17 | 0.812 | ||

| V18 | 0.773 | ||

| V19 | 0.75 | ||

| V20 | 0.832 | ||

| V21 | 0.797 | ||

| Eigen Value | 4.116 | 2.103 | 1.007 |

| KMO | 0.873 | Cumulative variance % | 76.62 |

First-order CFA

First-order CFA results consistently supported the latent constructs extracted in (Table 3,4) through EFA. From the result, the latent construct and the measured variables have strong reliability coefficients (construct validity, reliability, and absence of multicollinearity) (Table 5-8).

| Table 5 CFA (First Order) Critical Factors of ISO 9001 Effectiveness | ||||

| Latent Construct | Measured variables | Mean values | Standardized regression weights | Squared multiple correlations |

| Customer satisfaction | V1 | 4.13 | 0.942 | 0.863 |

| V2 | 4.15 | 0.936 | 0.852 | |

| V3 | 4.14 | 0.762 | 0.623 | |

| V4 | 4.12 | 0.832 | 0.746 | |

| Continous improvement | V5 | 3.5 | 0.864 | 0.784 |

| V6 | 3.47 | 0.759 | 0.669 | |

| V7 | 3.52 | 0.715 | 0.601 | |

| V8 | 3.45 | 0.793 | 0.697 | |

| Prevention of non-conformities | V9 | 4.21 | 0.822 | 0.731 |

| V10 | 4.28 | 0.693 | 0.587 | |

| V11 | 4.13 | 0.861 | 0.773 | |

| V12 | 3.49 | 0.784 | 0.686 | |

| Table 6 CFA (First Order) Critical Factors of Sustainable Performance | ||||

| Latent Construct | Measured variables | Mean values | Standardized regression weights | Squared multiple correlations |

| Environmental performance | V13 | 4.21 | 0.931 | 0.859 |

| V14 | 4.29 | 0.962 | 0.891 | |

| V15 | 4.16 | 0.862 | 0.774 | |

| Economic performance | V16 | 4.02 | 0.796 | 0.701 |

| V17 | 4.18 | 0.859 | 0.774 | |

| V18 | 4.05 | 0.863 | 0.78 | |

| V19 | 3.73 | 0.795 | 0.693 | |

| Social performance | V20 | 3.09 | 0.715 | 0.601 |

| V21 | 4.13 | 0.816 | 0.711 | |

| Table 7 ISO 9001 Effectiveness Model Reliability and Validity | ||||

| Latent construct | Cronbach's alpha | Average variance extracteda | Construct reliabilityb | Correlationc |

| Customer satisfaction | 0.921 | 0.719 | 0.932 | 0.671 |

| Continous improvement | 0.914 | 0.724 | 0.923 | 0.673 |

| Prevention of non-conformities | 0.876 | 0.703 | 0.877 | 0.662 |

| aAVE = Σλi2/n, (number of items i = 1, … n, λi = standardised factor loading). | ||||

| bCR = (Σλi)2/[(Σλi)2 + (Σδi)], (number of items i = 1, … n, λi = standardised factor loading, δi = error term). | ||||

| The highest squared correlation between the construct of interest and the remaining constructs. | ||||

| Table 8 Sustainable Performance Effectiveness Model Reliability and Validity | ||||

| Latent construct | Cronbach's alpha | Average variance extracteda | Construct reliabilityb | Correlationc |

| Environmental performance | 0.918 | 0.816 | 0.926 | 0.683 |

| Economic performance | 0.884 | 0.734 | 0.893 | 0.641 |

| Social performance | 0.851 | 0.703 | 0.851 | 0.615 |

| aAVE = Σλi2/n, (number of items i = 1, … n, λi = standardised factor loading). | ||||

| bCR = (Σλi)2/[(Σλi)2 + (Σδi)], (number of items i = 1, … n, λi = standardised factor loading, δi = error term). | ||||

| c The highest squared correlation between the construct of interest and the remaining constructs. | ||||

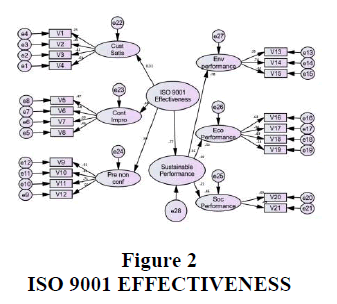

Second-order CFA

A second-order CFA assures the validity and reliability of the first-order latent constructs of ISO 9001 effectiveness and Sustainable performance. The goodness of fit measures shows an acceptable fit for the proposed second-order model, and a valid second-order latent is extracted.

SEM

The measurement model and structural model fit indices (Table 9 & 10) show that the theoretical model has sufficient empirical support. Examining the standardized regression weights for the direct relationships between the latent constructs of the Sustainable performance and the ISO 9001 effectiveness reveals that two of the three dimensions significantly influence the effectiveness of the ISO 9001. More precisely, the 'Environmental performance', and 'Economic performance' have a substantial direct impact on the effectiveness of ISO 9001.

| Table 9 Goodness of Fit Measures of the Models. | ||||

| The goodness of fit measures | First and second-order CFA | First-order CFA | Full CFA model | SEM model |

| The basic goodness of fit | ||||

| Chi square | 38.676 | 86.896 | 253.869 | 282.632 |

| Degrees of freedom | 22 | 51 | 180 | 186 |

| Probability level | 0.001a | 0.000a | 0.000a | 0.000a |

| Absolute fit index | ||||

| Chi square / degrees of freedom | 1.758 | 1.703 | 1.41 | 1.519 |

| RMSEA | 0.063 | 0.061 | 0.057 | 0.059 |

| RMR | 0.031 | 0.064 | 0.054 | 0.056 |

| GFI | 0.918 | 0.903 | 0.834 | 0.832 |

| Incremental fit index | ||||

| NFI | 0.961 | 0.934 | 0.891 | 0.882 |

| IFI | 0.976 | 0.973 | 0.946 | 0.946 |

| TLI | 0.933 | 0.958 | 0.954 | 0.968 |

| CFI | 0.957 | 0.948 | 0.927 | 0.925 |

| Parsimony fit index | ||||

| PCFI | 0.759b | 0.748b | 0.802b | 0.832b |

| PNFI | 0.742b | 0.706b | 0.742b | 0.781b |

| aIn case of N < 250, m(variables) <30, RMR < 0.08, RMSEA < 0.08, CFI > 0.95. | ||||

| bRelatively high values represent a better fit for the model – given that the respective values for the saturated model are 0.0. | ||||

| Table 10 Relationship Between Constructs | |||||||

| Relationship | Standardized regression weight | Standardized estimates | p-value | Squared multiple correlation coefficient | Hypothesis test result | ||

| Effectiveness of ISO Sustainable performance | 0.774 | 0.118 | 0.00* | 0.723 | Accept hypothesis | ||

| *Significance at p<0.05 | |||||||

The standardized regression weight for the direct relationship between ISO 9001 effectiveness and sustainable performance is positive and significant. Overall, 72% variation in Sustainable performance can be explained by ISO 9001 effectiveness Figure 2.

Discussion

Discussing the profile of the companies

ISO 9001 certified manufacturing MSMEs are included in the present study, similar to Kafetzopoulos et al., 2015a; Koc, 2007; Mangiarotti & Riillo, 2014; Murmura et al., 2018. Indian MSMEs are characterized based on their turnover, as in the studies of Bhat et al., 2021; Bisht & Sridhar, 2021.

Analyzing ISO 9001 effectiveness

ISO 9001 effectiveness has been studied extensively by Galetto et al., 2017; Pallawala et al., 2019; E. Psomas & Antony, 2014; Sun et al., 2019. The present study provides empirical evidence to support the theoretical frameworks of the existing research through the first order factorial structure for the dimensions of customer satisfaction, continuous improvement and prevention of nonconformities, and the second-order dimensions of ISO effectiveness.

The studies of Feng et al., 2007, and Kartha, 2022 suggest that the ISO 9001 should be evaluated based on the measures of organizational effectiveness. A measurement tool for manufacturing firms as reflected in the studies of (E. Psomas et al., 2013)(E. Psomas et al., 2011)(L. V. Singh et al., 2007)(Mahmood & Hasan, 2012) (Koc, 2007) (Ahmed, 2017) was introduced in the present study to affirm the dimensionality of ISO 9001 and confirmed and validated to evaluate ISO9001 effectiveness.

Analysing Sustainability performance indicators

Sustainable performance indicators, according to previous studies (Govindan et al., 2021)(Alghamdi et al., 2022)(Azapagic, 2004), consist of three factors divided into eight indicators integrating economic, environmental, and social performance. Performance indicators in this study are validated, and the results obtained were similar to the studies of (Amrina & Yusof, 2012)(Amrina & Yusof, 2011b) (Labuschagne et al., 2005) (Veleva et al., 2001) (Amrina & Vilsi, 2014).

Influence of ISO 9001 on sustainable performance

The proposed model of this study is in line with (Hinke et al., 2014)(Baki et al., 2020) (Sumaedi & Yarmen, 2015) (Kafetzopoulos et al., 2015a) (Demirbag et al., 2006) where measurement of sustainability performance is through economic, environmental and social indicators. Measurement of ISO 9001 effectiveness is through customer satisfaction, continuous improvement, and prevention of non-conformities. (Adam Pawliczek, 2013) has studied the impact of ISO on sustainability priorities in SMEs by comparing performances of groups of interest and tried to establish an effect on the awareness level of the owner on enterprise sustainability. Literature review observations have provided us with studies (Becker & van Dyk, 2018)(Sousa & Aspinwall, 2010) suggesting frameworks on how sustainability integration can be a part of an existing operation. The result of (Wang et al., 2021)(Tayo Tene et al., 2021) suggested that ISO 9001 adoption affects long-term sustainable growth. However, the impact of ISO on sustainable performance is not measured. Observations give a direct relationship between sustainability performance and ISO 9001 effectiveness through this study. This study is novel and the results discussed are creating new literature in the study area. Results from SEM indicate a substantial relationship between the ISO 9001 effectiveness and sustainable performance of manufacturing MSMEs.

Conclusion

ISO 9001 implementation in manufacturing MSMEs is a vital research subject, and the studies focused broadly on its critical factors, implementation strategy, and benefits. However, there are many new topics regarding the contribution, association, optimization, and sustainable business development by ISO 9001This study provides a relationship between the contribution of ISO 9001 toward the sustainable performance of the manufacturing MSMEs. ISO 9001 effectiveness was measured using three dimensions and is empirically validated. Through a thorough literature review, three dimensions of sustainability performance indicators were introduced and strongly validated. The present study is innovative and different from similar studies worldwide.ISO 9001 effectiveness is a significant parameter of quality management. According to the study's findings, ISO 9001 effectiveness directly influences the sustainable performance of Manufacturing MSMEs. As of the authors' knowledge, no studies have used ISO 9001 effectiveness to assess the sustainable implementation of the manufacturing MSMEs.

Practical Implecation

The findings of the present study carry meaningful implications for researchers and practitioners. Manufacturing MSMEs must focus on their effort to achieve the objectives of ISO 9001 standards. The suggested validated framework reflecting the dimensions can be a self-assessment tool for managers to decide on the elements that increase the ISO 9001 effectiveness. ISO 9001 effectiveness directly impacts the sustainable performance of the MSMEs. This study helps quality managers to focus on ISO standards which underlie factors to improve the sustainable performance of the MSMEs. As MSMEs are considered the engines for achieving sustainable growth, this study provides a sustainable development model for not only the Indian MSMEs but also for other MSMEs around the world. This study motivates non-ISO certified manufacturing MSMEs to implement ISO 9001 standards, thereby increasing the ISO effectiveness to improve their sustainable performance.

Research limitations and future research recommendations

Limitations of the study provide opportunities for future research proposals. Future research shall explore this study results concerning the samples from a more significant population of companies from other nations as this sample is limited to manufacturing MSMEs of India. Future research shall also investigate other operating performance dimension measures such as Finance, supply chain, and human resource development that could impact ISO 9001 effectiveness. Future studies may examine sustainable performance through opinions from more than one respondent. The data for the study is received through a questionnaire through email, which entitles a risk of biased responses. Future research recommendations are to adopt other data collection methods to reduce bias.

References

Abid, N., Ceci, F., & Ikram, M. (2022). Green growth and sustainable development: dynamic linkage between technological innovation, ISO 14001, and environmental challenges. Environmental Science and Pollution Research, 1-20.

Indexed at, Google Scholar, Cross Ref

Ahmed, W. (2017). ISO 9001 transition and its impact on the organizational performance: evidence from service industries of Pakistan. International Journal of Research in Business Studies and Management, 4(3).

Alghamdi, B., Khadawardi, H., Alghamdi, B., Almathami, K., Alshimai, A., Alqahtani, M., ... & Talukder, M. (2022). Key Performance Indicators for measuring sustainable performance: a case study of implementing Saudi Arabia's Vision 2030 strategy. Performance Improvement Quarterly, 34(4), 491-519.

Ali, K., & Johl, S. K. (2022). Impact of total quality management on SMEs sustainable performance in the context of industry 4.0. In Proceedings of International Conference on Emerging Technologies and Intelligent Systems: ICETIS 2021 (Volume 1) (pp. 608-620). Springer International Publishing.

Amrina, E., & Vilsi, A. L. (2014, December). Interpretive structural model of key performance indicators for sustainable manufacturing evaluation in cement industry. In 2014 IEEE International Conference on Industrial Engineering and Engineering Management (pp. 1111-1115). IEEE.

Amrina, E., & Yusof, S. M. (2011, December). Key performance indicators for sustainable manufacturing evaluation in automotive companies. In 2011 IEEE international conference on industrial engineering and engineering management (pp. 1093-1097). IEEE.

Amrina, E., & Yusof, S. M. (2012, December). Interpretive structural model of key performance indicators for sustainable manufacturing evaluation in automotive companies. In 2012 IEEE International Conference on Industrial Engineering and Engineering Management (pp. 656-660). IEEE.

Arumugam, V., Ooi, K. B., & Fong, T. C. (2008). TQM practices and quality management performance: An investigation of their relationship using data from ISO 9001: 2000 firms in Malaysia. The TQM Journal, 20(6), 636-650.

Pawliczek, A., & Piszczur, R. (2013). Effect of management systems ISO 9000 and ISO 14000 on enterprises’ awareness of sustainability priorities.

Received: 22-Apr-2024, Manuscript No. AEJ-24-14983; Editor assigned: 25-Apr-2024, PreQC No. AEJ-24-14983 (PQ); Reviewed: 10-May-2024, QC No. AEJ-24-14983; Revised: 15-May-2024, Manuscript No. AEJ-24-14983 (R); Published: 22-May-2024