Review Article: 2023 Vol: 27 Issue: 4S

Interpretive Structural Modelling: Human−Machine Worksystem Components

Roli Dave, National Institute of Industrial Engineering (NITIE), Mumbai

Vivek Khanzode, National Institute of Industrial Engineering (NITIE), Mumbai

Vikram Neekkhra, Armoured Static Workshop, Ahmednagar

Citation Information: Dave, R., Khanzode, V., & Neekkhra, V. (2023). Interpretive structural modelling: human-machine worksystem components. Academy of Marketing Studies Journal, 27(S4), 1-18.

Abstract

Background: The human-machine model was developed to facilitate the study of ergonomics with cognisable technology in industrial practices. This model illustrated the components of the work system and their interactions. Industrial practices are defined as work system and incidents and accidents may be termed as work system failure. Presently, preventive and corrective maintenance theories are based on component life cycles and the extent of exploitation. The complexities of the work system have increased with increasing levels of automation. However, the interactions in the work system have given marginal importance towards the study of work system failure. Purpose: This study investigates the importance of interactions of work system components. The hierarchical structural model of work system components was developed and their classification was carried out based on the nature of interactions in the work system. Method: The components and interactions in the human-machine model have been identified by a three-pronged approach using a literature review, thought experiment and expert opinion. The contextual relationship of the components and their interactions have been studied for their hierarchical structure using of level partitioning through Interpretive Structure modelling (ISM). The classification of work system components has been carried out by using MICMAC analysis. Findings: Environment, control and controlled process are positioned at a higher level in the hierarchical structure model and require emphasis. The environment and sensor are classified as driver components and influence the work system interactions of other components. Conclusion: The integrated approach of ISM and MICMAC analysis provided the hierarchical structure and classification of work system components. The level of components indicates the significance of components in the work system and the driving and dependence power of components indicate nature of components to focus to prevent work system failure. Practical Implication: The outcome of the study would be useful to the work system designer and operator to minimize the work system failure. Original Contribution: This is the first study to bring out the significance and classification of work system interactions. The finding is strengthened with a computer-based statistical approach without individual opinion biases

Keywords

Human Machine Interaction, Interpretive Structure Modelling, Work system Failure, MICMAC Analysis.

Introduction

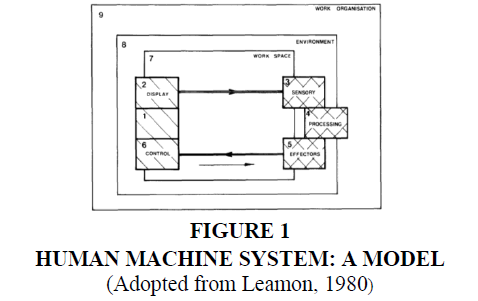

The work system is defined as a System comprising one or more workers and work equipment acting together to perform the system function, in the workspace, in the work environment, and under the conditions imposed by the work tasks (ISO 6385:2016(E), 2016). Leamon’ Human-machine model described the components of the work system as Human, Machine, Workspace, Environment and Organization (Figure 1). Humans and machines are placed at the core of the work system and sensory mechanism, processing, effectors and control, control process, and display are described as primary components of humans and machines respectively in the model (Leamon, 1980).

This model illustrated the boundary of the components in work systems and described their interactions Al-Zarooni & Bashir (2020). With the technology infusion in industrial practices the automation has been increasing in the work system with increasing levels of automation and complexity. Despite technological advances with improved design and safety aspects, the recent past witnessed work system failure in terms of incidents and accidents. There have been various models for work system evaluation having three different approaches; Human as a cause, System as a cause and System- person interaction as a cause (Khanzode et al., 2011). However, in most cases then work system failure analysis conveniently blamed the human error. The focus on work system interaction based approached have taken a backseat during design and evaluation.

Initially, ten interactions of work system components and their respective design issues were illustrated Bjørneseth et al. (2012). Whereas, the complex and tightly coupled work systems have more interactions than presented by human machine model (Leamon, 1980).Since, there are total nine components in the work system having 36 possible interactions. The authenticated reports of recent incident and accident have been analysed using task analysis, where the negative interactions responsible for work system failure were identified Bridger (2008). It is pertinent to note that the significance and contextual relationship of components and their interaction to be studied to prevent work system failure.

Interpretive structure modelling is used to study the complex system where multiple components have direct and indirect interaction (Sushil, 2012). In complex work system, It is difficult to identify the effect of interaction of components in isolation Gehman (2003). The contextual relationships of the components are established based on the opinion of group of domain experts Dao et al. (2009). It is scientific analysis of perception of group of domain experts with software based computational techniques. The classification of components based on driving and dependence power of the components is assessed for the designers and operator of the work system Kush waha (2016).

This paper is organised in four sub parts: first parts include the literature review of work system components and their interactions, second part explain the methodology of interpretive structural modelling and MICMAC analysis Ranter (1978). Results of analysis have been illustrated in the third section with classification of the components in four clusters. The implication and contribution of the study discussed in the last segment Dwivedi (2017).

Literature Review

A work system is defined as a system in which human participants and/or machines perform work (processes and activities) using information, technology, and other resources to produce specific product/services for specific internal and/or external customers (Steven Alter, 2017). These work system perform the task within defined workspace in a given environment and under organization policies and regulations Dwivedi et al. (2017). The work system evaluation is based on three approaches (i) Human as a Cause ; where human error is mainly responsible for work system failures, System as a Cause ; where systemic errors are responsible form failures and System – Person interaction as a cause ; where the interactions are responsible or failures (Khanzode et al., 2012)., the later has been rarely studied by researchers and off lately only ten interactions were identified by the Leamon (1980) in Human Machine model along with design issue of corresponding interactions.

The increasingly complex and tightly coupled automated work systems are invariably failing. The human errors have been conveniently made responsible for most work system failure (Endsley & Robertson, 1996; Lind, 2008). The recent work system are automated, where human role is decreasing and role of machine component is increasing (Richards & Stedmon, 2015). The changing work system have largely improved machine components to minimize the systemic errors. However, the work systems are still failing. Therefore, it is important to study the system-person interactions responsible for work system failure.

The Human Machine model of Leamon (1980) is taken as fundamental work system model. The model has nine primary components Eckerman & Børsen (2021). These components are interacting with each other in complex and automated work system in various industrial sectors. The classic work system failure cases analysed to study the work system interactions (Table 1).

| Table 1 Classic Cases Of Worksystem Failure |

|||||

|---|---|---|---|---|---|

| Ser No | Year | Classic Case | Sector | Author /Reports | Nature of Accident |

| 1 | 1977 | Tenerife Airport Disaster ) | Aviation | Digest and Circular, 1978 | Catastrophic failure |

| 2 | 1979 | Three Mile Island – Nuclear Disaster | Nuclear Energy | President’s Commission on The Accident at Three Mile Island, 1979 | Catastrophic failure |

| 3 | 1983 | Gimli Glider | Aviation | Williams, 2003 | Near Miss |

| 4 | 1984 | Bhopal Gas Tragedy | Process Industry | Eckerman, 2013 | Catastrophic failure |

| 5 | 1986 | Challenger Disaster | Aerospace | Roger Commission, 1986 | Catastrophic failure |

| 6 | 2003 | Columbia Spacecraft Disaster | Aerospace | Columbia Accident Investigation Board, 2003) | Catastrophic failure |

| 7 | 2009 | Air France | Aviation | BEA France, 2009 | Catastrophic failure |

| 8 | 2017 | Air Canada Near Miss | Aviation | National Transportation Safety Board, 2018 | Near Miss |

| 9 | 2018 | Lion Air Crash | Aviation | Catastrophic failure | |

(Author’s Own compilation).

The authenticated reports haven been studied to prepare the brief task analysis of events leading to work system failure. These events are identified for corresponding interactions in the work systems, leading to work system failure. The existing interactions and newly identified interactions have listed in the Table 2 and Table 3 respectively (Bridger, 2003; Leamon, 1980). These interactions from the literature inputs have been put through thought experiment and confirmed with domain expert during semi structured interview. These interactions were further required to be analysed for structural analysis of worksystem and classification of components without any biases using Interpretive Structural Modelling (ISM).

ISM was introduced by Warfield, (1974) to address the complex issues by interpretation of contextual relationship of its components or factors. These are organised in the order of their significance to facilitate the decision making at various level. The input for the ISM is sought from the group of experts. Based on the perception of domain experts the contextual relationships of the components are coded in the form of matrix. The direct and indirect inter-relationship of the components is computed for resolving the complex issue (Gupta et al., 2013). Mostly evaluation of such problems may be biased to individual opinion. The ISM methodology has an advantage of expert opinion being computed statistically based on computer based programming to prevent any biases (Sushil, 2012). Therefore, the results of ISM can be utilized for strategic decision making for complex issues to attain long term objectives (Mohammed et al. 2008). The hierarchical model is developed depending upon the contextual relationship of components of work system (Saxena et al. 1992). The ISM can be utilized to develop computer aided, well structured, systematic model with graphical representation. As compared to other techniques like ANP, AHP and TOPSIS, it does not require assessment of dominance level of component to establish the inter-relationship (Sonar et al. 2020).

Methodology

To analyse the interaction of the components of work system, various work system model were studied. The Human machine model illustrated by Leamon (1980) is taken as fundamental work system model for the study. This human machine model by Leamon (1980) have given that there are nine primary components in the work system. Each component has its own boundary and process flow in the work system is also explained. There are ten interactions were illustrated by the author. The forward citation of human machine model indicated that only 15 articles have cited the Leamon’s model since 1980.

These databases were searched using keywords aligned to our research gaps, such as level of automation, generation of automation, human machine interaction, digital labour, digital ergonomics, work system, complex system, coupling etc. the literature search was further extended towards changing work system with increasing level of coupling, automation and complexity. There have been 9 components interacting with each other having total of 36 possible interactions. Human machine model has already illustrated ten interactions (Table 2). The studies of changing work system and updated work system model have identified 11 new interactions in the work system (Table 3). It is also established that balance 15 interactions are not feasible.

| Table 2 Existing Worksystem Interactions |

|---|

| Interactions |

| Display - Workspace |

| Environment - Display |

| Workspace - Sensor |

| Environment - Sensor |

| Environment - Processing |

| Organization - Processing |

| Workspace - Effector |

| Table 3 New Worksystem, Interactions |

|---|

| Interactions |

| Display - Sensor |

| Control - Sensor |

| Sensor - Processing |

| Effector - Control |

| Controlled Process - Display |

| Display - Control |

| Processing - Effector |

(Author’s Own compilation).

To establish the facts for interactions in the work system, the work system failures cases were studied. The classic catastrophic failure cases like Bhopal Gas Accident, Gimli Glider, Three Mile Island, Challenger disaster, Tenerife airport disaster etc in past four decades and various other incidents and accidents were analysed as work system failure.

The case illustration was prepared from authenticated accident reports. The systematic sequences of events were made based on the inputs form investigation reports. The task analyses of events leading to work system failure were carried out. Every event was broken into elementary steps and corresponding interaction of the work system components have been identified. The work system failure analysis carried out based on the literature review and the session of thought experiments were conducted to identify the interactions of elementary steps of task analysis of event leading to failure. These interactions where also discussed experts for their relevance.

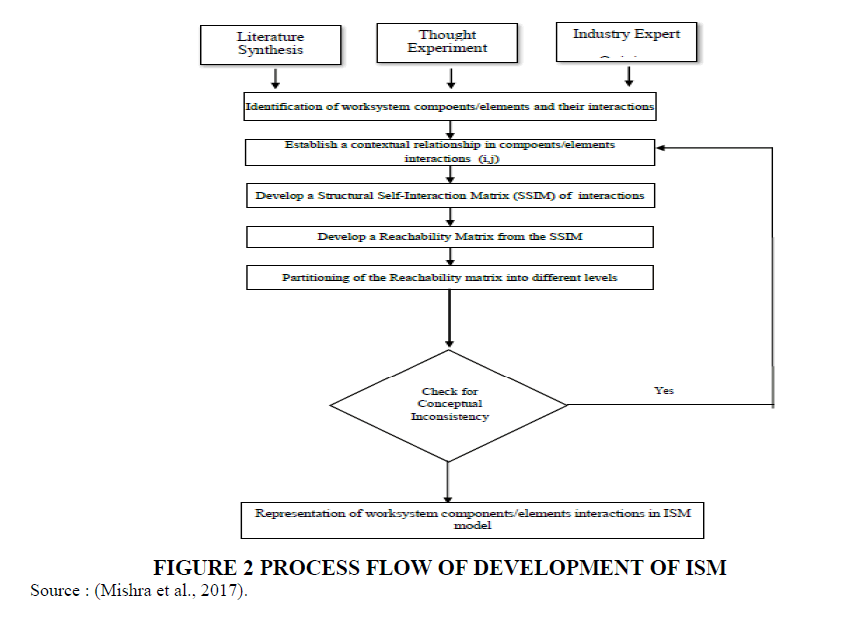

Interpretive Structural Modelling

The domain experts are selected for various industrial work system to obtain the input for development of interpretive structural modelling. The domain experts had vast experience of their respective field. The sample size of the domain expert as heterogeneous group should be 5 to 15 for better accuracy of data analysis (Murry & Hammons, 1995; Novakowski & Wellar, 2008). The group of experts from various industrial work system helped to reduce the biases in the assessment. The adequacy of assessment was given paramount importance having the expert’s minimum of 15 years of experience and have core competency and witnessed the technological transition in the work system. We have approach number of experts for their voluntarily contribution for the study. Towards the final words, few responses regretted due to paucity of time and high level of commitments. Finally, 8 domain experts have agreed for voluntarily contribution to the study. The profiles of domain experts have been illustrated in the Table 4. The flow chart of ISM process is presented in Figure 2.

| Table 4 Profile Of Industry Experts |

||||

|---|---|---|---|---|

| Industry | Designation | Exp (Years) |

Roles / Responsibility | Strategic / Commercial |

| Defense Land System | Commanding Officer Armoured Regiment |

17 | Trained in Tank Technology Responsible for modification of battle Tank |

Strategic (Tanks) |

| Railways | DGM (Operations) | 15 | Core team member of Metro Train coach manufacturing facilities | Commercial (Urban Transport) |

| Shipping | Captain of War Ship | 21 | Planning and execution of marine operations and rescues. | Strategic (War Ship) |

| Shipping | Chief Engineer (Merchant Ship) |

19 | Planning and maintenance of ships. | Commercial (Merchant Ships) |

| Aerospace | Deputy Controller (MSQAA) | 26 | Development, Manufacturing, Inspection and Maintenance of Missile system | Strategic (Missile System) |

| Aviation | Commanding Officer, UAV unit | 17 | Strategic deployment and operation of UAV units | Strategic (UAV) |

| Aviation | Captain (Private airlines) |

23 | Ex Air force pilot, Test pilot for IAF, Training of pilots and flying commercial aircraft | Commercial (Aircraft) |

| Aviation | GM (Operations) | 18 | Operation of Thermal power plant. State level Automatic Grid Management system |

Commercial (Grid Management) |

The selected domain experts were approached to establish the contextual relationship and interaction of components of work system. The newly identified interactions were also discussed for their relevance and validity. The similar approach were adopted by various researcher to establish the contextual relationship of components of complex work system like for information technology (Thakkar et al. 2008), Automobile industry (Dwivedi et al., 2017) and implementation of Industry 4.0 (Goel et al. 2022). The structural self-interaction matrix was prepared based on the input provided by the domain experts regarding direct and indirect relationship of components of work system.

Results

Step 1: Structural Self –Interaction Matrix

The brief of work system components and interactions was prepared for initial briefing of domain experts. The illustration of classic cases of work system failure were also prepared as sample of task and analysis and corresponding interaction. Based on the semi-structure interview with domain experts we have invited their inputs for their respective work system. The domain experts provided their feedback in the following coded form as per the instruction of the ISM technique. This feedback was compiled in the form of structural self-interaction matrix (SSIM). The techniques of ISM regarded as the inputs as follows to establish the structure within the work system with hierarchy of components based on their significance:

V: Factor i will help to attain factor ji

A: Factor j will help to attain facto ii

O: No relationship between factor i and j and

X: Factor i and j will help to attain each other.

The inputs were collected from all 8 domain experts regarding inter-relationship of components and correlated of their opinions of contextual relationship. Although, there were variation in the inputs from the domain experts the consensus method is adopted to correlate the responses and establish the interrelationship of components (Dwivedi et al., 2017; Kavilal et al., 2018). The domain experts’ inputs were based on their experience of various industrial work system, domain knowledge and field expertise. The inputs itself can be taken as practical validation of newly identified interaction of work system components. The initial SSIM was developed with symbols of inputs V, A, X, and O, thereafter the final SSIM is developed for further analysis.

These component relations are denoted with symbols for examples if the Organisation component lead to Control process component the relationship between the component 1 and component 8 is represented by ‘A’, similarly if component 3 workspace leads to attain component 8 controlled process , then it is represented by ‘V’, similarly if component 2 environment and 8 i.e. controlled process are interrelated and help to attain each other, then it is represented by symbol ‘X’ and Component 04 sensor and component 9 control have no relationship then it is represented by ‘O’.

Step 2: Reachability Matrix

The structural self-interaction matrix is transformed to develop the initial reachability matrix (Table 5). This is transformed as the instruction of the ISM technique, by substituting the V, A, X, O with 0 and 1 as given below (Singh & Kant, 2008) .

| Table 5 Structural Self –Interaction Matrix (Ssim) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Components | 09 | 08 | 07 | 06 | 05 | 04 | 03 | 02 | 01 | |

| 01 | Organization | O | A | O | O | V | O | O | A | - |

| 02 | Environment | X | X | O | V | V | O | V | - | |

| 03 | Workspace | X | V | X | A | X | V | - | - | - |

| 04 | Sensor | O | A | A | V | X | - | - | - | - |

| 05 | Effector | A | X | V | A | - | - | - | - | - |

| 06 | Processing | X | A | A | - | - | - | - | - | - |

| 07 | Display | X | V | - | - | - | - | - | - | - |

| 08 | Control Process | X | - | - | - | - | - | - | - | - |

| 09 | Control | - | - | - | - | - | - | - | - | - |

(i) If the SSIM entry in the (i,j) is V , the initial reachability matrix entry for (i,j) convert to 1, and the (j,i) entry convert to 0.

(ii) If the SSIM entry in the (i,j) is A , the initial reachability matrix entry for (i,j) convert to 0, and the (j,i) entry convert to = 1.

(iii) If the SSIM entry in the (i,j) is X , then initial reachability matrix entry for (i,j) convert to 1, and the (j,i) entry convert to 1.

(iv) If the SSIM entry in the (i,j) is O , then initial reachability matrix entry for (i,j) convert to 0, and the (j,i) entry convert to 0.

Step 3: Transitivity Matrix

The final reachability matrix also known as transitivity matrix. The transitivity is required to address the consistency in contextual relation of the components in the work system. The transitivity matrix is developed by using computer-based programming using MATLAB. It can be illustrated with example if the component ‘x’ if related to ‘y’ and component ‘y’ is related to ‘z’ then there is certain relationship exist between ‘x’ and ‘z’(Singh et al., 2007). The transitivity matrix is automatically developed by the programming by minimizing the rare chances of biases in the analysis.

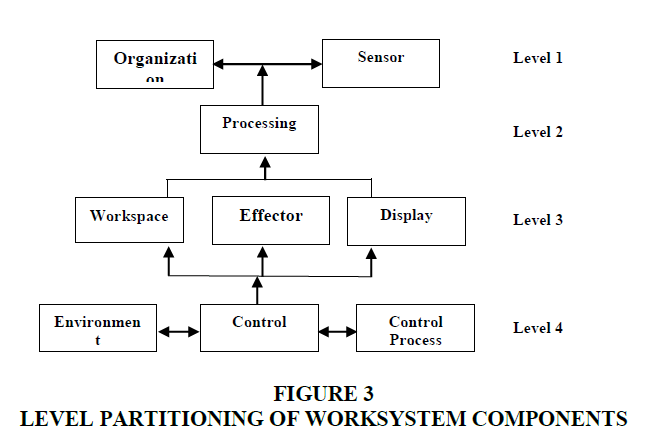

Step 4: Level Partitioning

Hierarchical structure of work system components developed through ISM and the level partitioning is carried out. To make the level partitioning the antecedent set and reachability sets are prepared for each component of work system. The antecedent set for any factor includes the component itself and other components which may interact with it. Once the reachability and antecedent sets are made from the matrix and intersection points are identified from the sets. Depending upon the intersections point the hierarchical structural model is developed. The level portioning is illustrated in following tables with each illustration Table 6.

| Table 6 Initial Reachability Matrix |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Components | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | |

| 01 | Organization | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| 02 | Environment | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| 03 | Workspace | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 |

| 04 | Sensor | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 |

| 05 | Effector | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 |

| 06 | Processing | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 |

| 07 | Display | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 |

| 08 | Control Process | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 |

| 09 | Control | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

In Table 7 the components 1 and 4 has matching reachability and antecedent set, therefore the component is considered as level 1 for hierarchical model. As the level 1 component of work system is identified then it is separated from other component. These similar steps repeated for identification of level of other components Tables 8-11. The final hierarchical ISM model is prepared based on the analysis in Figures 3 & 4.

| Table 7 Transitivity Matrix |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Components | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | |

| 01 | Organization | 1 | 0 | 0 | 0 | 1 | 1* | 0 | 0 | 0 |

| 02 | Environment | 1 | 1 | 1 | 1* | 1 | 1 | 1* | 1 | 1 |

| 03 | Workspace | 0 | 0 | 1 | 1 | 1 | 1* | 1 | 1 | 1 |

| 04 | Sensor | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 |

| 05 | Effector | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1* |

| 06 | Processing | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 |

| 07 | Display | 0 | 0 | 1 | 1 | 1* | 1 | 1 | 1 | 1 |

| 08 | Control Process | 1 | 1 | 1* | 1 | 1 | 1 | 1* | 1 | 1 |

| 09 | Control | 0 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1 |

| Table 8 Level Partition – Iteration 1 |

|||||

|---|---|---|---|---|---|

| Components | Reachability set | Antecedent set | Intersection set | Level | |

| 01 | Organization | 1 5 6 | 1 2 8 | 1 | 1 |

| 02 | Environment | 1 2 3 4 5 6 7 8 9 | 2 8 9 | 2 8 9 | |

| 03 | Workspace | 3 4 5 6 7 8 9 | 2 3 5 6 7 8 9 | 3 5 6 7 8 9 | |

| 04 | Sensor | 4 5 6 | 2 3 4 5 7 8 9 | 4 5 | 1 |

| 05 | Effector | 3 4 5 7 8 9 | 1 2 3 4 5 6 7 8 9 | 3 4 5 7 8 9 | |

| 06 | Processing | 3 5 6 9 | 1 2 3 4 6 7 8 9 | 3 6 9 | |

| 07 | Display | 3 4 5 6 7 8 9 | 2 3 5 7 8 9 | 3 5 7 8 9 | |

| 08 | Control Process | 1 2 3 4 5 6 7 8 9 | 2 3 5 7 8 9 | 2 3 5 7 8 9 | |

| 09 | Control | 2 3 4 5 6 7 8 9 | 2 3 5 6 7 8 9 | 2 3 5 6 7 8 9 | |

| Table 9 Level Partition – Iteration 2 |

|||||

|---|---|---|---|---|---|

| Components | Reachability set | Antecedent set | Intersection set | Level | |

| 02 | Environment | 2 3 7 8 9 | 2 8 9 | 2 8 9 | |

| 03 | Workspace | 3 7 8 9 | 2 3 7 8 9 | 3 7 8 9 | |

| 05 | Effector | 3 7 8 9 | 2 3 7 8 9 | 3 7 8 9 | |

| 06 | Processing | 3 9 | 2 3 7 8 9 | 3 9 | 2 |

| 07 | Display | 3 7 8 9 | 2 3 7 8 9 | 3 7 8 9 | |

| 08 | Control Process | 2 3 7 8 9 | 2 3 7 8 9 | 2 3 7 8 9 | |

| 09 | Control | 2 3 7 8 9 | 2 3 7 8 9 | 2 3 7 8 9 | |

| Table 10 Level Partition – Iteration 3 |

|||||

|---|---|---|---|---|---|

| Components | Reachability set | Antecedent set | Intersection set | Level | |

| 02 | Environment | 2 7 8 | 2 8 | 2 8 | |

| 03 | Workspace | 7 8 | 2 7 8 | 7 8 | 3 |

| 05 | Effector | 7 8 | 2 7 8 | 7 8 | 3 |

| 07 | Display | 7 8 | 2 7 8 | 7 8 | 3 |

| 08 | Control Process | 2 7 8 | 2 7 8 | 2 7 8 | |

| 09 | Control | 2 7 8 | 2 7 8 | 2 7 8 | |

| Table 11 Level Partition – Iteration 4 |

|||||

|---|---|---|---|---|---|

| Components | Reachability set | Antecedent set | Intersection set | Level | |

| 02 | Environment | 2 | 2 | 2 | 4 |

| 08 | Control Process | 2 | 2 | 2 | 4 |

| 09 | Control | 2 | 2 | 2 | 4 |

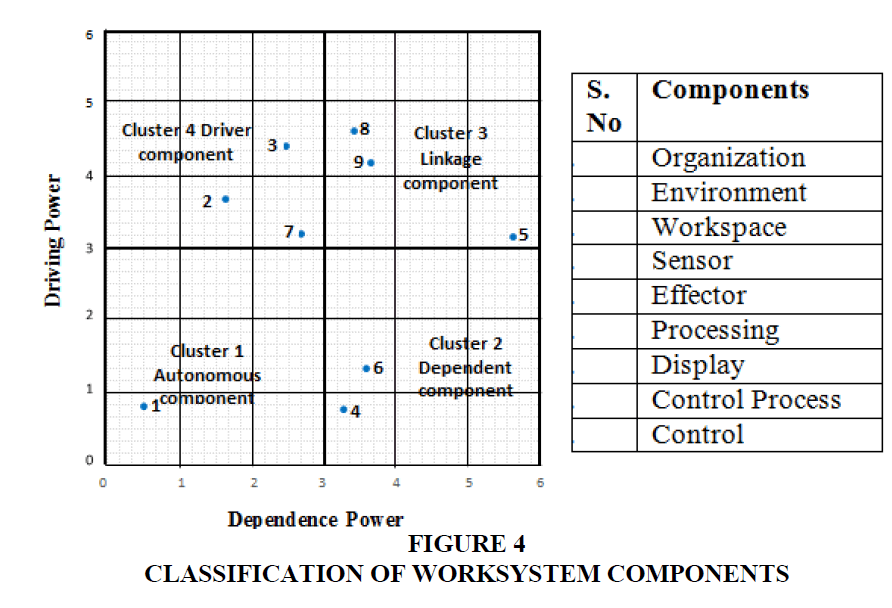

Fuzzy MICMAC Analysis

The MICMAC analysis is generally conducted based on the input received form domain experts, which is binary in nature. The binary inputs regarding the inter-relationship of work system components may not give out the correct judgement of relationship and significance of components. The limitation of traditional MICMAC analysis could overcome with incorporating the fuzzy set theory with complementing the feedback of domain expert with different value of judgement of contextual relationship. The fuzzy MICMAC analysis has been practiced by various researchers for classification of factors. The factors affecting additive manufacturing (Sonar et al. 2020) and interdependencies of electrical power system (Al-Zarooni & Bashir, 2020) have been analysed using Fuzzy MICMAC analysis. The scale of quantification of interrelationship of work system components are spread from no relationship (0) to very high relationship (0.9) with inter-spread of 5 values. The value of interrelationship are captured as; 0.1 depict very low, 0.3 depicts low, 0.5 depicts high for the purpose of analysis (Gorane & Kant, 2013; Mishra et al. 2017).

ISM modelling illustrates the contextual relationship and hierarchical structure of component in the work system. But the components are variable in interactions and the intensity of relationship cannot be same between the two components. Therefore, the binary relationship of 0 and 1 as input from domain expert may not be absolute for analysis. To overcome the limitation of ISM results for any strategic decision the Fuzzy MICMAC analysis would provide exact classification of components in the work system. MICMAC analysis is based on the concept of matrix multiplication properties. It was demonstrated by Dupperrin & Godet (1973) and widely used by the researchers. The detailed technique of Fuzzy-MICMAC analysis is as follows:

Binary Direct Relationship Matrix

The binary direct relationship matrix is prepared where the diagonal entries are made as zero. The transitivity of the interrelationship is ignored while developing the binary direct relationship matrix based on initial reachability matrix Table 12.

| Table 12 Binary Direct Relationship Matrix |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Components | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | |

| 01 | Organization | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| 02 | Environment | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| 03 | Workspace | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 |

| 04 | Sensor | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| 05 | Effector | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 |

| 06 | Processing | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 |

| 07 | Display | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 1 |

| 08 | Control Process | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 |

| 09 | Control | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 |

Development of Fuzzy Direct Relationship Matrix

The fuzzy direct relationship matrix is developed based on the inputs from domain experts for Fuzzy MICMAC analysis with respect to the interaction and inter relationship of components of work system. The inputs from all domain experts were collected and placed in the form of matrix as per the responses assigned to particular component (Table 13).

| Table 13 Fuzzy Direct Relationship Matrix |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Components | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | |

| 01 | Organization | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 |

| 02 | Environment | 0.1 | 0 | 0.5 | 0 | 0.7 | 0.5 | 0 | 0.7 | 0.3 |

| 03 | Workspace | 0 | 0 | 0 | 0.5 | 0.7 | 0 | 0.7 | 0.5 | 0.7 |

| 04 | Sensor | 0 | 0 | 0 | 0 | 0.3 | 0.7 | 0 | 0 | 0 |

| 05 | Effector | 0 | 0 | 0.1 | 0.7 | 0 | 0 | 0.7 | 0.7 | 0 |

| 06 | Processing | 0 | 0 | 0.3 | 0 | 0.5 | 0 | 0 | 0 | 0.7 |

| 07 | Display | 0 | 0 | 0.3 | 0.5 | 0 | 0.3 | 0 | 0.7 | 0.3 |

| 08 | Control Process | 0.3 | 0.7 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0 | 0.5 |

| 09 | Control | 0 | 0.5 | 0.5 | 0 | 0.9 | 0.5 | 0.7 | 0.3 | 0 |

Fuzzy-MICMAC Stabilized Matrix

The fuzzy MICMAC stabilized matrix is achieved by matrix multiplication of fuzzy direct relationship matrix using fuzzy matrix multiplication principles (Kandasamy et al., 2007). It is achieved by repetitive multiplication considering the fuzzy direct relationship matrix as base matrix (Table 14). Fuzzy matrix multiplication is carried out till the time the product matrix is also achieved as fuzzy matrix. The fuzzy MICMAC analysis is based on the driving and dependence power of components of work system by summation of entries of row and column for driving and dependence power respectively.

| Table 14 Fuzzy-Micmac Stabilized Matrix |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Components | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | Driving Power | |

| 01 | Organization | 0 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0.9 |

| 02 | Environment | 0.1 | 0 | 0.7 | 0 | 0.9 | 0.7 | 0 | 0.9 | 0.5 | 3.8 |

| 03 | Workspace | 0 | 0 | 0 | 0.7 | 0.9 | 0 | 0.9 | 0.7 | 0.9 | 4.1 |

| 04 | Sensor | 0 | 0 | 0 | 0 | 0.5 | 0.9 | 0 | 0 | 0 | 1.4 |

| 05 | Effector | 0 | 0 | 0.3 | 0.9 | 0 | 0 | 0.9 | 0.9 | 0 | 3 |

| 06 | Processing | 0 | 0 | 0.5 | 0 | 0.7 | 0 | 0 | 0 | 0.9 | 2.1 |

| 07 | Display | 0 | 0 | 0.5 | 0.7 | 0 | 0.5 | 0 | 0.9 | 0.5 | 3.1 |

| 08 | Control Process | 0.5 | 0.9 | 0 | 0.9 | 0.9 | 0.9 | 0 | 0 | 0.7 | 4.8 |

| 09 | Control | 0 | 0.7 | 0.7 | 0 | 0.9 | 0.7 | 0.9 | 0.5 | 0 | 4.4 |

| Dependence Power | 0.6 | 1.6 | 2.7 | 3.2 | 5.7 | 3.7 | 2.7 | 3.9 | 3.5 | ||

Classification of Worksystem Components

The work system components are analysed for their hierarchical structure through ISM model. Based on the driving and dependence power these components further analysed with fuzzy MICMAC. The driving power is plotted on ‘x’ axis and dependence power plotted on ‘y’ axis. The work system component Organization have driving power 0.9 and dependence power as 0.6 therefore the components is classified as per the designated values. The classification of components is divided into four clusters. driver, linkage, dependent and autonomous clusters.

Clusters of Work System Components

The work system components after having decided their hierarchical structure are categorized based on the driving and dependence power of components. The driving and dependence power is calculated based on the inputs received from domain experts and calculated from Fuzzy MICMAC Stabilized Matrix.

Autonomous Cluster

The work system component having weak driving and dependence power are categorized as autonomous component. Generally, these components do not have much influence in work system interaction. In this study the organisation is classified as autonomous factor, which is generally having less effect in the work system interaction. Organisation plays role in recruiting, training of human and scheduling of task. The availability of infrastructure (Environment and Workspace) are vital responsibility of organisation. The procedure, safety and regulations are main function of organisation.

Driver Cluster

The driver cluster encompasses the most important components of work system, which has strong driving and dependence power. These components are important variable which influence the work system interactions. Environment, workspace and display are classified as driver components. Environments have major role in functioning of human and machine. The performance of sensors, actuators and control process is also largely affected by environment. Display of control process has transformed from dial gauges to digital display with increasing complexity and coupling as touch panels etc. The location of display, colour and position of information on screen also important for work system. The complex work systems has spacio-temporal distributed and fragmented even where human and machine are operating in different workspace envelops

Linkage Cluster

The components have strong driving and dependence power are included in this cluster. These components act as facilitator for work system interactions and being driven by driving components in the work system. The linkage components also contribute towards interaction of dependent components. Effector, control, and control process have been placed as linkage components. Effectors in most cases are functioning as electronic actuators and at times also operating based on remote sensing operations. Control of work system are developed as gesture, sound, and biometric based control. The control process has largely operating based on varying degree of machine learning and artificial intelligence applications. These are integrated with sensors and actuators in work system.

Dependent Cluster

The components having weak driving power and strong dependence power constitute the dependent cluster. These components have considered as indicator for work system interactions. The processing and sensors are taken as components of dependent cluster. The environment and organization policies would impact the performance and functioning of processing. Similarly, environment, control process and display will also significantly affect the interaction of sensors in the work system.

Discussion

The ISM and MICMAC analysis as an integrated approach illustrated the work system components contextual relationship and classification. The level partitioning depicts the structural hierarchy of work system component with each other. It is observed that the factors have higher level also have high driving power to influence the other components(Gupta et al., 2013).The work system design and operation require to consider work system interactions with their corresponding design issues to prevent work system failure. The updated work system model must be developed for assessment of interactions of the components.

The increasing automation and complexity in the work system have made controlled process and control significantly important. The control process has become the automatic to autonomous to large extent with application of artificial intelligence and machine learning (Pacaux-Lemoine & Millot, 2016; Richards & Stedmon, 2015). The various industry like aviation has auto pilot which takes over the control and even the decision making under emergency condition of near miss are controlled and override by auto pilot actions rather than human pilot (Hocraffer & Nam, 2017; Westin et al. 2016). The controls have graduated from levers, handles and buttons to touch pads, gesture control and biometric based operations (Birte et al., 2012; Zavadskas, 2010). These controls have enhanced the complexity in work system and these have become more tightly coupled. The role of human in case of taking over the control of work system have been reduced as the higher technology-oriented control of work system have very little, where human can do anything (Inagaki, 2003). Therefor the control process and control are at higher level. The environment for operating of sophisticated control process, actuator, display, and sensors play an important role. The spacio-temporal work system have different workspace for human and machine, operating in the fragmented workspace. The interaction with environment is very high and at times the unpredicted performance of components while interacting with environment leads to work system failure (Hobbs & Williamson, 2002).

Similarly, earlier the workspace design, parameters and interactions were limited to anthropometric limits of human operator (Deepak K Kushwaha, 2016). In the contemporary work system, the workspace is also in fragmented envelops and not only limited to anthropometric limits of human due to use of remotely operated electronic actuator and advance control of work system. The display was located as per the capability of human sensor and processing but now in the artificial intelligence and machine learning based work system having inbuilt sensors, have gone beyond the tradition design parameters and interactions. In the complex work system the display and control common interfaces like touch screen and interactive panels (Noah et al. 2017).

The processing in the work system was mainly related to the training and decision making within stipulated time frame of critical situation (Westin et al. 2016). The algorithm-based machine learning, cyber physical system imbedded with artificial intelligence have been proven as game changer (Dao et al., 2009). The level of automation is to be decided by the organization where the regulations were guided by ergonomics principles, where the digital ergonomics will require to be accommodated for drafting the standard operating procedures and manuals. The training, scheduling, maintenance, compensations are being redefined in the work system interaction Prasanna Venkatesan & Sanket (2018).

Conclusion

This study has provided the hierarchical structure to the work system components. Based on the inputs from the domain experts of various industrial sectors the significance of work system components have been analysed to assess the leading cause of work system failure. The study of system- person interaction requires wider spectrum and deeper insight by the researcher for understanding the negative interactions of the work system. This study of interaction will be useful for designers, policy makers and operators to prepare check list, manuals and to set up standard operating procedure to prevent work system failure. These newly identified interactions in complex and automated work system may be studied for wider range of work system to establish their design issues. This would further cement the requirement of update work system model to study the system- person interactions. The classification of components indicates the nature of components, interacting in the work system. The development of models and classification of components is based upon inputs form the heterogeneous mix of domain experts and analysed by computer aided program reduces the risk of biases and effects of individual opinions.

References

Alter, S. (2013). Work system theory: overview of core concepts, extensions, and challenges for the future.Journal of the Association for Information Systems, 72.

Indexed at, Google Scholar, Cross Ref

Al-Zarooni, H., & Bashir, H. (2020). An integrated ISM fuzzy MICMAC approach for modeling and analyzing electrical power system network interdependencies.International Journal of System Assurance Engineering and Management,11, 1204-1226.

Bainbridget, L. (1983), “Ironies of Automation *”, Automatica, Vol. 19 No. 6, pp. 775–779.

BEA France. (2009), “Air France 447 Final Report”, Air France 447 Final Report, No. June 2009, p. 223.

Bridger, R. (2003), Introduction to Egonomics, Engineering, Vol. 8,

Columbia Accident Investigation Board. (2003), “Report of Columbia Accident Investigation Board, Volume I”, Vol. I No. August, pp. 1–248.

Day Ronal William. (2017), Design Error A HUMAN FACTORS APPROACH, First., Taylor & Francis Group, Boca Raton London New York, New York.

Dhillon, B.S., & Liu, Y. (2006), “Human error in maintenance: a review”, Journal of Quality in Maintenance Engineering, Vol. 12 No. 1, pp. 21–36.

Digest, A.A. and Circular, I. (1978), “Secretary of Aviation Report On Tenerife Crash KLM , B-747 , PH-BUF and Pan Am B-747 N736 collision at Tenerife Airport Spain on 27 March 1977 Report dated October 1978 released by the Secretary of Civil Aviation ”, No. October.

Dix Alan. (2016), “Human-computer interaction, foundations and new paradigms”, Journal of Visual Languages and Computing, Elsevier

Dwivedi, G., Srivastava, S. K., & Srivastava, R. K. (2017). Analysis of barriers to implement additive manufacturing technology in the Indian automotive sector.International Journal of Physical Distribution & Logistics Management,47(10), 972-991.

Indexed at, Google Scholar, Cross Ref

Eckerman, I., & Børsen, T. (2021). Corporate and governmental responsibilities for preventing chemical disasters: Lessons from Bhopal. InEthics of Chemistry: From Poison Gas to Climate Engineering(pp. 113-140).

Indexed at, Google Scholar, Cross Ref

Endsley, M. R., & Robertson, M. M. (1996, October). Team situation awareness in aviation maintenance. InProceedings of the Human Factors and Ergonomics Society Annual Meeting(Vol. 40, No. 21, pp. 1077-1081). Sage CA: Los Angeles, CA: SAGE Publications.

Indexed at, Google Scholar, Cross Ref

Goel, P., Kumar, R., Banga, H. K., Kaur, S., Kumar, R., Pimenov, D. Y., & Giasin, K. (2022). Deployment of Interpretive Structural Modeling in Barriers to Industry 4.0: A Case of Small and Medium Enterprises.Journal of Risk and Financial Management,15(4), 171.

Indexed at, Google Scholar, Cross Ref

Gorane, S. J., & Kant, R. (2013). Modelling the SCM enablers: an integrated ISM?fuzzy MICMAC approach.Asia Pacific Journal of Marketing and Logistics.

Indexed at, Google Scholar, Cross Ref

Gupta, V., Acharya, P., & Patwardhan, M. (2013). A strategic and operational approach to assess the lean performance in radial tyre manufacturing in India: a case based study.International Journal of Productivity and Performance Management,62(6), 634-651.

Indexed at, Google Scholar, Cross Ref

Hobbs, A., & Williamson, A. (2002). Unsafe acts and unsafe outcomes in aircraft maintenance.Ergonomics,45(12), 866-882.

Indexed at, Google Scholar, Cross Ref

Kandasamy, W.B.V., Smarandache, F. and Kandasamy, I. (2007), “THEORY AND FUZZY MODELS”, Vol. 5 No. June 2013, pp. 1–54.

Karwowski, W. (2005), “Ergonomics and human factors: the paradigms for science, engineering, design, technology and management of human-compatible systems.”, Ergonomics, Vol. 48 No. 5, pp. 436–463.

Kavilal, E.G., Prasanna Venkatesan, S. and Sanket, J. (2018), “An integrated interpretive structural modeling and a graph-theoretic approach for measuring the supply chain complexity in the Indian automotive industry”, Journal of Manufacturing Technology Management, Vol. 29 No. 3, pp. 478–514.

Khanzode, V. V., Maiti, J., & Ray, P. K. (2012). Occupational injury and accident research: A comprehensive review.Safety science,50(5), 1355-1367.

Indexed at, Google Scholar, Cross Ref

Leamon, T. B. (1980). The organisation of industrial ergonomics—A human: machine model.Applied Ergonomics,11(4), 223-226.

Indexed at, Google Scholar, Cross Ref

Lind, S. (2008). Types and sources of fatal and severe non-fatal accidents in industrial maintenance.International Journal of Industrial Ergonomics,38(11-12), 927-933.

Indexed at, Google Scholar, Cross Ref

Mishra, N., Singh, A., Rana, N. P., & Dwivedi, Y. K. (2017). Interpretive structural modelling and fuzzy MICMAC approaches for customer centric beef supply chain: application of a big data technique.Production Planning & Control,28(11-12), 945-963.

Indexed at, Google Scholar, Cross Ref

Mohammed, I. R., Shankar, R., & Banwet, D. K. (2008). Creating flex?lean?agile value chain by outsourcing: an ISM?based interventional roadmap.Business Process Management Journal,14(3), 338-389.

Indexed at, Google Scholar, Cross Ref

Murry Jr, J. W., & Hammons, J. O. (1995). Delphi: A versatile methodology for conducting qualitative research.The review of higher education,18(4), 423-436.

Indexed at, Google Scholar, Cross Ref

National Transportation Safety Board. (2018), “Taxiway overflight Air Canada Flight 759 Airbus A320-211, C-FKCK San Francisco, California July 7, 2017”

Novakowski, N., & Wellar, B. (2008). Using the Delphi technique in normative planning research: methodological design considerations.Environment and Planning A,40(6), 1485-1500.

Indexed at, Google Scholar, Cross Ref

Onnasch, L. (2015), “Crossing the boundaries of automation - Function allocation and reliability”, International Journal of Human Computer Studies, Elsevier, Vol. 76, pp. 12–21.

Onnasch, L., Wickens, C.D., Li, H. and Manzey, D. (2014), “Human Performance Consequences of Stages and Levels of Automation”, Human Factors, Vol. 56 No. 3, pp. 476–488.

Park, J., Seager, T.P., Rao, P.S.C., Convertino, M. and Linkov, I. (2013), “Integrating risk and resilience approaches to catastrophe management in engineering systems”, Risk Analysis, Vol. 33 No. 3, pp. 356–367.

Perrow, C. (1984), “Normal Accidents”. President’s Commission on The Accident at Three Mile Island. (1979), “The Need for Change: The legacy of Three Mile Island”.

Regazzoni, D. and Rizzi, C. (2013), “Digital Human Models and Virtual Ergonomics to Improve Maintainability”, Computer-Aided Design & Applications, Italy, Vol. 11 No. 1, pp. 10–19.

Richards, D., & Stedmon, A. (2015). To delegate or not to delegate: A review of control frameworks for autonomous cars.Applied ergonomics,53, 383-388.

Indexed at, Google Scholar, Cross Ref

Roger Commission. (1986), “Challenger_Rogers_Commission_Report”, Rogers Commision Reort on Challenger’s Accident, p. 256.

Saxena, J. P., & Vrat, P. (1992). Scenario building: a critical study of energy conservation in the Indian cement industry.Technological Forecasting and Social Change,41(2), 121-146.

Indexed at, Google Scholar, Cross Ref

Shrivastava, S., Sonpar, K. and Pazzaglia, F. (2009), “Normal accident theory versus high reliability theory: A resolution and call for an open systems view of accidents”, Human Relations, Vol. 62 No. 9, pp. 1357–1390.

Singh, M. D., & Kant, R. (2008). Knowledge management barriers: An interpretive structural modeling approach.International Journal of Management Science and Engineering Management,3(2), 141-150.

Indexed at, Google Scholar, Cross Ref

Singh, R. K., Garg, S. K., & Deshmukh, S. G. (2007). Interpretive structural modelling of factors for improving competitiveness of SMEs.International Journal of Productivity and Quality Management,2(4), 423-440.

Indexed at, Google Scholar, Cross Ref

Sonar, H., Khanzode, V., & Akarte, M. (2020). Investigating additive manufacturing implementation factors using integrated ISM-MICMAC approach.Rapid Prototyping Journal,26(10), 1837-1851.

Indexed at, Google Scholar, Cross Ref

Sushil. (2012), “Interpreting the interpretive structural model”, Global Journal of Flexible Systems Management, Vol. 13 No. 2, pp. 87–106.

Thakkar, J., Kanda, A., & Deshmukh, S. G. (2008). Interpretive structural modeling (ISM) of IT?enablers for Indian manufacturing SMEs.Information Management & Computer Security,16(2), 113-136.

Indexed at, Google Scholar, Cross Ref

Warfield, J. N. (1974). Developing subsystem matrices in structural modeling.IEEE Transactions on Systems, Man, and Cybernetics, (1), 74-80.

Indexed at, Google Scholar, Cross Ref

Williams, M. (2003), “The 156-tonne Gimli Glider”, Flight Safety Australia, Vol. 7 No. 3, pp. 22–27.

Zhang, F., Fleyeh, H., Wang, X. and Lu, M. (2019), “Construction site accident analysis using text mining and natural language processing techniques”, Automation in Construction, Elsevier, Vol. 99 No. January, pp. 238–24

Received: 24-Feb-2023, Manuscript No. AMSJ-23-13257; Editor assigned: 25-Feb-2023, PreQC No. AMSJ-23-13257(PQ); Reviewed: 08-Mar-2023, QC No. AMSJ-23-13257; Revised: 28-Mar-2023, Manuscript No. AMSJ-23-13257(R); Published: 04-Apr-2023