Research Article: 2020 Vol: 19 Issue: 5

Information System of Decision Support in the Management Environment of Ecological Project

Alexey I. Shinkevich, Kazan National Research Technological University

Tatyana V. Malysheva, Kazan National Research Technological University

Elmira Sh. Shaimieva, Kazan Innovative University named after V. G. Timiryasov

Guzel I. Gumerova, Financial University under the Government of the Russian Federation

Abstract

For the sustainable development of industrial enterprises, it is necessary to optimize the project environmental management system in order to ensure resource efficient production. In this regard, the formation and development of a systematic approach to the automation of project management of the organization of ecological production systems is a priority area of scientific knowledge. The purpose of the article is to develop scientific and practical recommendations for organizing an information system of decision support in the management environment of ecological project of industrial enterprises. To form the structure of the decision support system, the methodology of conceptual modeling and the system architecture of software tools were used. As methods of simulation modeling of an alternative solution at the stage of production readiness for an ecological project, random number generation was used to determine the probabilistic potential of the enterprise. In the article, a conceptual model of an automated system for managing environmental projects of an industrial enterprise is formed, taking into account the input and output parameters of environmental friendliness of production, disturbing and controlling effects according to the project lifecycle algorithm. A structural-substantial model of information system of decision support in the management environment of ecological project of industrial enterprise has been developed. The method of generating random numbers was used to simulate a ready-made solution according to the module “Assessment of the readiness of a production system” for a subsystem of tasks and alternatives for decision-making. The research materials can be used in the development of information systems for supporting management decisions for the purposes of project management at the level of industrial enterprises and executive authorities in charge of sustainable development of production systems.

Keywords

Decision Support System, Environmental Project, Project Management, Automated Control System, Simulation, Environmental Friendliness of Production, Resource Intensity of Production.

JEL Classifications

C44, D24, M11

Introduction

An important and common global instrument for addressing environmental problems of industrial production is the development, implementation and certification of an environmental management system in compliance with international standards. The benefit of applying environmental management standards for enterprises is to reduce production costs by conserving raw materials and fuel and energy resources, organizing a waste management system and return flows of resources.

The works of many scientists are devoted to improving the environmental safety of production facilities. However, despite some scientific groundwork, a mechanism for the practical implementation of environmental management principles in the production system has not yet been developed. Using the tools of project management allows you to create a comprehensive methodology for the implementation of the project approach to greening production. The essence of the environmental project is to change the parameters of environmental friendliness of production after the completion of the project in comparison with the parameters of environmental friendliness of production before the implementation of the project. We believe that the development of decision support systems for the design of ecological production systems with a given quality should be carried out on the basis of scientific systems engineering approaches that provide for the automation and informatization of project management processes.

The purpose of the article is to develop scientific and practical recommendations for the organization of information system of decision support in the management environment of ecological project of industrial enterprise.

Literature Review

Numerous works of foreign and domestic researchers are devoted to the issues of improving the environmental friendliness of industrial production and the problems of environmental design. Interest in this topic is due to the importance of the development of intelligent systems for managing ecological production based on the scientific knowledge obtained, the derived principles and patterns, the achievements of information technology. The main directions of research in the field of technologies and mathematical modeling of project management in the field of project environmental management are determined by works of Jagtap (2020); da Silva (2017); Shinkevich et al. (2016); Kuchta & Stanek (2020); Ahmadi-Javid et al. (2019); Narayanan et al. (2020).

In order to expand knowledge about automated decision support information systems in the environmental field, Marmo et al. (2019) developed a methodology for constructing an information efficiency model to support facility management, Erskine et al. (2019) investigated individual decision making efficiency using spatial decision support systems, Rauzy & Yang (2019) formed algorithms for decision-making diagrams, Burger et al. (2018) systematizing the adoption of software decisions in the field of waste management, López-Morales (2018) examined multi-criteria decision-making in inconsistent groups of management experts. The directions of increasing resource efficiency and competitiveness of industrial production based on data mining are reflected by Malysheva et al. (2017 & 2018); Rajskaya et al. (2019); Shinkevich et al. (2018).

However, despite the extensive theoretical and methodological base and analytical data, there is a lack of research to solve the problems of adaptation of domestic enterprises to international environmental standards, their implementation and informational support of environmental projects. The lack of completeness of scientific and practical knowledge and solutions in the field under study does not allow an objective assessment of the processes of organization and management of ecological production systems.

Methodology

In order to form models of an automated control system and information system of decision support in the management environment of ecological project of industrial enterprise, the methodology of conceptual modeling and the system architecture of software tools are used, supported by the CASE-technology tools. To solve the problem of simulation, the Microsoft Excel “Analysis Package” application was used, which has a special utility for generating random numbers with different types of distributions. In the case of the random number generation is determined arbitrary discrete distribution, where the discrete random variable X - is an index of sustainability of the production system, which takes values of x1, x2,..., xn. The quantity X takes on each of the values with some probability  where the probability

where the probability  is expressed as the unit costs for the modernization of technological lines.

is expressed as the unit costs for the modernization of technological lines.

As an object of simulation were identified chemical production enterprises, which in 2017-2019 carried out the modernization of production, i.e. had costs of capital repairs of production lines. The initial data for generating random values of the environmental friendliness index of the production system are presented in Table 1.

| Table 1 Initial Data for Generating Random Numbers of the Ecological Index of the Production System | ||||

| Industrial enterprise name | Resource intensity (Ire) | Sustainability (Ieco) | Unit costs for modernization (Mpt) |

|

| Ire = [0.1] | Ieco = [0.1] | Absolute value, % | ∑ Mpti=1 | |

| LLC “ Kamaz-Energo ” | 0.341 | 0.659 | 2.764 | 0.162 |

| LLC “ Baulyuks" | 0.438 | 0.562 | 0.082 | 0.005 |

| LLC “ Armstrong Building Products ” | 0.466 | 0.534 | 1.524 | 0.088 |

| LLC “ Tatneft Presscomposite" | 0.527 | 0.473 | 0.124 | 0.007 |

| JSC “ Kvart" | 0.542 | 0.458 | 0.457 | 0.027 |

| PJSC “ Kazanorgsintez ” | 0.563 | 0.437 | 0.784 | 0.045 |

| PJSC “ Nizhnekamskshina" | 0.595 | 0.405 | 7.962 | 0.464 |

| PJSC “ Nizhnekamskneftekhim ” | 0.597 | 0.403 | 2.006 | 0.117 |

| LLC “ Elastokam" | 0.664 | 0.336 | 0.123 | 0.007 |

| LLC “ Alabuga- Volokno” | 0.726 | 0.274 | 0.002 | 0.001 |

| LLC “ Eftek ” | 0.748 | 0.252 | 0.390 | 0.023 |

| JSC “ Nizhnekamsktekhuglerod ” | 0.749 | 0.251 | 0.573 | 0.033 |

| LLC “ NZGSH ” | 0.760 | 0.240 | 0.351 | 0.021 |

Results and Discussion

An important element in the development of methods for managing environmental projects from the standpoint of systems engineering is the creation of a functional model of the project life cycle, which allows determining the stages of process management and their interrelationships. Modeling the design process makes it possible to define objects and their functions, which, if necessary, can be equipped with programmable controllers to fulfill specific goals and restrictions using computer systems. A functional model is needed to prepare technical specifications for the development of software for the implementation of an environmental project in an automated shell or control system. In relation to the project of greening production, we will use the term AEPMS – automated environmental project management system.

The basis of the AEPMS is the algorithm for the implementation of the project for the greening of industrial production, which, within the framework of an automated system, is subject to program control for the purpose of its optimal execution. The function of AEPMS is to collect, process, store and transmit information necessary to optimize the management of an environmental project using hardware, and decision making is carried out by a person or a decision maker.

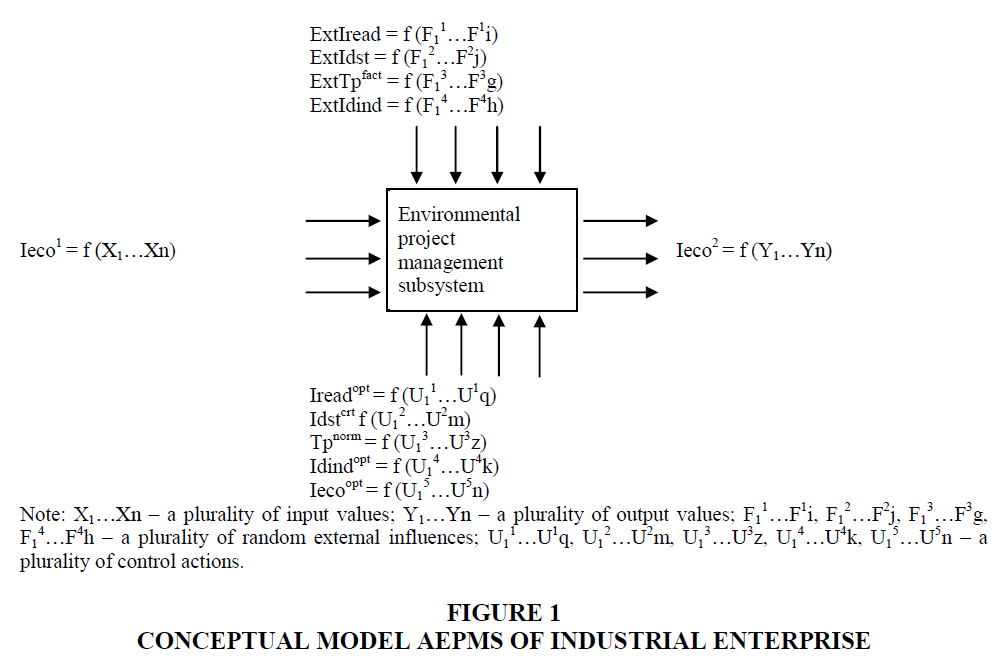

The conceptual model of the object under study - a subsystem for managing the life cycle of an ecological project in AEPMS, which describes the parameters and variables, connections between subsystems, inputs and outputs of the object, is shown in Figure 1.

The control object is affected by input values - a set of indicators X1…Xn, coming from other elements of the production system and forming the input environmental friendliness index of production (Ieco1). A random external influence F from the side of other subsystems of the production system and from beyond its limits appears on the control object. The parameters of external influence determined the indicators - externalities (Ext), influencing the formation of the following key indices:

1. Production system readiness index (Iread);

2. Risk index of destabilization of the production system (Idst);

3. Actual time for the implementation of the stages of the project life cycle (Tpfact);

4. Index of deviation of design indicators (Idind).

The generated indices ExtIread, ExtIdst, ExtTpfact, ExtIdind are a function of the set of corresponding indicators F11…F1i, F12…F2j, F13…F3g, F14…F4h – parameters reflecting the nature and magnitude of external influences.

The control impact on the control object U in order to efficiently execute the environmental project is expressed through the following indices:

1. Optimal production system readiness index (Ireadopt);

2. The index of the risk of destabilization of the production critical (Idstcrt);

3. The time for the implementation of the stages of the project life cycle normative (Tpnorm);

4. The index of deviation of design indicators optimal (Idindopt);

5. Environmental index optimal Iecoopt.

These indices are a function of the set of corresponding indicators U11…U1q, U12…U2m, U13…U3z, U14…U4k, U15…U5n – parameters set by the production system to manage environmental design in accordance with the tasks set.

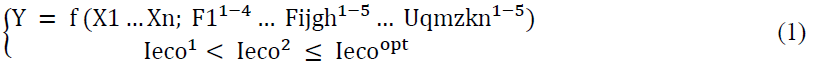

As a result of external influences (externalities) and predetermined parameters of the control object at its output generates an output value – a set of indicators Y1…Yn that form the final Index of environmental friendliness of production (Ieco2). The set of output values is in functional dependence with the input data, disturbing and control actions. Thus, the mathematical model of the AEPMS control object, the environmental design management subsystem, can be represented as a system of equations and inequalities:

Where, Ieco2= f (Y1…Yn)

When developing an AEPMS, a set of control points is determined, according to which the control system receives information from sensors that process the parameters of the current state of the object under external influences and control actions. The decision support system for environmental design management operates on the basis of information about the values and modes of operation of the control object, within the specified minimum or maximum values of the controlled parameters. Thus, we get automated decision support information system (further – ADSIS) in environmental project management of production systems. ADSIS allows you to operate with a large amount of data, provide predictive values, timely signal the state of an object, and i.e. manage the life cycle of an environmental project. ADSIS does not exclude a person from the management process, but allows him to use elements of artificial intelligence that reduce the risk of making bad decisions.

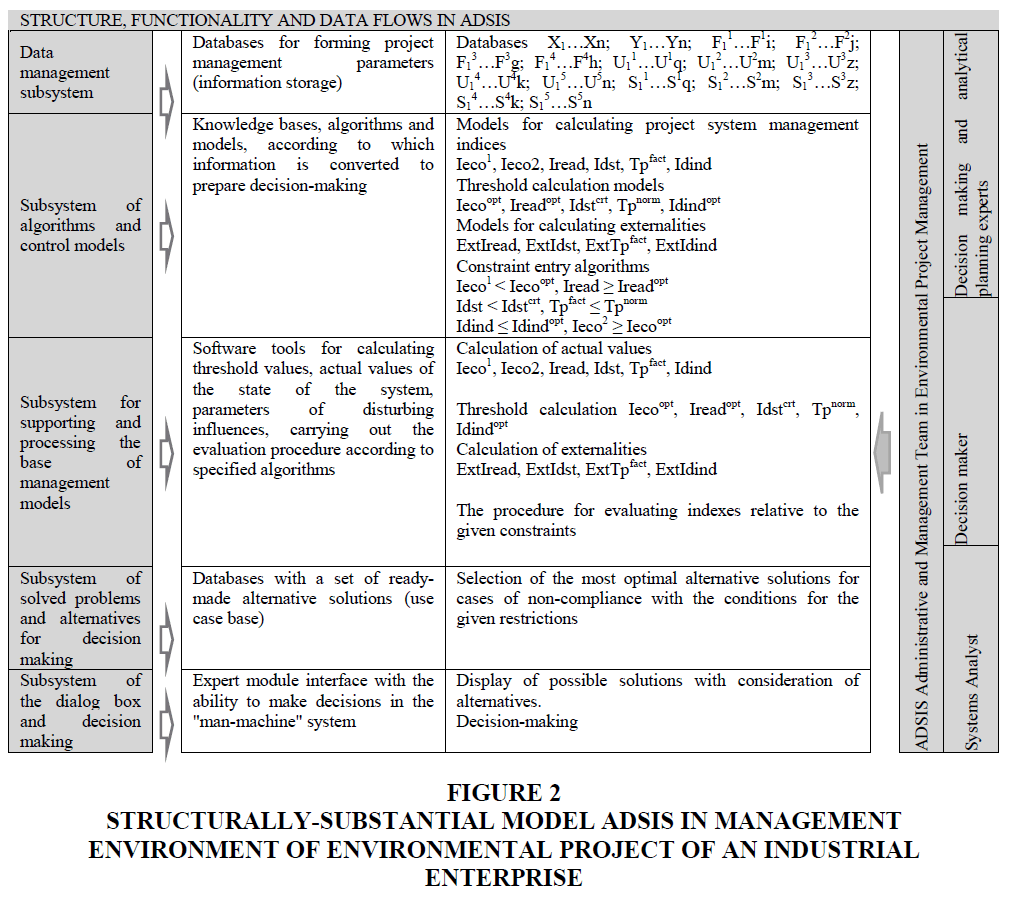

In general, ADSIS is a collection of hardware, software and organizational tools that allow you to manage information and provide support in decision-making on the lifecycle of an environmental project. The structure of the decision support information system includes five subsystems:

1. Subsystem of algorithms and control models;

2. Subsystem of support and processing of the base of management models;

3. A subsystem of solved problems and alternatives for making a decision;

4. A subsystem of the dialog box.

At the same time, the ADSIS administrative and management group is supposed to consist of the following:

1. Experts in decision making and analytical planning;

2. Decision maker;

3. Systems analyst.

Figure 2 shows the structural and content model of ADSIS, which visualizes the information and software content of subsystems, indicating databases, models, calculation and analytical procedures for the implementation of an environmental project. The values of these indices describing the current state of the system and participating in making decisions about moving along the tree of the project life cycle algorithm are formed under the influence of externalities ExtIread, ExtIdst, ExtTpfact, ExtIdind. Factors influencing environmental design need to be studied, modeled and predicted in the pre-design mode. As a result of scientific and practical research of possible externalities and modeling solutions to minimize negative externalities, the ADSIS subsystem is proposed - a database with a set of ready-made alternative solutions. Based on the precedent database carried out information to select the most optimal alternative solutions for the cases of non-compliance of the specified constraints.

Figure 2 Structurally-Substantial Model ADSIS in Management Environment of Environmental Project of an Industrial Enterprise

We will simulate a ready-made solution for the module “Assessment of the readiness of a production system” for the implementation of an environmental project for a database of alternative solutions. Under an unsatisfactory condition according to the production system availability index, when, Iread<Ireadopt, there are two options for the further route of the environmental project:

1) Returning to the previous stage of the life cycle and adjusting the project due to the lack of readiness of the system;

2) An appeal to the database of alternative solutions for the selection of ready-made solutions and their expert discussion.

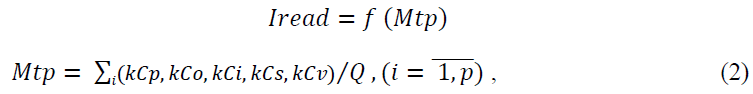

One of the solutions for the second variant of the ecological project route can be based on simulation modeling of the possibility of further progress along the tree of the project life cycle algorithm. This decision is due to the measure of the technical readiness of the production system - the scale of the ongoing modernization of engineering equipment, including the reconstruction of external networks (unit costs for overhaul of technological lines):

Where Mpt – unit costs for the modernization of technological lines of the enterprise;

Cp – expenses for the design of modernization of technological lines of the enterprise;

Co – cost of installed production equipment;

Ci – the cost of tools and working capital required for installation work;

Cs – cost of the required production area;

Cv – residual value of released equipment suitable for use on other sites or for sale to the outside;

Q – the volume of products produced on a given technological line;

k – the number of projects on modernization of technological processes;

p – the number of projects for the modernization of technological processes.

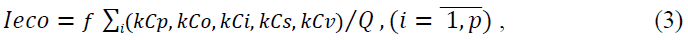

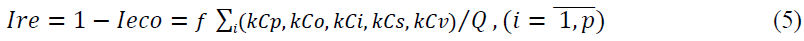

In turn, the specified target parameter of the environmental project - the Ieco environmental friendliness index is a function of the production system readiness index Iread, i.e Ieco = f (Iread). Thus, we simulate the dependence of the environmental friendliness index of the production system on the unit costs for the modernization of technological lines and it can be represented by the following mathematical expression:

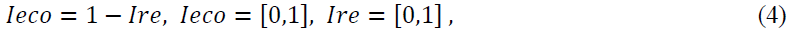

Suppose that the environmental friendliness index Ieco, considered in this case as the level of the production system's impact on the ecosystem, can be mathematically represented as:

Where, Ire – production system resource intensity index.

At the same time Ieco and Ire take a value from 0 to 1. The closer the environmental friendliness index is to 1 (Ieco → 1), the higher the environmental friendliness of the production system, i.e. the degree of impact of production on the ecosystem decreases as it approaches unity. Conversely, the closer the resource intensity index is to 0 (Ire → 0), the lower the resource intensity of the production system, i.e. the degree of impact of production on the ecosystem decreases as it approaches zero.

We write the index of resource intensity of the production system as:

Simulation modeling of one of the solutions for the module “Assessment of the readiness of the production system” for the database of alternative solutions can be based on the method of generating random numbers. Based on the dependencies obtained above, we will generate the post-design parameters of the environmental friendliness index of enterprises, using the databases on the resource intensity of production systems and unit costs for the modernization of technological lines (Table 2). The given value X is the current or input environmental friendliness index of the production system, the probability (distribution density) p is the unit cost of modernizing technological lines. We will generate up to five variants of random numbers to increase the likelihood of modeling, which we will further transform into the arithmetic mean  of the random numbers x1 – x5. The ratio of the generated random average (output sustainability index Ieco2) and the set value (input environmental index Ieco1)

of the random numbers x1 – x5. The ratio of the generated random average (output sustainability index Ieco2) and the set value (input environmental index Ieco1)  /X allows predicting a possible positive or negative result of the implementation of an environmental project.

/X allows predicting a possible positive or negative result of the implementation of an environmental project.

| Table 2 Results of Simulation Modeling of the Environmental Friendliness Index of the Production System by the Method of Generating Random Numbers | |||||||||

| Industrial enterprise name | Value | Probability | The generated random number (random discrete distribution) | Average random number |

Ratio  / X / X |

||||

| X | ? | x 1 | x 2 | x 3 | x 4 | x 5 |  |

/ ? / ? |

|

| LLC “ Kamaz-Energo ” | 0.659 | 0.162 | 0.46 | 0.66 | 0.41 | 0.66 | 0.41 | 0.52 | 0.78 |

| LLC “ Baulyuks ” | 0.562 | 0.005 | 0.41 | 0.40 | 0.41 | 0.41 | 0.66 | 0.46 | 0.81 |

| LLC “ Armstrong Building Products ” | 0.534 | 0.088 | 0.41 | 0.41 | 0.41 | 0.41 | 0.40 | 0.40 | 0.76 |

| LLC “ Tatneft-Presscomposite ” | 0.473 | 0.007 | 0.66 | 0.41 | 0.24 | 0.66 | 0.53 | 0.50 | 1.06 |

| JSC “ Kvart ” | 0.458 | 0.027 | 0.41 | 0.41 | 0.53 | 0.66 | 0.40 | 0.48 | 1.05 |

| PJSC “ Kazanorgsintez ” | 0.437 | 0.045 | 0.44 | 0.53 | 0.66 | 0.40 | 0.41 | 0.49 | 1.12 |

| PJSC “ Nizhnekamskshina ” | 0.405 | 0.464 | 0.53 | 0.41 | 0.44 | 0.44 | 0.41 | 0.44 | 1.09 |

| PJSC “ Nizhnekamskneftekhim ” | 0.403 | 0.117 | 0.41 | 0.41 | 0.66 | 0.41 | 0.41 | 0.46 | 1.13 |

| LLC “ Elastokam ” | 0.336 | 0.007 | 0.41 | 0.66 | 0.40 | 0.40 | 0.41 | 0.46 | 1.35 |

| LLC “ Alabuga- Volokno” | 0.274 | 0.001 | 0.44 | 0.41 | 0.41 | 0.53 | 0.53 | 0.46 | 1.69 |

| LLC “ Eftek ” | 0.252 | 0.023 | 0.53 | 0.53 | 0.66 | 0.40 | 0.41 | 0.51 | 2.01 |

| JSC “ Nizhnekamsktekhuglerod ” | 0.251 | 0.033 | 0.41 | 0.66 | 0.53 | 0.40 | 0.41 | 0.48 | 1.92 |

| LLC “ NZGSH ” | 0.240 | 0.021 | 0.41 | 0.41 | 0.53 | 0.44 | 0.44 | 0.44 | 1.85 |

Returning to the formulation of the simulation modeling problem, we interpret the obtained mathematical value from the standpoint of the likely readiness of the production system for the implementation of an environmental project. So, let us define that under an unsatisfactory condition according to the index of readiness of the production system Iread<Ireadopt it is possible to make a positive decision about the transition to the next stage of the project life cycle if inequality Ieco2>Ieco1 is fulfilled, that is, increasing the environmental friendliness of production as a result of the project.

In order to simulate an alternative solution for the database of alternative solutions for the module “Assessment of the readiness of the production system” in case of an unsatisfactory condition for the index of the readiness of the production system (Iread < Ireadopt), three options are possible depending on the value of the ratio Ieco2 / Ieco1 (Table 3).

| Table 3 Modeling of Alternative Solutions for the Module “Assessment of the Production System Readiness” Under the Condition Iread < Ireadopt | ||||

| Industrial enterprise name | Ieco2 | Ieco2/Ieco1 | Possible solution for the module “Assessment of the production system readiness” in case of an unsatisfactory condition according to the readiness index ( Iread<Ireadopt) | |

|

/ X / X |

|||

| LLC “ Eftek ” | 0.51 | 2.01 | Ieco2 > Ieco1 | High probability of readiness of the enterprise for an environmental project. The decision is “ Yes ” . |

| JSC “ Nizhnekamsktekhuglerod ” | 0.48 | 1.92 | Ieco2 > Ieco1 | |

| LLC “ NZGSH ” | 0.44 | 1.85 | Ieco2 > Ieco1 | |

| LLC “ Alabuga- Volokno” | 0.46 | 1.69 | Ieco2 > Ieco1 | |

| LLC “Elastokam” | 0.46 | 1.35 | Ieco2 > Ieco1 | Average likelihood of an enterprise being ready for an environmental project. The decision is “ Yes ” . |

| PJSC “ Nizhnekamskneftekhim ” | 0.46 | 1.13 | Ieco2 > Ieco1 | |

| PJSC “ Kazanorgsintez ” | 0.49 | 1.12 | Ieco2 > Ieco1 | |

| PJSC “ Nizhnekamskshina ” | 0.44 | 1.09 | Ieco2 > Ieco1 | |

| LLC “ Tatneft-Presscomposite ” | 0.50 | 1.06 | Ieco2 > Ieco1 | |

| JSC “ Kvart ” | 0.48 | 1.05 | Ieco2 > Ieco1 | |

| LLC “ Baulyuks ” | 0.46 | 0.81 | Ieco2 > Ieco1 | Low probability of the enterprise's readiness for an environmental project. The decision is “ No ” |

| LLC “ Kamaz-Energo ” | 0.52 | 0.78 | Ieco2 > Ieco1 | |

| LLC "Armstrong Building Products ” | 0.40 | 0.76 | Ieco2 > Ieco1 | |

The Table 3 shows that for four enterprises (LLC “Eftek”, JSC “Nizhnekamsktekhuglerod”, LLC “NZGSH”, and LLC “Alabuga-Volokno”) the excess of the output environmental index over the input is more than 1.5 times. In our opinion, the obtained parameters can be the basis for making a positive decision or an assumption about a high probability of the enterprise's readiness to implement an environmental project. The average probability of the readiness of the enterprise for environmental design is observed where Ieco2/Ieco1, is in the range from 1.0 to 1.5. In this case, it is also possible to make a positive decision about moving along the tree of the project life cycle algorithm (LLC “Elastokam”, PJSC “Nizhnekamskneftekhim”, PJSC “Kazanorgsintez”, PJSC “Nizhnekamskshina”, LLC “Tatneft-Presscomposite” JSC “Kvart”). Accordingly, the enterprises LLC “Baulyuks”, LLC “Kamaz-Energo”, LLC “Armstrong Building Products” as a result of environmental design, there may be no positive results of changing the environmental friendliness of production: Ieco2/Ieco1 less than 1.0. In this connection, a negative decision is likely to be made about the potential of the production system for environmental design.

The solved problem is a separate fragment of a complex decision support system. The proposed approach to modeling AEPMS from the standpoint of systems engineering can have practical application in the development of ADSIS for the implementation of projects for the greening of industrial enterprises.

Conclusion

Thus, the study made it possible to obtain the following scientific and practical recommendations for the organization of an information decision support system in the environment of environmental project management of industrial enterprises:

1. The necessity of a systematic approach to the development of decision support systems, providing for the automation and informatization of the processes of project management of complex objects, has been substantiated. A conceptual model of an automated system for managing environmental projects of an industrial enterprise has been formed, taking into account the input and output parameters of environmental friendliness of production, disturbing and control influences according to the project life cycle algorithm. The mathematical form of the AEPMS control object is presented in the form of a system of equations and inequalities.

2. Developed a structural-content model of information system of decision support in the management environment of ecological project of industrial enterprise. The structure, functionality and data flows in ADSIS are represented by five subsystems, including three repositories of design data and models, a data transformation subsystem and a dialog box for decision making. To make a decision in the “man-machine” system, an ADSIS administrative and management group is provided, which includes expert decision-making analysts, a decision maker and a system analyst.

3. By the method of generating random numbers, an imitation modeling of a ready-made solution was carried out according to the module “Assessment of the readiness of a production system” for a subsystem of tasks and alternatives for decision-making. Based on the given information on the indices of resource intensity and environmental friendliness, the unit costs for the modernization of the technological lines of the enterprise by the method of discrete distribution, the probable output value of the environmental friendliness of production was generated. Three possible options for solving the movement along the tree of the project life cycle are proposed, depending on the ratio of the input and output index of environmental friendliness of production. The research materials can be used in the development of information systems for supporting management decisions for the purposes of project management at the level of industrial enterprises and executive authorities in charge of sustainable development of production systems.

Acknowledgement

The article was supported by a grant from the Kazan Innovative University named after V. G. Timiryasov.

The research was carried out within the framework of the grant of the President of the Russian Federation for state support of leading scientific schools of the Russian Federation, project number NSH-2600.2020.6.

References

- Ahmadi-Javid, A., Fateminia, S.H., & Gemünden, H.G. (2020). A method for risk response planning in project portfolio management. Project Management Journal, 51(1), 77-95.

- Burger, C., Kalverkamp, M., & Pehlken, A. (2018). Decision making and software solutions with regard to waste management. Journal of Cleaner Production, 205, 210-225.

- da Silva, L.M. (2017). The social in corporations: the possibility of being responsible or innovative. Journal on Innovation and Sustainability, 8(4), 60-74.

- Erskine, M.A., Gregg, D.G., Karimi, J., & Scott, J.E. (2019). Individual decision-performance using spatial decision support systems: a geospatial reasoning ability and perceived task-technology fit perspective. Information Systems Frontiers, 21(6), 1369-1384..

- Jagtap, M. (2020). Predicting penetration of the project buffer time of critical chain project management (CCPM) using a linear programming approach. IIM Kozhikode Society & Management Review, 9(2), 143-151.

- Kuchta, D., & Stanek, S. (2020). Application of simulation to selecting project strategy for autonomous research projects at public universities. Administrative Sciences, 10(1), 18.

- López-Morales, V. (2018). Multiple criteria decision-making in heterogeneous groups of management experts. Information, 9(12), 300

- Malysheva, T.V., Shinkevich, A.I., Ostanin, L.M., Zhandarova, L.F., Muzhzhavleva, T.V., & Kandrashina, E.A. (2018). Organization challenges of competitive petrochemical products production. Revista ESPACIOS, 39(09).

- Malysheva, T.V., Shinkevich, A.I., Zelenkina, E.V., Denisov, I. S., Vorotyntseva, T.M., Dmitrieva, O.A., & Kurdyumov, V.I. (2017). Development and concentration efficiency study of enterprises innovation activity in real sector of economy. Eurasian Journal of Analytical Chemistry, 12(7), 1347-1356.

- Marmo, R., Nicolella, M., Polverino, F., & Tibaut, A. (2019). A methodology for a performance information model to support facility management. Sustainability, 11(24), 7007.

- Narayanan, S., Balasubramanian, S., Swaminathan, J.M., & Zhang, Y. (2020). Managing uncertain tasks in technology?intensive project environments: A multi?method study of task closure and capacity management decisions. Journal of Operations Management, 66(3), 260-280

- Rajskaya, M.V., Sagdeeva, A.A., Gusarova, I.A., Panteleeva, Y.V., Malysheva, T.V., & Ershova, I.G. (2019). Differentiated approach problems to innovative development management in Russian regions. Humanities & Social Sciences Reviews, 7(4), 1262-1268.

- Rauzy, A., & Yang, L. (2019). Decision diagram algorithms to extract minimal cutsets of finite degradation models. Information, 10(12), 368..

- Shinkevich, A.I., Malysheva, T.V., Ryabinina, E.N., Morozova, N.V., Sokolova, G.N., Vasileva, I.A., & Ishmuradova, I. I. (2016). Formation of network model of value added chain based on integration of competitive enterprises in innovation-oriented cross-sectorial clusters. International Journal of Environmental & Science Education, 11(17).