Research Article: 2024 Vol: 27 Issue: 2

Influence of Artificial Intelligence on Lateral-Transshipment: Case Study, Mono-Echelon and Two-Retailer Inventory System

Elleuch Fadoi, University of Sfax

Sarra Sghaier, University of Sfax

Semi Boudabbous, University of Sfax

Citation Information: Fadoi, E., Sarra, S., & Boudabbous, S. (2024). Influence of Artificial Intelligence on Lateral-Transshipment: Case Study, Mono-Echelon and Two-Retailer Inventory System. Journal of Management Information and Decision Sciences, 27 (2), 1-10.

Abstract

We consider a single-tier inventory system composed of two retailers in which inventory choices at each depot are coordinated in a centralized manner. Lateral transshipments are permitted as recourse actions within the same tier of the inventory system to reduce the level of Service. However, this transshipment process usually results in unwanted delivery delays. In this research work, we propose a multiobjective model of the transshipment problem composed of two-Retailers which addresses the optimization of three contradictory objectives: (1) minimize the expected overall cost, (2) maximize the service rate. Artificial Intelligence (AI) is the present and future of technology. But how can it be implemented to improve production processes and the supply chain? Artificial Intelligence opens up an infinite number of scenarios to explore and develop, such as the possibility of seizing new commercial opportunities for greater growth, profitability and sustainability. In our research work, we emphasize the cooperation between these two new notions : Artificial intelligence and Lateral Transshipment. For this, a series of simulation experiments are performed to find the best transshipment policy, in terms, of minimizing the Average Global Desservice Rate.

Keywords

Artificial Intelligence, Transshipment Policies, Complete-Pooling, Partial-Pooling, Simulation, Supply Chain Management.

Introduction

Lateral transshipment has become a common concern among business leaders in recent years. There is a lot of research on this area. It is defined as the redistribution of inventory from retailers with available inventory to retailers who cannot meet customer demands or to retailers who expect large losses due to high risk (Kukreja et al., 2001). The work of (Rudi et al., 2001) examines a periodic inventory policy in an inventory system consisting of a single echelon and two retailers. And they extends the research to a multi-retailer case from that of (Kukreja et al. 2001). The emergency lateral transshipment model of repairable products was analyzed by Minner et al. (2003) for the case of the two-echelon inventory system Disney et al. (2003) consider a single-echelon continuous review inventory system which contains n depots and takes the expensive consumable product as the object, study the one-to-one lateral transshipment model. They Works on the optimal ordering policy of sellers in the presence of lateral transshipment circumstances and they provide a new decision rule for lateral transshipment of the system and prove that it can determine the transshipment size as well as some important issues. Marquez et al. (2004) analyze the emergency lateral transshipment policy between the two-tier continuous review inventory system which uses the policy. They conduct a quantitative analysis of the value of the lateral transshipment policy of regional inventory distribution systems, which consist of a distribution center and several retail outlets. Zhong et al. (2007) develop a batch ordering policy in a single-echelon, multi-location cross-docking inventory system Marquez et al. (2004) and they study the inventory management model of cluster supply chain system with the existence of emergency lateral transshipment (Min et al., 2010).

Silbermayr et al. (2017) investigated the problem of emergency lateral transshipment with environmental sustainability. The research of Nakandala et al. (2017) focuses on the study of an emergency lateral transshipment model for perishable products in a fresh produce supply chain. This research is concerned with applying a more comprehensive transshipment decision method to help the practitioner make profitable decisions. Timajchi et al. (2019) discussed an inventory flow problem with a transshipment of pharmaceutical items. Feng et al. (2018) analyzed such advanced research to study emergency lateral transshipment and preventive transshipment in a comparable partially delayed setting. Dehghani & Abbasi (2018) propose a policy of emergency transshipment of perishable foodstuffs in supply chains. They developed a heuristic solution to calculate performance metrics. Timajchi et al. (2019) analyzed deterioration in pharmaceuticals and proposed a side-shift option to meet demand while simultaneously minimizing costs and accidental losses. Yi found the optimal emergency transshipment and replenishment decisions within a decentralized inventory system framework. They build a multistep stochastic model that captures the uncertainty of demand and changing customer behaviour.

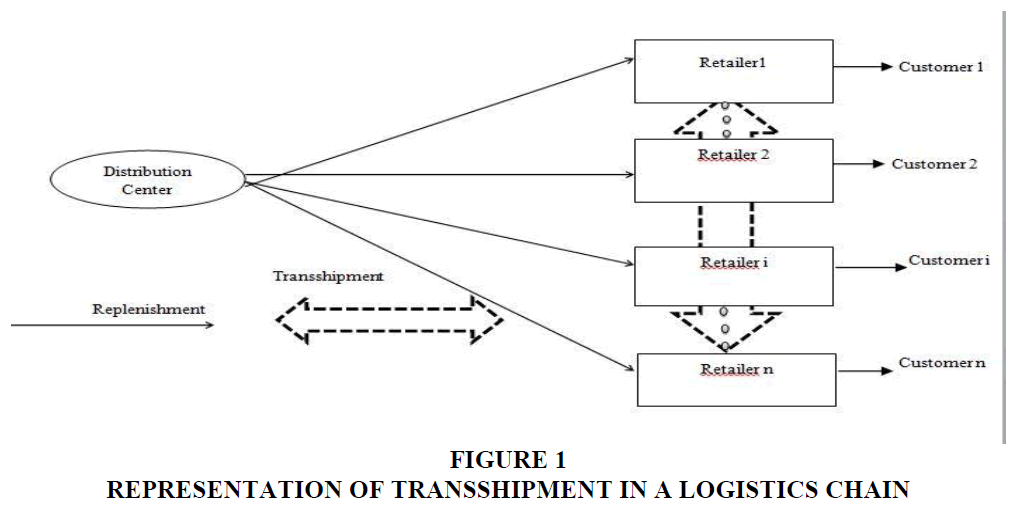

This collaboration usually takes the form of "Transshipment-Lateral", also simply called "Transshipment" (Figure 1), which allows stocks to be pooled to alleviate the uncertainties relating to requests arriving at sites of the same level, and, thus to obtain effects analogous to those of a consolidation of stocks. Transshipment can also generate flexibility of service.

Today technology is becoming crucial in companies ‘life. It’s transforming human capital and economic (Verma & Sood, 2018). Particular and firms are taking advantage from AI. In the next decade, Sabir et al. (2023) mentioned that more than 1 billion people worldwide will be replaced by AI. For business, AI allows companies to raise them revenues, manage, collect, evaluate and stock big data (exemple AI). AI is an intelligence made by humans and implemented on machines. It uses the “cognitive and affective” parts of the human mind. Practioners tried to have a creative machine that act as human, learn to break with issues and communicate with the environment (Verma & Sood, 2018; Jain & Aggrawal, 2020). Human have created AI in order to replace them (Min, 2010). Such “thinking machine”. Previous research has mentioned the importance of technology in giving and collecting informations, finance, moving goods, delivery, for customers management but AI seems to be more specific and more advanced (Richey et al., 2023).

AI reshapes supplychain and logistics. Some companies use “drones” for product delivery, tracking orders and decrease manual work (Jain & Aggarwal, 2020). For business, AI allows companies to raise them revenues, manage, collect, evaluate and stock big data.

AI is an intelligence made by humans and implemented on machine. It uses the “cognitive and affective” parts of the human mind. Practioners tried to have a creative machine that act as human, learn to break with issues and communicate with the environment (Verma & Sood, 2018; Jain & Aggrawal, 2020). AI reshapes supplychain and logistics. Some companies use “drones” for product delivery, tracking orders and decrease manual work (Jain & Aggarwal, 2020).

Today technology is becoming crucial in companies ‘life. It’s transforming human capital and economic (Verma & Sood, 2018). Particular and firms are taking advantage from AI. In the next decade, Sabir et al. (2023) mentioned that more than 1 billion people worldwide will be replaced by AI (Liao et al., 2020).

Qualitative Study

Research Design

The relation between AI and transshipment doesn’t exist in the literature, that’s why we tried to examine it through an exploratory study (Pessot et al., 2023).

The aim of this qualitative study is to investigate the impact of AI on transshipment. We realised an in-depth interview with the company X which is in Tunisia. The X online interview helps us to understand more the functioning of the company.

Our interview follows Lincoln and Guba recommendations for credibility, transferability, dependability and confirmability when using qualitative study. So, we first, released the interview, then transcribed the data. We used thematic analysis to divide the findings into categories depending on common divisor Table 1.

| Table 1 Qualitative Analysis | |

| Asked Question | Answer |

| What is the main order’s lead time from the central warehouse to retailer? | Constant |

| What is the main order‘s quantity to be delivered from central warehouse to retailer? | 36 |

| What is the distance between warehouse and retailer? | 29 km |

| What is the law of random demand? | N (250,50) |

| What is the Quantity of unsold stock? | Stock Level-Demand |

Description of the Problem

Our goal is to minimize the total cost of the two-retailer inventory system by improving the service rate of each warehouse by decreasing the out-of-stock quantity. This results in an improvement in average overall profit across the entire inventory system. This can be done by applying cooperation between these retailers called « Emergency Lateral transshipment », or by applying the transshipment policy, “Complete-Pooling” or “Partial Pooling”. Each time we modified the threshold of the “Partial-Pooling” transshipment policy, the unit cost of transshipment and the periodicity T. We consider an inventory system consisting of two identical retailers (i = 1, 2) owned or operated by the same entity and a manufacturer that sells to these retailers during a single period (Merkert & Hoberg, 2023).

Parameters

The notations used in this paper are as follows:

n: Number of retailers;

i: Retailer index (counter) with i = 1, 2;

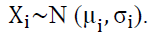

DiT: Demand during the periodicity T at the retailer i (random variable) follows the normal law (μ,σi).These demands are independent and identically distributed (i. i. d);

Qi: The quantity of supply for the retailer i;

R: Inventory position revision period, which is divided into k intervals of time of periodicity T;

Si: Maximum level of stock at retailer i at the start of the supply cycle;

PSiT: Stock position at retailer i at each time period T;

TDGi: Average Global Desservice Rate for i retailers;

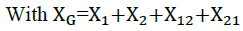

(XG): Average Global Profit for the two retailers i, with i = 1, 2.

(XG): Average Global Profit for the two retailers i, with i = 1, 2.

Vi: Unit selling price for each site i, with i = 1.2.

C = C12 = C21: Unit cost of transshipment whatever the direction of lateral transfer,

Cpi: Unit cost of shortage for such a site i.

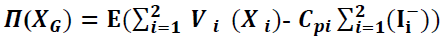

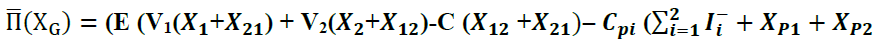

Mathematical Function of Average Global Profit

The Average Global Profit function of our centralized inventory system for two “Without-Transshipment” retailers contains the selling price of the customer product and the cost of the shortage.

It takes the general form of the equation 1.

(1)

(1)

Case “With-Transshipment”

Conceptual Model

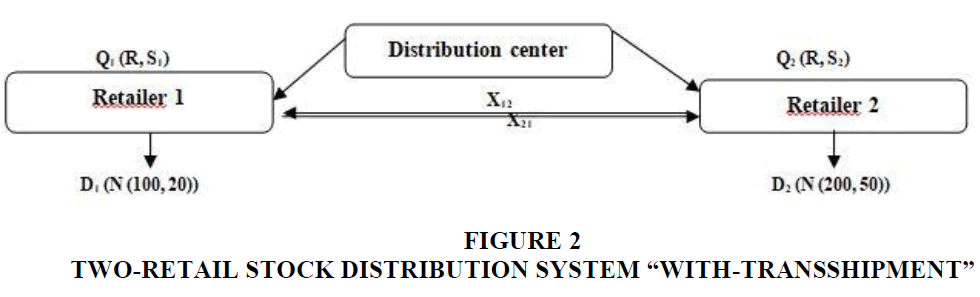

If one of the two retailers is in the out-of-stock position, then cooperation can be established between them to meet their random demand. This collaboration usually takes the form of "Transshipment-Lateral", also quite simply known as "Transshipment" (Figure 2), which allows stocks to be pooled to alleviate the uncertainties relating to demands arriving at sites of the same level (Paterson et al., 2011).

In this section, we will study two transshipment policies successively named "Complete-Pooling" and "Partial-Pooling".

Transshipment Policies

“Complete-Pooling”

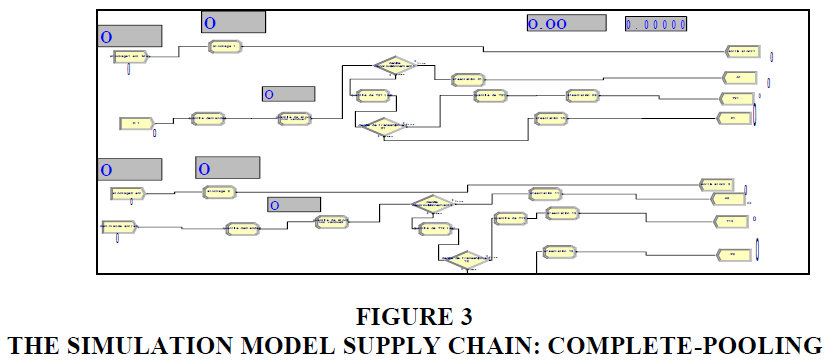

For the first transshipment policy called “Complete-Pooling” the modeling by the ARENA 16.0 software can be presented in Figure 3.

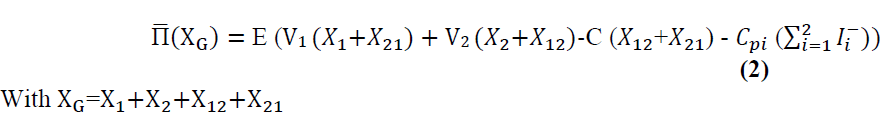

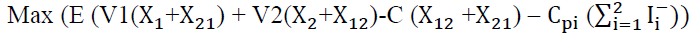

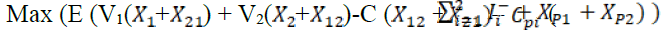

Mathematical Function of Average Global Profit

The function of Average Global Profit for our centralized system composed of two levels and two retailers, by integrating transshipment and applying the "Complete-Pooling" policy, can be formulated by the equation 2.

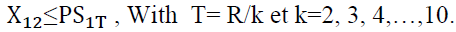

Objective Function

The objective is to identify the most economically profitable transshipment policy for a centralized system over a finite time horizon R, by seeking the lowest possible Average Global Desservice Rate.

For this, the objective function of the "Complete-Pooling" transshipment policy will be defined in the form of the equation (3)

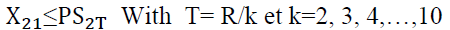

S/C

(3)

(3)

With

and k :being the number of periodicities, avec k=2, 3, 4,…,10. And

and k :being the number of periodicities, avec k=2, 3, 4,…,10. And

Partial-Pooling

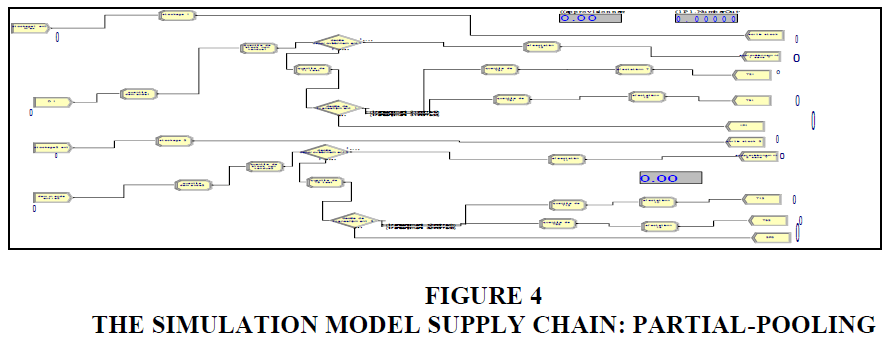

For the second transshipment policy called “Partial-Pooling” the modeling by the ARENA 16.0 software can be presented in Figure 4.

Mathematical Function of Average Global Profit

The function of the average global profit apply the transshipment policy "Partial-Pooling", requires the integration of the quantity lost for each retailer after the accumulation of stock.

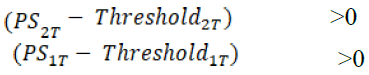

The average global profit function will be formulated by the equation (4).

(4)

(4)

And Xp1: The quantity lost for retailer 1 after the accumulation of stock with partial transshipment.

Xp2: The quantity lost for retailer 2 after the accumulation of stock with partial transshipment.

Objective Function

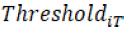

For the second transshipment policy (“Partial-Pooling”), the objective function will be defined in the form of equation (5).

S/C

With  = Twice the Demand, Next Demand and 30% of

= Twice the Demand, Next Demand and 30% of

And XP1: The quantity lost for retailer 1 after the accumulation of stock with partial transshipment.

And XP2: The quantity lost for retailer 2 after the accumulation of stock with partial transshipment.

With T= R/k et k=2, 3, 4,…,10.

Strictly positive integer, ∀i=1, 2

Strictly positive integer, ∀i=1, 2

With

and k :being the number of periodicities, With k=2, 3, 4,…,10.

and k :being the number of periodicities, With k=2, 3, 4,…,10.

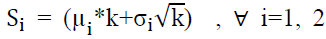

Simulation Results

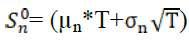

We recall that, according to Aggrawal, 2020, the initial replenishment level for a demand which follows the normal law (N ( i, i))of the mean and the standard deviation, will take the form of the equation and will be calculated by applying equation 6.

(6)

(6)

With:

T: number of periods

μi : average demand during the period T of retailer i, with i=1, 2.

σi: standard deviation of demand of retailer i, with i=1, 2.

We have considered in all the examples of our research that:

The revision period R = 30 days;

The unit sale price for retailer 1 equal to 75 $ and that of retailer 2 is worth 100$;

The unit cost of rupture whatever the site is equal to 20 $;

The unit cost of transshipment =2 $, 0.5 $, k = 2, 3, 4,…, 10 (Table 2).

| Table 2 Determination of Average Global Desservice Rate | |||||

| k | Without- transshipment | Complete- Pooling | Partial-Pooling | ||

| Twice the Demand | Next Demand | Security Stock=30% of PSiT | |||

| 2 | 0.600 | 0.350 | 0.320 | 0.110 | 0.050 |

| 3 | 0.700 | 0.490 | 0.312 | 0.087 | 0.040 |

| 4 | 0.550 | 0.179 | 0.128 | 0.063 | 0.022 |

| 5 | 0.770 | 0.307 | 0.251 | 0.077 | 0.057 |

| 6 | 0.650 | 0.465 | 0.357 | 0.095 | 0.070 |

| 7 | 0.765 | 0.505 | 0.412 | 0.203 | 0.100 |

| 8 | 0.9825 | 0.610 | 0.502 | 0.297 | 0.182 |

| 9 | 1.005 | 0.870 | 0.620 | 0.392 | 0.207 |

| 10 | 1.121 | 0.900 | 0.595 | 0.437 | 0.275 |

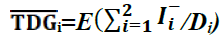

In this section of our research work, we formulate the average overall Disservice rate for the two retailers, which designates the rate of the quantity satisfied to meet customer demand instead of being a quantity out of stock, by the equation (7).

(7)

(7)

From the analysis of Table 2, we note that the average overall Downtime rate has a close relationship with the change in periodicity and that it increases beyond k = 4, and takes the form of an increasing curve.

But we analyze the effect of transshipment policies on minimizing the average overall service rate. We then notice that the first transshipment policy “Complete-Pooling” aims to reduce the rate of the quantity of unsatisfied customer orders whatever the periodicity and for example for k = 3 this reduction is worth from 0.700 to 0.490 and that the second “The “Partial-Pooling” policy aims to reduce it as quickly as possible and this will be explicit for the last transshipment threshold which is equal to the Safety Stock = 30% of the PSi.

We then see that the collaboration between two sites 1 and 2 increases the probability of cycles without breaks in each warehouse of the planned transshipment quantity transferred from 2 to 1 and likewise from 1 to 2 for an increase in the quantity to be ordered for the site 1 and for site 2. Which results in an improved probability of customer satisfaction after the application of transshipment.

Conclusion

The number of publications on Lateral transshipment studies has expanded the last years. Investigation on the concept appeared since 1990s. Nevertheless, most of the research didn’t study the impact of artificial intelligence on lateral transshipment. In fact, Companies need to go for the new technology’ standards to meet the industry demands. This challenge can make decline in revenues if they ignore innovative technology. A lot of firms have started applying « Artificial Intelligence » in them strategy. That helped them to improve them businesses. This “new digital tools” improve the data for a real-time supply chain and a better decision-making. Recognized that AI can boost to take efficient and effective decision. Although the importance of applying AI in the industry is a necessity, we recognize that human manager is also needed and important for the functioning of the company. AI will not make human obsolete by the complete each other.

In addition to looking to a new relation in the literature, our study can reshape lateral-Transshipment model and facilite the interaction between warehouses. So, it will reduce transportation cost. The main benefit of our model is that it is very easy to use, accessible, clear for purchasing, supply chain and logistics practitioners.

Future research needs to look at how AI can change transshipment process? How can AI develop a more flexible transshipment network? Moreover, future research should investigate on how to create smart transshipment that can adapt, by itself, to environment dynamics. What role can AI play to predict data for transshipment?.

References

Dehghani, M., & Abbasi, B. (2018). An age-based lateral-transshipment policy for perishable items. International Journal of Production Economics, 198, 93-103.

Indexed at, Google Scholar, Cross Ref

Disney, S. M., Potter, A. T., & Gardner, B. M. (2003). The impact of vendor managed inventory on transport operations. Transportation research part E: logistics and transportation review, 39(5), 363-380.

Feng, P., Wu, F., Fung, R. Y., & Jia, T. (2018). Evaluation of two transshipment policies in a two-location decentralized inventory system under partial backordering. Transportation Research Part E: Logistics and Transportation Review, 118, 207-224.

Indexed at, Google Scholar, Cross Ref

Jain, P., & Aggarwal, K. (2020). Transforming marketing with artificial intelligence. International Research Journal of Engineering and Technology, 7(7), 3964-3976.

Kukreja, A., Schmidt, C. P., & Miller, D. M. (2001). Stocking decisions for low-usage items in a multilocation inventory system. Management Science, 47(10), 1371-1383.

Indexed at, Google Scholar, Cross Ref

Liao, Y., Li, J., Hu, X., Li, Y., & Shen, W. (2020). Application of lateral transshipment in cost reduction of decentralized systems. Sustainability, 12(12), 5081.

Indexed at, Google Scholar, Cross Ref

Marquez, A. C., Bianchi, C., & Gupta, J. N. (2004). Operational and financial effectiveness of e-collaboration tools in supply chain integration. European Journal of Operational Research, 159(2), 348-363.

Merkert, R., & Hoberg, K. (2023). Global Logistics and Supply Chain Strategies for the 2020s: Vital Skills for the Next Generation. Springer.

Indexed at, Google Scholar, Cross Ref

Min, H. (2010). Artificial intelligence in supply chain management: theory and applications. International Journal of Logistics: Research and Applications, 13(1), 13-39.

Indexed at, Google Scholar, Cross Ref

Minner, S., Silver, E. A., & Robb, D. J. (2003). An improved heuristic for deciding on emergency transshipments. European Journal of Operational Research, 148(2), 384-400.

Nakandala, D., Lau, H., & Shum, P. K. (2017). A lateral transshipment model for perishable inventory management. International Journal of Production Research, 55(18), 5341-5354.

Indexed at, Google Scholar, Cross Ref

Paterson, C., Kiesmüller, G., Teunter, R., & Glazebrook, K. (2011). Inventory models with lateral transshipments: A review. European Journal of Operational Research, 210(2), 125-136.

Indexed at, Google Scholar, Cross Ref

Pessot, E., Zangiacomi, A., Marchiori, I., & Fornasiero, R. (2023). Empowering supply chains with Industry 4.0 technologies to face megatrends. Journal of Business Logistics, 44(4), 609-640.

Richey Jr, R. G., Chowdhury, S., Davis‐Sramek, B., Giannakis, M., & Dwivedi, Y. K. (2023). Artificial intelligence in logistics and supply chain management: A primer and roadmap for research. Journal of Business Logistics, 44(4), 532-549.

Indexed at, Google Scholar, Cross Ref

Rudi, N., Kapur, S., & Pyke, D. F. (2001). A two-location inventory model with transshipment and local decision making. Management science, 47(12), 1668-1680.

Sabir, A. A., Ahmad, I., Ahmad, H., Rafiq, M., Khan, M. A., & Noreen, N. (2023). Consumer acceptance and adoption of AI robo-advisors in FinTech industry. Mathematics, 11(6), 1311.

Silbermayr, L., Jammernegg, W., & Kischka, P. (2017). Inventory pooling with environmental constraints using copulas. European Journal of Operational Research, 263(2), 479-492.

Indexed at, Google Scholar, Cross Ref

Timajchi, A., Al-e-Hashem, S. M. M., & Rekik, Y. (2019). Inventory routing problem for hazardous and deteriorating items in the presence of accident risk with transshipment option. International journal of production economics, 209, 302-315.

Indexed at, Google Scholar, Cross Ref

Verma, P., & Sood, S. K. (2018). Fog assisted-IoT enabled patient health monitoring in smart homes. IEEE Internet of Things Journal, 5(3), 1789-1796.

Indexed at, Google Scholar, Cross Ref

Zhong. Y., X. Jia, and X. Li. ( 2007). “Systems dynamics,” Science Press, Beijing.

Received: 17-Jan -2024, Manuscript No. jmids-24-14366; Editor assigned: 19-Jan -2024, Pre QC No. jmids-24-14366 (PQ); Reviewed: 25- Jan-2024, QC No. jmids-24-14366; Published: 28-Jan-2024