Research Article: 2024 Vol: 27 Issue: 3

Influence of Artificial Intelligence on Lateral-Transshipment

Elleuch Fadoi, Sfax University

Sarra Sghaier, Sfax University

Sami Boudabbous, Sfax University

Citation Information: Fadoi, E., Sghaier, S., & Boudabbous, S. (2024). Influence of artificial intelligence on lateral-transshipment. Journal of Management Information and Decision Sciences, 27(3), 1-11.

Abstract

We consider a single-tier inventory system composed of two retailers in which inventory choices at each depot are coordinated in a centralized manner. Lateral transshipments are permitted as recourse actions within the same tier of the inventory system to reduce the level of Service. However, this transshipment process usually results in unwanted delivery delays. In this research work, we propose a multiobjective model of the transshipment problem composed of two-Retailers which addresses the optimization of three contradictory objectives: (1) minimize the expected overall cost, (2) maximize the service rate. Artificial Intelligence (AI) is the present and future of technology. But how can it be implemented to improve production processes and the supply chain? Artificial Intelligence opens up an infinite number of scenarios to explore and develop, such as the possibility of seizing new commercial opportunities for greater growth, profitability and sustainability. In our research work, we emphasize the cooperation between these two new notions: Artificial intelligence and Lateral Transshipment. For this, a series of simulation experiments are performed to find the best transshipment policy, in terms, of minimizing the Average Global Desservice Rate

Keywords

Artificial Intelligence, Transshipment Policies, Complete-Pooling, Partial-Pooling, Simulation, Supply Chain Management.

Introduction

Lateral transshipment has become a common concern among business leaders in recent years. There is a lot of research in this area. It is defined as is the transfer of goods and merchandise from one warehouse to another located on the same line, usually to avoid customs duties or tariffs. In international trade, it is often used to bypass trade barriers or to avoid political instability in the destination country (Kukreja et al., 2001). According to the work of Feng et al. (2019) this retailer cooperation tool is frequently used in retail stores such as clothing, toys, etc. Managers in this sector have been encouraged to share stocks for better performance. Marquez et al. (2004) studied the cooperation policy between retailers: ''emergency lateral transshipment'' between the continuous type review inventory system at two retailers. They carry out a quantitative analysis of the interest of the policy of lateral transshipment of systems between regions of the same level, consisting of a distribution center and several points of sale. Zhong et al. (2007) developed an ordering policy for products transshipped in batches in an inventory system composed of a single echelon and multi-retailers Marquez et al. (2004) and studied the inventory management model of 'a clustered supply chain system with the existence of emergency transshipment application (Paterson et al., 2011).

However, none of this research has taken into account the support of the same level in a supply chain, in particular that of competitors (Tang et al., 2018).

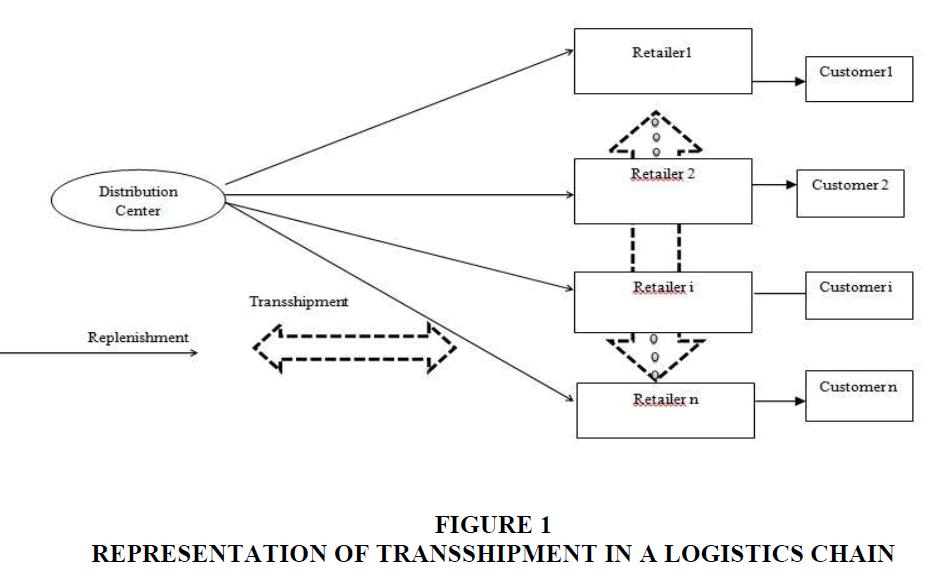

Silbermayr et al. (2017) studied the problem of emergency lateral transshipment with environmental sustainability. A main line of research related to our work concerns inventory decisions in transshipment. Inventory sharing by transshipment is one of the emergency methods used to reduce totally and/or partially lost sales and inventory distress. Research by Nakandala et al. (2017) focus on the analysis of an emergency lateral transshipment model for perishable products over time in a supply chain of fresh consumer products. This research aims to apply the decision method through the application of complete pooling which aims to help the practitioner make profitable decisions. Timajchi et al. (2019) discussed a problem of physical flows of stored products of pharmaceutical types. Feng et al. (2018) analyzed this advanced research in the field of Transshipment in making such a combination between emergency and preventive transshipment in a comparable partially delayed context. Dehghani & Abbasi (2018) and Timajchi et al. (2019) analyzed the spoilage of perishable products and proposed a lateral shift option to meet demand while simultaneously minimizing transportation and distribution costs and random accidental losses. Yi found the optimal Transshipment-Lateral and emergency replenishment decisions under a decentralized inventory system framework. They build a multi- step random model that focuses primarily on demand uncertainty and changing customer behavior. This collaboration between different retailers at the same level generally takes the form of “Lateral Transshipment”, presented in (Figure 1).

Today technology is becoming crucial in companies ‘life. It’s transforming human capital and economic. Artificial intelligence is any computer system capable of reproducing human intelligence from a mass of conglomerated data (Liao et al., 2020).

There are several types of artificial intelligence. In logistics and transport, you will often find two of them, which are:

• Machine learning, or “automatic learning”. This AI technique involves letting algorithms discover recurring patterns in a set of data. Thanks to this analysis, the algorithms can then learn autonomously to perform a task, or to make predictions (Minner et , 2003).

• Deep learning, this technique is based on the neural network The AI algorithm is then capable of mimicking the actions of the human brain, to solve complex problems (such as, for example, facial recognition, or driving autonomous cars) (Verma & Sood, 2018). Particular and firms are taking advantage from AI. In the next decade, Sabir et al. (2023) mentioned that more than 1 billion people worldwide will be replaced by AI. For business, AI allows companies to raise them revenues, manage, collect, evaluate and stock big data (exemple AI). AI is an intelligence made by humans and implemented on machines (Rudi et al., 2001). It uses the “cognitive and affective” parts of the human mind. Practioners tried to have a creative machine that act as human, learn to break with issues and communicate with the environment (Verma & Sood, 2018; Jain & Aggrawal, 2020). Human have created AI in order to replace them (Min, 2010). Such “thinking machine” Previous research has mentioned the importance of technology in giving and collecting informations, finance, moving goods, delivery, for customers management but AI seems to be more specific and more advanced (Richey et al. 2023).

AI reshapes supplychain and logistics. Some companies use “drones” for product delivery, tracking orders and decrease manual work (Jain & Aggarwal, 2020). For business, AI allows companies to raise them revenues, manage, collect, evaluate and stock big data.

AI is an intelligence made by humans and implemented on machine. It uses the “cognitive and affective” parts of the human mind. Practioners tried to have a creative machine that act as human, learn to break with issues and communicate with the environment (Verma & Sood, 2018; Jain & Aggrawal, 2020). AI reshapes supplychain and logistics. Some companies use “drones” for product delivery, tracking orders and decrease manual work (Jain & Aggarwal, 2020).

Today technology is becoming crucial in companies ‘life. It’s transforming human capital and economic (Verma & Sood, 2018). Particular and firms are taking advantage from AI. In the next decade, Sabir et al. (2023) mentioned that more than 1 billion people worldwide will be replaced by AI.

Qualitative Study Research Design

The relationship between AI and transshipment does not exist in the literature, which is why we tried to examine it through an exploratory study.

The objective of this qualitative study is to study the impact of AI on transshipment. We carried out an in-depth interview with companies located in Tunisia. The online interview helps us better understand how these companies operate (Pessot et al., 2023).

Our interview follows Lincoln and Guba's recommendations for credibility, transferability, dependability, and conformability when using a qualitative study. So we first published the interview and then transcribed the data. We used thematic analysis to divide the results into categories based on a common divisor.

Respondent data was collected from December 19, 2023 to January 27, 2024 with 37 Tunisian companies applying cooperation between Transshipment-Lateral and Artificial Intelligence.

The demographic data collected includes several categories, namely the types of activity, sector of work, company size, etc (Table 1).

| Table 1 Qualitative Analysis | |

| Asked Question | Answer |

| What is the main order’s lead time from the central warehouse to retailer? | Constant |

| What is the main order‘s quantity to be delivered from central warehouse to retailer? | According to the law and the company |

| What is the distance between warehouse central and retailer? | Longer than that between different retailers of the same level |

| What is the law of random demand? | N (µ,σ), P ( k) |

Qualitative Analysis

The objective of these companies is to minimize the total cost of the inventory system at two retailers by improving the service rate of each warehouse by decreasing the quantity out of stock with the application of Intelligence. 79% of business leaders consider the lack of visibility into their supply chain as their main concern. They would like to have clear visibility across the entire supply chain in order to be able to react in the event of unforeseen events (Min, 2010).

The logistics chain includes different stages which can be complex to manage, in particular the problem of the last mile. The use of technology based on artificial intelligence makes it possible to optimize each of these steps (Disney et al., 2003).

Inventory management is a complex issue these days and managing the right stock in the right place at the right time can be a real headache.

Based on historical data, orders and current stocks, Artificial Intelligence predicts the needs of the entire network and suggests optimized decisions (purchases, transfers, etc.). It will thus identify the products that sell the fastest or the slowest and model a more precise inventory accordingly. This makes it possible to adjust stocks to avoid shortages and limit excess merchandise. Artificial Intelligence will also be able to anticipate consumers' purchasing intentions based on different elements such as the weather, events, time of day, etc. This is very useful for predicting the right stocks that will be available at the right time and thus reducing the delivery time to the customer who will be more satisfied.

In Tunisia, many companies have access to Artificial Intelligence in logistics. But, what are the gains?

According to our questionnaire, of these Tunisian companies which make a collaboration between Artificial Intelligence and transshipment we will conclude that, this combination targets:

• Achieve better purchasing performance

• Ensure better stock availability

• Ensure a reduction in transport costs

• Cause a drop in the value of stocks

Thanks to machine learning, artificial intelligence is already capable of predicting the purchasing behavior of your customers. The technology will analyze internal information from

your warehouses (orders placed, products ordered, etc.) and external data from the Internet (forums, social networks, forecast studies, etc). By cross-referencing them, Artificial Intelligence is then able to predict future order peaks.

Thanks to these predictions, you can anticipate stock shortages and avoid overstocking by adjusting your supply strategy.

According to our questionnaire, we find the following answer: By connecting robots to an artificial intelligence computer system, they are able to put products into stock when they arrive, or to scan them, to take inventory in an automated manner.

And also, Thanks to this application, you can optimize the human resources available to you in your supply chain, and limit stock errors. In warehouses where storage is done at height, you also avoid the risk of handling accidents, since your logistics providers no longer have to go to places that are difficult to access.

Conclusion

The number of publications on Lateral transshipment studies has expanded the last years. Investigation on the concept appeared since 1990s. Nevertheless, most of the research didn’t study the impact of artificial intelligence on lateral transshipment. In fact, Companies need to go for the new technology’ standards to meet the industry demands. This challenge can make decline in revenues if they ignore innovative technology. A lot of firms have started applying « Artificial Intelligence » in them strategy. That helped them to improve them businesses. This “new digital tools” improve the data for a real-time supply chain and a better decision-making. Pessot recognized that AI can boost to take efficient and effective decision. Although the importance of applying AI in the industry is a necessity, we recognize that human manager is also needed and important for the functioning of the company. AI will not make human obsolete by the complete each other

In addition to looking to a new relation in the literature, our study can reshape lateral- Transshipment model and facilite the interaction between warehouses. So, it will reduce transportation cost. The main benefit of our model is that it is very easy to use, accessible, clear for purchasing, supply chain and logistics practitioners.

Future research needs to look at how AI can change transshipment process? How can AI develop a more flexible transshipment network? Moreover, future research should investigate on how to create smart transshipment that can adapt, by itself, to environment dynamics. What role can AI play to predict data for transshipment?.

References

Dehghani, M., & Abbasi, B. (2018). An age-based lateral-transshipment policy for perishable items. International Journal of Production Economics, 198, 93-103.

Indexed at, Google Scholar, Cross Ref

Disney, S. M., Potter, A. T., & Gardner, B. M. (2003). The impact of vendor managed inventory on transport operations. Transportation research part E: logistics and transportation review, 39(5), 363-380.

Indexed at, Google Scholar, Cross Ref

Feng, P., Wu, F., Fung, R. Y., & Jia, T. (2018). Evaluation of two transshipment policies in a two-location decentralized inventory system under partial backordering. Transportation Research Part E: Logistics and Transportation Review, 118, 207-224.

Indexed at, Google Scholar, Cross Ref

Feng, P., Wu, F., Fung, R. Y., Jia, T., & Zong, W. (2019). The order and transshipment decisions in a two-location inventory system with demand forecast updates. Computers & Industrial Engineering, 135, 53-66.

Indexed at, Google Scholar, Cross Ref

Olson, C., & Levy, J. (2018). Transforming marketing with artificial intelligence. Applied Marketing Analytics, 3(4), 291-297.

Kukreja, A., Schmidt, C. P., & Miller, D. M. (2001). Stocking decisions for low-usage items in a multilocation inventory system. Management science, 47(10), 1371-1383.

Indexed at, Google Scholar, Cross Ref

Liao, Y., Li, J., Hu, X., Li, Y., & Shen, W. (2020). Application of lateral transshipment in cost reduction of decentralized systems. Sustainability, 12(12), 5081.

Indexed at, Google Scholar, Cross Ref

Marquez, A. C., Bianchi, C., & Gupta, J. N. (2004). Operational and financial effectiveness of e-collaboration tools in supply chain integration. European Journal of Operational Research, 159(2), 348-363.

Indexed at, Google Scholar, Cross Ref

Min, H. (2010). Artificial intelligence in supply chain management: theory and applications. International Journal of Logistics: Research and Applications, 13(1), 13-39.

Indexed at, Google Scholar, Cross Ref

Minner, S., Silver, E. A., & Robb, D. J. (2003). An improved heuristic for deciding on emergency transshipments. European Journal of Operational Research, 148(2), 384-400.

Indexed at, Google Scholar, Cross Ref

Nakandala, D., Lau, H., & Shum, P. K. (2017). A lateral transshipment model for perishable inventory management. International Journal of Production Research, 55(18), 5341-5354.

Indexed at, Google Scholar, Cross Ref

Paterson, C., Kiesmüller, G., Teunter, R., & Glazebrook, K. (2011). Inventory models with lateral transshipments: A review. European Journal of Operational Research, 210(2), 125-136.

Indexed at, Google Scholar, Cross Ref

Pessot, E., Zangiacomi, A., Marchiori, I., & Fornasiero, R. (2023). Empowering supply chains with Industry 4.0 technologies to face megatrends. Journal of Business Logistics, 44(4), 609-640.

Indexed at, Google Scholar, Cross Ref

Richey Jr, R. G., Chowdhury, S., Davis‐Sramek, B., Giannakis, M., & Dwivedi, Y. K. (2023). Artificial intelligence in logistics and supply chain management: A primer and roadmap for research. Journal of Business Logistics, 44(4), 532-549.

Indexed at, Google Scholar, Cross Ref

Rudi, N., Kapur, S., & Pyke, D. F. (2001). A two-location inventory model with transshipment and local decision making. Management science, 47(12), 1668-1680.

Indexed at, Google Scholar, Cross Ref

Sabir, A. A., Ahmad, I., Ahmad, H., Rafiq, M., Khan, M. A., & Noreen, N. (2023). Consumer acceptance and adoption of AI robo-advisors in FinTech industry. Mathematics, 11(6), 1311.

Indexed at, Google Scholar, Cross Ref

Silbermayr, L., Jammernegg, W., & Kischka, P. (2017). Inventory pooling with environmental constraints using copulas. European Journal of Operational Research, 263(2), 479-492.

Indexed at, Google Scholar, Cross Ref

Tang, C. S., Yang, S. A., & Wu, J. (2018). Sourcing from suppliers with financial constraints and performance risk. Manufacturing & Service Operations Management, 20(1), 70-84.

Indexed at, Google Scholar, Cross Ref

Timajchi, A., Al-e-Hashem, S. M. M., & Rekik, Y. (2019). Inventory routing problem for hazardous and deteriorating items in the presence of accident risk with transshipment option. International Journal of Production Economics, 209, 302-315.

Indexed at, Google Scholar, Cross Ref

Verma, P., & Sood, S. K. (2018). Fog assisted-IoT enabled patient health monitoring in smart homes. IEEE Internet of Things Journal, 5(3), 1789-1796.

Indexed at, Google Scholar, Cross Ref

Zhong. Y., X. Jia, & X. Li. (2007). “Systems dynamics,” Science Press, Beijing, 2007.

Received: 02-Mar-2024, Manuscript No. jmids-24-14718; Editor assigned: 04-Mar-2024, Pre QC No. jmids-24-14718(PQ); Reviewed: 18- Mar-2024, QC No. jmids-24-14718; Published: 25-Mar-2024