Research Article: 2022 Vol: 21 Issue: 6S

Green Supply Chain and Impact on Electronically Devices at Samsung Company

Dalia Younis, Arab Academy of Science Technology and Maritime Transport

Keywords

Green Supply Chain, Electronically Devices, Supply Chain Management, Information Technology Implementation

Citation Information

Younis, D. (2022). Green supply chain and impact on electronically devices at Samsung Company. Academy of Strategic Management Journal, 21(S6), 1-12.

Abstract

The research uses design qualitative: As a collected data will be used to uncover trends in thought and opinions, dive deeper into the problem. The descriptive method, and the analytical method by following an inductive approach. Type of information: primary data and secondary data will be already available as the data to be collected. The study was based on an investigation that aspires to test the theory through developing of hypothesis regarding the impact of GSCM and rl on e-waste. The study tested the mentioned variables hence modifying the theory in light of the findings. Therefore, the adoption of a deductive approach was appropriate for this study. The data collection process commenced to collect data, the research designed and administrated phone interview. The research also used secondary data, which is the type of data collected for another purpose but used in this research. Secondary sources included articles, books, journals, newspapers, academic surveys, and the internet. The researchers gathered information through literature review from other literature authored by other writers relevant to the top of the study. This included journals and books.

Introduction

Environmental thinking is the aim of being integrated into supply chain management through the emergence of the green supply chain, which is one of the essential topics in the awareness spread regarding environmental issues in the last few decades. Many organizations respond to environmental issues by implementing green principles to companies; by using environmentally friendly raw materials, reducing the usage of petroleum power, recycling papers for packaging, and recycling electronic waste. The concept of green supply chain management has emerged in the last few years. It covers every stage in manufacturing, from the first stage to the last one, of the life cycle, i.e., from the approval of the product design till the moment of recycling. It covers many other functions besides manufacturing, but, it also includes the various activities involved in reverse logistics. Reverse logistics is defined as the process of transporting products from their place of use to their place of production for reuse, rework, repairs, remanufacturing, or recycling. Since reverse logistics is an integral part of green supply chain management, it is important to represent the connection between them and analyze their importance within the organization's performance, in order to have a complete supply chain (pandian & Abdul-kader, 2014).

Problem and Motivation of Research

The purpose, in this research, behind choosing Egypt as the country of study, not only because it is one of the highest consuming countries of electronics in the middle east, but also it has a remarkable increase of awareness regarding dealing with waste correctly among different industries. In other words, this research will first examine the general reverse logistics and its characteristics to gain a deeper understanding of the subject. This will be done to acquire the necessary background information required to research, understand and analyze the different reverse logistics characteristics of the mobile phone industry and to create recommendations for the recovery, repairing, remanufacturing, and recycling of mobile phones in today's environmental context.

In order to first gain a better and more profound understanding of grl, the present research will strive to answer the following questions:

1. What is the rl, and what activities include?

2. What are the grl motivators?

3. What are the challenges of the grl flow in the e-waste?

Research Objective

The following specific objectives guided the study:

1. To identify rl and grl.

2. To reduce the e-waste in Egypt

3. To reduce the damage to the environment through the implementation of grl.

Conceptual Background

Green Supply Chain Management

The green supply chain concept was first developed in 1996 by Michigan state university during the research entitled "environmentally responsible production."

The scholars at Michigan state university had proved to be an effective way of managing it. Later, they found the establishment of green supply chain management in such enterprises as IBM effectively resolved the conflict between environmental protection economic interests, so it is admired by people.

The green supply chain originates from the notion of supply chain management and the theory of sustainable development. It's a new topic. People weren't studying it deep enough. There is no unified, clear, authoritative definition yet. Management of the green supply chain is one system. It covers acquiring, processing, packaging, warehousing, transporting, selling, and end-of- life treatment, recycling. The process is guided by the principle of resource allocation optimization, enhancing benefits, achieving the objective of environmental compatibility. In general, it is a green system that brings together suppliers, manufacturers, distributors, retailers, consumers, the environment, rules, and cultural elements. It's also the logistics combination, information flow, cash flow, knowledge flow.

In general terms, the green supply chain management is a supply chain guided by the theories of sustainable development. Its purpose is to achieve the goal of improving welfare, achieving environmental compatibility, and optimizing materials by improving speed, certainty, and other related channels. Because of this, short-term benefits and long-term benefits cannot be handled well. Therefore, the establishment of green supply chain management is necessary so that the enterprise can have sustainable development.

Green supply chain management is a complex system, involving suppliers, manufacturers, distributors, retailers, customers, and logistics providers from the perspective of the participants.

Green supply chain management started mainly from product design and ended with the recycling of the final product. It covers mainly the following five aspects; they are green procurement, green design, green production, green distribution, green logistics, green consumption, and green recycling. Three of them will be discussed later green design, green procurement, and green production.

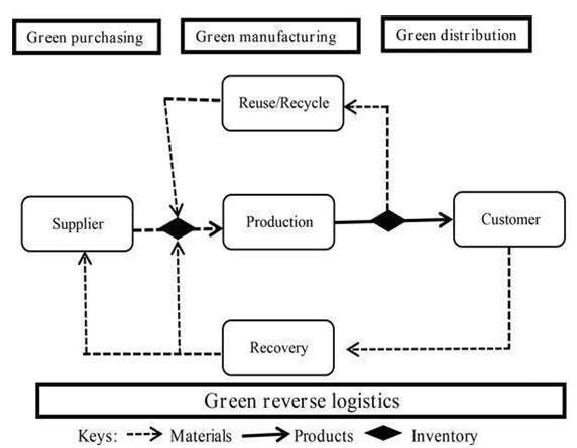

Figure 1: Simple Model of Green Supply Chain Management

Source: Application of environmental management principles to the entire set of activities across the whole customer order cycle, including design, procurement, manufacturing and assembly, packaging, logistics, and distribution.

1. Integrating natural deduction into SC the executives, including the biological plan of items, buying green materials and parts, reengineering of assembling ventures towards eco-friendly, turn around coordination is the executives of the item after its valuable life.

2. Integrating ecological thought onto firms' SC, including reverse coordination's.

3. Reducing and controlling the destructive effects of SC on earth.

4. Adoption of a natural plan, sourcing green materials and synthetic compounds, and give green training to workers under moral authority.

5. Green flexibly chain incorporates the eco-friendly idea into gracefully anchor the board to improve natural manageability with various green works on including, green buying, green dispersion, and warehousing, green transportation with utilization of biofuels, green assembling forms and the items' finish of-life the board.

6. In the world, as the natural mindfulness is expanding, firms are confronting substantial weight from various partners, including government and clients, to relieve their hurtful impact on the earth. Undoubtedly, corporate division needs to consider incorporating their strategic approaches in administration and assembling industry with manageability and diminishing start to finish gracefully anchor expenses to accomplish the upper hand. Since the most recent few decades, developing effects of an earth-wide temperature boost, environmental change, waste, and air contamination issues have included expanding overall consideration of specialists to think all the more eco- friendly and discover ideal conceivable arrangements towards "green." rath recognized GSCM (flexible green chain the board) has an impact in rousing authoritative supportability. With the natural concerns rising constantly, GSCM merits an industrious network worry in created countries. Further, it has as of late woken up the creating countries to green development.

Green Design

Study shows that in the design stage, around 70-80 percent of the product performance is determined. (toppinen et al., 2013; khalil et al., 2013; wang & luo, 2010) while the design usually costs only 10 percent of the total cost, however. Therefore, in the design stage of products, full consideration should be given to the ecological and environmental impacts. The designs can thus reduce energy consumption and pollute the environment. Green designs include mainly research into standardized, modular, removable, and recoverable design.

1. The standardized design makes parts of the structure relatively fixed, thus reducing processing difficulties and energy consumption. It can also decrease the complexity of technological devices.

2. The modular design is designed to meet the rapid development of green products, making it easy to assemble, disassemble, and maintain the product.

3. The removable design means that all parts of the structure have a reasonable, accessible, and separate coupling structure, which is easy to remove without damaging parts to reduce pollution from the environment.

4. The recyclable design is a design that achieves maximum component reuse.

Green Procurement

The procurement consists of buying raw materials (christopher, 2005). It is a supplier concern and a logistics concern. Many aspects should be considered in order to keep the whole routine clean and secure. To ensure that the entire supply chain is carried out successfully, consideration should be given to both the supplier and the logistics.

Green Production

Consideration should be given to the input and output of the manufacturing process, resource consumption, and environmental impact during the green production process. That includes the flow of materials, the consumption of resources, and waste production. The following aspects should be considered as regards green production.

1) Green skills. The environmental factors should be considered first in the selection process for the plan.

2) Productive resources. The reduction of waste and scrap material should be considered, with a higher level of processing technology.

3) Enhance manufacturing humanity by adjusting working hours and reducing labor intensity and other measures to increase employee enthusiasm and productivity creativity.

4) Attach importance to protecting the environment.

Obstacles to Green Supply Chain Management Practices

Researchers have identified many roadblocks that organizations face when implementing GSCM. As is the case with any novel company concept, firms are likely to face obstacles as they strive to develop this business model. The Ryder center for supply chain management (2008) identified three obstacles businesses face when greening their supply networks. These include a scarcity of appropriate technology to aid in the endeavor to become green, a desire for business processes to gather the necessary data in the supply chain to enable the use of the available technology, and a trade-off between green demands and lean approaches (Jlopleh – warner, 2012) It has been noted that technology enables the development of energy-efficient solutions that have a far more significant favorable effect on the environment. Thus, information technology can contribute to a more sustainable supply chain by optimizing the resources required to run the organization. The researchers cautioned that green supply chain technology would be challenging to implement in isolation from the supply chain system's business activities. As a result, the green supply chain and the supply chain are mutually reinforcing. Mollenkopf & colleagues (2010) claimed that lean and green initiatives are frequently viewed as mutually exclusive, owing to their shared emphasis on waste reduction. Lean manufacturing focuses on lowering inventory as it moves through the supply chain, minimizing its negative environmental impact. However, lean solutions that rely on just-in- time (jit) delivery of small batch sizes to promote sufficiency may necessitate more significant transportation, packaging, and handling, which contradicts the green approach.

Most businesses that employ green supply chain techniques incorporate environmental considerations into their SC systems rarely (cash & Wilkerson, 2003). They contended that their approach is frequently motivated by the desire to green an existing process or component of the supply chain. While this may benefit the environment, environmental considerations are usually overlooked when individuals responsible for monitoring a business's overall supply chain performance make supply chain modifications. Additionally, they stated that it is only after supply chain improvements have been implemented and their impact on the environment has been determined that the concept of greening the supply chain has a chance to arise (cash & Wilkerson, 2003). According to research on the challenges to GSCM application in the Indian automobile sector, the cost is a significant constraint in GSCM compared to traditional SC. Green techniques such as green design, green production, and green labeling of packaging, among others, need an excessive initial expenditure. The researchers agreed that environmental engagement entails two distinct expenses: direct costs and transaction costs. These costs, alkhidir & zailani (2009) assert, are likely to provide significant obstacles to GSCM deployment. Any strategic program's success requires the support and dedication of senior management (Hamel & Prahalad, 1989; zhu & Sarkis, 2007). Support from senior management is especially beneficial for environmental activities such as GSCM. It possesses a considerable influence on, and support for, the actual formation and implementation of green initiatives within the organization (zhu & Sarkis, 2007). GSCM is typically continuously supported by top management through strategic strategies and action plans for successful deployments. As a result, without top management backing, the execution of GSCM efforts will stall.

Green Supply Chain Management Strategies

Researchers and professionals of GSCM have identified various strategies that, if well applied, can lead to the realization of the benefits of GSCM. According to Simpson & Simpson (2008), one such strategy is risk-based strategies that focus on risk minimization Organizations apply this strategy in response to shareholders' requirements, and it is ideal for an organization that retains minimal internal environmental management resources. Since the technique depends on insignificant between hierarchical commitment, it may include considering essential statements in buying contracts for providers to meet all appropriate administrative prerequisites (Simpson & Simpson, 2008). Lord, et al., (2005) commented that this system falls under the built-up international organization for standardization (ISO) 14001. They further noticed that most associations, including Ford Motor Company, utilize the procedure with their providers through to their graceful chains (king et al., 2005) to offer built- up ecological execution benefits (Melnyk, 2003), outsider administration execution a framework all around acknowledged by associations.

The eco-efficiency strategy or lean-and-green approach to GSCM has developed as one of the complex strategies that organizations adopt to address the impact of their activities on the environment (Simpson & Simpson, 2008). This strategy draws environmental performance benefits for the supply chain beyond mere regulatory compliance through suppliers' requirements to meet operations-based efficiency objectives. Much environmental performance comes from specific manufacturing practices that provide secondary environmental performance benefits (Melnyk, 2003). The efficiency-based has both economic and environmental performance benefits to the supply chain and requires a higher level of engagement between customers and suppliers (Simpson & Simpson, 2008). This strategy ties environmental performance to operational processes in the supply chain. It allows the Expansion of execution prerequisites into the flexible chain amplifies financial execution and gives optional ecological execution benefits through waste and asset use decreases. The technique requires a more elevated contribution level between gracefully chain accomplices emerging from the increasingly complex utilization between firm execution prerequisites. Be that as it may, utilizing this procedure to encourage more prominent productivity in the flexible chain doesn't require the improvement of co-particular assets explicit to ecological execution (Simpson & Simpson, 2008).

Innovative-based GSCM strategies have been identified to expedite greening the supply chain in most organizations (Simpson & Simpson, 2008). This procedure is not quite the same as the effectiveness-based system due to its utilization of a graceful chain natural execution technique that is all the more explicitly ecological. Bowen & others (2001) saw that associations are progressively mindful of the potential for limited buying strategies to insource parts or administrations from providers that might be lawfully rebellious with ecological guidelines or who themselves secure products in a naturally flippant manner. When a flexible fasten starts to think about specific procedures, advances, or complex execution guidelines for providers, such as compound evasion, the degree of information trade and social speculation starts to change. Moving from an effectiveness-based GSCM procedure to a more considerable degree of advancement or joining of natural execution in the graceful chain and item configuration requires particular ecological assets (Lenox & king, 2004).

According to Simpson & Simpson (2008), closed-loop strategies are a recent type of GSCM strategy representing the complex and collaborative form of GSCM. In its basic form, the closed- loop strategy is often referred to as 'reverse logistics,' which involves the capture and recovery of materials for either remanufacture (high-value) or recycling (low value) (kocabasoglou et al., 2007). These materials can arise during production, as returned goods, post-use, and end-of-life. The strategy integrates environmental performance to the whole supply chain. Prominent examples of companies that have used closed-loop strategy include Kodak's return and remanufacture of its disposable cameras, Hewlett Packard's retrieval of used printer cartridges, and BMW's end-of-life vehicle requirements for suppliers(guide et al., 2002).

However, the motivation for a closed-loop strategy remains low for fundamental reasons of poor and distributed control over the reverse supply chain, lack of available infrastructure, and the inability of supply chains to believe that such activity is economically viable (Simpson & Simpson, 2008).

Richey & colleagues (2005) observed that designing and successfully using a closed- loop strategy presents one of the most complex endeavors for a single organization to do within its supply chain. In its basic form, 'closed-loop' may involve product take-back and reverse logistics implemented only in the retail portion of the supply chain. In more complex closed- loop systems, used or obsolete products and waste are taken back by the producer and remanufactured or recycled (Richey et al., 2005).

Strategies for a Green Supply Chain Management

Researchers and practitioners in GSCM have developed a variety of tactics that, when properly implemented, can result in the realization of GSCM's benefits. According to Simpson & Simpson (2008), one such method is risk-based strategies that prioritize risk mitigation. Businesses pursue this strategy in response to shareholder demands, and it is optimal for businesses with limited internal environmental management resources. The technique's reliance on small commitments between hierarchical levels may include considering strong statements in purchasing contracts with providers to ensure compliance with applicable administrative requirements (Simpson & Simpson, 2008). According to Lord, et al., (2005), this system conforms to the established international organization for standardization (ISO) 14001. Additionally, they observed that most organizations, including Ford Motor Company, utilize the procedure with their suppliers through their graceful chains (king et al., 2005) to offer built-up ecological execution benefits (Melnyk, 2003), outsider administration execution, and a general recognized framework. The eco- efficiency strategy, often known as the lean-and-green approach to GSCM, has evolved into one of the more complicated ways that firms use to address the environmental effect of their activities (Simpson & Simpson, 2008). Beyond legal compliance, this technique helps the supply chain's environmental performance by requiring suppliers to satisfy operational efficiency goals. Much environmental performance is derived through industrial processes that have been identified as providing secondary environmental performance benefits (Melnyk, 2003). The efficiency-based approach improves the supply chain economically and environmentally, and it necessitates a higher level of collaboration between customers and suppliers (Simpson & Simpson, 2008). This technique connects environmental performance to supply chain operating procedures. It enables the expansion of execution prerequisites into a flexible chain, enhancing financial execution and providing optional environmental execution benefits through waste and asset utilization reductions. The technique necessitates a higher level of contribution from gracefully chain accomplices due to the increasingly sophisticated utilization requirements for firm execution. However, employing this technique to promote greater productivity in the flexible chain does not necessitate enhancing co- specific assets related to ecological execution (Simpson & Simpson, 2008). Numerous firms have identified innovative GSCM solutions to accelerate greening their supply chains (Simpson & Simpson, 2008). This approach is distinct from the effectiveness-based system in that it makes use of a more ecological graceful chain natural execution technique. Bowen & colleagues (2001) observed that associations are increasingly conscious of the potential for restricted purchasing strategies to insource components or administrations from providers who may be legally in violation of environmental regulations or who secure products in a naturally flippant manner. When a flexible fastener considers special procedures, advancements, or complicated execution rules for suppliers, such as compound evasion, the degree of information exchange and social speculation changes. Transitioning from a performance-based GSCM procedure to a higher level of advancement or integration of natural execution in the graceful chain and product design necessitates specific ecological assets (Lenox & king, 2004). According to Simpson & Simpson (2008), closed-loop strategies are a relatively new type of GSCM strategy that exemplifies the complex and collaborative nature of GSCM. In its simplest form, the closed-loop strategy entails the capture and recovery of materials for remanufacturing (high-value) or recycling (low-value) (kocabasoglou et al., 2007). These materials may be generated during manufacture, as returned goods, post-use, or at the end of their useful lives. The approach encompasses the entire supply chain in terms of environmental performance. Several notable instances of corporations that have implemented a closed-loop strategy include Kodak's return and remanufacture of disposable cameras, HP's recovery of old printer cartridges, and BMW's requirements for suppliers of end-of- life vehicles (guide et al., 2002). However, motivation for a closed-loop strategy remains low for fundamental reasons such as insufficient and dispersed control over the reverse supply chain, a lack of relevant infrastructure, and supplier networks' unwillingness to think such activity is economically viable (Simpson & Simpson, 2008). According to Richey & colleagues (2005), developing and successfully implementing a closed-loop strategy is one of the most difficult tasks a single firm can do inside its supply chain. In its simplest form, 'closed-loop' may refer to product return and reverse logistics applied exclusively in the retail segment of the supply chain. In more elaborate closed-loop systems, the manufacturer takes back used or obsolete products and garbage and remanufactures or recycles them (Richey et al., 2005).

Study Hypotheses

The study hypotheses, which are derived from the theoretical background of the study variables, were selected, the results of previous studies were collected and reviewed, the relationship between the variables clarified, and based on the study problem, and the achievement of its objectives, this study is based on the main hypothesis:

There is a positive effect for statistical significance at the level of significance (a <0.05). Dimensions of green supply chain management (green design, green procurement, green production) Impact on Samsung's electronic devices.

The following sub-hypotheses emerge from this hypothesis:

1. There was a positive effect of statistical significance on the level of significance (a<0.05). The dimensions of green supply chain management (green design, green procurement, green production) affect reuse / recycling at Samsung.

2. There was a positive effect of statistical significance on the level of significance (a<0.05). The dimensions of green supply chain management (green design, green procurement, and green production) affect production at Samsung.

3. There was a positive effect of statistical significance on the level of significance (a<0.05). The dimensions of green supply chain management (green design, green procurement, and green production) affect customers at Samsung.

4. There was a positive effect of statistical significance on the level of significance (a<0.05). The dimensions of green supply chain management (green design, green procurement, and green production) affect supplier at Samsung.

5. There was a positive effect of statistical significance on the level of significance (a<0.05). The dimensions of green supply chain management (green design, green procurement, and green production) affect recovery at Samsung.

Study Methodology

In this study, the researcher relied on the descriptive and analytical method, which includes the office method, as it is the most important methodology used in collecting data and information, and in addition to that, the field survey method, and the factors affecting human resources in Samsung Company and their analysis.

Study Population and Sample

The current study population refers to all potential consumers of the "Samsung" brand of green human resource management. It depends on the "easy or appropriate" sample, and since the research falls within the framework of marketing, it is based on Accordingly, 500 questionnaires were distributed, and 467 were retrieved, of which 432 were appropriate sample questionnaires. In September 2019 in Alexandria, the sample included all slides at the beginning of the statistical treatment, and data was collected Educational studies, because this serves the study objectives with income levels, gender and age, starting from the age of 18 years, as well as the educational level. a . Contributes to answering her questions and testing hypotheses.

Study Tool

The researcher previously referred to the use of the questionnaire list, and developed it to comply with the objectives of this study, and this study included a set of phrases to study the effect of green supply chain management on electronic devices in Samsung in Alexandria governorate, and the five Likert scale was used (completely disagree, disagree, no I specify, agree, completely agree) based on the foregoing, the questionnaire included thirty (30) paragraphs distributed into three parts, the first part of which includes demographic information for the sample items represented by gender, age, educational level, and income. The second part includes the dimensions of green supply chain management in (15) paragraphs distributed on each of (green design, green procurement, green production). ) starting from paragraph no. 5 up to paragraph 19, and the third part deals with the mental image of expressive electronic devices(about it in (11) paragraphs starting from paragraph (20) up to paragraph (3).

Statistical Treatment

The data were collected, analyzed, and statistically processed, using the statistical program (SPSS, v.26), and the researcher relied on descriptive and analytical statistical methods to process the data, and included: the frequency distribution, percentages to describe the study sample, and arithmetic averages, to measure the attitudes of the sample members about the study variables, the regression method and the single-contrast analysis of variance tests were used to test the statistically significant differences in the attitudes of their individuals. Likert scale coding was also adopted where the number (05) was monitored for the level of approval "strongly agree" to represent the maximum positive trend, the number (01) for the level of consent. Strongly disagree to represent the extreme negative direction, according to the likert scale used.

1. Analysis of the general characteristics of the study sample:

| Table 1 Distribution of the Study Sample Items According to Demographic Characteristics |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | The number | The ratio | Monthly income | The number | The ratio | |||||

| Mention | 256 | 59.30% | Less than 18,000 | 146 | 33.80% | |||||

| Female | 176 | 40.70% | 40,000-18,000 | 152 | 35.20% | |||||

| More than 40,000 | 134 | 31% | ||||||||

| Age | The number | The ratio | Educational level | The number | The ratio | |||||

| 18 the 30 | 239 | 55.30% | secondary | 106 | 24.50% | |||||

| 31 the 45 | 155 | 35.90% | Collectors | 259 | 60% | |||||

| Over 45 | 38 | 8.80% | high | 67 | 15.50% | |||||

| Total | 432 | 100 | Total | 432 | 1000 | |||||

To test the extent of the internal consistency of the scale paragraphs and despite the absence of standard rules regarding the appropriate values of the alpha factor for administrative and human sciences to measure reliability, it is considered in application to be.

Based on the above, it is clear from the results of the descriptive analysis of the study sample according to its demographic characteristics most of the sample members have university degrees by 60%, and this is reflected in terms of awareness, diversity of knowledge and training with live age, the predominant majority in the studied sample ranges between 18 years of age for behavior, while for related impressions there are 176 females, equivalent to 40.7%, which is less than the estimated number of males and 30 years of age by 55.3%. 40,000 - b 256 is mentioned, that is, 59.3%. As for the level of income, the income bracket was more than 18,000. By 35.2%, which in turn reflects the majority of young people entering Alexandria.

2. Reliability of the scale used: To verify the stability of the study instrument, the Cronbach alpha coefficient was calculated.

Acceptable in research related to (alpha that>0.60) the measurement results showed an increase in the Cronbach alpha coefficient for all measures of the study:

| Table 2 The Index of the Stability of the Internal Consistency of the Dimensions of the Resolution (Alpha of the Cronbach Scale) |

||

|---|---|---|

| Variable | Number of paragraphs | Cronbach alpha |

| Green supply chain management | 15 | 0.703 |

| Electronic devices | 11 | 0.68 |

It is evident from the above table that the stability coefficients for all dimensions of accuracy are acceptable green supply chain management, which is estimated at (0.703), and the mental picture of the result (0.680), is greater than 0.6, which means that Cronbach alpha values are it indicates the existence of a high coherence and coherence relationship between the paragraphs of the one sub-dimension scale, the paragraphs of the main dimensions, as well as for the dimensions of the study tool as a whole, and this indicates the possibility of stability. Of the results that can be produced when applying the questionnaire.

3. An assignment test for the study: There is a positive effect for statistical significance at the level of significance (a<0.05). Dimensions of green supply chain management (green design, green procurement, green production) Impact on Samsung's electronic devices.

| Table 3 The Arithmetic Mean and Standard Deviation of the Study Variables |

|||||

|---|---|---|---|---|---|

| Variable | Dimensions | Arithmetic mean | standard deviation | t | The average of the significant |

| Green Supply Chain Management | reuse/recycling | 2.9358 | 0.77393 | -1.725 | 0.085 |

| production | 3.3177 | 0.92303 | 7.154 | 0 | |

| customers | 3.3187 | 1.04132 | |||

| supplier | 3.1907 | 0.70384 | 6.361 | 0 | |

| recovery | 3.256 | 0.5876 | |||

Based on the previous tables, the surveyed sample members have positive, statistically significant tendencies towards managing the green supply chain, Samsung "for electronic devices and this is what the numbers indicated, represented by the level of significance, the total arithmetic mean estimated by (3.1907), which surpasses the theoretical mean of the study (3) and has an asymptotic dispersion, and this is what the adult standard deviation showed (0.70384).

3. Summary of the results of the individual variance analysis of the differences in the perception of the corporate image in terms of (age, age, Educational level),

| Table 4 Analysis of Variance of the Study Variables |

|||||

|---|---|---|---|---|---|

| Study variables | Demographic variables | The difference | Average sum of squares | F | The level of morale |

| Green Supply Chain Management | Age | Ages | 0.514 | 0.518 | 0.596 |

| Single lifetime | 213.001 | ||||

| education level | Single education levels | 0.494 | 0.498 | 0.608 | |

| Individuals with an educational level | 213.021 | ||||

| Income | Income levels | 0.098 | 0.098 | 0.906 | |

| Individuals have a single income | 213.418 | ||||

The First Sub-Hypothesis: “There are statistically significant differences at the level of significance (0,05). By managing the green supply chains "Samsung" for electronic devices attributable to the age variable, we find an explanation for the results shown in the table, the average sum of squares of error among individuals of one age is greater than between ages, which is what the computed is greater than the tabular, as well as that the level of significance here is 0.596 which is greater than the level of significance of the study f, which is 0.05, which leads us to reject the alternative hypothesis and accept the null hypothesis, the text. There are statistically significant differences in consumer perception of "Samsung" electronic devices (α≤ at the level of significance) 0.05 smart traceable age variable.

The Second Sub-Hypothesis: there are statistically significant differences at the significance level (0.05). Through the management of the green supply chains "Samsung" of electronic devices attributed to the variable of age, we find an explanation of the results shown in the table. The average sum of squares of error among individuals at one age is greater than between ages, which was calculated greater than the table. The significance here is 0.608, which is greater than the significance level of the study f which is 0.05, which leads us to reject the alternative hypothesis and accept the null hypothesis, the text. There are statistically significant differences in the consumer's perception of “Samsung” electronic devices (α≤ at significance level) 0.05 educational level variable.

Results

This research investigated one of the supply chain management disciplines: green reverse logistics and e-waste industry. As shown in this research, green reverse logistics is an important business area and, due to many factors such as environmental concerns, legislation, and customer demands, firms have started to invest time and efforts in order to build efficient reverse flows to gain competitive advantages and respect new environmental laws.

Reverse logistics is a complex field and presents many challenges that have to be overcome when businesses implement reverse flows. These challenges are still complex as reverse logistics remains a new business area, and expertise, in this domain, is still being built. The evaluation and selection of the 3pl for the mobile industry segment is a top management level strategic decision. The quantity of e-waste is tremendously increasing, and it has become a menace to society and environmental burden. The legislations act like Restrictions on Hazardous Substances (ROHS) directive, and Waste Electrical and Electronic Equipment Directive (weee) are gaining importance in the current business environment. The electronics appliances manufacturing companies are more interested in focusing upon their core competencies, and services of 3pl are the right choice for them to separate reverse logistics operations. Therefore, hiring the services of 3pl is an important issue, and the present work is very significant in this regard. Nowadays, efficient reverse logistics operation is regarded as a focused problem. The development of a sound reverse logistics system is beneficial to environmental protection, and the companies may improve their financial health by handling the return professionally. Mostly the manufacturing industries do not have enough competence to manage their product reverse flow in the supply chain; thus, they have to only option to outsource their reverse logistics operations to the 3pl service provider for the conduct of reverse logistics (rl) activities. To make the ahp-topsis model more effective, top management must establish key criteria for the evaluation and selection of third-party logistics service providers. The attributes may increase or decrease as per the industry's needs; in a real-life business environment, it is very difficult to find suitable criteria for the evaluation and selection of outsourcing partners. In the present work, a decision model has been developed for the mobile phone manufacturing company only. However, the same decision model may apply to a different market segment with minor modifications. The hybrid ahp-topsis method presented in this research properly guides policymakers to evaluate 3pl reverse logistics service providers. It supports them to visualize the intensity of the impact of various criteria on the alternatives available before reaching the final decision.

Recommendations

1. The study recommends increasing awareness on the level of green reverse logistics management practices in the Egyptian electronic waste supply chain; this will help reduce the disposal of mobile phone parts.

2. There is a need to adopt various grlm practices among the stakeholders in the egyptian mobile phone supply chain. There is a need to devise measures to reduce the challenges faced by stakeholders in the Egyptian electronic waste supply chain relating to green supply chain practices.

1) The importance of government support in the recycling industries for electronics and the provision of adequate facilities for investors to enter the recycling sector.

2) Qualifying specialized staff in environmental issues and taking advantage of their expertise in this aspect.

3) There is a need to enact and legislate a law prohibiting the export and recycling of electronic waste for use in the state.

4) The legislative framework for e-waste management that incorporates responsibilities to importers, manufacturers, and owners.

5) We need to enhance and collect accurate data on quantities and types of e-waste generated and appear in waste streams.

6) Need to enhance the participation of the concerned stakeholders in e-waste management.

7) Need to develop a proper collection, transportation, recycling, exporting, or disposal system.

8) Need to build local capacity/experts on e-waste management.

9) Need to identify recycling technologies for known e-waste stream.

References

Abdulrahman, M.D., Gunasekaran, A., & Subramanian, N. (2014). Critical barriers in implementing reverse logisticsin the chinese manufacturing sectors. International Journal of Production Economics.

Crossref, Google Scholar, Indexed at

Almada, F.C., Andrade, E.M., Ferreira, A.C., Silva, P.C.S., & Chiappetta, C.J. (2013). Practices of environmentallyresponsible reverse logistics systems in brazilian companies. International Journal of Business Performance and Supply Chain Modelling, Apple (2009), Http://Apple.Com

Bioplastics, E., 2020. Eu Study Lacks Acknowledging Benefits Of Compostable Packaging. [Online] European Bioplastics E.V. Available At: <Https://Www.European-Bioplastics.Org/Eu- Study-Lacks-Acknowledging-Benefits-Of-Compostable-Packaging/> [Accessed 5 July 2020].

Crossref, Google Scholar ,Indexed at

Bowman, R. (2006), “Looking Backward : Sony Ericsson Takes On Challenge Of Reverse Logistics”, Global Logistics & Supply Chain Strategies.

Centre For Environment For The Arab Region And Europe (Cedare). (2011, November). NeedsAssessment Of The E- Waste Sector In Egypt. Https://Www.Sustainable-Recycling.Org/Wp-Content/Uploads/2015/07/Egypt_Cedare_Needsassmt_2011.Pdf

Clift, R., & Wright L. (2000). Relationship Between Environmental Impacts Added Value Along The Supply Chain. Technology Forecast Soc Shange.

Crossref, Google Scholar, Indexed at

Council Of Supply Chain Management Professionals (Cscmp). (2010). Supply Chain And LogisticsTerms And Glossary

Crossref, Google Scholar, Indexed at

Danda, , Peters, A. A. (2005), “Reverse Logistics In The Computer Industry”.

Goldsby, T.J., & Closs, D.J. (2000), Using activity based costing to reengineer the reverse logistics channelinternational.

Halldorsson, A. (2008). “Reverse Logistics”, Supply Management.

Jlopleh - Warner, V. (2012). Green supply chain management and supply chain responsiveness among food andbeverages manufacturing firms in Nairobi, Kenya. University Of Nairobi, School Of Business.

Law And Regulations On Solid Waste Management.

Meade, L., & Sarkis, J. (2002). “A Conceptual Model For Selecting And Evaluating Third-Party Reverse Logistics Providers”.

Crossref, Google Scholar, Indexed at

Motorola, Http://Www.Motorola.Com/

Nokia, Http://Www.Nokia.Com

Pandian, G., & Abdul-Kader, W. (2014). Performance Evaluation Of Reverse Logistics Enterprise - An Agent-BasedModeling Approach. Iie Annual Conference. Proceedings, 3144.

Rogers, D.S., Lambert, D.M., Croxtons, K.L., & Garcia- Dastugue, S.J. (2002), “The ReturnManagement Process”.

Samsung, Http://Www.Samsung.Com,

Soto Zuluaga, J.P.S. (2005), “Reverse Logistics: Models And Applications”.

Walter G., Steinborn J., Spengler T., Luger T., & Herrmann C. (2009). Implementation Of The Weee- Directive-Economic Effects And Improvement Potentials For Reuse And Recycling In Germany. International Journal Of Advanced Manufacturing Technology.

Waste Recycling: A Multitiered Network Equilibrium Framework For E- Cycling”.

Received: 28-May-2022, Manuscript No. ASMJ-22-11803; Editor assigned: 30- May -2022, PreQC No. ASMJ-22-11803 (PQ); Reviewed: 12- Jun - 2022, QC No. ASMJ-22-11803; Revised: 24-Jun-2022, Manuscript No. ASMJ-22-11803 (R); Published: 07-Jul-2022