Research Article: 2019 Vol: 23 Issue: 4

Factors Influencing the Adoption of Management Accounting Practices (MAPs) by Manufacturing Small and Medium Enterprises (SMEs) in Durban, Kwazulu-Natal

Mbali, Portia Msomi, Durban University of Technology

Musawenkosi Ngibe, Durban University of Technology

Celani, John Nyide, Durban University of Technology

Abstract

Globally, manufacturing SMEs have been confronted with transformation, requiring them to be more focused on cost efficiency in order to be more sustainable. This has meant that manufacturing SMEs needed to find different business strategies and approaches to meet this global transformation. Literature shows that the introduction and usage of management accounting practices (MAPs) in manufacturing SMEs can contribute significantly towards their sustainability and meeting the global transformation needs. This paper intended to determine the critical environmental factors influencing the adoption of MAPs by manufacturing SMEs located in Durban, KwaZulu-Natal, South Africa. This study adopted a quantitative research approach using a 5 point Likert scale questionnaire as the data collection instrument. The target population consisted of manufacturing SME owners, managers who were involved in the business decision making. A non-probability (purposive) sampling was used to select the relevant sample size for this study. A total of 80 questionnaires were distributed to the target population with 51 questionnaires being completed and returned. Based on the empirical findings, the study identified that both internal and external environmental factors such as size of the firm, firm age, resources for training needs, technology and government support have a critical influence towards the adoption of MAPs. The study recommended that it is crucial for manufacturing SMEs to identify the most appropriate MAPs which can be imbedded in their operations to improve business performance and sustainability.

Keywords

Management, Accounting Practices, Manufacturing, SMEs, Environmental Factors, Durban.

Introduction

Small and Medium Enterprises (SMEs) play a crucial role in the development and sustainability of a nation (Nandan, 2010; Fiseha & Oyelana, 2015; Ayandibu & Houghton, 2017), as they provide employment to thousands and immensely contribute to the South African Gross Domestic product (GDP) ranging from 70% to 95% (Statistics South Africa, 2018). This clearly indicate that SMEs are indeed the back-bone of any country and these businesses need to be nourished and supported in order to bring equilibrium towards the sustainability of the economy (Valaei et al., 2017; Obi et al., 2018). Management accounting literature has predominantly dealt with the adoption of management accounting practices in large organisation and less emphasis on the adoption of MAPs has been dealt with in the SME spectrum. Management accounting practices are sets of techniques aimed at providing managers with financial information to help them make decisions and maintain effective control over business resources (Lopez & Hiebl, 2014; Charted Institute of Management Accounting, 2015). For manufacturing SMEs to remain competitive and sustainable, they need to properly manage their scarce resources using proper information and control systems which are provided through management accounting (Mitchell & Reid, 2000; Eniola & Ektebang, 2014). The adoption of MAPs has been reported as an influence to the existence of manufacturing organisations (Kapkiyai & Kimitei, 2016). This is due to their ability to provide various tools, techniques and valuable internal and external information including for budgeting, profit planning and performance evaluation (Yalein, 2012; Azudin & Mansor, 2017). Management accounting practices enables a firm to perform cost management more precisely, thereby improving the success of operations (Uyar, 2019).

There seems to be growing concerns in terms of the adoption of MAPs by manufacturing SMEs in Durban, KwaZulu-Natal Province in South Africa. The adoption rate of MAPs by manufacturing SMEs is still a critical concern in the field of management accounting research more precisely in developing countries (Ghenhall & Langfield-Smith, 1998; Saeb & Smith, 2014; Johnson, 2015). Despite them being recognised as key contributors to business performance. Becker, Ulrich & Staffel (2011) revealed that this slow adoption of MAPs amongst manufacturing SMEs is due to the scarce resource constrains faced by such entities, size and complexity in which they operate under and the changes in business environment. This study seeks to determine critical factors influencing the adoption of MAPs by manufacturing SMEs located in Durban, KwaZulu-Natal.

Aims and Objections

The aim of this study is to determine the environmental factors affecting the adoption of MAPs in manufacturing SMEs in Durban, KwaZulu-Natal.

Objectives

1. To examine internal and external environmental factors affecting the adoption of MAPs by manufacturing SMEs in the manufacturing sector in Durban.

2. To determine the implications of internal and external environmental factors towards business sustainability.

Problem Statement

Manufacturing SMEs in South Africa, have been identified by the government as a priority in increasing both formal and informal job employment so as to reduce the high unemployment rate which is currently estimated at 26.7% (Statistics South Africa, 2018). These businesses have been recognised as a strategic tool for radical economic transformation in KwaZulu-Natal (Ngibe & Lekhanya, 2019). Given their strong resilient contribution to the country’s’ economy, their long-term growth and competitiveness has been compromised by the chronic and often acute constraints on their access to formal-sector finance, among other systemic and institutional problems in developing countries (Kapkiyai & Kimitei, 2016; Sibanda et al., 2018). Mungal (2014); Doh & Kim (2014); Thomas (2014); Lekhanya (2015) asserted that manufacturing SMEs in Durban and in KwaZulu-Natal in general are affected by environmental factors such as lack of entrepreneurial knowledge, poor business skills, education, training, technology, competition, innovation and risk factors. Amoako (2013); Peter et al. (2018) revealed that lack of manufacturing SMEs knowledge and ability to adopt MAPs prevents them from acquiring government and private funding to improve the entity’s’ economic life. The continued lack of MAP adoption by manufacturing SMEs is viewed by Nandan (2010); Lopez & Hiebl (2015) as a catalyst to the slow growth of manufacturing SMEs.

Literature Review

The contingency based theory that exist amongst Management Accounting research, majority of scholars are in common agreement that it is both the internal and external factors that are the key variables involved in identifying the appropriate set of MAPs to be adopted regardless of the diversity of the business (Otley 1980, Ahmad & Mohamed Zabri, 2015; Otley 2016; Azudin & Mansor, 2018). This demonstrates just how crucial it is for any organisation to identify its own specific characteristics that support them in adopting the relevant MAPs in order to be more sustainable (Otley, 2016). Drury (2015) asserts that incorporating the usage of Management Accounting (MA) is imperative to manufacturing SMEs since it deals specifically with both financial and non-financial information that contributes to the decision making process. By implementing MAPs a firm can effectively plan and control its business resources whilst maximising its profits in order to achieve a sound business (CIMA, 2015). However, the question of which MAPs are required to enhance or maintain competitive edge in the market is inexplicit for businesses due to the constant changes in the market (Joshi & Li, 2016). For manufacturing SMEs, the same concerns exist and this study intends to explore the factors influencing the adoption of MAPs by applying the contingency based theory. The following section of factors was discussed through literature by investigating internal as well as external factors.

Internal Factors Influencing The Adoption Of Maps By Manufacturing Smes

Level of Education and Owners Experience Influence the Adoption of MAPs

The level of education of manufacturing SME owners plays a significant role in identifying which MAPs must be adopted by the enterprise (Armitage et al., 2016). Neneh (2018) asserts that the performance of an organisation is highly influenced by the owner’s education. Andersén & Samuelsson (2016) suggests that to remain relevant and compatible in the manufacturing SME sector, it is imperative that, the owner adds or creates new knowledge through education. Azudin & Mansor (2018) highlights that without proper level of education; manufacturing SME owners will continue finding it challenging and difficult to integrate MAPs into their businesses. Yeboah (2015), Omsa et al. (2018) postulates that there is a significant correlating relationship between the level of education possessed by the manufacturing SME owner and the adoption of MAPs. Ng & Kee (2018) contest that education is not only the key factor in adopting MAPs but views experience as a key element in the adoption of MAPs. Lampadarios (2016) asserts that in order for manufacturing SMEs to be successful in this diverse global environment, they will need to have adequate experience in order to adopt relevant MAPs to improve business performance. Baporikar et al. (2016) argues that the majority of manufacturing SME fail to adopt MAPs due to the lack of experience by the owners.

Size of Firm Influence the Adoption of MAPs by Manufacturing SMEs

The size of a firm is a significant element that is used to identify which MAPs must be adopted by manufacturing SMEs (Ahmad & Mohamed Zabri, 2015). Azudin & Mansor (2018) claim that there are specific MAPs which can only be adopted by certain manufacturing SMEs simply because of the size of those firms. Abder-Kader & Luther (2008) support that the size of a firm is a characteristic that influence the adoption of specific MAPs by SMEs. Large firms find it easier to adopt modernised or contemporary MAPs than small businesses (Ahmad & Mohamed Zabri, 2015; Sahoo & Yadav, 2018). SME find it difficult to adopt contemporary MAPs due to limited scarce resource to support this transformation (Abder-Kader & Luther, 2008).

Age of Firm Influence the Adoption of MAPs by Manufacturing SMEs

Most manufacturing SMEs cease to exist after the birth phase and this is due to the lack of application of MAPs by such entities (Yeboah, 2015; Valtakoski & Witell, 2018). This is due to numerous challenges they encounter internally and externally (Shahzadi et al., 2018; Essel et al., 2019). AlKhajeh & Khalid (2018) suggest that the age of a firm influences the adoption of MAPs significantly. Yeboah (2015); Hiebl et al. (2018) revealed that firms over the age of six who adopted MAPs saw a greater improvement on their business performance. Wang (2016) claims that manufacturing SMEs fail to adopt MAPs because they are denied access to financial assistance due to the age of their firms. Fernández-Olmos & Ramírez-Alesón (2017) concluded that the future of sustaining manufacturing SMEs is through incorporating MAPs from as early as birth phase.

Structure of Firm Influence the Adoption of MAPs by Manufacturing SMEs

The complexity of a firms’ structure doesn’t hinder the adoption of MAPs since they are specific to meet the needs of business (Senftlechner & Hiebl, 2015). Otley (2016) asserts that it is crucial for each manufacturing SME to identify proper MAPs that will be sufficient for their firm structure. Ipinnaiye et al. (2017) supports that the simple the structure the easier it is to identify which MAPs are practical to be implemented. To ensure the survival of manufacturing SMEs, it is highly advisable that they adopt the relevant MAPs which are supported by the firm structures (Gandhi et al., 2018). Kalkhouran et al. (2015) argues that it is rather difficult for manufacturing SMEs to imbed MAPs in their businesses due to their simple structure and limited resources. In order for manufacturing to be more viable and be able to expand their structures it is vital that they adopt MAPs which will create better opportunities (Suh & Lee, 2018).

Training of Staff Influence the Adoption of MAPs by Manufacturing SMEs

The availability of resources for training employees in order to use MAPs effectively is essential for manufacturing SMEs (Whittaker et al., 2016). Acquiring skills, competencies and knowledge for manufacturing SMEs owners to adopt MAPs need to be enhanced through training (Dincer & Acar, 2017). Training of manufacturing SMEs staff will not only aid in the adoption of MAPs but it will increase the product innovation as staff will be able to identify gaps (Maes & Sels, 2014). Omri (2015) supports that adopting MAPs by the manufacturing SMEs can help create innovative strategies that will sustain product life cycle and help maintain sustainability. Training manufacturing SMEs to utilise properly MAPs improves business performance and develops more competencies (Ghebrihiwet, 2019). Despite the positive influence derived from the objectives of training, there is not a guarantee that the MAPs will be adopted effectively by manufacturing SMEs (Padachi & Lukea Bhiwajee, 2016). Ipinnaiye, Dineen & Lenihan (2017) concludes that for manufacturing SMEs to be competitive training should be part of the firms’ strategy.

External Factors Influencing The Adoption Of Maps By Manufacturing Smes

Business Environment Influence the Adoption of MAPs by Manufacturing SMEs

Jamali et al. (2017) describes globalisation as that one element which takes manufacturing SMEs out of their comfort zone and the survival these enterprises in the environment can be facilitated by adopting the modernised MAPs. With new environmental regulations that affect the manufacturing standards, it is imperative that the manufacturing SMEs abide to such regulation (Jamil et al., 2015). MAPs dealing with environmental issues have been introduced not only for large businesses but for SMEs as well, as this forces manufacturing SMEs to diversely manage their scarce resources, pioneering planning, controlling, decision making, risk and better appraisal system (Dalberg, 2011; Abdelzaher & Abdelzaher, 2017). Cardoş et al. (2014) environmental factors make it compelling for manufacturing SMEs to adapt sophisticated MAPs in order to maintain a competitive edge while also retaining customer loyalty.

Government and Supporting Agencies Influence the Adoption of MAPs by Manufacturing SMEs

Government and supporting agencies act as a catalyst that provides financial assistance in a form of start-up capital, cash flow injection for business operation and supports the training needs for manufacturing SMEs (Oparaocha, 2015). Since manufacturing SMEs have been identified as major contributors of the GDP across the globe, government and supporting agencies need to promote training to enhance the adoption of MAPs (Asah et al., 2015). SEDA, Khulula Enterprise Finance and Ntsika Enterprise Promotions are the most dominant supporting agencies which are pioneers in assisting manufacturing SMEs in South Africa (Agwa-Ejon & Mbohwa, 2015). It is crucial that manufacturing SMEs make use of such platforms in order to obtain sufficient MAPs that will take the business performances to greater heights (Gomes et al., 2018).

Technology Influence the Adoption of MAPs by Manufacturing SMEs

Technology is one of the major elements of gaining a competitive edge for any business as it enables firms to be more proficient by making the production process faster (Ahmad & Mohamed Zabri, 2015; Jamil et al., 2015; Pillay, 2016). Amara & Benelifa (2017); Bharati & Chaudhury (2015) claim that the use of technology by manufacturing SMEs has been captured in ascent as a tool that activates or promotes product innovations, increases directive or integrated communication from the various functions in the organisation and allows flexibility. However, technology is a major concern across all manufacturing SMEs in this diverse global market, as enterprises need to gain or maintain their competitive edge (Karadag, 2015; Ahmad, 2017). Karadag (2015) found that manufacturing SMEs had a low adoption rate of MAPs due to lack of utilising technology which prevented them from benefiting in low production cost. Yeboah (2015) identified lack of education and informal education as a factor contributing to the lack of adopting newer or current technologies. Contrary to Durban, South Africa, in America, medium firms were more aware of the newer technologies as compared to the smaller firms (Bharati & Chaudhury, 2015). This means that developing countries still lag behind in terms of adopting the current technologies and software’s which are compatable to the relevant MAPs (Giotopoulos et al., 2017). A greater level of technology enforced by manufacturing SME requires sophisticated MAPs which will leads to higher business turnover (Martí & Quas, 2018). This will require support from management, firm size, resources and infrastructure (Schneider et al., 2015).

Competition within the Market Influence the Adoption of MAPs by Manufacturing SMEs

All firms want to be preferred by customers who require them to have a better competitive advantage and this can be achieved by the four components which include: quality, delivery, low cost and flexibility (Hussain et al., 2015). A countries economy heavily depends on the manufacturing sector and this means that there are more market pressures that exist in that sector, and more competition requires more manufacturing firms to adopt the most strategic MAPs in order to claim their business value (Ho et al., 2016). However, Grubic & Peppard (2016) urge that it is the skills, experience and knowledge of MAPs that drives a competitive edge for manufacturing SMEs in the market. Marketing by manufacturing SMEs plays a huge role in maintaining the right level of customer satisfaction, product specifications and innovative methods of production processes (Rekarti & Doktoralina, 2017). It is evident that technology forces manufacturing SMEs to adopt newer or modernised MAPs using the latest technology in order to gain a greater market share (Soto-Acosta et al., 2017). Andersén & Samuelsson (2016), claims that a firm's competitive advantage is driven by many diversified elements that constitute a greater value, distinct, and by smartly allocating the limited resources accordingly. As found by Ocloo et al. (2018) competition influences the adoption of relevant MAPs which are essential in gaining a competitive edge.

Changes in the Economy Influence the Adoption of MAPs by Manufacturing SMEs

In South Africa recession has faced the country over the years and this directly affects the trading of SMEs and could possibly have an influence on the adoption of MAPs. Mc Namara, Murro & O'Donohoe (2017) found that in Europe the inflation rate had an influence on the performance of SMEs towards the GDP as well as the infrastructure to ascertaining finance in the banking sector was declining. Ipinnaiye et al. (2017) revealed that inflation not only affects the performance but also is a driver to the levels of growth, output, pricing or costing of produce or services under the endures circumstances for SMEs. Other factors that were identified by scholars as part of the changes in the economy was a crime, in which South Africa was ranked number 72 in the GEMs report and this showed that crime had an impact on the firms' survival abilities (Sitharam & Hoque, 2016).

Management Accountants (MAs) and Accounting Practitioners (APs)

Accountants are professions who render accounting services, as well as managerial and advisory services (Kirsten et al. 2015). Management accountants and Accounting practitioners understand the nature of the various entities that require a series of services from them and they are equipped with knowledge and skills to assist managers in carrying out the company's objectives. The majority of manufacturing SMEs who acquire such services aim to improve the performance of the firm (Carey, 2015; Fagbemi & Olaoye, 2016). The rate of employing MAs or APs by manufacturing SMEs highly depends on the affordability or availability of resources (Cherry, 2016; Maziriri & Mapuranga, 2017). Furthermore, Carey (2015) found that in the United State of America, Australia and the United Kingdom Mas and APs were highly trusted by the various companies typically SMEs as they provide high valuable advices. With scarce resources, the owner ends up taking the task which could be rendered by the MA or APs which then raises the questions of accuracy and reliability of the information provided (Nandan, 2010). Kirsten et al. (2015) highlighted that the owners of manufacturing SMEs lack accounting skills as well as the knowledge of running a business, as a result, they end up confusing information which has an implication on their decision making. Moreover, all decisions taken by a business owner have a direct influence on the business performance and proper knowledge and skills are required to execute this phase.

Methodology

This research study adopted a quantitative research approach where questionnaires in a Likert scale form were utilised to collect data from the targeted population. The targeted population consisted of manufacturing SMEs situated within Durban central business district (CBD) in KwaZulu-Natal. A conclusive report of all registered manufacturing SMEs within the CBD is not available on public domain. The Durban Chamber of Commerce reflected that there are about 2000 SMEs registered, but the report lacks to provide a conclusive report reflecting the number of registered manufacturing SMEs operating in Durban CBD. Based on this, a nonprobability (purposive) sampling technique was therefore identified as the ideal sampling method to be adopted based on its characteristics on situations where the population is unknown. The manufacturing SMEs operating within Durban CBD were consulted to gather data pertaining to internal and external factors that influence their ability to adopt MAPs that are crucial for business growth and sustainability. The questionnaires were hand distributed to manufacturing SMEs. A total of 80 questionnaires were distributed to manufacturing SMEs within the CBD and 51 questionnaires were returned. A 64% response rate was achieved regardless of the challenges faced during the data collection phase.

Data Analysis

Data collected from the questionnaires was coded and analysed using SPSS version 25.0. Descriptive analysis was done and reflected in frequencies and percentages. This was conducted to determine the level of agreement and disagreement of respondents on internal and external factors that contribute to the adoption of MAPs.

Validity and Reliability

Validity and reliability of the data collection instrument was improved by sending the instrument to research expert within the field of entrepreneurship and small businesses and to a qualified statistician. This was done to ensure that there was no ambiguity or duplication of the tested variables. A reliability test was also conducted and measured using Cronbach’s Alpha at 0.70. A strong reliability score of 0.76 was achieving, meaning that this study had a respectable measure of reliability. The reliability test score is reflected in Table 1 below.

| Table 1: Reliability Statistics | ||

| Cronbach's Alpha | Cronbach's Alpha Based on Standardized Items | N of Items |

|---|---|---|

| 0.762 | 0.771 | 15 |

Result and Discussions

The objective of this section was to identify critical environmental factors that influence the adoption of MAPs by manufacturing SMEs in Durban CBD. These factors were divided into two, namely, internal factors and external factors. The empirical findings of this study are presented in bar graphs.

Internal Factors Affecting the Adoption of MAPs by Manufacturing SMEs

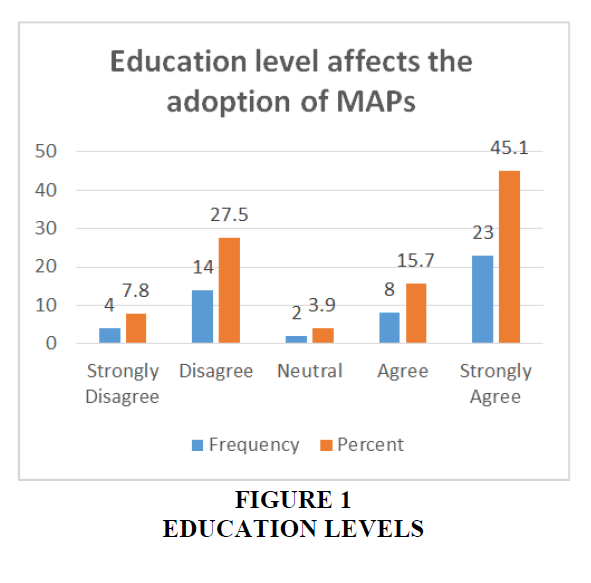

Figure 1 reflects whether the level of education possessed by of manufacturing SME owners influences the adoption of MAPs. Based on the findings above, almost half of the respondents 23 (45.1%) strongly agreed and 8 (15.7%) agreed that the level of education of owners influences the adoption of MAPs within the manufacturing SME sector, while 2 (3.9%) of the respondents were neutral to the statement, with only 14 (27.5%) disagreeing and 4 (7.8%) strongly disagreeing with the statement. This clearly indicates that, the respondents valued education and regarded it as a key component in improving business processes which are key to the firms continued existence.

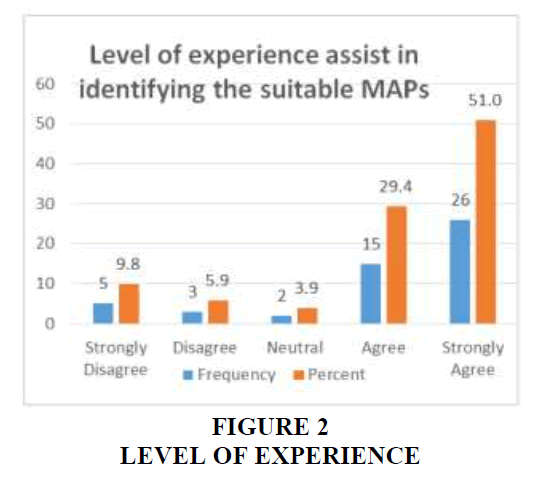

Based on the findings reflected in Figure 2, more than half of the respondents 26 (51%) strongly agreed and 15 (29%) agree that the level of experience influences the adoption of MAPs with only 5 (9.8%) and 3 (5.9%) strongly disagreeing and disagree with the statement respectively and only 2 (3.9%) respondents were neutral. These findings indicate that in order for manufacturing SMEs to be able to adopt MAPs, they will have to acquire adequate experience to help them identify and use relevant MAPs that will suit the needs of the firm.

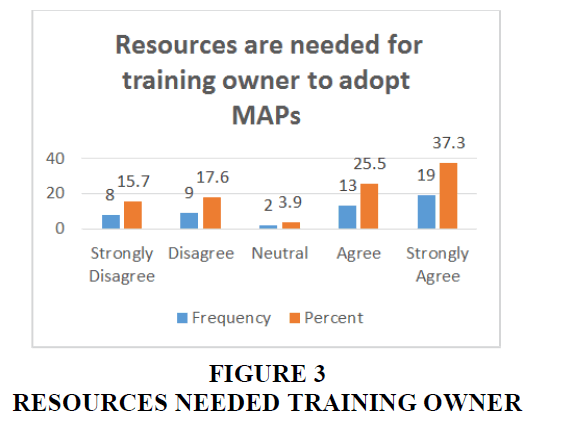

Figure 3 reflects that resources needed for training owner to adopt MAPs. A moderate number of the respondents 19 (37.3%) strongly agreed and 13 (25.5%) agreed that resources are essential for training the owner to adopt MAPs. Only 9 (17.6%) and 8 (15.7%) respondents disagreed and strongly disagreed respectively with the statement and only 2 (3.9%) respondents were neutral. These findings are in line with literature in that manufacturing SMEs need resources for them to adopt MAPs.

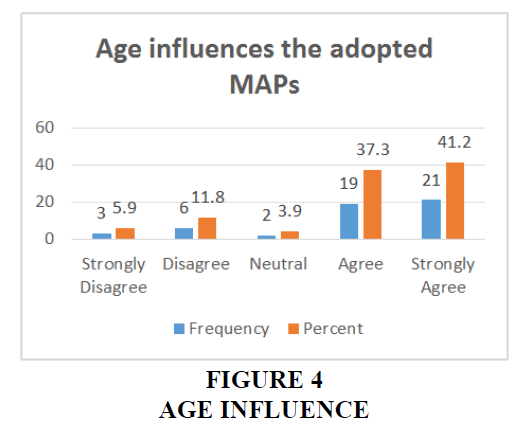

Based on the findings in Figure 4, a significant number of the respondents 21 (41.2%) strongly agreed and 19 (37.3%) agreed that the age of the firm plays a critical role in the adoption of MAPs. Only 6 (11.8%) respondents disagree and 3 (5.9%) respondents strongly disagreed to the statement, while only 2 (3.9%) respondents were neutral to the statement. These findings clearly indicate that the adoption of MAPs is closely linked with the age of the firm. This is because age is linked with experience and in order for manufacturing SMEs to be able to adopt MAPs, they will have to understand the objectives of the firm and how the firm intends to incorporate those MAPs to improve and expedite business processes.

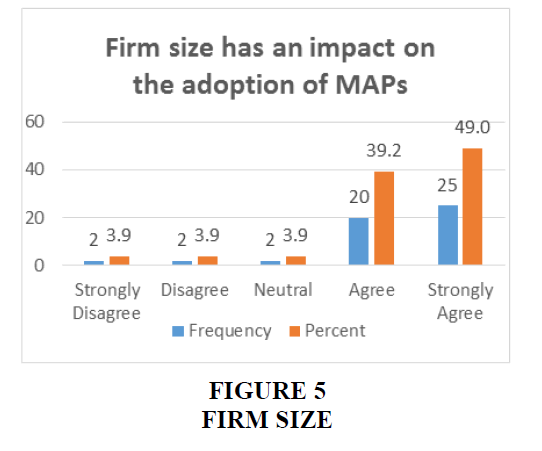

Figure 5 reflects whether firm size has an impact on the adoption of MAPs. Almost half of the respondents 25 (49%) strongly agreed and 20 (39.2%) agreed that firm size influences the adoption of MAPs in manufacturing SMEs. Only 2 (3.9%) respondents strongly agreed and disagreed respectively with the statement, with neutral also recording a 3.9%. These findings clearly indicate that the adoption of MAPs is strongly aligned with the firm size. This may be due to the fact that large manufacturing SMEs are more complex and can adopt sophisticated MAPs as they are conducive in expediting business processes and performance.

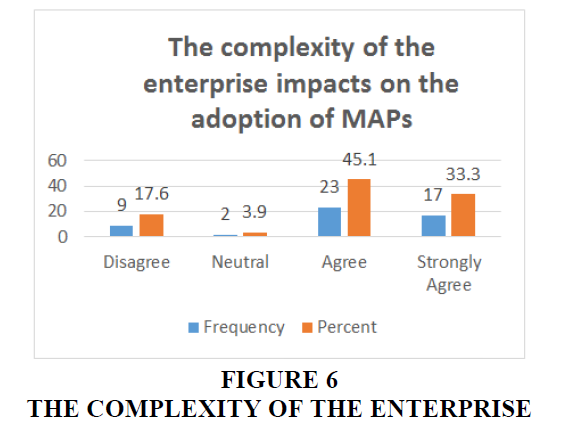

Based on Figure 6, a considerate number of the respondents 23 (45.1%) indicated agreed and 17(33.3%) strongly agreed that the complexity of the enterprise impacts on the adoption of MAPs by manufacturing SMEs. Only 9 (17.6%) respondents disagree with the statement with 2(3.9%) being neutral. The following section focuses on the external factors.

External Factors Affecting the Adoption of MAPs by Manufacturing SMEs

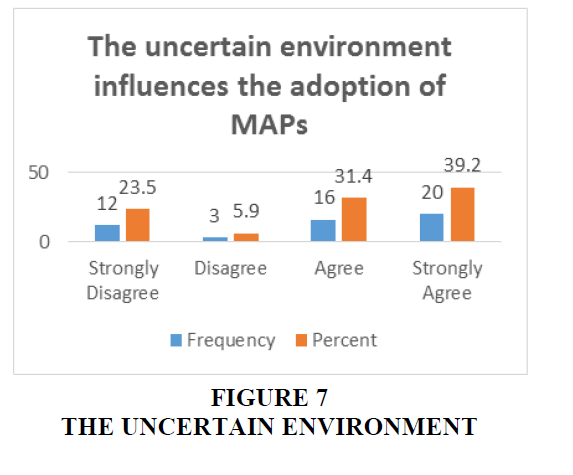

Based on Figure 7 above, a significant number of the respondents 20 (39.2%) and 16 (31.4%) strongly agreed and agreed respectively that the uncertainty in business environment influences the adoption of MAPs. Very few respondents were in disagreement with the statement with 3 (5.9%) disagreeing and 12 (23.5%) strongly disagreeing with the statement.

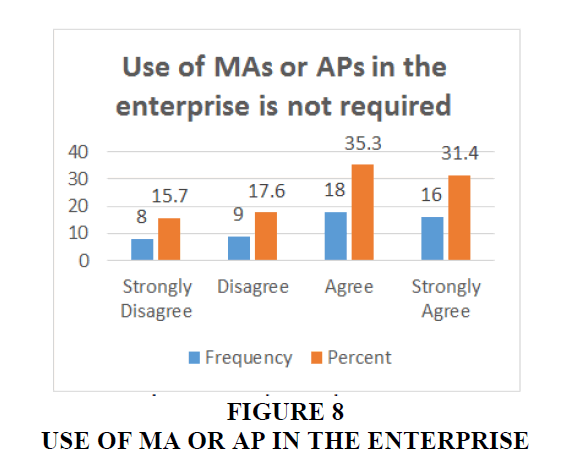

The findings depicted in Figure 8 reflects whether the use of Management Accountants and Accounting Practitioners is required in manufacturing SMEs. A considerable number of the respondents 18 (35.3%) and 16 (31.4%) agreed and strongly agreed that manufacturing SMEs do not require the use of MA or APs. The failure of manufacturing SMEs to acquire the services of Management Accountants and Accounting Practitioners is probably due to their affordability as their services do not come cheap.

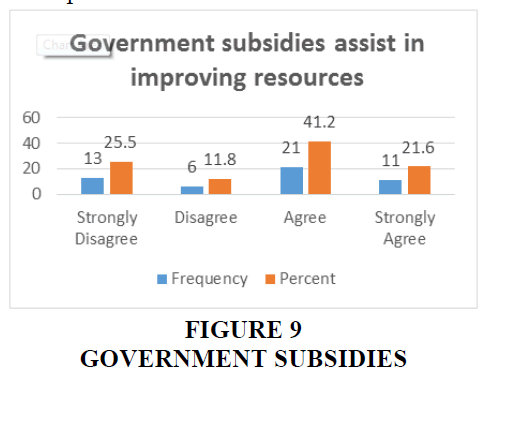

Based on Figure 9 above, a significant number of the respondents 21 (41.2%) agreed and 11 (21.6%) strongly agree that government subsidies play a critical role in improving the manufacturing SMEs resources which are greatly needed in the adoption of MAPs. Only few respondents 13(25.5%) strongly disagreed and 6 (11.8%) disagreed that government subsidies assist in the improvement of resources. These finding clearly indicate that government funding is key to the development of manufacturing SMEs more specifically in supporting of the adoption of MAPs.

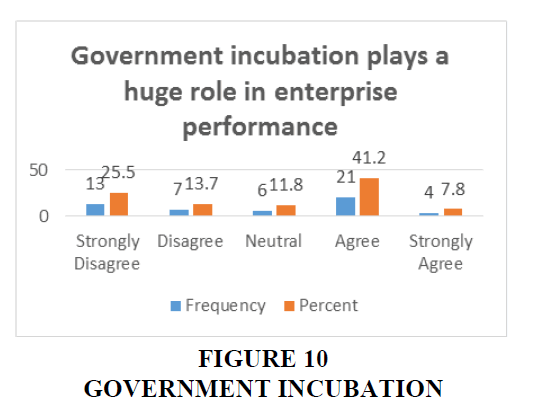

Based on the findings, as reflected in Figure 10, government business incubation plays a fairly moderate contribution towards the enterprise performance. This is reflected by a considerable number of respondents 21 (41.2%) who agreed that government incubation plays a huge role in the enterprise performance. Fewer respondents 13 (25.5%) and 7 (13.7%) disagreed and strongly disagreed respectively with the statement, while 6 (11.8%) were neutral. These findings clearly show that almost half of the respondents don’t consider government business incubators as a key factor to business performance. This might be due to government incubators inability to provide field related development and support, and catering for the specific needs of businesses as they are distinctively different.

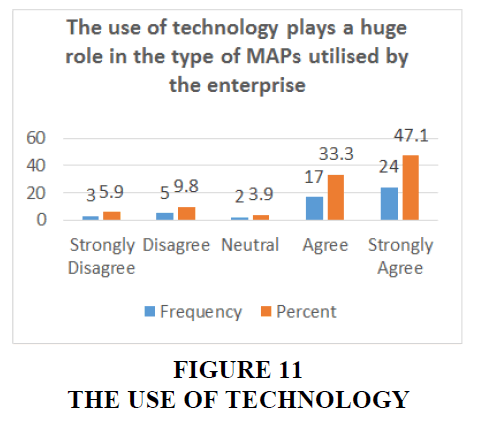

Figure 11 above reflects whether the use of technology plays a huge role in the type of MAPs utilised by the enterprise. Almost half 24 (47.1%) of the respondents strongly agreed and 17 (33.3%) agree that the type of MAPs utilised by manufacturing SMEs is heavily dependent on technology systems currently used by the firm. Only 5 (9.8%) and 3 (5.9%) disagreed and strongly disagreed with the statement respectively while 2 (3.9%) respondents were neutral. The findings strongly indicate that manufacturing SMEs ability to adopt MAPs is strongly aligned with the current technologies and systems used by a firm. This means that for MAPs to have a positive influence on the entities’ performance, good technological support is needed.

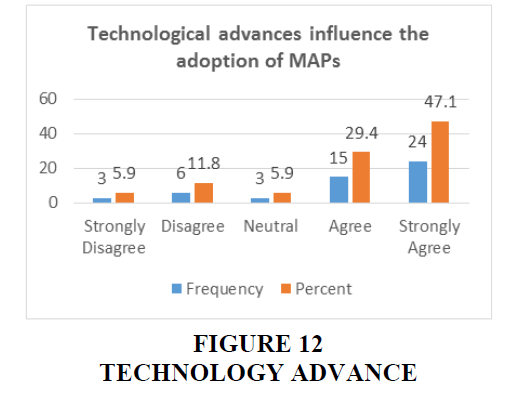

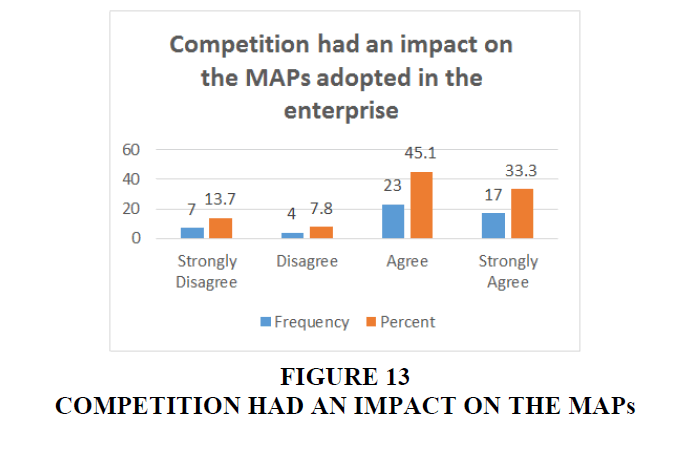

Based on findings in Figure 12 above, shows the results pertaining to the technology advancements have a significant influence on the adoption of MAPs with 24 (47.1%) of the respondents strongly agreeing and 15 (29.4%) of the respondents agreeing. 3 (5.9%) of the respondents were neutral with the statement while 6 (11.8%) disagreed and 3 (5.9%) strongly disagreed with the statement. The findings clearly indicate that the majority of the respondents viewed technological advances as a key contributing factor in adopting MAPs. This means that manufacturing SMEs need to continuously upgrade their MAPs to be compatible with the current technologies and software (Figures 13 & 14).

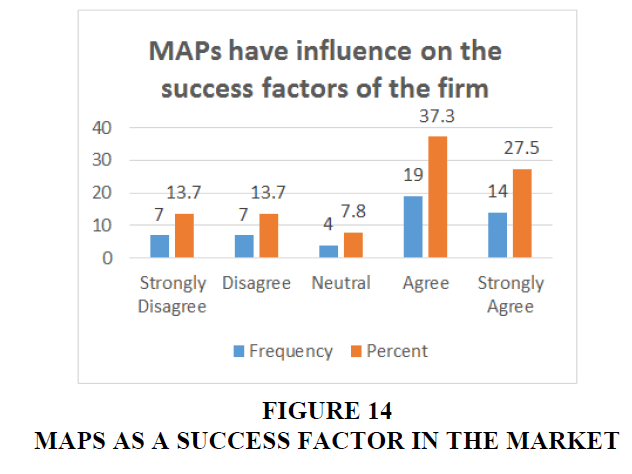

Based on the findings in Figure 15 above, a significant number of the respondents 23 (45.1%) and 13 (33.3%) agreed and strongly agreed that business competition influences the adoption of MAPs. Only 7 (13.7%) respondents strongly disagreed and 4 (7.8%) disagreed that competition had any influence on the adoption of MAPs by manufacturing SMEs in Durban. These results conclusively indicate that competition plays a key role in the adoption of MAPs. This might be due to the fact that other manufacturing SMEs are gradually starting to realise the importance of MAPs and have identified them as a strategic tool to gaining competitive advantage. Based on the findings in Figure 14 above, a moderate number of the respondents 19 (37.3%) agreed and 14 (27.5%) strongly agreed that the adoption of MAPs can be identified as a success factor for manufacturing SMEs performance in the market. However, only 7 (13.7%) respondents strongly disagreed and disagreed respectively with the statements, while 4 (7.8%) respondents were neutral. This may be the case for smallest and medium enterprises as they have a manageable control system that can allow better success factors which will enhance the business performance.

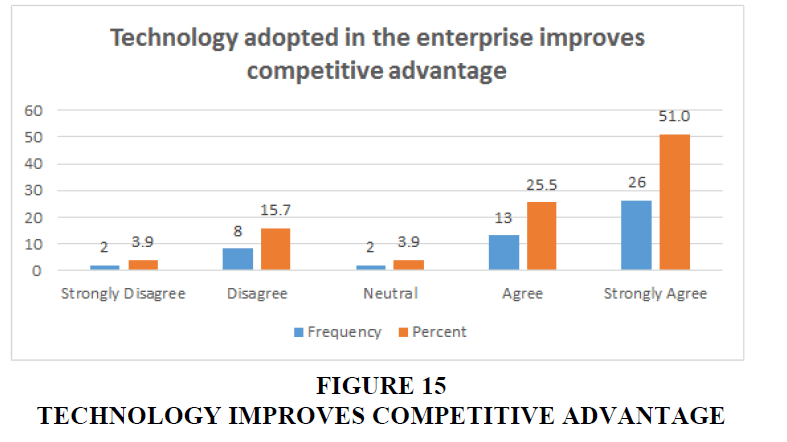

The findings in Figure 15 above, reflects whether technology improve competitive advantage of manufacturing SMEs in Durban. The findings show that a significant number of the respondents 26 (51.0%) strongly agreed and 13 (25.5%) agreed that the technology adopted by manufacturing SMEs in Durban improve competitive edge. Only 8 (15.7%) and 2 (3.9%) disagreed and strongly disagreed, while 2 (3.9%) were neutral to the statement. These findings conclusively show that technology is one of the key components in attaining competitive edge. This means that, in order for manufacturing SMEs to acquire competitive advantage, they will need to constantly adopt new technology systems to better improve their business performance.

Conclusions And Recommendations

Conclusions

The following conclusions are based on the empirical findings of the study and are in line with objectives of the study. It is concluded that firm size, availability of resources, firm age and level of experience are critical internal factors that influenced the adoption of MAPs by manufacturing SMEs in Durban. The study also concluded that technology, competition, technological advances, government subsidy and government incubation were all identified as key external environmental factors that contributed in the adoption of MAPs by manufacturing SMEs. This will not only have a significant impact on the operations of the firm but will greatly improve the management of resources, budgeting and facilitate decision making process. This study further concluded in line with the studies conducted by Otley (1980), Ahmad & Mohamed Zabri (2015); Otley (2016); Azudin & Mansor (2018) that the adoption of MAPs can be considered regardless of the diversity of the firm. The study also concludes that in order for manufacturing SMEs to remain competitive in the market, strategic MAPs should be enforced because without the usage of proper MAPs, manufacturing SMEs will find it extremely challenging to exist and be dominant in the market economy and be able to absorb the pressures and expectation that come with the 4th industrial revolution.

Recommendations

The following recommendations were made based on the objectives mentioned above. The empirical findings of this study indicated that the adoption of MAPs by manufacturing SMEs in Durban is highly influenced by both internal and external environmental factors. For manufacturing SMEs to be more sustainable in this rapid changing business environment, the usage of relevant MAPs need to be imbedded on their business operations. The study recommends that irrespective of the size, there is a great need for manufacturing SMEs to adopt relevant MAPs at birth phase as this will enhance their business performance and sustainability. The early usage of MAPs will help them identify and invest in MAPs that will sufficiently accommodate the needs of the firm. Further, the study recommends that manufacturing SMEs should adopt MAPs regardless of the firm age. This is due to the fact that application of MAPs can be adopted at any given stage. This requires manufacturing SMEs to invest and manage their resources strategically to accommodate for training needs of manufacturing SME owners to improve the awareness and adoption of MAPs. The study further recommends that manufacturing SME owners should not solely rely on their level of experience but rather increase their competency levels and knowledge in relation to MAPs as they have been identified as the solution to manufacturing SMEs sustainability. For manufacturing SMEs to enjoy and exploit the usage of MAPs, they will have to intensively invest on technological systems conducive to the adoption of MAPs. Manufacturing SMEs can use this as a strategic tool over its competitors.

In terms of government business incubators and subsidy, it is recommended that the government should improve the services and business financial support provided to manufacturing SMEs. The services should be specifically catered and provided to meet the specific needs of a firm. Once support has been provided, follow-ups and checks should be done timeously to avoid any relapse that may occur. It is therefore viewed that the lack of adoption of MAPs by manufacturing SMEs in Durban will have serious business implications for firms in terms of generating profits, growth and sustainability. This will also affect the province of KwaZulu-Natal as it heavily relies on manufacturing SMEs for providing both informal and formal employment and contributing immensely towards the economy of KwaZulu-Natal. It is therefore imperative that manufacturing SME owners seek for government and private funding that will enable them to improve the entity’s’ economic life.

References

- Ahmad, K., & Mohamed Zabri, S. (2015). Factors explaining the use of management accounting practices in Malaysian medium-sized firms. Journal of Small Business and Enterprise Development, 22(4), 762-781.

- Amara, T., & Benelifa, S. (2017). The impact of external and internal factors on the management accounting practices. International Journal of Finance and Accounting, 6(2), 46-58.

- Armitage, H.M., Webb, A., & Glynn, J. (2016). The use of management accounting techniques by small and medium‐sized enterprises: a field study of Canadian and Australian practice. Accounting Perspectives, 15(1), 31-69.

- Ayandibu, A.O., & Houghton, J. (2017). The role of small and medium scale enterprise in local economic development (LED). Journal of Business and Retail Management Research (JBRMR), 11(2), 133-139.

- Azudin, A., & Mansor, N. (2017). Management accounting practices of SMEs: The impact of organizational DNA, business potential and operational technology. Asia Pacific Management Review, 1-5.

- Azudin, A., & Mansor, N. (2018). Management accounting practices of SMEs: The impact of organizational DNA, business potential and operational technology. Asia Pacific Management Review, 23(3), 222-226.

- Baporikar, N., Nambira, G., & Gomxos, G. (2016). Exploring factors hindering SMEs’ growth: Evidence from Namibia. Journal of Science and Technology Policy Management, 7(2), 190-211.

- CIMA. (2015). Management accounting tools for today and tomorrow. UK: CIMA Publishing.

- Drury, C. (2015). Management and Cost Accounting. 8th ed. London: Cengage Learning.

- Essel, B.K.C., Adams, F., & Amankwah, K. (2019). Effect of entrepreneur, firm, and institutional characteristics on small-scale firm performance in Ghana. Journal of Global Entrepreneurship Research, 9(1), 1-20.

- Fagbemi, T.O., & Olaoye, J.A. (2016). An evaluation of accounting information system and performance of small scale enterprises in Kwara State, Nigeria. DBA Africa Management Review, 6(1), 1-16.

- Fernández-Olmos, M., & Ramírez-Alesón, M. (2017). How internal and external factors influence the dynamics of SME technology collaboration networks over time. Technovation, 64, 16-27.

- Fiseha G.G. & Oyelana, A.A. (2015). An Assessment of the Roles of Small and Medium Enterprises (SMEs) in the Local Economic Development (LED) in South Africa. Journal of Economics, 6(3), 280-290.

- Hiebl, M.R., Quinn, M., Craig, J.B., & Moores, K. (2018). Management control in family firms:A guest editorial. Journal of Management Control, 28(4), 377-381.

- Jamil, C.Z.M., Mohamed, R., Muhammad, F., & Ali, A. (2015). Environmental management accounting practices in small medium manufacturing firms. Procedia-Social and Behavioral Sciences, 172, 619-626.

- Joshi, S., & Li, Y. (2016). What is corporate sustainability and how do firms practice it? A management accounting research perspective. Journal of Management Accounting Research, 28(2), 1-11.

- Maziriri, E.T., & Mapuranga, M. (2017). The impact of management accounting practices (maps) on the business performance of small and medium enterprises within the Gauteng Province of South Africa. The Journal of Accounting and Management, 7(2), 12-25.

- Ngibe, M., & Lekhanya, L.M. (2019). Critical factors influencing innovative leadership in attaining business innovation: a case of manufacturing SMEs in KwaZulu-Natal. International Journal of Entrepreneurship, 23(1), 1-20.

- Obi, J., Ibidunni, A.S., Tolulope, A., Olokundun, M.A., Amaihian, A.B., Borishade, T.T., & Fred, P. (2018). Contribution of small and medium enterprises to economic development: Evidence from a transiting economy. Data in brief, 18, 835-839.

- Omsa, S., Ridwan, M., & Jayadi, M. (2018). The effect of strategic management practices on SME performances in Makassar, Indonesia. American Journal of Theoretical and Applied Business, 3(4), 71-80.

- Otley, D. (2016). The contingency theory of management accounting and control: 1980-2014. Management accounting research, 31, 45-62.

- Otley, D.T. (1980). The contingency theory of management accounting: achievement and prognosis. In Readings in accounting for management control. Springer: Boston, MA.

- Uyar, M. (2019). The management accounting and the business strategy development at SMEs. Problems and Perspectives in Management, 17(1), 1-10.

- Peter, F., Adegbuyi, O., Olokundun, M., Peter, A.O., Amaihian, A.B., & Ibidunni, A.S. (2018). Government financial support and financial performance of SMEs. Academy of Strategic Management Journal, 17(3), 1-10.

- Sahoo, S., & Yadav, S. (2018). Lean implementation in small-and medium-sized enterprises: An empirical study of Indian manufacturing firms. Benchmarking: An International Journal, 25(4), 1121-1147.

- Shahzadi, S., Khan, R., Toor, M., & Haq, A.U. (2018). Impact of external and internal factors on management accounting practices: a study of Pakistan. Asian Journal of Accounting Research, 3(2), 211-223.

- Sibanda, K., Hove-Sibanda, P., & Shava, H. (2018). The impact of SME access to finance and performance on exporting behaviour at firm level: A case of furniture manufacturing SMEs in Zimbabwe. Acta Commercii, 18(1), 1-13.

- Valtakoski, A., & Witell, L. (2018). Service capabilities and servitized SME performance: contingency on firm age. International Journal of Operations & Production Management, 38(4), 1144-1164.

- Yeboah, M.A. (2015). Determinants of SME growth: An empirical perspective of SMEs in the Cape Coast Metropolis, Ghana. The Journal of Business in Developing Nations, 14(1), 2-31.