Review Article: 2022 Vol: 26 Issue: 4

Factors Affecting the Post-Harvesting Wastage of Fruits and Vegetables Along the Food Supply Chain: An Empirical Study

Sashikala Parimi, IBS, IFHE

Samyadip Chakraborty, IBS, IFHE

Citation Information: Parimi, S., & Chakraborty, S. (2022) Factors affecting the post-harvesting wastage of fruits and vegetables along the food supply chain: An empirical study. Academy of Marketing Studies Journal, 26(4), 1-17.

Abstract

Forecasting based studies highlight that Food production crisis is going to worsen in India by 2030 and by 2050 it would become very critical. India, which currently is the second most populous country in the world, will need 60 percent more food production and also drastically prevent food loss by 2050. Although there are technologically advanced mechanisms to reduce the wastage of harvested fruits and vegetables, farmers are concerned about spillover of products during post-harvest supply stage. Along the various stages of movement and storage along the supply chain, large portion of harvested fruits and vegetables get wasted. The study explores and analyses the factors affecting food wastage in post harvesting of fruits and vegetables at three stages: i). when the fruits and vegetable items are with farmers, ii) procurement and storage phase with wholesaler/ cold-storages and iii) wastage at retailer level. The study narrows down on key factors and empirically analyzes the impact of a) productivity and quality standards, b) awareness linked knowledge, c) quantity related aspects, d) efficiency and wastage related aspects and e) transportation linked aspects, on post-harvest loss of fruits and vegetables in the state of West Bengal with the help of 335 respondents along key stages of agricultural supply chain. The study results suggest the key factors that that are affecting the post-harvest wastage of food and thus portrays a ready to refer guideline and framework that might help in creating the nuanced understanding regarding the overarching goal of minimization of food wastage through identification and analysis of the factors, significantly impacting the post-harvest wastage of food.

Keywords

Post Harvest Wastage, Agriculture, Agri Supply Chain, fruits and Vegetables.

Introduction

India is the second most populous country in the world with 1.21 billion people according to the last census data released by in 2013. During the decade 2001-2011, there is an increase of 181.96 million population, since 2001; indicating that 17.31% of the world’s population is represented by India. Thus, one out of every six people in the world live in India. With a growth rate of 1.58%, the population of India is forecasted to be more than 1.53 billion by the end of 2030. The supply of the food needs to be increased by 60% to meet the demand of food by 2050. The researchers and the planners of agricultural products are focusing on increasing the food production and not on the post-harvest food losses. The increase in the production of food alone is not sufficient to meet the needs of the increased population but there is dire need in the reduction of food losses in the post-harvest process at farm, retail and the consumer’s level. The literature indicates that 95% of the investment on the research for the last three decades concentrated on the increase in productivity and only 5% is dedicated to reducing the losses (Kader (2005); Kader et al, (2004)). Increase in agricultural productivity is just not sufficient though it is vital to guarantee the global food security. In order to achieve sustainable food security, the availability of food need to be increased by reducing the post-harvest losses at farms, retail and consumer levels.

India is the one of the largest producer of fresh fruits and vegetables, milk, spices, fish etc. India produces about 81.285 MT fruits and 162.187 MTs of Vegetables which contribute to 14% of country’s share in the world production of vegetables. The most popular vegetables from more than 70 types in India are tomato, brinjal, chilli, cauliflower, cabbage, peas, potatoes, onions and leafy vegetables. Among these vegetables, potato is cultivated more followed by tomato, onion and brinjal. They provide employment and generate high income especially for small farmers. The main disadvantage of vegetable production in India is because of lack of efficient supply chain for the distribution of fruits and vegetables. The per capita availability of fruits and vegetables is low due to the post-harvest losses which are about 25-30% of the production. Apart from this the quality of substantial quantity of the food produced deteriorates by the time it reaches the consumers relating to perishability due to which the prices fluctuate and may lead to various other problems. The major factors which cause this situation are lack of usage of technology and proper supply chain. Though the fruit and vegetable sector has grown significantly both in volume and variety, it is not been matched by the developments in Supply chain in many developing countries. The importance of traditional supply chains is more in spite of rise of modern supply chains for certain products and certain type of consumers. In the perishable products the advantages of traditional supply chain occur with three man interrelated factors such as ability to offer products at low prices, considerable flexibility in product standards and convenience for consumers due to flexible market locations. Food losses can be quantitative if the decrease in weight is measurable or qualitative if there is a change in the nutrient value, taste, colour or texture (Buzby et al, 2012). The quantitative loss occurs due to spillage, consumption by pest and due to physical changes in temperature, moisture content and chemical changes. If there is reduction weight due to drying which is necessary process for all grains, it should not be counted as loss, The food losses are due to insect pest, mites, rodents and birds leading to the changes in fat, proteins etc. This is qualitative deterioration makes food unfit for human consumption and can be considered as loss of food.

Food waste is a subset of food losses. Food waste occurs when an edible food item is not utilized by humans (Buzby et al, 2012). When an object which is discarded or is required to discard is defined as waste as per the report in 2009 by Wastes and Resources Action Program (WRAP) (Quested and Johnson, 2009). The various factors which contribute to the food loss may be due to mechanization such as handling, processing, weather conditions, production practices, management decisions, transport facilities , infrastructure. The technologies used in the supply chain have an impact on the losses occurred at every step of supply chain. The larger losses occur during drying, storage, processing and in transportation due to less mechanized supply chain in the developing countries. The present supply chain which is connecting the farmers to both organized and unorganized is highly inefficient with several intermediaries and manual handling (Deliya et al 2012).

Literature Review

The loss of food until it reaches the consumer is quite significant and the post-harvest losses ranges from 15 to 50% in the developing countries. The loss due to perishable products is more compared to non-perishable products (Parfitt et al., 2010). In order to increase the availability of the food it is not only necessary to increase the productivity in agriculture but also reduce the losses. According to a study in Ethiopia, the knowledge of post-harvest handling is limited in the supply chain due to which the losses are high in post-harvesting (Wakijira, 2010). According to Kader, 2003 losses occur in all the post-harvest activities such as handling, storage, processing, packaging, transportation and marketing and suggested that handling and processing of the food are very crucial in order to ensure food-safety and reduce losses.

There would be variations in the supply of the products due to different growing seasons, weather changes and production technologies used. The production is commonly scattered and large number of farmers produce for local markets with a limited number of traders. In order to reach the central markets there would be large number of middlemen between the producers and the consumers (Shukla et al, 2013).

The infrastructure, access to information, new production technology, credit and external services are weak and limited in the supply chains of developing countries (Trienekens, 2011). The losses and wastage of food is majorly due to insufficient operational activities such as handling, storage and transportation within the supply chains (Murthy et al., 2009).

In developing countries, the main focus is to improve and upgrade processes, quality and distribution and acquire more knowledge all operations and activities of the supply chain management and implementation of advanced post-harvest technologies (Kitinoja et al., 2011).

The post-harvest losses can be both in terms of quality and quantity. These losses may happen at any stage of the supply chain starting from harvesting, transportation, packaging at market places (Hodges et al., 2011; Kader, 2009). The qualitative losses can occur due to biological deterioration which may be because of water stress, mechanical injuries, respiration rate, compositional changes and so on (Kader, 2004) which are due to the impact of environmental factors such as temperature, humidity, sanitary factors and the concentration of ethylene, carbon dioxide and oxygen. The measurement of qualitative losses is complicated whereas the measurement of quantitative losses is very important in developing countries. In developing countries for the products to reach the markets and minimize post-harvest losses, there is a need for better education of producers, improvement in the infrastructure, developed value chains, collaboration between the stakeholders in the supply chain (Hodges et al., 2011). Proper post-harvest technologies have to be adopted in order to reduce the losses and to increase the shelf-life with acceptable safety and quality of fruits and vegetables. This is the case in developing countries due to lack of communication, poor wholesale markets and market information among the stakeholders. The other factors which are contributing to the food losses are the facilities of storage, unloading, loading and packaging which are very poor and do not exist. Inadequate transportation facility is another factor contributing to post-harvest losses. Knowledge and information on handling the fruit and vegetables efficiently with proper equipment is necessary in order to minimize losses (Kader, 2004).

Objectives

To understand the factors that affect the food wastages in the context of post harvesting logistics with specific reference to fruits and vegetables across different levels of food supply chain.

1. To examine the factors that affects the food wastage with farmers in the post harvesting of fruits and vegetables.

2. To analyze the factors that affects the food wastage in procurement and storage of fruits and vegetables.

3. To examine the factors that affects the food wastage with wholesalers/retailers of fruits and vegetables.

Hypotheses

Productivity and Quality Standards

The most important factor is quality in the supply chain of the food industry to deliver fresh fruits and vegetables keeping in view the health of the consumers. The fresh food has to be delivered in time and in good quality to the consumer. It is a challenge for the food supply chain to maintain the shelf life of the fresh produce and to prevent from deteriorating the quality so that the productivity increases and less rejection by the consumer. This is one of the major challenges in the developing countries like India due to lack of quality standards to meet the export quality, poor hygiene, safety standards, high quality degradation., (Singh et al,(2009), Narula,(2011)).

The chances of deterioration and the chance of damage and loss increases as the duration of the storage of food in increases. So, the storage time plays an important role in loss of foods for which the shelf life is short. The shelf life of the product decreases as the product travels through the various stages of the supply chain. This leads to both qualitative and quantitative losses which leads to the total post-harvest losses as the product travels through the supply chain (Kwami et al, 2019)

Quality and safety problems deliberated are due to poor yield and quality standards of international markets, poor hygiene and safety standards. The control over product safety and quality across the supply chain is due to of manual handling, lack of tracking and traceability facilities, higher quality degradation etc (Veena et al, 2011).

Now a days the awareness of the need for safety of food and quality has been publicized due to eruption of foodborne diseases around the world (Karippacheril et al, 2011). Hence in order to safeguard the food safety, improving the product quality and withstand the competitive advantage in the market the food producers are looking at the supply chain traceability which has the ability to trace the movement in the supply chain starting from the supplier, transportation, retailer to the final consumer along the supply chain. This helps in improvement in operational performance, optimizing the inventory, product quality and food safety (Bechini et al. 2008). Along with this with the advancements in the technology such as Radio Frequency Identification (RFID) helped the food producers to trace and track the food products using real time data(Bechini et al. 2008).

The packaging of the fruits should be ventilated in order to protect the fruits from the mechanical damage (Thompson et al, 2002, Hofman et al., 2013). Proper care should be taken in the packaging of the fruits so that the packages are strong enough to protect the fruit and not to load too much of fruit on top of each other and the package should hold a maximum weight of 20 kg as the fruits get damaged when a heavy box is dropped on top of another (Thompson et al, 2002).According to Choudhury (2006), the rate of loss is high in India due to lack of packaging houses as the fresh produce is generally packed the field or even transported without any packaging during transportation

It is necessary to have high quality of proper packaging of fresh fruits and vegetables as they are perishable so as to maintain their shelf life. In this regard cost is an important factor as high cost of packaging makes it challenging for the farmers to do proper packaging (Jain,2007; Mathi, 2007; Sharma et al, 2011). Based on the extant literature the following hypothesis is formulated.

H1: Lack of productivity and quality standards positively effects the post-harvest losses.

Awareness Linked Knowledge (ALK)

The important aspect of the supply chain to run smoothly is the flow of information It is very much necessary in the case of fresh and perishable food products due to short shelf space. This is considered to be one of the major reasons for the wastage and loss of fresh produce (Viswanadham, 2007). It was also found that lack of information on demand is the reason for the wastage of food (Buyukbay et al. 2011). According to the study conducted by Kader (2005) lack of information is one of the socio economic factor leading to the post-harvest losses. The fresh food at the retail level gets wasted due to the reason that the food remains unsold even after the expiry date. This is due to lack of information regarding the demand and the retailers order more than the real demand (Mena et al., 2011). Further it was studied that experience and knowledge about the technology, market information and new knowledge of farmers regarding technology, market information plays a very important role in the supply chain of perishable fresh food produce because they are the main source and supplier of all the fresh produce and his education, experience and knowledge regarding the technology, market information and new equipment are the factors responsible for losses in the supply chain of perishable fresh produce. Majority of the farmers are small land holder and share croppers and they have very little knowledge regarding the technology, demand in the market, and financial incentives (Shukla et al, 2013).

Babalola et al. (2010) found in his study that most of the farmers around 82.95 % were illiterate which could be a contributory factor to high losses in production of tomato because they cannot appreciate and use most post-harvest technology available and only farmers with post primary education can appreciate and use it. Author also found that majority of the farmer 68.17 % had below the experience of 16 years in tomato production in Imeko-Afon local government area of Ogun state and this could have an effect on losses in the tomato production. Ozcan (2007) also listed lack of training and experience for workers as one of the reasons for post-harvest losses. Sharma et al, (2011) also found in his study on Economic analysis of post-harvest losses in vegetable in Uttarakhand that the losses at grower level results from lack of farmer’s knowledge about the post-harvest management. They also have the very less knowledge about appropriate maturity of fresh produce and proper time of harvesting which results in losses.

For an efficient supply chain proper information is most essential. It is not possible for a supply chain to run successfully without accurate information regarding the market demand, food processing units etc (Mathi, 2007; Vishwanadham, 2007). The farmers in India do not have this information, because of which they are facing heavy losses, late delivery of goods in the market (Veena et al., 2011).

The farmer needs education for best practices in harvest and post-harvest handling which include the most evident techniques that include better sorting, removing defective garins and retaining higher quality for storage (Golob, 2009). A training on these issues was integrated into its multi-faceted PHL reduction strategy with Purchase for Profress (P4P) by The World Food Programme (WFP).

In India the diversified climate supports in producing all varieties of fruits and vegetables. But every year approximately 40% of fruits and vegetables are wasted due to improper handling, storage, packaging, and transportation. There is a lack of knowledge on proper handling practices which is leading to post harvest losses, poor quality and safety standards Siddique et al (2015).

There is a lack of usage of advancement in technology and using inefficient and obsolete techniques and old machinery and this is a concern for the farmers and agricultural businessmen. In other words, lack of suitable technologies, and advanced techniques in food processing, non-implementation of competent technology, usage of machinery which is cost effective machinery and packaging technology leads to post harvest losses (Singh et al., 2009; Narula, 2011). Based on the above discussions the following hypothesis is formulated.

H2: Lack of Awareness linked Knowledge positively effects the post-harvest losses.

Quantity Related Aspects (QRA)

From the time of harvest to consumption of the grains there would be losses both qualitatively and quantitatively. In addition to the factors increase in food production and increase in population another factor considered is the reduction in food losses in the supply chain. Whether the losses are due to the quantity damaged or deterioration in quality, it is related to the post-harvest best practices such as storage, handling, processing and stock management (Adebe et al, 2006).

The post-harvest food losses is defined as the decrease in the quantity and quality of food which becomes unsuitable for human consumption (Grolleaud 2002).

The harvested crop and the yield is stored at the farm before transporting to the processing divisions. The harvesting can be manual or mechanical as in the case of tomatoes and wine grapes (Ferrer et al., 2008). The constraints of scheduling harvest operations is complex as it has limited time window and resources.

Based on the quantity harvested and market demand, a production plan can be decided to minimize delay in processing , maximize stock level of half processed products and rotting of the raw material, (Tsubone et al. (1983)). A production can be planned by considering the variability of the quantity to be harvested based on the market demand to minimize the idle time of the main processing line and inventory levels of the final products.

Weiss model was applied to get the optimal quantity for perishable products in small to medium size grocery stores with delivery surcharges. (Ferguson et al. (2006)). Based on the extant literature the following hypothesis is formulated.

H3: Lack of awareness on Quantity related aspects such as market demand and production plan leads to post harvest losses.

Efficiency and Wastage Related Aspects (EWR)

The supply chain with large of intermediaries would be highly inefficient especially in the case of perishable fresh produce. In India the perishable fresh produce is collected in sizeable share and the traditional supply chain is very long and disjointed. (Singh et al., 2009). The analysis on the losses of fresh vegetables revealed that losses at wholesale level depend on the number of stakeholders in the marketing channel and the length of the channel (Verma et al, 2004). The losses in the quality and quantity of the fresh produce i.e. in the supply chain of fresh fruits and vegetables is the large number of intermediaries and they do not care about the losses incurred to the farmer and are not interested in spending for better cold storage and other facilities (Narula, 2011). In order to reduce these losses companies came up with several models so that the fresh produce can be directly procured from the farmer coined as contract faming which eliminates the layers of intermediaries and reduce the famers’ dependency on these intermediaries.

Transportation is one of the major factors which leads to the losses and wastage of the fresh produce in the logistics and supply chain (Murthy et al., 2009). According to Rehman et al. (2007) the losses majorly occurred during the transportation of the fresh produce to the market. Insufficient and poor transportation facilities are the main reasons in the transportation of fresh produce problem (Sharma et al, 2011; Kader, 2005). According to the study conducted by Singh et al. (2008), the level and degree of post-harvest losses in Uttar Pradesh is due to transportation and distribution of agricultural commodities which was around 24% of the total loss. A crucial factor in transportation is time to deliver the fresh produce in a timely manner with proper quality. Losses may occur if the produce is not delivered in time due to deterioration in quality (Verma et al, 2004). There is a difficulty in collecting and transporting small quantities of the fresh produce from different small farms which leads to the post-harvest losses. The farmers pick the crops in the morning, pack them in wooden crates and transport them to the local market in a truck Rehman et al. (2007). Usage of ordinary transportation, irresponsible driving and rough roads are the reasons of post-harvest losses in the supply chain management of Guava in Allahabad, Uttar Pradesh ((Verma et al, 2004, Mathi (2007).

The handling of the fresh fruits and vegetables is done crudely and transported in open trucks. There would be losses in such case as it may take twenty four hours or more for the fruits and vegetables to reach the retailer and an open market vendor or push cart after harvesting. The fresh produce is also transported in an open truck without any proper cushioning or packaging and it is exposed to the sun due to which the quality deteriorates (Jain, 2007).

The food wastage is caused due to faulty system of transport and delays in the delivery of the fresh produce to the retail market. The shelf life becomes short at the retailer level because of the delay in the delivery and reaches the store shelf late in the case of perishable food supply chain (Mena et al., 2011) which leads to penalty (Shukla et al, 2013). In the developing countries like India transportation is a big challenge due to the unavailability of proper mode of transportation, high cost of transportation, lack of temperature-controlled vehicle for the transport of the goods etc., (Negi et al, 2015).

In order to maintain the quality of fresh produce and increase the shelf life it is necessary to adopt improved mode of transportation such as reefer truck for perishable product so that the losses can be reduced during transportation (Murthy et al., 2007).

Some crops required special facilities like controlled temperature transportation and unavailability of such is the reason for the marketing loss (Ozcan, 2007). Produce are handled roughly and transported in open trucks. It takes twenty four hours or more to the fresh produce to arrives at the retailer, typically an open-market vendor or a pushcart after harvesting. As it is piled into large cane baskets or on to truck beds without cushioning or packaging, that leaves it exposed to the sun in temperature and deteriorates the quality of the fresh produce (Jain, 2007)

In order to minimize the deterioration and to maintain the quality of fruits and vegetables it is necessary to use a cold chain (Kader, 2004). The value of the product is well maintained with a proper functioning of the cold chain (Salin et al, 2003). The losses in quality and quantity of losses of perishable goods can be reduced with a well-developed cold chain. The constraints of a cold chain are the humidity control, storage, handling and lack of or poor refrigeration. It is also essential to keep the product cooled at the loading and unloading area as similar to transportation (Kader et al., 2004). In developing countries the cold chains are scarce due to uncertainty in power supply, inefficient usage and management of cool transport and storage (Kader, 2009). According to a case study led by Salin et al, 2003 in Thailand and Philippines, the major constraint in the cold chain is the lack of proper functioning of cold storage and high distribution costs.

Infrastructure plays an important role and considered to be the backbone of any industry. The infrastructure requirement in case of food supply chain and especially in the case of perishable fresh produce are cold chain, transportation, road connectivity, and network, port infrastructure, marketing facilities etc., one of the main reasons of food losses and wastage in India is poor infrastructure for perishable food supply chain Singh, et al. (2009). The food losses in the post-harvest at every stage of the supply chain occurs due to gaps in cold chain such as poor infrastructure, insufficient cold storage capacity, non-availability of cold storages in the vicinity of the farms, poor transportation infrastructure in the developing countries Viswanadham (2007). In order to maintain and sustain the quality and increase shelf life the supply chain of the perishable food requires proper maintenance of temperature and well equipped cold chain infrastructure (Rathore et al., 2010) and proper marketing systems and facilities (Singh et al., 2008). According to Negi et al, 2015 the cold chain in India has emerged as one of the weakest link in the supply chain of fruits and vegetables sector leading to losses. In India due to lack of proper infrastructure, cold storage in the reach of the farms, sufficient cold storage capacity, proper transportation the amount of food wasted is around 40 million tonnes of $13 billion (Maheshwar et al, 2006).

In India around 40 million tonnes amounting to $13 billion is wasted annually due to poor infrastructure, unavailability of cold storage in the vicinity of the farms, insufficient cold storage capacity, poor transportation infrastructure (Maheshwar et al, 2006). There is also the problem of ownership within the supply chain. Due to this holistic view of a supply chain there are post-harvest losses (Shukla et al., 2013). The extent of losses also depends on the road connectivity and network. In India most of North and eastern regions are hilly landscape areas which are abundant sources of fruits and vegetables. Due to lack of proper road connectivity and network, it takes long time to transport the fresh fruits and vegetables to the market and this leads to the deterioration in the quality and the condition of the produce leading to wastage and losses (Kader et al., 2004). The issues and challenges related to supply chain of fruits and vegetables in Uttarakhand were discussed by (Negi et al., 2015) and highlighted the losses and wastage in this area due to lack of proper infrastructure

An important necessity for the farmers in the fruits and vegetables sector is the proper and adequate supply chain infrastructure to deliver the fresh produce in the right time and right condition. The main weakness of the supply chain in India is the lack of this infrastructure which leads to huge losses. The major challenges related to infrastructure are lack of cold storage and warehouses in the rural areas (Jain, 2007). The loading and unloading facilities from farm to the market (Satyanarayana et al, 2007) in these areas are very poor with improper road connectivity, poor transportation facilities such as road, rail etc.(Veena et al, 2011 ), insufficient marketing infrastructure in terms of grading, standardization and other required machinery at the farm place and the market place( Singh et al, 2009; Narula, 2011; Sharma et al, 2011). Based on the discussions by the authors in the literature the following hypothesis is framed.

H4: Lack of Efficiency and understanding on wastage related aspects positively effects the post-harvest losses.

Transportation Linked Aspects (TLA)

The food wastage is caused due to faulty system of transport and delays in the delivery of the fresh produce to the retail market The shelf life becomes short at the retailer level because of the delay in the delivery and reaches the store shelf late in the case of perishable food supply chain (Mena et al., 2011) which leads to penalty (Shukla et al, 2013). In the developing countries like India transportation is a big challenge due to the unavailability of proper mode of transportation, high cost of transportation, lack of temperature controlled vehicle for the transport of the goods etc., (Negi et al., 2015).

In order to maintain the quality of fresh produce and increase the shelf life it is necessary to adopt improved mode of transportation such as reefer truck for perishable product so that the losses can be reduced during transportation. (Murthy et al., 2007).

In order to deliver the perishable food like fruits and vegetables and has short shelf life to the consumer in a right time and right quality it is necessary to have proper transportation with required controlled temperature. This is big challenge in India due to unavailability of proper mode of transportation, high cost of transportation, lack of temperature controlled vehicle for the movement of goods. The major factors which contributes to post-harvest losses in the supply chain of perishable food before reaching main market is the lack of transportation, storage facilities, cold chain facilities, poor logistics and connectivity in the bumpy and mountain areas. Due to non-existence of storage facilities in rural areas and then food need to transported to farther areas, there is need to pay high transportation cost for the food to be sold before it gets spoiled (Barrett 1996). Since transportation costs are high, the vehicles are regularly over-packed which leads to stiffing of food and can lead to spoilage of food and also leads to higher accident rates, which aggravates PHL. Based on the literature review the following hypothesis is formulated.

H5: Lack of proper transportation and related aspects positively effects the post-harvest losses.

Post-Harvest Losses (PHL)

In the value chain of food grains need to be transported from field to processing facilities, field to storage facilities and processing units to market. Due to lack of suitable transportation infrastructure there is damage of food products and losses due to spillage. In South Asian countries the food products are transported in bullock carts or open trollies at the field level whereas they are transported in bags, bullock carts, bicycles, small motor vehicles or open trucks for self-usage. There occurs huge spillage and contamination due to improper and poorly maintained modes of transportation. Low quality Jute bags are used during transportation and for even storage, which leads to high spillage rates due to leakage.

From the various biotic factors, insect pests mostly cause huge losses in the food grains around 30-40%. It was estimated that the losses in maize due to insect swarm was upto 50% in Ghana. In a study conducted by Pantenius et al, (1988) insects and pests were responsible for 80% - 90% of storage losses in grains.

Among all the biotic factors, insect pests are considered most important and cause huge losses in the grains (30–40%). Some studies in Ghana reported that the maize losses due to insect infestation could be up to 50%, if all quantity losses, quality losses, and income loss due to early sale are considered in the estimation. From field studies in Pantenius et al, (1988) observed that insects and pests were responsible for 80–90% of storage losses in grains.

Methodology

Sampling Frame

The sampling frame for the study is the farmers, procurement and storage partners and retailers from the districts of West Bengal. The districts considered are North 24 Parganas and South 24 Parganas of West Bengal.

Sampling Technique

Two districts from West Bengal were selected randomly. From each of these districts two subdivisions were considered. From each sub division two blocks were selected and the middle men are selected using Fete – e- complete (check) and from each block 30 farmers were selected from the list of farmers available randomly.

From each district one sub division (Barasat-Basirhat) of North 24 Parganas and (Diamond Harbour) of South 24 Parganas of West Bengal were considered. From each sub division two villages have been selected and the middle men were selected using convenient sampling and from each block 30 farmers from two blocks were selected from the list of farmers available randomly from the Gram Panchayat office of the concerned village

The first stage of review was done exhaustively so as to create an exhaustive list of questionnaire item triggers for the FGD to be conducted. From the review stage, 32 triggers were obtained or identified as evident to be supported by extant literature, which was subsequently purified and fed into the q-sorting process. After the detailed Q-sorting stages as prescribed by Moore et al., (1991), a finalized survey questionnaire instrument consisting of 24 items was prepared and made ready for data collection. Since the study was to be conducted across two steps with native population having their mother tongue other than English, an extra step had to be introduced after Q-sort based finalization as well. This step concerned translating the questionnaire item into local vernacular format (Bengali for the survey to be conducted in West Bengal). A post translation respondent acceptance has been verified and cross-checked, aiming at ensuring that the objectivity of the survey instrument has not been compromised in the process of translation and also to ensure that the phrasing in the language, other than the original mode of English, in which the questionnaire development was conducted , had on one side one to one correspondence and on the other hand was successful in capturing the local variations and local cultural and practice-based essences.

Data Collection

The data was collected from the partners of the supply chain using questionnaire to understand the factors that affect the food wastages in the context of post harvesting logistics with specific reference to fruits and vegetables across different levels of food supply chain. The list of farmers under each block was obtained. The list of procurement and storage partners was generated from farmers as well as wholesalers/retailers. The data related to wholesalers/retailers was collected from yellow pages. Data The statistical techniques used in this study were: exploratory factor analysis (EFA) and confirmatory factor analysis (CFA), followed by SEM. EFA was used to ensure that the uni-dimensionality of the constructs held good after the modification during Q-sorting and also to ensure the reliability of the construct measures using Cronbach’s alpha (Nunnally, 1978). While the EFA and the construct reliability checking were performed using SPSS 20 software package, AMOS 20.0 software package was used for performing CFA and SEM analysis.

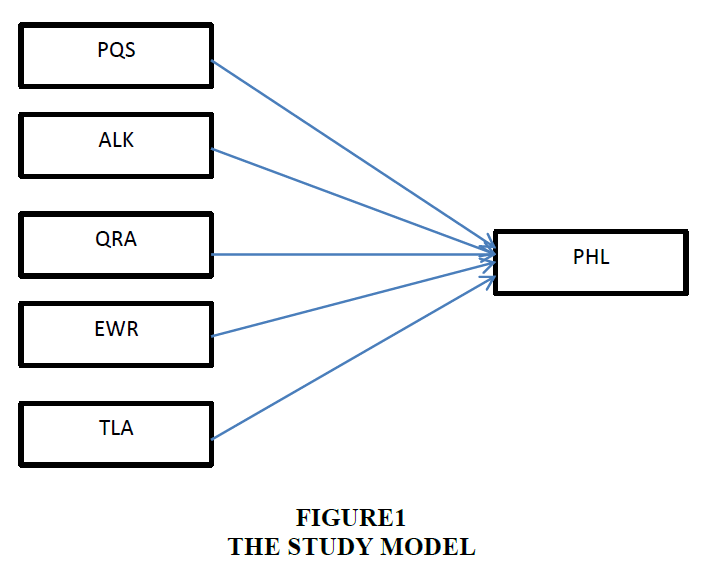

The path coefficients and the relationships as shown in the model between the antecedents and consequent constructs have been computed for the model by considering the responses from the respondents. The study used a step by step process right from item generation based on literature support and industry practices based on practitioner’s literature. A pilot study was conducted using the experts to eliminate and rephrase the questionnaire and the wordings of the items (Figure 1).

In this study, Churchill’s method for developing and testing reflective scales was followed (Churchill 1979); four broad steps: construct development, checking for content and face validity; dimensionality testing; checking for internal consistency; checking and ensuring convergent, discriminant, and nomological validity of the measures (Anderson, et al, 1988; Churchill 1979). In the first stage, based on the literature and existing definitions, pools of items were generated through thorough probing. Since the construct items were taken from both literature and practitioner’s articles, after the successful generation of the initial pool, a substantive validity test was carried out followed by scale purification (Anderson, et al 1991). As part of pre-pilot testing in consultation with 2 academic researchers initially from the pooled items the irrelevant items were removed or modified and based on unanimity pilot testing was done. In this study Q-sort technique (Moore et al, 1991) was used and the instrument was subjected to Q-sort techniques till the three vital Q-sort indicators of raw-agreement score, item placement ratio and Cohen’s kappa values were all above 0.9. The Q-sort scores of round 1 and 2 are provided below in Table 1.

| Table 1 Q-Sort Results Rounds 1 and 2 | ||

| Indices | Round 1 | Round 2 |

| Raw agreement Score | 0.79 | 0.93 |

| Placement (hit) ratio | 0.81 | 0.95 |

| Cohen‘s Kappa | 0.80 | 0.96 |

After the pilot study using Q-sort the final instrument that was used for the final large-scale study representing five constructs of PQS(5 items), ALK(9items), QRA(3 items), EWR(4 items) and TLA(3 items) i.e. a total of 20 items across 5 constructs.

Sample Size

In this study the questionnaire has 20 items. Thus as per the thumb rule of 5 and its recommendations, a minimum sample size of 100 should be sufficient to go ahead with the study in line with the recommendations of adequate sample size of five responses per item (Hair et al., 2006).

Though based on literature and Q-sort exercise the five constructs stood out, whether after the Q-sorting still the factor structure stood out or not was investigated using exploratory factor analysis (EFA) using Varimax rotation. The EFA table with rotated factor structure and the individual loadings are provided in Table 2.

| Table 2 Item Loadings and T-Stats | ||

| All constructs were measured on a 7 point Likert scale with 1= Strongly Disagree to 7= Strongly Agree | ||

| Level of productivity quality standards and (PQS) | Loadings | t-stats |

| Quality hygiene and safety standards | 0.893 | 29.507 |

| Control of quality and product safety | 0.936 | 46.644 |

| Details about tracking and traceability | 0.926 | 39.803 |

| Quality degradation during transfer and logistics | 0.883 | 24.450 |

| Quality of Packaging and stuffing material | ||

| Level of Awareness-linked Knowledge (ALK) | ||

| Awareness about actual market demand | 0.922 | 38.453 |

| Awareness about Type of demand | 0.944 | 59.628 |

| Accurate timing for optimal planting/ harvesting/transporting/storing | 0.947 | 61.124 |

| Requisite quantity for harvest | 0.916 | 41.899 |

| Necessary technology and precautions | 0.816 | 19.23 |

| Usage of advanced equipment | 0.932 | 45.023 |

| Information on financial incentives | 0.801 | 18.08 |

| Awareness about best practices (harvesting, storage and handling) | 0.719 | 16.32 |

| Awareness about perishability time horizon / shelf life | 0.814 | 18.91 |

| Quantity related aspects (QRA) | ||

| Quantity of Harvest handled at each level | 0.911 | 40.357 |

| Quantity ceiling of processing capability | 0.941 | 55.116 |

| Quantity(per unit time) processing capability | 0.927 | 44.169 |

| Efficiency & Wastage Related aspects (EWR) | ||

| Wastage along the concerned supply chain stage | 0.931 | 40.407 |

| Wastage in reaching the processing unit in the concerned supply chain stage | 0.968 | 114.265 |

| Losses during transportation and storage in the concerned stage | 0.958 | 66.724 |

| Lack of cold chain and infrastructure | 0.928 | 41.097 |

| Transportation linked aspects (TLA) | ||

| Unavailability of vehicles with requisite optimal specifications required for storage and logistics | 0.904 | 33.654 |

| Transportation cost with respect to volume and value density | 0.955 | 70.548 |

| Losses during transportation and handling in the concerned phase | 0.829 | 25.636 |

| Post-harvest Loss (PHL) | ||

| Wastage of grains and crops in vehicles and on-move logistics after harvest | 0.756 | 16.892 |

| Rotting of crops and grains in absence of proper storage at storage sites | 0.684 | 11.342 |

| Loss of harvested grains and crop by rodents and pests | 0.712 | 15.235 |

| Damage of grains and crops as part of packaging and bagging | 0.598 | 8.781 |

The EFA conducted, had acceptable Kaiser-Meyer-Olkin (KMO) measure of sample adequacy values and also the Bartlett’s test of sphericity results were found to be significant at 0.1% level Total Variance explained was> 60% and KMO value >0.8, Bartlett’s test of sphericity result significant at 0.000. Further the convergent and discriminant validity have also been checked.

All the Cronbach Alpha values were above 0.8 (in Table 3) which showed very high reliability of the instrument. The validity and reliability of the scales were established. The diagonal elements which represented the respective AVE (average variance extracted) values for each construct in Table 4, were all higher than the other non-diagonal elements which represented squared inter-construct correlation and this showed good convergent and discriminant validity.

| Table 3 Reliability Statistics | ||

| Construct | AVE | Construct Reliability (Cronbach’s Alpha) |

| PQS | 0.888 | 0.896 |

| ALK | 0.9077 | 0.853 |

| QRA | 0.7835 | 0.869 |

| EWR | 0.8246 | 0.888 |

| TLA | 0.8532 | 0.864 |

| PHL | 0.7875 | 0.813 |

| Table 4 Discriminant Validity | ||||||

| Construct | PQS | ALK | QRA | EWR | TLA | PHL |

| PQS | 0.7900 | |||||

| ALK | 0.0213 | 0.8240 | ||||

| QRA | 0.2199 | 0.0524 | 0.6140 | |||

| EWR | 0.0006 | 0.0010 | 0.0036 | 0.6800 | ||

| TLA | 0.2671 | 0.0321 | 0.0012 | 0.3116 | 0.7280 | |

| PHL | 0.0356 | 0.0637 | 0.0097 | 0.4521 | 0.3102 | 0.6203 |

The diagonal elements represent the construct AVE values, while the off-diagonal elements happen to be representing the squared inter-construct correlations. The diagonal elements values being greater than 0.5 and also being greater than the off-diagonal element values indicated convergent and discriminant validity respectively (Anderson et al, 1988).

Further confirmatory factor analysis (CFA) was carried out in order check the model fit indices of the measurement model which was subsequently used for checking the inter-construct relationships and linkages and subsequently the hypothesized relationships were checked and outputs were noted in the structural model. So initially CFA was carried out followed by structural equation modeling (SEM) to calculate the path indices. The model has been tested. The CFA outcome revealed a good model fit of the measurement model. The model fit indices for the measurement model were all as per the acceptable criteria (CMIN/DF = 1.307, CFI = 0.955, IFI = 0.0966, TLI = 0.92, GFI= 0.870 and RMSEA = 0.037 (Where, CMIN/DF represents Chi-square/degrees of freedom (i.e. c2/d.f.), GFI = Goodness of fit index, CFI = Comparative fit index, TLI = Tucker Lewis index, NFI= Normed fit index, IFI = Incremental fit index and RMSEA = Root mean square error of approximation.) According to the standard criterion highlighted by Byrne (2009) the fit indices values appears acceptable and thus indicated a reasonable fit of the measurement model with the data; thereby confirming the factor structure as well. For the measurement model fit index calculations (CFA) combined responses was calculated. Since the respondent set was quite large and met the 1 is to 5 criteria for successfully running SEM, the separate calculation could be carried out. The responses obtained was 335. As per Anderson et al. (1988) for carrying out the SEM the number of sample points to the number of instrument items should be at least 5 is to 1, i.e. for 1 item 5 sample responses are needed. Since the number of items was 24 across all the five constructs and hence minimum each group needed 120 responses (Balaji et al., 1996).

In this case we had above 120 responses and so the SEM based path analysis could be carried out separately. The path analysis (structural model) response using Amos 20 is provided in table 5. The model fit indices for the structural model are provided in Table 6.

| Table 5 Structural Model: Hypothesis Testing & Path Analysis for Total Model | |||

| Complete set of respondent firms | |||

| Hypothesis | Path estimate | Significance | Result |

| H1: PQS àPHL | 0.234 | ** | Supported |

| H2: ALK àPHL | 0.396 | *** | Supported |

| H3: QRA àPHL | 0.138 | NS | Non- Supported |

| H4: EWR àPHL | 0.356 | *** | Supported |

| H5: TLA à PHL | 0.463 | ** | Supported |

| (CMIN/DF) = 1.307, CFI = 0.955, IFI = 0.966, TLI = 0.952, GFI= 0.870 and RMSEA = 0.037 | |||

| Table 6 Structural Model: Hypothesis Testing & Path Analysis | |||

| Hypothesis | Path estimate | Significance | Result |

| H1: PQS àPHL | 0.387 | *** | Supported |

| H2: ALK àPHL | 0.345 | NS | Non- Supported |

| H3: QRA àPHL | 0.479 | *** | Supported |

| H4: EWR àPHL | 0.532 | *** | Supported |

| H5: TLA à PHL | 0.312 | *** | Supported |

The model fit indices for the overall structural model were all as per the acceptable criteria.

The Hypotheses testing results for the total model is provided in Table 5. Out of the 5 hypothesized relationships in the entire model, 4 hypotheses were supported and the respective path coefficients (estimates) were found to be statistically significant.

The Hypotheses testing the results are provided in Table 6. The path coefficients of the structural equation model along with their p-values (associated with the standardized path coefficients) have been computed and they provided direct evidence of the hypotheses being accepted or rejected (Table 6) According to the results (table 6) the path coefficients between Product and quality standards and Post-Harvest losses (coefficient (c)= 0.387, p<0.01) Awareness linked knowledge and post-harvest losses (c = 0.345, non-significant), quality related aspects and post-harvest losses (H3: c = 0.479, p<0.001),efficiency and wastage related aspects and post-harvest losses (c = 0.532, p<0.001), Transport linked aspects and post-harvest losses(c = 0.312, p<0.001) have been found to be significant and thus supporting H1, H3, H4 and H5 respectively. The path coefficients of the other related hypotheses Awareness linked knowledge and post-harvest losses (c = 0.345, non-significant), was found to be insignificant and hence this hypothesis was rejected (Babu et al., 2012).

Discussion on Statistically ‘Supported’ Hypotheses

The statistically supported hypotheses are Product and quality standards, Quantity related aspects, Efficiency and wastage related aspects and Transportation linked aspects.

Though Awareness linked knowledge is not supported as the farmers in west Bengal had an idea about the actual market demand. They are clear on the timing for the harvest and they transport or store the fresh produce in an optimal manner. They are using the advanced technology for harvesting and use the best practices in harvesting.

The third factor which influences the post-harvest losses is Quantity related aspects. This factor is supported as the farmers though they are aware of the timing of the harvest there is no proper planning of the quantity to be harvested at each level. The quantity of fresh produce depends on the market demand which the farmers at West Bengal are aware of, they need to have a production plan so as to minimize the delay in processing, to minimize the idle time of the main processing line and inventory levels of the final products.

Discussion, Analysis and Conclusion

In this study the total sample impact and SEM coefficients have been compared and checked for statistical significance four out of five hypothesized relationships PQS, QRA, EWR and TLA with that of PHL turned out to be significant. The relationship between ALK and PHL was not supported.

Limitations of the Day

Although this study has made several theoretical and practical contributions concerning agro supply chain network necessary cautions being taken, this study happens to be not free from limitations.

1. First, the sample size being limited, only to West Bengal. The analysis can be improved by considering more states which are majorly agro based so that the study can be more generic and more representative.

2. The study has been carried out in a cross-sectional research design which only provides a snapshot of the current operations and situation. However the inter-construct relationships in the current study context might be better understood when studied in longitudinal research design. The data pertaining to the constructs like Product and quality standards , Awareness linked knowledge, efficiency and wastage , Transport linked aspects, Quantity related aspects and post-harvest losses has been collected at one point in time. Though no such opinions exist when thought along a longitudinal research design, they too make sense and the strength of the relationship might change (increase or decrease) over time. This kind of inherent flaw in the method typically makes longitudinal studies turn out to be attractive alternatives. Due to time constraint as well as feasibility of the study the cross-sectional design of research has been chosen instead of longitudinal research design.

References

Anderson, J. C., & Gerbing, D. W. (1988). Structural equation modeling in practice: A review and recommended two-step approach. Psychological bulletin, 103(3), 411.

Indexed at, Google Scholar, Cross Ref

Barrett, C.B. (1996). Urban Bias in Price Risk: The Geography of Food Price Distributions in Low-Income Economies. Journal of Development Studies, 32(6): 830-849.

Indexed at, Google Scholar, Cross Ref

Bechini, A., Cimino, M., Marcelloni, F. and Tomasi, A. (2008) Patterns and technologies for enabling supply chain traceability through collaborative e-business, Information and Software Technology, 50, 342-359.

Indexed at, Google Scholar, Cross Ref

Buyukbay, E., Uzunoz, M., & Bal, H. (2011) Post-harvest losses in tomato and fresh bean production in Tokat province of Turkey. Scientific Research and Essays, 6(7), 1656-1666.

Indexed at, Google Scholar, Cross Ref

Buzby, J.C., & Hyman, J. (2012). “Total and Per Capita Value of Food Loss in the United States.” Food Policy, 37, 561-570.

Indexed at, Google Scholar, Cross Ref

Byrne, B.M. (2001). Structural equation modeling with AMOS. Mahwah, New Jersey: Lawrence Erlbaum Associates, Inc.

Indexed at, Google Scholar, Cross Ref

Deliya, M., Thakor, C., &Parmar, B. (2012) A Study on differentiator in Marketing of fresh fruits and Vegetables from Supply Chain Management Perspective. Abhinav: National monthly Refered Journal of Research in Commerce and Managment 1: 40-57.

Ferrer, J.C., MacCawley, A., Maturana, S., Toloza, S., Vera, J. (2008). An optimization approach for scheduling wine grape harvest operations. International Journal of Production Economics 112(2), 985–999.

Indexed at, Google Scholar, Cross Ref

Grolleaud M..(2002) Post-harvest losses: discovering the full story. Overview of the phenomenon of losses during the post-harvest system. Rome, Italy: FAO, Agro Industries and Post-Harvest Management Service.

Kader, A.A. & Rolle, R.S. (2004). The role of post-harvest management in assuring the quality and safety of horticultural produce (Vol. 152). Food & Agriculture Org.

Moore, G.C., & Benbasat, I. (1991). Development of an instrument to measure the perceptions of adopting an information technology innovation. Information Systems Research, 2(3), 192-222.

Indexed at, Google Scholar, Cross Ref

Murthy, D.S., Gajanana, T.M., Sudha, M., & Dakshinamoorthy, V. (2009). Marketing and Post harvest losses in fruits: Its implications on Availability and economy. Indian Journal of Agricultural economics, 64(2), 259-275.

Narula, S. A. (2011). Reinventing cold chain industry in India: need of the hour. Interview with Mr Sanjay Aggarwal. Journal of Agribusiness in Developing and Emerging Economies, 1(2).

Indexed at, Google Scholar, Cross Ref

Negi, S., & Anand, N. (2015). Supply Chain of Fruits & Vegetables’ Agribusiness in Uttarakhand (India): Major Issues and Challenges. Journal of Supply Chain Management Systems, 4(1 & 2), 43-57.

Indexed at, Google Scholar, Cross Ref

Sharma, G., & Singh, S. (2011). Economic Analysis of Post-harvest Losses in Marketing of Vegetables in Uttarakhand. Agricultural Economics Research Review, 24, 309-315

Indexed at, Google Scholar, Cross Ref

Tsubone, H., Muramatsu, R., & Soshiroda, M. (1983) Designing an effective production system for processing agricultural products, International Journal of Production Research, 21:1, 17-30

Wakijira, M. (2010) Solar drying of fruits and windows of opportunities in Ethiopia. African Journal of Food Science, 4, 13:790-802.

Received: 10-May-2022, Manuscript No. AMSJ-22-11847; Editor assigned: 11-May-2022, PreQC No. AMSJ-22-11847(PQ); Reviewed: 24-May-2022, QC No. AMSJ-22-11847; Revised: 26-May-2022, Manuscript No. AMSJ-22-11847(R); Published: 28-May-2022