Review Article: 2024 Vol: 28 Issue: 6S

Factors Affecting Sustainable Retail Supply Chains: LP and MILP Modeling

Shankha Sengupta, IBS, IFHE, Hyderabad

Sandeep A, IBS, IFHE, Hyderabad

Siva G.V., IBS, IFHE, Hyderabad

Citation Information: Sengupta, S., Sandeep, A., & Siva, G.V. (2024). “Factors affecting sustainable retail supply chains: lp and milp modeling.". Academy of Marketing Studies Journal, 28(S6), 1-10.

Abstract

This paper explores the concept of Sustainable Supply Chain Management (SSCM) as a response to the urgent need for environmental and social sustainability within supply chain operations. The traditional focus on economic performance metrics has shifted towards a triple-bottom-line approach, incorporating environmental quality, social justice, and economic prosperity. Key elements of SSCM include waste and emission reduction, resource efficiency, ethical labor practices, and circular economy models. Despite significant implementation challenges, SSCM offers opportunities for value creation through improved reputation, operational efficiency gains, and innovation in sustainable products and technologies. The paper also presents a generalized framework for developing a mathematical model to optimize sustainable retail supply chains, considering objectives, decision variables, constraints, and sustainability metrics.

Keywords

Sustainable Supply Chain Management, Sustainability, Triple Bottom Line, Environmental Sustainability, Social Sustainability, Economic Sustainability, Circular Economy, Optimization Model.

Introduction

Sustainability has become an urgent priority in society, business, and across supply chain operations. Environmental issues like climate change, pollution, biodiversity loss, and resource depletion threaten the ability of future generations to meet their needs (WCED, 1987). Social challenges like poverty, inequality, and unethical labor practices also demand attention. Businesses are major contributors to these sustainability challenges, but also have the resources and influence to drive positive change (Linton et al., 2007).

The traditional model of supply chain management focused narrowly on economic performance metrics like cost, quality, speed and flexibility (Mentzer et al., 2001). Sustainable supply chain management (SSCM) represents a systemic shift, expanding the focus to also minimize environmental and social impacts while maintaining economic performance (Carter & Rogers, 2008). SSCM considers the full product life cycle from raw material sourcing through end-of-life disposal or recovery. It also examines sustainability impacts across tier 1, tier 2 and smaller upstream suppliers that feed into the next level of production.

Key defining elements of SSCM include waste and emission reduction, resource efficiency and circular resource flows, and ethical issues like labor rights, equity and social development throughout global operations (Seuring & Müller, 2008). Beyond risk mitigation, properly integrated SSCM creates value through improved reputation, branding, operational efficiency gains and innovation in sustainable products and technologies (Linton et al., 2007).

Significant implementation challenges exist however, requiring new capabilities, cross-functional structures, partnering strategies and advanced technologies to enable transparency, traceability and performance management across multi-tier supply networks (Brandenburg et al., 2014).

Defining Sustainable Supply Chain Management

SSCM evolved from the concept of green supply chain management, but with a broader focus encompassing the triple bottom line of sustainability - environmental quality, social justice, and economic prosperity (Carter & Easton, 2011). It integrates these sustainability principles into the full life cycle of products from design to end-of-life management (Abbasi & Nilsson, 2012). The goal is balancing economic efficiency, environmental load minimization, and social well-being instead of purely economic profit motives (Hassini et al., 2012).

Environmental Sustainability

A major emphasis in SSCM research has been reducing the environmental footprint through efforts like lowering carbon emissions, water and energy usage in logistics and transportation, designing eco-friendly packaging, eliminating toxic materials, and adopting circular economy business models around reuse, remanufacturing and recycling (Dey et al., 2011). Life cycle assessments reveal hot spots to target, and new technologies like the Internet of Things and big data analytics help enable real-time monitoring and closed-loop processes (Brandenburg et al., 2014). Key focus areas include:

Reducing Carbon Emissions

Considerable attention is directed at lowering carbon emissions from transportation and logistics which account for 14% of global greenhouse gas emissions (World Economic Forum, 2009). Strategies involve optimizing logistics networks, modal shifts to rail or sea freight, consolidating shipments, and investing in energy efficient fleet upgrades (Erol et al., 2011). Many companies now track and report carbon emission levels and reduction targets for themselves and logistics partners.

Sustainable Packaging

Packaging optimization and design improvements lower waste and enable reuse opportunities. This includes strategies like lightweighting, nanostructured antimicrobial coatings to prevent food spoilage and extend shelf-life, bio-based materials from renewable feedstock, and integration of recycled content (Hellström & Saghir, 2007). Smart packaging features like RFID tags also aid recoverability and closed loop recycling.

Circular Economy Models

The concept of a circular economy aims to radically shift away from the traditional linear take-make-waste model to closed loop systems focused on reuse, remanufacturing and recycling (Geissdoerfer et al., 2017). It traces product constituent materials through multiple product life cycles via loops of reuse, restoration, and recycling to minimize virgin resource inputs while maximizing economic value creation. Companies like Caterpillar, Renault, Philips and H&M have begun circular economy pilots.

Life Cycle Assessments

Sustainability initiatives target environmental hot spots revealed through life cycle assessments (LCAs) mapping the resource usage and emissions at each product life cycle stage - from raw material extraction, manufacturing, transport, use phase and eventual disposal (Muthu, 2015). LCA data enables fact-based target setting and impact monitoring instead of subjective estimates of progress.

Social Sustainability

The social dimension receives less attention but includes safe working conditions, fair wages, ethical sourcing policies, gender equity and collaborating to benefit communities in the supply chain (Mani et al., 2016). Most focus currently is on auditing and compliance in first tier suppliers, with calls for better visibility further upstream small enterprises where risks are higher (Wilhelm et al., 2016). Sustainability training, local capacity building, health camps and educational initiatives represent supplier development opportunities that generate shared value (Aktar, 2013).

Safe and Ethical Working Conditions

Many supply chains span developing countries where lack of visibility leads to higher risks of human rights and labor violations like child labor, excessive overtime, and unsafe exposure to hazards (Mani et al., 2016). Beyond auditing suppliers, companies are establishing ethical sourcing programs with capacity building projects to improve conditions through collaboration instead of cutting off partnerships (Aktar, 2013).

Community Development

Leading companies pursue philanthropic projects to uplift communities in their supply chain. Efforts include setting up health camps, providing training and education, disaster relief initiatives and investing to build local infrastructure like schools or clinics as part of their sustainability agenda (Ahi & Searcy, 2015). This aims to generate goodwill and shared value.

Diversity and Inclusion

There is a growing focus on addressing gender inequality and empowering women across global supply chains. Companies track and aim to improve women workforce participation, implement equal pay policies, provide skills training, ensure workplace safety and support access to health services as well as leadership opportunities (ILO, 2019).

The social sustainability aspects of SSCM present complex challenges but also opportunities to create positive systemic impact aligning business success with ethical and societal good. Collaborative mindsets can pave the path ahead.

Economic Sustainability

Barriers to SSCM often come down to economics - the perception of higher costs without tangible returns. Researchers emphasize total cost analyses over full product life cycles rather than only first cost and short-term savings (Zimmer et al., 2016). This requires accounting for externalities like pollution expenses, water usage fees, possible fines for unsustainable practices etc. to demonstrate reductions that benefit the bottom line long-term. Integrating sustainability strategically throughout operations mitigates risks, drives innovation in products and processes to boost competitiveness (Linton et al., 2007).

Total Cost of Ownership

While sustainability measures often require upfront investments, the total cost over full product lifecycles can reveal net savings. Analyses should include expenses related to all environmental and social externalities alongside operational costs (Hassini et al., 2012). Life cycle costing provides a comprehensive assessment methodology.

Risk Management

SSCM reduces various sustainability-related risks. This risk mitigation against rising costs of resources, stricter regulations, reputational damages, protests and lawsuits creates economic value. It also improves access to ethical investment capital and often generates goodwill with consumers willing to pay premiums for sustainable offerings (Closs et al., 2011).

Innovation Impetus

The constraints and challenges posed by sustainability pressures end up spurring tremendous innovation. Product and process enhancements lower environmental footprints and costs simultaneously. Developing greener technologies and circular business models creates competitive advantage and new revenue streams in emerging sustainability markets (Dangelico et al., 2013).

Developing a mathematical model for factors affecting sustainable retail supply chains involves identifying key variables that influence sustainability within the supply chain context and formulating mathematical relationships among them. Here's a generalized framework for such a model:

1. Objective Function: Define the objective of the model, typically to maximize sustainability while minimizing costs or other trade-offs.

2. Decision Variables: Identify decision variables that can be controlled or optimized within the supply chain. These might include:

• Allocation of resources (e.g., raw materials, labor, transportation).

• Inventory levels.

• Production quantities.

• Supplier selection and sourcing decisions.

• Transportation routes and modes.

• Packaging choices.

• Facility location and design.

3. Constraints: Define constraints that limit the decision variables. These can include:

• Capacity constraints (e.g., production capacity, warehouse space).

• Demand requirements.

• Regulatory requirements (e.g., environmental regulations, labor laws).

• Budgetary constraints.

• Lead times and service level agreements.

4. Sustainability Metrics: Identify key sustainability indicators relevant to retail supply chains. These may include:

• Carbon footprint.

• Energy consumption.

• Water usage.

• Waste generation and recycling rates.

• Social responsibility metrics (e.g., fair labor practices, community engagement).

• Environmental impact assessments (e.g., life cycle assessments).

Let:

• T: total transportation cost.

• E: total energy consumption.

• C: total carbon footprint.

• I: total inventory holding cost.

• S: total sourcing cost.

Then, we can formulate the objective function to minimize the overall cost while maximizing sustainability:

Minimize Z = T+I+S, subject to constraints:

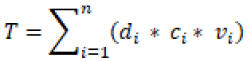

1. Transportation Cost constraint:

where,

di = distance travelled for route i

ci = cost per unit distance for route i

vi = volume of goods transported on route i

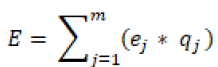

2. Energy Consumption constraint:

where,

ej = energy consumption per unit produced for product j

qj = quantity of product j produced

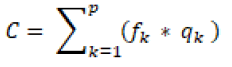

3. Carbon Footprint constraint:

where,

fk = carbon footprint per unit produced for product k

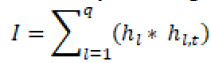

4. Inventory Holding Cost constraint:

where,

hl = holding cost per unit for item l

hl,t = average inventory level of item l over time t

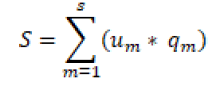

5. Sourcing Cost constraint:

where,

um = unit sourcing cost for material m

qm = quantity of material m sourced

In the context of sustainable supply chain management, MILP can be applied to address various optimization problems aimed at improving sustainability performance while considering multiple objectives and constraints. Here's how MILP can be applied to sustainable supply chain management:

Optimal Network Design

MILP can be used to determine the optimal configuration of the supply chain network considering factors such as transportation modes, facility locations, and inventory levels. By incorporating sustainability objectives such as minimizing carbon emissions, reducing transportation costs, and optimizing resource utilization, MILP can help design supply chain networks that are both efficient and sustainable.

Inventory Management: MILP models can optimize inventory levels across the supply chain while considering sustainability criteria such as minimizing waste, reducing excess inventory, and promoting lean practices. By balancing inventory costs with sustainability objectives, MILP can help organizations achieve efficient inventory management while minimizing environmental impact.

Supplier Selection and Sourcing: MILP can aid in the selection of suppliers and sourcing decisions by considering sustainability criteria such as environmental performance, social responsibility, and ethical sourcing practices. By incorporating multiple objectives such as cost minimization and sustainability maximization, MILP can help organizations make informed decisions about supplier selection and sourcing strategies.

Production Planning and Scheduling: MILP models can optimize production planning and scheduling processes to minimize energy consumption, reduce waste generation, and improve resource efficiency. By considering factors such as production capacity, demand variability, and sustainability objectives, MILP can help organizations achieve production schedules that are both cost-effective and environmentally sustainable.

Transportation and Logistics Optimization: MILP can optimize transportation and logistics operations to minimize fuel consumption, reduce carbon emissions, and improve transportation efficiency. By considering factors such as vehicle routing, mode selection, and shipment consolidation, MILP can help organizations design transportation and logistics networks that are both economically viable and environmentally sustainable.

Reverse Logistics and Closed-Loop Supply Chains: MILP can optimize reverse logistics processes and closed-loop supply chain operations to maximize product recovery, minimize waste, and promote recycling and reuse. By considering factors such as product returns, remanufacturing, and recycling options, MILP can help organizations design closed-loop supply chains that are both environmentally sustainable and economically feasible.

Objective: Minimize the total cost of the supply chain while considering environmental impact and social responsibility.

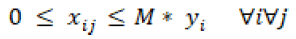

Decision Variables: Let's define the following decision variables:

xij = quantity of product shipped from facility i to facility j

yi = binary variable indicating whether facility i is open (1) or closed (0)

zij = binary variable indicating whether transportation mode i to j is selected (1) or not (0)

Parameters:

Cij = Unit cost of shipping product from facility I to facility j

Dij = Distance from facility i to facility j

Eij = Environmental impact of shipping from facility i to facility j

Si = Social responsibility score of facility i

M = A large positive constant to represent a sufficiently large number

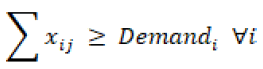

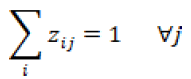

Constraints:

1. Demand Constraint: Ensure that demand at each facility is met.

2. Capacity Constraint: Ensure that production and transport capacity constraints are not exceeded.

3. Facility Opening Constraint: Ensure that only one transportation mode is selected for each route.

4. Binary Variable Constraints:

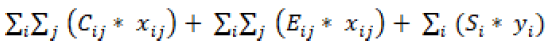

Objective Function:

Minimize:

This model aims to minimize the total cost, environmental impact, and social responsibility score of the supply chain while ensuring that demand is met and capacity constraints are respected. The binary variables yi determine whether facilities are operational, and zij select transportation modes. The constraints ensure that only one transportation mode is selected for each route and that binary variables are correctly defined.

5. Mathematical Relationships: Formulate mathematical relationships that capture how decision variables and constraints impact sustainability metrics. These could be linear, nonlinear, or even stochastic relationships, depending on the complexity of the factors involved. For example:

• The carbon footprint of transportation can be modeled as a function of distance traveled, transportation mode, and vehicle efficiency.

• Energy consumption in production facilities can be modeled based on production volume, equipment efficiency, and energy sources.

• Social responsibility metrics can be modeled based on supplier practices, worker conditions, and community engagement initiatives.

6. Optimization: Develop optimization algorithms or techniques to solve the model and find the optimal solutions that balance sustainability objectives with other performance measures (e.g., cost, service level).

7. Validation and Sensitivity Analysis: Validate the model using historical data or simulation techniques. Perform sensitivity analysis to understand how changes in input parameters affect the model outputs and identify critical factors influencing sustainability in the retail supply chain.

8. Implementation: Implement the model within retail supply chain management systems or decision support tools to guide real-world decision-making processes and improve sustainability performance over time.

Conclusion

Sustainability has become an imperative for retail supply chains facing complex environmental and social challenges while also needing to maintain economic viability. This literature review has examined progress as well as persistent barriers in implementing more sustainable practices.

Significant advancements are underway in areas like emissions reduction, sustainable transportation modes, responsible sourcing policies, packaging improvements, and technology enablers such as Blockchain traceability and closed-loop supply chain digital platforms. Leading retailers are moving their sustainability initiatives beyond mere compliance and risk management towards measures that boost innovation, efficiency, brand value and market share.

However, barriers inhibit wider adoption across retail supply chains, especially deeper tier small and medium suppliers with limited resources. Challenges include higher operational costs, problems calculating return on investment, lack of quality data for decision making, cultural resistance to change, siloed versus integrated organizational structures, and inability to control external partners' actions.

Tackling these barriers necessitates more collaborative mindsets and systems thinking across entire retail ecosystem networks. Retailers must provide incentives through coupled business and sustainability objectives, training programs, upgraded technology access and financing options to bring suppliers onboard sustainability strategies and investments. Governments also have a key role in establishing regulations, reporting frameworks and infrastructure to accelerate the sustainability agendas of retail supply chains.

Effective retail sustainability management requires collective action across stakeholders, functions and life cycle stages to transition from incremental initiatives to transformations in how retail value chains source, produce, transport, market, recycle and repurpose products. Overall there appears to be growing momentum and readiness for retail companies to step up as sustainability change agents.

References

Abbasi, M., & Nilsson, F. (2012). Themes and challenges in making supply chains environmentally sustainable. Supply Chain Management: An International Journal, 17(5), 517-530.

Indexed at, Google Scholar, Cross Ref

Ahi, P., & Searcy, C. (2015). An analysis of metrics used to measure performance in green and sustainable supply chains. Journal of cleaner production, 86, 360-377.

Indexed at, Google Scholar, Cross Ref

Aktar, I. (2013). The role of partnerships in enabling social responsibility: a supplier diversity perspective. Supply Chain Management: An International Journal, 18(3), 263–270.

Brandenburg, M., Govindan, K., Sarkis, J., & Seuring, S. (2014). Quantitative models for sustainable supply chain management: Developments and directions. European journal of operational research, 233(2), 299-312.

Indexed at, Google Scholar, Cross Ref

Brundtland, G. H., & Mansour, K. (2010). World Commission on Environment and Development (WCED). 1987. Our common future, 2010.

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: moving toward new theory. International journal of physical distribution & logistics management, 38(5), 360-387.

Indexed at, Google Scholar, Cross Ref

Carter, C. R., & Liane Easton, P. (2011). Sustainable supply chain management: evolution and future directions. International journal of physical distribution & logistics management, 41(1), 46-62.

Indexed at, Google Scholar, Cross Ref

Closs, D. J., Speier, C., & Meacham, N. (2011). Sustainability to support end-to-end value chains: the role of supply chain management. Journal of the Academy of Marketing Science, 39, 101-116.

Indexed at, Google Scholar, Cross Ref

Dangelico, R. M., Pontrandolfo, P., & Pujari, D. (2013). Developing sustainable new products in the textile and upholstered furniture industries: Role of external integrative capabilities. Journal of Product Innovation Management, 30(4), 642-658.

Indexed at, Google Scholar, Cross Ref

Dey, A., LaGuardia, P., & Srinivasan, M. (2011). Building sustainability in logistics operations: a research agenda. Management Research Review, 34(11), 1237-1259.

Indexed at, Google Scholar, Cross Ref

Doherty, S., & Hoyle, S. (2009). Supply chain decarbonization: The role of logistics and transport in reducing supply chain carbon emissions. In World Economic Forum, Geneva.

Erol, I., Sencer, S., & Sari, R. (2011). A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecological Economics, 70(6), 1088-1100.

Indexed at, Google Scholar, Cross Ref

Geissdoerfer, M., Savaget, P., Bocken, N. M., & Hultink, E. J. (2017). The Circular Economy–A new sustainability paradigm?. Journal of cleaner production, 143, 757-768.

Indexed at, Google Scholar, Cross Ref

Hassini, E., Surti, C., & Searcy, C. (2012). A literature review and a case study of sustainable supply chains with a focus on metrics. International journal of production economics, 140(1), 69-82.

Indexed at, Google Scholar, Cross Ref

Hellström, D., & Saghir, M. (2007). Packaging and logistics interactions in retail supply chains. Packaging Technology and Science: An International Journal, 20(3), 197-216.

Indexed at, Google Scholar, Cross Ref

International Labour Organization (ILO). (2019). The business case for change. Retrieved from https://www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---act_emp/documents/publication/wcms_709363.pdf

Linton, J. D., Klassen, R., & Jayaraman, V. (2007). Sustainable supply chains: An introduction. Journal of operations management, 25(6), 1075-1082.

Indexed at, Google Scholar, Cross Ref

Mani, V., Agrawal, R., & Sharma, V. (2015). Social sustainability in the supply chain: analysis of enablers. Management Research Review, 38(9), 1016-1042.

Indexed at, Google Scholar, Cross Ref

Mentzer, J. T., DeWitt, W., Keebler, J. S., Min, S., Nix, N. W., Smith, C. D., & Zacharia, Z. G. (2001). Defining supply chain management. Journal of Business logistics, 22(2), 1-25.

Indexed at, Google Scholar, Cross Ref

Muthu, S. S. (2020). Assessing the environmental impact of textiles and the clothing supply chain. Woodhead publishing.

Indexed at, Google Scholar, Cross Ref

Seuring, S., & Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of cleaner production, 16(15), 1699-1710.

Indexed at, Google Scholar, Cross Ref

Touboulic, A., & Walker, H. (2015). Theories in sustainable supply chain management: a structured literature review. International journal of physical distribution & logistics management, 45(1/2), 16-42.

Indexed at, Google Scholar, Cross Ref

Wilhelm, M. M., Blome, C., Bhakoo, V., & Paulraj, A. (2016). Sustainability in multi-tier supply chains: Understanding the double agency role of the first-tier supplier. Journal of operations management, 41, 42-60.

Indexed at, Google Scholar, Cross Ref

Zimmer, K., Fröhling, M., & Schultmann, F. (2016). Sustainable supplier management–a review of models supporting sustainable supplier selection, monitoring and development. International journal of production research, 54(5), 1412-1442.

Indexed at, Google Scholar, Cross Ref

Received: 11-Mar-2024, Manuscript No. AMSJ-24-14590; Editor assigned: 12-Mar-2024, PreQC No. AMSJ-24-14590(PQ); Reviewed: 29-May-2024, QC No. AMSJ-24-14590; Revised: 26-Jul-2024, Manuscript No. AMSJ-24-14590(R); Published: 03-Aug-2024