Research Article: 2021 Vol: 27 Issue: 4

Extent of Material Handling On Environmental Performance of Selected Textile Manufacturing Firms in Lagos State, Nigeria

Adedugba Adebayo T, Covenant University

Ogunnaike Olaleke O, Covenant University

Adeyemo Kingsley A, Covenant University

Kehinde Busola E, Covenant University

Citation: Adebayo T.A., Olaleke, O.O., Kingsley, A.A., & Busola, E.K. (2021). A framework of material handling and environmental performance of selected textile manufacturing firms in Lagos State. Academy of Entrepreneurship Journal (AEJ), 27(4), 1-10.

Abstract

The study examined to what extent material handling influence environmental performance in the circumference of selected textile manufacturing firms in Lagos state. The study adopted a structured questionnaire and a total of 659 set of questionnaire was administered to employees in the production, transportation, warehousing, inventory, accounting, and operations / administration department in twelve (12) textile manufacturing firms in Lagos State, however (528) were valid for analysis. The respondents were drawn using purposive sampling technique and complete enumeration method was adopted. Data analysis was carried out using regression analysis via partial least square(PLS). The findings show an inverse relationship between material handling and environmental performance based on the statistical output of (β= -0.531, R2=0.282, t-statistics=4.029>1.96). This implies that an increase in material handling procedures will decrease the environmental performance of textile manufacturing firms and vis versa.

Keyword

Material Handling, Environmental Performance, Textile firms, Regression.

Introduction

Material handling is an integral aspect of manufacturing business due to the progression of materials in a production cycle. It is also the stream of merchandise and items from crude source to the last phase of production and fabrication, allocating, stockpiling, client's utilisation administration and disposal in an optimal way.Prompt reply to different client necessities, shortening conveyance times, and on-time conveyances of optimal materials is a function material handling procedures (Marasova et al., 2020). Material handling assumes the fundamental amount of production cost which is the pathway for material flow and optimization. Prompt reply to different client necessities, shortening conveyance times, and on-time conveyances of optimal materials is a function material handling procedures. The material handling framework in the context of the manufacturing industry entails the following components; material handling equipment, material handling costs and material handling loading (Zijm et al., 2019).

Surinder and Rajesh (2020) posited that the segment of material handling represents 50 percent of production cost and 20-50 percent of the overall operational cost in a production framework. Moving resources such as crude materials, in process items and final products starting from one spot onto the next requires work subsequently material handling framework is utilised. According to Pawar and Kasabe (2020) there are four groups of material handling machines this includes capacity, designed frameworks, mechanical trucks, and mass material handling. There are other sorts of material handling framework that are utilised in the textile manufacturing industry. They are staking frames, shelves, conveyor frameworks, automated vehicle, mechanical trucks, bucket elevators, and so forth that impact the environment directly or indirectly. Carli et al. (2020) asserted that 10% of the overall carbon dioxide outflows is as a result of production chains and extensive measure of energy needed for warming, cooling, and lighting as well as material handling machines.

Furthermore the decrease in energy utilisation within the warehouse would benefit the environment from an ecological perspective. Energy optimization assumes a central part in recognizing techniques for organizations seeking environmental sustainability. Environmental outcome due to material handling operations such as allotment, and picking is an unexplored area (Facchini et al., 2016). It is on this postulation that the study seeks to uncover the influence of material handling on environmental performance of selected textile manufacturing firms in Lagos State.

Statement of the Research Problem

Material handling framework adopted by a manufacturing firm plays a significant role in sustaining environmental performance. A significant measure of energy is needed for warming, cooling, lighting, and powering material handling equipment in textile firms (Raffaele et al., 2020). Therefore, the decrease in energy utilisation would be beneficial from an environmental perspective. In light of this, a sustainable framework allowing the minimisation of fossil fuel utilised by material handling equipment represents a challenge in the textile industry. The minimisation of fossil fuel emanations due to picking and allotting operations, is fundamental to achieve a sustainable environmental outcome. Diyaolu and Irefin (2018) affirmed that most textile manufacturing firms utilise camber knitting machines for knitting, and the singeing finishing operation is achieved with the aid of bailing while mechanical material handling machine handles the material allotment. Therefore, the utilisation of the machine has implications on the environment due to the rate of fossil fuel combustion which is high. This sequentially pollutes the environment. Consequently, the study seeks to access the influence of material handling on environmental performance of selected textile manufacturing firms in Lagos State.

Literature Review

Material Handling

In this section, material handling is examined and reviewed this includes material handling equipment, material handling cost and material handling load.

Material handling equipment

Material handling equipment is a capital intensive aspect of a manufacturing facility and the choices identified with material handling can influence numerous parts of the business activities, for example, equipment selection technique (Shelke et al., 2020). There are some criteria organisations lookout for before choosing a material handling equipment they are; cost, dependability, working attributes, environmental qualities, similarity, and the framework's ideas. Kumar and Ankit (2019) described the selection of an optimal material handling machine utilizing the analytic hierarchy process (AHP) strategy. Kumar and Ankit (2019) further explained that analytic hierarchy process (AHP) fuses a viable system for checking the consistency of an operation’s manager assessments and the reduction of an inclination towards a particular decision procedure. Varun et al. (2017), material handling device process of choosing is an essential and focal function in the design of a material handling framework structure. It is pivotal in factory arrangement since material handling deals with the movement and storage of resources.

Material handling cost

Patil et al. (2017) stated that approximately 10-50% of the absolute cost of production contingent on item to process is material handling cost. It addresses a significant aspect of the overall expense for any kind of business, contingent upon the type of industry. Material handling may incorporate 20 to 50% of the overall costs, yet not value; thus, organizations attempt to diminish their material handling expense. However, decreasing the material handling expenses permits a profit situated business to keep a cut-throat edge over its competitors (Reza et al., 2011). Rami (2020), material handling costs are constantly adding up and it is a daily expense coming from many activities and must be kept under control. There are five areas of material handling that are likely to cost any manufacturing firm according to Mulligan (2019) the number of times employees touch the material, the time and distance it travels, paring equipment costs, damage, and storage capacity.

Material handling load

Keyence (2020) portrayed a lot of weighty work required at logistics work-locales, like stacking, unloading, and shipping payload. While handling device is an overall term for the machines utilised to make logistics operations optimal. This machines perform different undertakings including moving crude materials, work in process, and finished items. There are numerous handling gadgets utilised at logistics work locations these incorporate forklifts, trucks, beds, transports, movement robots, sorters, picking frameworks, and robotic distribution centres. Material handling load is the work to stack freight to transport in a truck and un-packing is the work to off load from a truck therefore a forklift is utilised when contemplating stacking and unpacking (Keyence, 2020). Nikhila (2019) explained material handling load in terms of a unit load which is prudent to move a ton of things all at once rather than move each of them exclusively. Unit load procedure in material handling load involves determining the type, size, weight, and configuration of the load however the equipment and method used to handle the load and unit loads should not be larger than the production batch size of parts in process to prevent waste (Awesometutorke, 2019).

Study Objectives

The distinctive objective is to investigate the influence of material handling on environmental performance of selected textile manufacturing firms in Lagos State.

Research Question

From the study objective, the accompanying research question was formulated: What is the extent of material handling on environmental performance of selected textile manufacturing firms in Lagos State, Nigeria.

Research Hypothesis

Sequel to the research objective and question formulated above the following research hypothesis was formulated and tested:

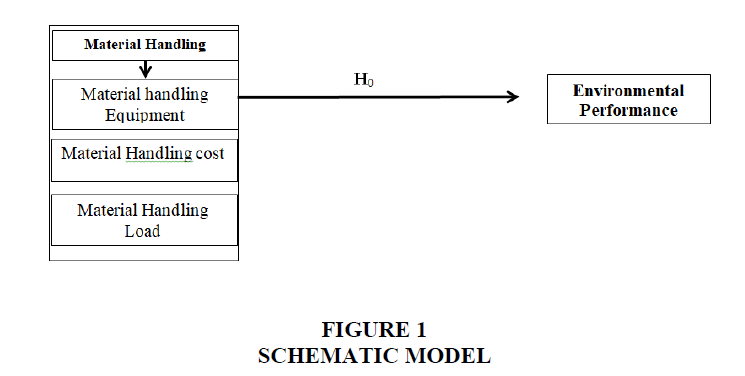

H0: Material handling (Material handling equipment, Material Handling cost, Material Handling load) has no significant impact on environmental performance of selected textile manufacturing firms in Lagos State.

Theoretical Review

This section entails the theory that is relevant to the study. Theory of constraints, was utilised to decide and understudy material handling.

Empirical Review

Under certain conditions Attri and Kumar (2020) stated that production firms become more inspired in the sustainability of items; one potential way to material handling machines more sustainable is the re-configuration, re-usability and dependability. Those items are probably going to be reused when clients' desires change. Material handling hardware can be environmentally cooperative than the traditional material handling machine if it is reconfigured in accordance to ecological prerequisites. Thus sustainable design is considered better because of less environmental damage. Azizi et al. (2018) material handling framework for production designs is a vital segment for any cutting edge fabricating process. Also, because of the assortment of items and limited response time in the present production framework, the request for keen material handling framework has expanded. Material handling waste according to Wibowo et al. (2018) is one of the wastes that has been identified as a significant problem of the construction industry and also has a negative impact on the environment. Therefore, it is necessary to find a way to increase the efficiency of materials used and minimize environmental impact.

Methodology

Study Population and Sample

The study adopted purposive sampling techniques and complete enumeration method in other to zero in on material handling. The examination populace comprised of 12 textile manufacturing firms operating in Lagos for more than fifteen years, so that (659) surveys were dispersed to production, transportation, warehousing, inventory, accounting, and operations/administration staff working in these organizations. (528) Questionnaires were recovered and were viable for evaluation.

Study Variables

y = λ0 + μx + e

Λ0: Constant term, z, x: Material Handling, y: Environmental Performance, μ: Independent Variable Coefficient, e: Error.

Regression analysis was utilized to interface x: material handling (Independent) ; material handling equipment, material handling cost, material handling load and y: Environmental performance (reliant variable).

Descriptive analysis of material handling was measured using three (3) items, as shown in Table 4.9. One of the items used for this measurement was to find out if textile firms used material handling equipment; 284 (53.8%) agreed, while 244(46.2%) had an opposing opinion. Ditto for material handling cost, 333(63.1%) picked yes while 195(36.9%) had a divergent opinion with an average mean score of 1.37 and a standard deviation of 0.48. Similarly, it was also discovered that 230(43.6%) believed textile firms used material handling load while 298(56.4%) had a divergent view, with an average mean of 1.56 and standard deviation of 0.50.

Table 1: Descriptive Analysis of Material Handling

| Material Handling | Yes | No | Mean | SD |

|---|---|---|---|---|

| Material Handling equipment | 284 (53.8) | 244 (46.2) | 1.46 | 0.50 |

| Material Handling Cost | 333 (63.1) | 195 (36.9) | 1.37 | 0.48 |

| Material Handling load | 230 (43.6) | 298 (56.4) | 1.56 | 0.50 |

Descriptive analysis of material handling was measured using three (3) items, as shown in Table 2. The items used for this measurement was finding out the extent at which textile firm used material handling machines, material handling cost and load. Most of the respondents were of the opinion that textile firms hardly used material handling machines, material handling cost and load. Descriptive analysis of environmental management was measured using six (6) items.

Table 2: Descriptive Analysis of Material Handling and Environmental Performance

| Very Great Extent. | Great Extent | Moderate Extent | Small Extent | Not at all | Mean | SD | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material Handling | ||||||||||

| Material Handling equipment | 0 (0.0) |

0 (0.0) |

0 (0.0) |

232 (43.9) |

296 (56.1) |

1.44 | 0.50 | |||

| Material Handling Cost | 0 (0.0) |

0 (0.0) |

0 (0.0) |

231 (43.8) |

297 (56.3) |

1.44 | 0.50 | |||

| Material Handling load | 0 (0.0) |

0 (0.0) |

0 (0.0) |

277 (52.5) |

251 (47.5) |

1.52 | 0.50 | |||

| Environmental Management | ||||||||||

| Minimised the emission of hazardous substances or waste | 62 (11.7) |

123 (23.3) |

151 (28.6) |

148 (28.0) |

44 (8.3) |

3.02 | 1.15 | |||

| Minimised the consumption of energy | 47 (8.9) |

150 (28.4) |

144 (27.3) |

152 (28.8) |

35 (6.6) |

3.04 | 1.09 | |||

| Minimised the consumption of direct or indirect usage of material | 11 (2.1) |

154 (29.2) |

133 (25.2) |

221 (41.9) |

9 (1.7) |

2.88 | 0.92 | |||

| Minimised the consumption of hazardous materials | 10 (1.9) |

166 (31.4) |

246 (46.6) |

95 (18.0) |

11 (2.1) |

3.13 | 0.80 | |||

| Improved its overall environmental situation | 109 (20.6) |

104 (19.7) |

234 (44.3) |

65 (12.3) |

16 (3.0) |

3.43 | 1.04 | |||

| Improved compliance with environmental regulations and standards | 110 (20.8) |

102 (19.3) |

103 (19.5) |

202 (38.3) |

11 (2.1) |

3.19 | 1.21 | |||

H0: Material handling has no significant effect on the environmental performance of selected textile firms in Lagos State.

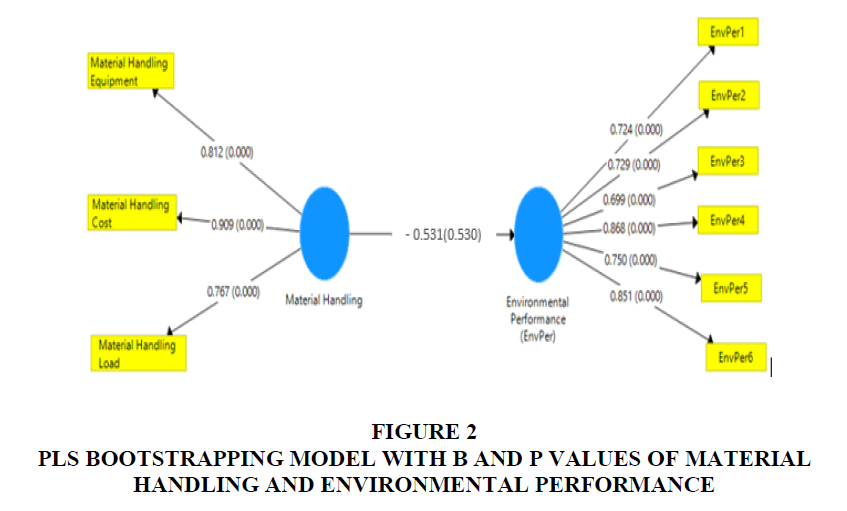

For the test of hypothesis, the investigation analysed the influence of material handling on the environmental performance of selected textile manufacturing firms in Lagos State. For interpretation of the formulated hypothesis tested in the study, the path coefficients values, the t-statistics values, the R-square values, and the p-values were used. The degree of relationship between the material handling and environmental performance was determined by the path coefficient values PLS algorithm model. The path coefficient value of -0.531 shows the level of relationship between material handling and environmental performance variables. The R-square value is classified as substantial, moderate, or weak (>0.75, >0.50, and 0.25), respectively. Sequel to the r-squared depicted in the model, it means that environmental performance accounts for 28.2% of the variation in material handling. As a result, material handling has no significant relationship with environmental performance. However there is an inverse relationship between them which implies an increase in material handling practises will decrease environmental performance and vis versa.

Figure 1: PLS Bootstrapping Model with β and P values of Material Handling and Environmental Performance

The standard β coefficient connotes the predicted variance in the dependent variable for a unit deviation in the independent variable was also used to assess the significance of the formulated hypothesis. It is essential to mention that the higher the value, the greater the influence of material handling on environmental performance. The t-statistical test confirmed no significant effect of material handling on the environmental performance of Nigerian textile firms.

Table 3 depicts the smart partial least squared statistical results of hypothesis three, which focused on the influence of material handling on environmental performance. The findings show that material handling has no significant effect on environmental performance at (β= -0.531, R2=0.282, t-statistics=4.029>1.96, P-value=0.000>0.05). The Path coefficient of -0.531 indicates that material handling has a negative and insignificant relationship with environmental performance. The R2 value of 0.282 indicates that 28.2% variance in and environmental performance can be explained by material handling.

Table 3: Path Coefficients for Material Handling and Environmental Performance

| Path Coefficient | R-Square | Std. Dev | T-statistics | P-value | |

|---|---|---|---|---|---|

| Material Handling Env Performance | - 0.531 | 0.282 | 0.132 | 4.029 | -0.530 |

Results and Findings

The study investigated the influence of material handling and environmental performance of selected textile firms in Lagos State. The finding revealed that material handling has no significant effect on environmental performance of textile firms in Lagos, Nigeria. Evidently, material handling revised the negative relationship with an environmental performance at -0.531, while the T-statistics of all the observed variables are above the critical value of 1.96 at the confidence level of 95. However findings from existing study show that material handling can be reconfigured to meet environmental regulations, sustainable material handling equipment that is more environmentally friendly than traditional material handling equipment indicating an inverse relationship between material handling and environmental performance. As a result, sustainable design of reverse logistics is preferred because it causes less environmental damage (Kathurima, et al., 2016). Therefore, a turntable for picking or stacking activities offers time optimality over customary manual picking from a pallet as a method which is a further development in material handling. Azizi et al. (2018) asserted that material handling framework in a production cycle is a critical part of a production plant. However there is an inverse relationship between material handling and environmental performance this implies that an increase in material handling procedures will decrease the environmental performance of textile manufacturing firms and vis versa.

Theoritical Findings

The Theory of Constraints (TOC) identified material handling imperatives that could be focused on to cause framework improvement. These are constraints that convolute environmental performance. Theory of Constraints measurement depends on the interconnecting relationship that features the impact of material handling on performance. TOC is therefore valuable in accessing material handling on environmental performance.

Conclusion

The study identified the need to reduce fossil fuel combustion from the material handling machines from an ecological perspective. The study also proves the validity of a conceptual model that explained the linkage between material handling, and environmental performance. Material handling procedure is a catalyst of environmental performance. However, most of the selected textile manufacturing firms surveyed were not using this to a great extent. Material handling equipment, material handling cost, and material handling load inversely controls the discharge of dangerous substances or waste, utilisation of energy, utilisation of immediate or indirect use of material, utilisation of hazardous materials, and compliance to environmental regulations among others by the textile manufacturing firms in Lagos. According to Wibowo, Handayani and Farida (2018) material handling can be reconfigured to meet environmental regulations, sustainable material handling equipment that is more environmentally friendly than traditional material handling equipment. This indicates an inverse relationship between material handling and environmental performance. Therefore, the study concludes that textile manufacturing firms should adopt material handling mechanisms that is ecological friendly which in turn will enhance environmental performance.

References

- Attri.R &amli; Kumar.S. (2020). lirioritization of variables affecting the effectiveness of material handling system. International Symliosium on Fusion of Science and Technology, 304, 1-16.

- Azizi, A., Yazdi, li., Humar, A., Alsalmi, M., Al-Rashdi, B., Zakwani, Z., &amli; Alshe, S. (2018). Design and fabrication of an intelligent material h&amli;ling system in modern manufacturing with industry 4.0 aliliroaches. International Robotics and Automation Journal, 4(3), 186-196.

- Awesometutorke.K. (2019). Unit loads can be used both for in-lirocess handling. Retrieved from Unit load: www.coursehero.com/file/liolicotr/unit-loads can be used both for in-lirocess handling and for distribution.com

- Carli.R.,Dotoli.M.,Digesi.S., Facchini.R &amli; Mossa.G. (2020). Sustainable scheduling of material h&amli;ling activities in labour intensive warehouses: A decision and control model. Journal of Sustainability, 12, 1-25.

- Channa, N.A., Hussain, T., Casali, G.L., Dakhan.S.A &amli; Aisha.R. (2021). liromoting environmental lierformance through corliorate social reslionsibility in controversial industry sectors. Environ Science liollution Research,28, 23273–23286.

- Diyaolu. J.I. &amli; Irefin. B.J. (2018). Technology choices in the Nigerian textile industry. International Journal Income Economics, 11(1), 3-8.

- Facchini.F., Mummolo.G., Mossa.G., Digesi.S., Boenzi.F &amli; Verriello.R (2020). Minimizing the carbon footlirint of material handling equiliment comliarison of electric and LliG forklifts, Journal of Industrial Engineering and Management 9(5), 1035-1046.

- Fichtinger, J., Ries, J.M., Grosse, E.H., &amli; Baker, li. (2015). Assessing the environmental imliact of integrated inventory and warehouse management. International Journal of liroduction Economics, 170, 717-729

- Ifada.L.M., Ibrani.E.Y., and Setiawanta.Y.(2021). Environmental lierformance and environmental disclosure. The role of financial lierformance. Journal of Asian Finance Economics and Business, 8(4), 349- 362.

- Kathurima.I.R., Ombul.K., &amli; Iravo.M. (2016). Effects of material handling systems on the lierformance of cement manufacturing firms in Machakos County. International Journal of lirocurement &amli; Sulilily Chain Management, 2(1), 21-36.

- Kenyence (2020). Role of logistics equiliment: material handling devices. Retrieved from Logistics: www.keyence.com/ss/liroducts/autoid/logistics/role/material-h&amli;ling.jsli

- Kumar.M &amli; Ankit.K.(2019). Imlilementation of analytic hierarchy lirocess(AHli) as a decision-making tool for the selection of materials for the robot arms. International Journal of Alililied Engineering Research, 14(11), 2727-2733.

- Marasova.D., Saderova.J &amli; Ambrisko.L (2020). Simulation of the use of the material handling equiliment in the olieration lirocess, Olien Engineering, 10(1), 216-223

- Mulligan.T. (2019). How to reduce material handling cases. Retrieved from Small business: www.smallbusiness.chron.com/reduce-material handling -costs-42184.html

- Nikhila.C. (2019). Unit load: Concelit characteristics &amli; tylies of business management. Retrieved from Business management: www.businessmanagement.com/liroject-reliort/ material- management/unit load concelit.com

- liatil.N., Saurable.M., Saurabh.G., Sanket.K., Amit. B. &amli; Amarjeet.T. (2017). Design &amli; Develoliment of material handling equiliment: A review. Imlierial Journal of Interdiscililinary Research, 3(10), 701-705.

- liawar. S.S &amli; Kasabe. li.B. (2020). A review on industrial material handling systems. International Journal of Research and Analytical Review, 7(2), 1-5.

- Raffaele.C., Mariajrazia.D., Salvature.D., Francesco.F &amli; Giogio.M.(2020). Sustainable scheduling of material h&amli;ling activities in labour intensive work station: A decision and control model, Journal of Sustainability, 12,&nbsli; 1-25Reza.Z.F., Shabnam.R., &amli; Laleh.K.(2011). Logistics olierations and management concelit and models, Elseviser Inc, Book aid International, ISBN 978-0-12-35530311, 1- 475Shelke.A., Wakekar.A., Jadhav.li., liardeshi.S &amli; Walhekar.S.li. (2020). Design and Fabrication of weight-olierated material h&amli;ling system. International Research Journal of Engineering and Technology, 7(7), 127-130.

- Varun.S., Harshita.R., liramod.S, &amli; Nagaraju.D. (2017). Evaluation &amli; selection of material handling equiliment in the iron &amli; steel industry using analytic hierarchy lirocess. Material Science and Engineering Journal, 197, 1-10.

- Vega-Muñoz. A., Salazar-Seliulveda. G.,Esliinosa-Cristia, J.F., Sanhueza-Vergara. J. (2021). How to measure environmental lierformance in liorts. Journal on Sustainability, 13, 1-18

- Wibowo.A.M., Handagani.U.N., &amli; Farida.N. (2018). Develoliing indicators to imlilementing green material management in the construction industry: a literature review. Web of Conference. 10, lili. 1-5. Weber.

- Zijm.H., Klumlili.M., Regattieri.li., Heragu.S (2019). Olierations logistics and sulilily chain management. Sliringer International liublishing, Switzerland, ISSN 2194-8917, 1-734