Research Article: 2025 Vol: 24 Issue: 2

Exploring the Market Value Chain Dynamics of Chepa (Semi-Fermented Fish): A Promising Solution to Alleviate Nutritional Deficiency

Jannatul Ferdous, Sylhet Agricultural University

J. Khandakar, Independent University

Citation Information: Ferdous, J, Khandakar, J. (2025). Exploring the market value chain dynamics of chepa (semi-fermented fish): a promising solution to alleviate nutritional deficiency. Academy of Strategic Management Journal, 24(S2), 1-16.

Abstract

Chepa, a widely consumed processed fish product in Bangladesh, is prepared through the semi-fermentation process using small fish varieties such as Phaisa and Puti. The study aimed to explore the business dynamics of Chepa production and marketing, focusing identifying challenges and issues in the process. In the study, focus group discussion (FGD) and face to face interviewing were conducted using semi-structured questionnaires. Additionally, PESTLE framework was employed to assess the operational aspects of the Chepa business. The study identified seven key stakeholders in the different nods of the Chepa value chain, highlighting their role alongside supporting entities. The production process involved careful categorization of dried fish based on size and quality. Notable, women constituted predominant workforce in the midstream segment, specially contributing to fish processing. Unlike other food items, Chepa fermenting processes carried out in treated earthen pots without using any chemicals and pesticide, resulting in a distinctive flavor and color. The study underscores the profitability of Chepa industry, although fishermen earned the lowest profit among the shareholders. Furthermore, the declining population of small fish in water body like haor, posing a threat to their livelihoods. The PESTLE analysis highlighted the importance of an integrated, and multidisciplinary approach to food safety and quality, stressing the importance of training and institutional development. The outcomes of our study offer valuable insights for policymakers and stakeholders, guiding efforts towards establishing a sustainable and resilient Chepa industry.

Keywords

Chepa, Value Chain, Semi Fermentation, Stakeholder, PESTLE, Profit Introduction.

Introduction

The fishing industry in Bangladesh has undergone significant development in recent decades, propelling the country to achieve self-sufficiency in fish production and secure its position as the world’s third-largest fish producer Shamsuzzaman et al., (2020), Sunny et al., (2020).

This industry not only contributes significantly to the national Gross domestic product (GDP) 3.61% and agricultural GDP 24.41% but also provides livelihoods for over 11% of country’s population. Globally, fish, rich in essential nutrients and fatty acids, fills 17% of the total animal protein consumed by human Hasan et al., (2021). With the world’s population continually expanding, there is an anticipated surge in demand for diverse, protein-rich processed fisheries products. The COVID- 19 pandemic has terrifically highlighted the vulnerability of the world food system, disrupting supply networks, especially for perishable goods like fresh fish, due to delays in shipping, trade and labour, alongside unpredictable supply, and demand trends. Hence, it is the time for transitioning to sustainable supply chains that involves rethinking vulnerabilities arising from an excessive reliance on conventional operations. In this context, Bangladesh’s unique semi-fermented fish, Chepa, stands out as a product with immense potential for international export. Chepa, primarily prepared from Puti (Puntius spp) and Phaisa ((Setipinna spp.) fish, is a highly popular dish in Bangladesh, enjoyed by people across regions. Notably, Chepa boasts higher protein, and lipid contents compared to fresh and sun-dried Puti fish. Importantly, Chepa is produced without salt or preservatives, enhancing its health benefits and tenderness Sarkis (2020).

In regions like Kuliarchar in the north central Kishoreganj district, intricate network of the Meghna and Bhramaputra rivers, along with numerous haors and canals, forms a significant geographical feature, a vibrant fishing community thrives. This area has earned its reputation as the country’s foremost fishing hub. Therefore, nearly 95% of the local population’s livelihoods are intricately tied to fishing and the production of dried fish, including Chepa. However, the economic stability of these residents is markedly fragile and disadvantaged, largely due to the lack of information about the current market trends and opportunities for value addition. According to a report of Samiul Islam, in the 2020-21 season, Bangladesh produced 46.21 lakh metric tons of fish, 20% of which was processed as dried fish, including Chepa. This robust domestic demand signals an opportunity for Bangladesh to explore international trade. To capitalize this opportunity, it is crucial to strengthen the Chepa industry along with the role of stakeholders, viewed through the lens of a value chain perspective.

In Bangladesh, several studies have explored Chepa’s nutritional value and quality assessment and ecological implication Hossain et al., (2017). There remains limited understanding of details of market dynamics. To address this gap, our study employs a PESTLE analysis, encompassing Political, Economic, Social, Technology, Legal and Environmental factors. Based on these facts, our study aims to elucidate the Chepa industry’s business mode with value addition, foster cooperation among stakeholders and evaluate its competitiveness in the global export markets.

Materials and Methods

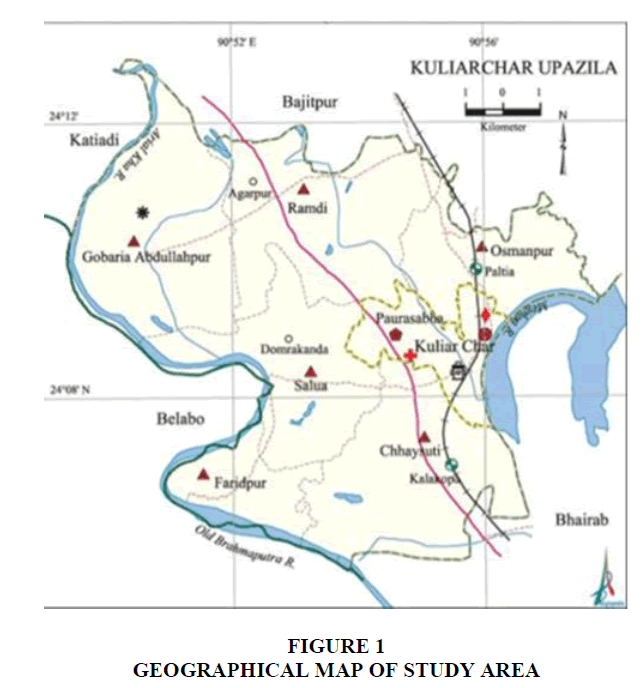

Description of Study Area: The study was conducted in Daspara village, located in Kuliarchar Upazila within the Kishoreganj District, part of Dhaka Division in Bangladesh. This village, home to approximately 1000 residents, is predominantly inhabited by people practicing the Hindu religion. Located along the Kali river, which converges with the Meghna river at Mendipur village after a 2 kilometer stretch, Daspara village is surrounded by a significant number of haor, making it a prominent fishing hub. As a result, the economic activities in this region are primarily reliant on water resources. Our observation revealed that nearly 95% of the village’s population is engaged in fishing activities, particularly in the production of dry fish and Chepa. The study area features 39 wet fish arata (storehouse) and 70 fish drying yards. Chapa production in this region is primarily carried out during the winter season due to the abundance of raw materials and suitable environmental conditions, such as low humidity and ample sunlight for uniform drying. Figure 1 shown the map of study area (source: Bangladesh National portal).

Sampling and Sample Size

A purposive sampling technique was used to select participant ranging from input suppliers to end consumers including fishermen, wet fish arotder, Chepa producers, Chepa wholesalers, retailers, consumers, and other stakeholders involved in the backward and forward linkages of the value chain that Chepa passthrough. A total of 106 actors were randomly selected Table 1.

| Table 1 Category of Actors and Representative Sample Size | |

| Stakeholders | Sample Size |

| Fishermen | 10 |

| Wet Fish Arotder | 10 |

| Chepa Producer | 15 |

| Arotder | 10 |

| Wholesaler | 10 |

| Worker (Male+ female) | 20 |

| Retailer | 10 |

| Consumer | 10 |

| Other backward and forward stakeholder | 11 |

| Total | 106 |

Data Collection

Over a span of 2 years and 6 months, from November 2018 to March 2020, a comprehensive survey was meticulously conducted. The survey commenced with a pilot visit, during which a preliminary questionnaire was developed for stakeholders. Through several revisions and adjustments based on feedback from subsequent surveys, the questionnaire was finalized. This questionnaire consisted of both closed-ended questions, designed for straightforward responses and open-ended questions, aimed to elicit descriptive details and novel insights. Special attention was paid to unexpected yet valuable information that emerged during the survey, contributing significantly to the research objectives. A total of 106 actors from different nods of the value chain were interviewed. These personal interviews focused on various facets, including the raw input collection system, raw products processing (such as gutting, cleaning, grading, and drying), marketing strategies, actors’ roles, financial aspects (income and expenditure), and consumer behavior. To supplement individual interviews, a checklist was employed to guide the informal discussion, generating valuable data that couldn’t be gleaned from individual interviews. Furthermore, focus group discussions (FGDs) were conducted with groups of 10 participants, held twice to ensure the data’s validity and depth. In addition to primary data collection, secondary data were sourced from published journal articles and unpublished district documents.

Computation of Profit

The study involved a comprehensive analyzing of the marketing costs and margins associated with Chepa businesses. Various factors were taken into account, such as the price of raw fish, collection of raw fish, drying, grading, sorting, processing, fermentation, storage, transportation, and other related marketing expenses. Price variations depending on value addition in different segments of value chain were considered, accounting for spatial and temporal differences. A simple profit margin analysis was used to compute gross margin/ gross profit of Chepa business.

Total Cost = Total Fixed Cost +Total variable cost

Profit = Selling price – Total cost

Margin = (Profit/Production cost)× 100

The marketing cost per kilogram of Chepa was computed by adding the shop rent, electricity bill, transportation cost, and personnel expenses.

Data analysis

To enhance accuracy, data collection commenced with local units and subsequently converted into standardized units. Descriptive statistics, graphs and charts were generated using MS-Excel. Lucid chart was employed for creating detailed flowcharts in the analysis process.

Status of Inputs to Produce Chepa

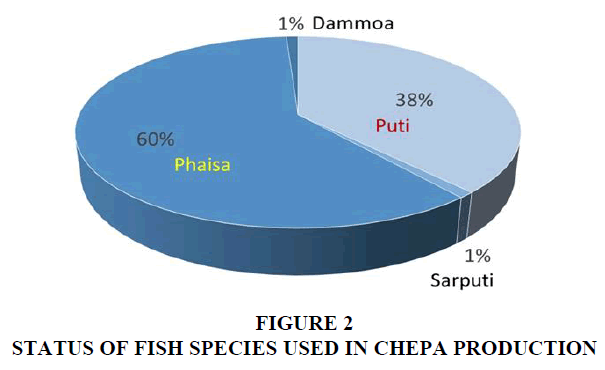

In the study area Kuliarchar, Chepa was primarily produced from fish species like Puti (Puntius sophore, Puntius ticto, and Puntius chonconius), Phaisa (Setipinna phasa, Setipinna taty,Thryssa purava, and Thryssa hamiltonii). Additionally, less commonly used fish in Chepa production included Sharputi (Putius sarana), Bata (Labeo bata), Boga (Labeo boga) and Dammoa ( Pelona ditchela). Specially in Kuliarchar, 60% of Chepa was derived from Phaisa, 38% from Puti, while Dammoa and Sarputi each constituted 1% of the production Figure 2.

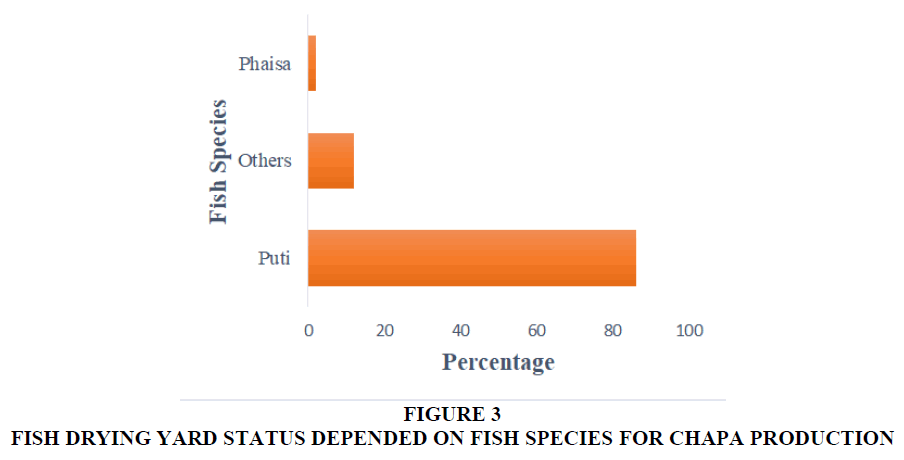

A distinctive feature of Chepa production lies in its use of sun-dried fish for fermentation, as opposed to fresh fish. Thus, Chepa production is primarily undertaken during the winter season due to the abundance of raw materials and favorable environmental conditions such as low humidity and ample sunlight, ensuring consistent and homogeneous drying. Prior to fermentation, fresh fish is dried in specialized fish drying yards locally referred to as “Dangi” or “Changery”, constructed using bamboo, bamboo-stick, and ropes. In our study area, we identified a total of 70 Changeries with 86% allocated for drying Puti, 2% for Phaisa, and 12% for other species , notably Shol, Gozar, and Boal Figure 3.

Figure 2 illustrated Phaisa as the most used raw material for Chepa, although in local Changeries, Puti was more commonly processed (Fig 3). To address this disparity, our investigation revealed that Chepa producers sourced dried Phaisa from Chattagram and Cox-bazar. The reasons behind collecting dried Phaisa was more cost-effective, time-efficient, and less labor-intensive method compared to processing Puti.

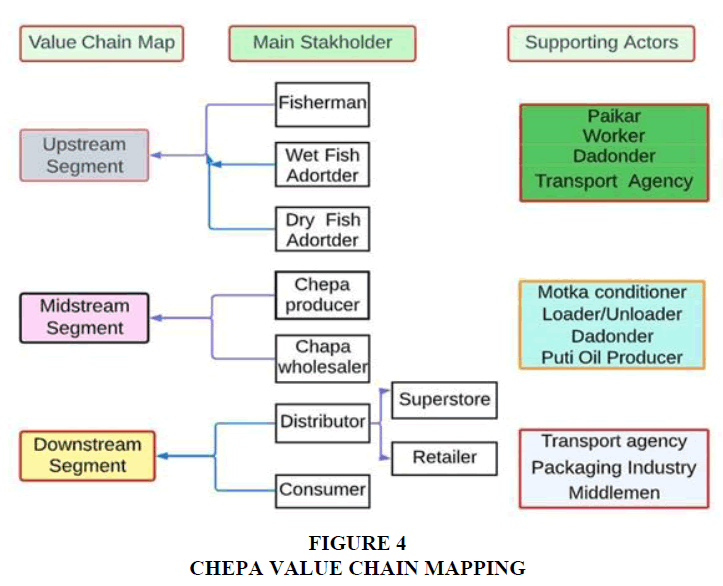

Value Chain Mapping and Addressing the Contribution Of Actors

Academically, value chains can be conceptualized as comprising three distinct segments: upstream, the midstream, and downstream. Moreover, the value chain is typically classified into primary stakeholder and supporting actors based on shareholder activities. Considering these three segments and activities, our analysis has identified seven major stakeholders involved in various stages of production to end consumption. These stakeholders include fishermen, commission agents like wet fish arotders, dry fish arotders, Chepa producer, Chepa wholesaler, distributor in different market settings (such as superstores and retailers), and ultimately, consumers (Fig 4). Additionally, we have recognized several supporting stakeholders including paikar (brokers), workers, puti oil producers, motka conditioners, motka fillers, transport agencies, loader/unloader, dadonder (money lenders) and so on (Figure 4).

Our study revealed that key stakeholders specialized in supplying raw materials, such as Fishermen, Wet and Dry fish arotder, operate in upstream segment. In the midstream segment, these raw materials are processed and traded to different markets by actors like Chepa producer and Chepa wholesalers. Finally, in the downstream segment, Chepa is traded from markets to consumers, including superstores and retailers Figure 4. In the upstream node of the value chain, fishermen played vital roles in commencing the value chain process. They caught fishes of diverse size from the Meghna River, Kali River and nearby Haors using traditional boats and gear nets mainly between October and March Pramanik et al., (2017). In this diverse work, despite paying for their own work as well as covering the expense of equipment like boats and nets, fishermen earned meager profits. They sold their raw inputs to paikers and/ or wetfish arotder at prices ranging from BDT 55-110/kg, with fluctuations based on fish size, quality and distance for transportation Table 2. This price variation highlights the challenges faced by fishermen, who are significantly dependent on arotder or dadonder due to their limited capabilities, leading to a substantial power imbalance.

| Table 2 Market Price Share of Each Stakeholder in the Chepa Value Chain | ||||

| Key stakeholder | Value addition | Cost | ||

| Buying Price (BDT/kg) | Selling Price (BDT/kg) | |||

| Fishermen | Fishermen serve as suppliers of raw materials, offering their time and labor without participating in value-added activities. | 55-110 | ||

| Wet fish arotder | They primarily sell the fish to dry fish producers via public auction in the market, thereby adding value to the place and facilitates the freezing system. | 55-110 | 120-150 | |

| Dry Fish arotder | Upon collecting wet fish, various activities such as grading, sorting, and gutting occur at this specific point in the chain. Subsequently, the fish are dried in the fish drying yard using sunlight. Furthermore, dry Puti, along with other species of dry marine fish, is supplied to the Chepa producer. | 120-150 | 170-200 | |

| Chepa Producers | Chepa producers load the Motkka with dry Puti or dried Phaisa after conditioning it with Puti oil. Then the Motka, along with Puti oil, is buried or stored at gola for 3-4 months to allow fermentation, given that Chepa is a semi-fermented fish | 170-200 | 400-550 | |

| Chepa wholesaler | This stakeholder obtained the final good from the Chepa producer and added time value by preserving it for a lengthy period of time so that it could be used in the off-season. | 400-550 | 400-800 | |

| Trader | Superstore | Usually, they added value by using high-quality packaging and grading the products. In addition, this process involves various expenses both variables and fixed, such as purchase price, packing cost, transport cost, labor, electricity, and taxes, among others. | 400-800 | 1500-1800 |

| Retailer | The retailer enhances value by maintaining proximity between Chepa and the customer. Various vehicles are utilized for this operation. Retailers commonly package Chepa by enveloping them in paper and polythene, securing them with ropes, rather than employing manufactured packaging materials. | 400-800 | 600-1100 | |

| Consumers | The customer serves as the ultimate end-user of the product, for whom all value is created and added. | |||

The process of adding value to the raw materials primarily begins with wet fish arotder, who employ various facilities like freezing. Subsequently, dry fish arotder initiate procedures such as sorting, grading, drying, and gutting (to remove unwanted materials). To ensure the production of high- quality Chepa, these order processors categorize the raw materials into three groups based on the size and quality of the fish: Grade A: this category includes fresh fish that are standard in size, usually measuring between 4.0-4.5 inches. Grade B: these are fresh fish as well, but smaller in size compared to grade A, Grade C: this category comprises slightly damaged fish and those smaller in size locally known as Gador Puti. According to arotder report, Grade A and Grade B raw materials are subjected for Chepa production, while Grade C materials are set aside for sun-drying to prepare normal Puti shutki. This meticulous categorization process ensures the production of Chepa with desired quality standards.

During this production phase, the predominant workforce consists of females who contribute significantly to the process. Interestingly, these women do not receive monetary compensation for their work. Instead, they opt to keep the guts of the Puti fish, which are used to produce oil. This sort of oil serves the purpose of conditioning the Mokta (earthen pot), where fermentation occurs. The value of this oil is noteworthy, priced between BDT 70-100 per liter. Moreover, within this upstream segment, several supporting stakeholders were observed including paikar, dadonder and worker so forth Figure 4 & Table 2.

Likewise, in the midstream segment, Chepa producers emerge as key player. They engage in a multitude of activities, such as gathering dried fish, preparing them for fermentation, and trading the finished goods. These stakeholders hold significant importance, adding substantial value and supplying the finished product to buyers in the subsequent segment of the value chain.

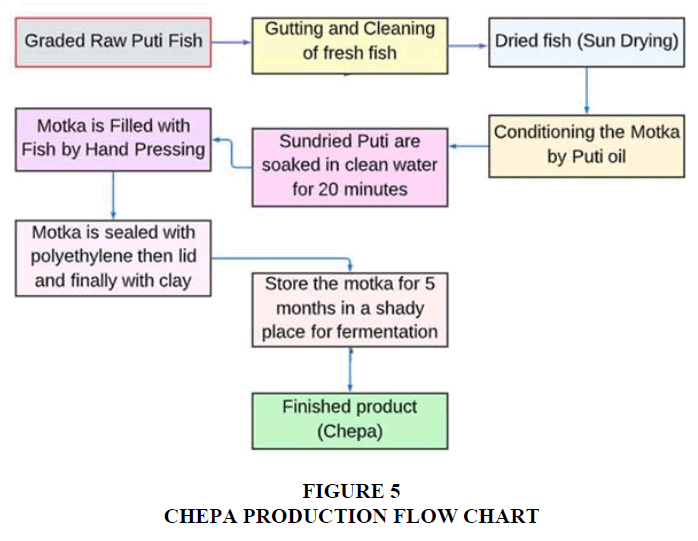

Figure 5 illustrates the Chepa production process. In brief, the earthen pot, known as Motka, is initially treated with Puti oil and then filled with dried Puti. Subsequently, the filled Motka is sealed with a polythene sheet and clay, and left to ferment for 4-6 months until it acquires its distinctive flavor and color (Fig. 5). These Motka are usually stored in a shaded area locally referred to as Gola. It is important to note that, unlike dried fish, the raw materials absorb water during fermentation, resulting in an increase in the weight of the final product, Chepa. Typically, 1 kg of dried Puti results in 1.5 kg of Chepa, ensuring a substantial profit margin of 28.71% for Chepa producer (shown in Table 2 and 3). However, this profitability is contingent on the season. According to our findings, during peak fishing seasons, the cost of production is BDT 425.32/kg, while the selling price ranges from BDT 400-800/kg, depending on the quality of Chepa Table 3.

| Table 3 Production Cost of Puti Chepa | ||

| Cost Item | Cost (BDT/Motka) | Cost (BDT/kg) |

| Cost for Raw materials | 16800 | 300 |

| Fixed Cost | 183 | 4.57 |

| Variable Cost | 730 | 18.25 |

| Total Preparation Cost | 17713 | 425.32 |

| Selling Price | 22800 | 570 |

| Profit | 5087 | 127.17 |

| Margin | 28.71% | |

Chepa wholesalers play a significant role in the middle of the value chain by purchasing Chepa from Chepa producers in bulk and then distributing them to retailers in small quantities. Additionally, several other stakeholders are involved in the process, including Puti oil producers, Motka conditioners, Motka fillers, Loaders/Unloaders, dadonders, and Gola owners, in addition to these key players.

In the same vein, downstream participants in the Chepa value chain include traders and consumers. Depending on customer preferences and location, supermarkets and retailers package the product. Notably, supermarket packaging is of higher quality compared to local shops. Consumers access and utilize the product through various value-adding stages via different channels including online platforms, marking the final stage of the chain Table 2. From Table 2, it is also speculated that the market types are one of the major determinants of Chepa’s market price, with superstores selling at BDT 1500/kg and small retailer stores selling at BDT 800-1100/kg. It is noteworthy that both variable and fixed expenses, such as purchase price, packing cost, transport cost, labor cost, electricity, and taxes contribute to the significant price variation among the actors within a node, particularly in supermarkets.

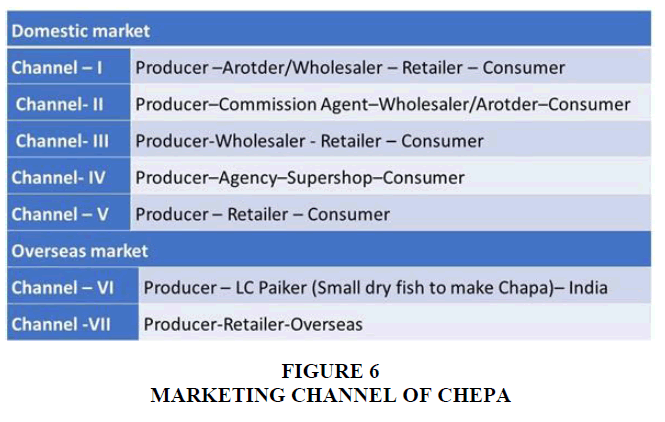

Marketing Channel

Marketing channel strategies are dynamic and primarily depend on the nature of the product, market types and geographical locations. Chepa, being a semi-fermented fish product with the ability to be preserved for long time at ambient temperature, offers diverse marketing opportunities. In our study, we identified seven marketing channels Figure 6 for Chepa trading encompassing five channels for the domestic market and two for the international market. Remarkably, our study noticed a lack of well-established trading patterns in the international market. Local vendors claimed that substantial amounts of dried Puti a key ingredient in Chepa production, are exported to India but not directly to other countries. Additionally, in regions like the Middle East, UK, where a significant Bangladeshi population resides, there is limited export of Chepa, occurring in segmented fashion.

Transportation

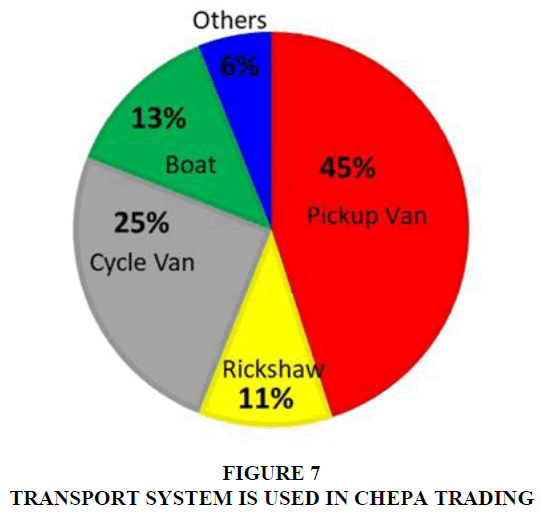

Having a well-defined and cost-effective transportation strategy is essential for business growth. In the case of a long supply chain, profitability can be impacted due to profit erosion, primarily caused by high transport cost. In the study areas, several types of vehicles such as boats, cycle vans, rickshaws, pickup vans, lorries and buses, were employed at different stages of product transportation. Among these modes of transportation, pickup vans made the most significant contribution. Usually, shoulder loads, cycle van, and rickshaw are used to transport the Chepa at a short distance, whereas pickup vans are preferred for longer distance. Our result showed that Pickup Van (45%), Cycle Van (25%), Boat (13%), Rickshaw (11%), and others (6%) were utilized for Chepa transportation Figure 7.

PESTLE Analysis of The Chepa Industry In Bangladesh

For understanding the holistic view of the Chepa industry and minimize the threats we analyzed the PESTLE framework De Silva Table 4. Our study observed a gradual escalation of political pressure as political persons gained control over haors and fish catching hubs through leasing arrangements. This situation adversely affected the small fishermen due to non-practicing of specific co-management laws. Economically, fishermen faced vulnerability with declining in average fish catches directly impacting fishermen’s income and investment opportunities. Socially there was a notable shift with the inclusion of local Muslim in the industry, leading harmonious association, indicating a positive change in religious sentiment. Additionally, advancements in marketing facilities were attributed to improvements in communication processes, such as better road and transport infrastructure, facilitating the flow of information. However, there was a lack of robust accountability measures from the national government to support fishing communities, contrasting with strong local government determination to help the industry.

| Table 4 Pestle Analysis of the Chepa Industry | |||

| Factors | Response in Percentage | ||

| Increased | Decreased | Unchanged | |

| Political Factors | |||

| Pressure from political entities on fishermen and other stakeholder of upstream segment | 60 | 30 | 10 |

| Prospects for a cooperative approach to influence future policymaking and actively participate in political decision. | 80 | 20 | 00 |

| Enhancing transparency in the value chain by providing easily accessible information on market prices. | 60 | 30 | 10 |

| International agreement | 25 | 70 | 5 |

| Economic Factors | |||

| Unequal income distribution | 80 | 10 | 10 |

| The reduced average fish catches impact fishermen’s income and limit their capital available for investment. | 60 | 20 | 20 |

| Limited financial knowledge affects operation of Business | 30 | 40 | 30 |

| Uses of banking system | 40 | 30 | 30 |

| Social factors | |||

| Acceptance of subpar inputs | 70 | 20 | 10 |

| Concern about high price and low-quality | 95 | 00 | 5 |

| Lack of awareness regarding food safety, hygiene and certification | 30 | 10 | 60 |

| Health issues due to poor-quality raw materials and storage system | 30 | 30 | 40 |

| Lack of training and Scientific knowledge of quality Chepa production among the actors | 5 | 5 | 90 |

| Impact of religious sentiments on industrial practices | 20 | 70 | 10 |

| Insufficient knowledge in handling, grading, packing and processing facilities with limited technology | 25 | 5 | 70 |

| Underdeveloped marketing facilities | 20 | 60 | 20 |

| Technology | |||

| Inadequate infrastructure (Infrastructure facilities, tools, and Technology) | 20 | 70 | 10 |

| Lack of mechanized production technology | 20 | 10 | 70 |

| Paucity of freezing facilities | 50 | 00 | 50 |

| Selectivity of fishing gear (i.e. gillnets) | 85 | 10 | 05 |

| Lack of fish drying technology (usually used sundried fish) | 80 | 00 | 20 |

| Lack of modern storage facilities of raw and dried fish | 40 | 35 | 25 |

| Insufficient transport facilities both roads and vehicles | 25 | 50 | 25 |

| Poor knowledge of value addition | 10 | 10 | 80 |

| Legal Factors | |||

| Absence of regulations, and monitoring on Quality standards | 5 | 10 | 85 |

| Food safety | 10 | 70 | 20 |

| Hygiene standards for Fish handling | 5 | 25 | 70 |

| Unlawful use of fishing net | 90 | 10 | 00 |

| Regulation in foreign export markets | 60 | 15 | 25 |

| General Trade agreements | 40 | 20 | 40 |

| Environmental Factors | |||

| Insufficient availability of clean water | 70 | 20 | 10 |

| Inadequate sewage management system | 75 | 20 | 5 |

| Impact of tropical weather conditions and climatic change | 80 | 10 | 10 |

| Limited awareness about personal hygiene and sanitation practices | 10 | 10 | 80 |

| Absence of hygienic facilities for fish drying and processing centers. | 60 | 30 | 10 |

| Concerns regarding the Sustainability of fish stocks | 10 | 75 | 15 |

| Trend in post-harvest losses | 30 | 40 | 30 |

Discussion

Traditionally, Puti (Puntius spp) has been the preferred fish species for Chepa production in Bangladesh. However, our study has shown a decline in the use of Puti as an economical raw material. Instead, a significant portion of Chepa production now relies on Phaisa fish. Various research studies have indicated that the overuse of agricultural inputs like chemical fertilizers and pesticide, together with recent climatic changes, has adversely impacted the biodiversity of small fish like Puti. This led to the progressive depletion of Puti from natural water bodies like river, hoar. Thereby, the price of Puti has risen. In contrast, Phaisa comprises several marine species that are abundantly available and less price. Due to this availability and low cost, Chepa producers are increasingly turning to Phaisa to address the limitation posed by the diminishingly supply of traditionally used Puti fish. As mentioned earlier, 95% of the inhabitants in the study area rely greatly on fishing for their livelihood. If the fishing resources continue to dwindle, the lives of the fisherman as well as other shareholders become increasingly catastrophic. In Bangladesh, fisheries resources, termed as Jalmahals are under the administrative ownership of the Ministry of Land (MoL) and are regulated by the Government Jalmahals Management Policy of 2009. According to this policy, the government can help replenish these small fish in natural water bodies by imposing bans on the capture, sale and transporting of small fish like Puti during its peak spawning season from April to July. Likewise, several initiatives have been undertaken by the government, such as establishing sanctuaries, prohibiting Jatka catches for eight months of the year, imposing bans on fishing during the breeding seasons, banning fishing at sea for 65 days, and conducting special combing operation, to enhance hilsa production in Bangladesh. Additionally, adopting a community-based fisheries management system would contribute to managing available resources equitably and sustainably. Unlike the current revenue-driven fisheries management system, this strategy prioritizes conservation over profit. As a result, achieving national objectives like poverty alleviation through fisheries becomes feasible, striking a balance between the need for production and conservation of vital resources. Furthermore, the study noted that fishermen tend to generate lower profits compared to other actors in the value chain. Various research studies have suggested that improving the governance of the value chain can be achieved by establishment of cooperatives or the implementation of auction systems. These strategies have the potential to deliver economic benefits for small suppliers such as fishermen.

Several research have emphasized the superior nutritional profile of dried small fish, highlighting its significance for public health. Hamilton-Hart & Stringer (2016), Byrd et al., (2021). Thus, maintaining and preserving nutritional quality of finished products is a crucial concern. The quality of dried fish can be jeopardized due to various hazards metals like Pb, Cd, and Cr, pesticide residues, and the presence of highly pathogenic bacteria like E. coli, Salmonella sp., and Vibrio sp in the production chain Banna et al., (2022). Interestingly, upon examining the Chepa production flow chart Figure 5, it is evident that no toxic chemicals or preservatives are used. Additionally, Chepa can be stored at room temperature for six months a year. The nutritional status of Chepa compared with others form of Puti shown in Table 5. This makes Chepa an excellent global protein source and a promising export item for Bangladesh.

| Table 5 Nutritional Status of Different Puti Products | ||||||

| Product Types | Moisture (%) | Protein (%) | Lipid (%) | Carbohydrate (%) | Ash (%) | References |

| Fresh (Puti) | 75.89 | 15.99 | 3.98 | - | 4.91 | [19] |

| Sun dried (Puti) | 25.13 | 48.82 | 9.84 | - | 16.11 | [20] |

| Chepa (Puti) | 59.4 | 15.9 | 2.7 | 21.9 | [21] | |

Marketing analysis, our study echoes that the involvement of multiple market intermediaries significantly influences price fluctuations and overall profitability Rana et al., (2020), Begum et al., (2017), Monir et al., (2013), Rasul et al., (2020) and emphasizing that a direct producer-to-consumer approach proves to be most efficient marketing route. In fact, it surpasses the effectiveness of other marketing channels Majumdar (2017). Additionally, our study aligns with existing literature, affirming that the number of intermediaries profoundly impacts the nodes within the value chain and the pattern of products value growth Bari et al., (2014).

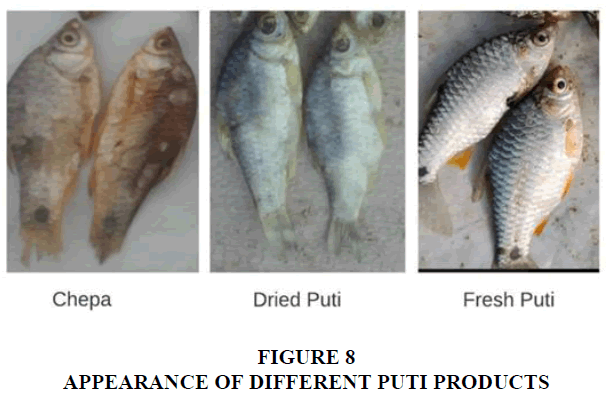

From Table 4 PESTLE analysis exposes several challenges in maintaining the quality of Chepa. To address these problems, multifaceted approach should be taken, Preventing environmental contamination specially the entry of heavy metals and hazardous chemicals to the aquatic ecosystem. Organizing public health awareness campaign targeting all stakeholders in the production chain Fishery & Statistics (2018). Educate them about fundamental hygiene, sanitation practices. Offering training on safe Chepa production and waste management and designing efficient packaging and storage facilities Figure 8.

Unfortunately, Chepa lacks a recognizable brand identity image in the international export market. Therefore, to establish its branding, we need to emphasis on both technical as well as institutional development Nayeem et al., (2010). A holistic approach involving improved production practices, heightened public awareness, strengthened institutions and strict adherence to international quality and safety standards, can elevate the Chepa industry in Bangladesh, ensuring sustainable growth and access to global markets Jacinto & Pomeroy (2011).

Conclusion

In this study, we paid effort to explore two major aspects of the Chepa market value chain which are addressing the potential as well as constraints in the Chepa production and role actress playing in trading system. We found that fishermen are the utmost vulnerable actors among the stakeholders. Furthermore, ensuring a convenient transport system with less intermediary actors is a key point for the further development of this sector. Thus, Proper marketing strategies and appropriate monitoring should be done to ensure ostensibly trustworthy markets of Chepa. It is therefore necessary to provide institutional and organizational support, government aid, extension services and more research along with knowledge of Chepa marketing. In addition, this study's findings are particularly useful to academics, policymakers, and industry-related stakeholders in formulating and reviewing value chain strategies for Chepa production, distribution, and internalization. This research not only has a number of lessons for practitioners, particularly in the domain of Chepa production and the food industry, but it may also shed light on the components of the Chepa value chain which have an important role in cost calculation within the industry based in Bangladesh. Furthermore, the results of the study provide an insight into how the livelihood of the fishermen, health safety issues related to the production process, and the limitation of the quality production may hamper the prospects of the industry and why future research and initiatives must be taken to develop understanding, trust, and awareness. From the applications point of view, this study helps the food industry to be aware of the issues related to Chepa production and its value chain, allowing them to take proactive action in order to achieve greater response addressing national and international demand.

References

Banna, M. H. A., Al Zaber, A., Rahman, N., Siddique, M. A. M., Siddique, M. A. B., Hagan Jr, J. E., ... & Khan, M. S. I. (2022). Nutritional value of dry fish in Bangladesh and its potential contribution to addressing malnutrition: a narrative review. Fishes, 7(5), 240.

Indexed at, Google Scholar, Cross Ref

Bari, S. M., Marine, S. S., Hossain, M. A., Rashid, A., & Islam, M. A. (2014). MARKETING STRATEGIES FOR DRY FISH IN SYLHET DISTRIC T OF BANGLADESH.

Begum, M., Afroz, H., Hossain, M. N., Akter, F., & Hossain, N. (2017). Nutritional assessment of semi-fermented fish product (Chepa Shutki) from three different regions of Bangladesh. International Journal of Biosciences, 10, 1-5.

Byrd, K. A., Thilsted, S. H., & Fiorella, K. J. (2021). Fish nutrient composition: a review of global data from poorly assessed inland and marine species. Public health nutrition, 24(3), 476-486.

Indexed at, Google Scholar, Cross Ref

Hamilton-Hart, N., & Stringer, C. (2016). Upgrading and exploitation in the fishing industry: Contributions of value chain analysis. Marine Policy, 63, 166-171.

Indexed at, Google Scholar, Cross Ref

Hasan, R., Hossain, M. A., Islam, M. R., & Iqbal, M. M. (2021). Does commercial probiotics improve the growth performance and hematological parameters of Nile tilapia, Oreochromis niloticus?. Aquat. Res, 4(2), 160-168.

Indexed at, Google Scholar, Cross Ref

Hossain, A., Hossain, M. A. R., Ahmed, S., & Satter, A. (2017). Fish fermentation in Lalpur, Brahmanbaria district: ecological implication and value chain analysis. Asian-Australasian Journal of Bioscience and Biotechnology, 2(2), 159-172.

Indexed at, Google Scholar, Cross Ref

Majumdar, B. C. (2017). Comparison of the changes in nutritional quality of three important small indigenous fish species in Bangladesh at room temperature (27-31 C): A review. J. Animl. Res. Nutri, 26, 32.

Indexed at, Google Scholar, Cross Ref

Monir, M. S., Haque, M. R., & Rahman, S. (2013). Dry fish marketing in Nilphamari district of Bangladesh. Journal of Science and Technology, 11, 32-36.

Nayeem, M. A., Pervin, K., Reza, M. S., Khan, M. N. A., Shikha, F. H., & Kamal, M. (2010). Present status of handling, transportation and processing of traditional dried Punti (punti shutki) and semi-fermented fish (chepa shutki) products in Mymensingh district, Bangladesh. Journal of Agroforestry and Environment, 4, 13-16.

Pramanik, M. M. H., Hasan, M. M., Bisshas, S., Hossain, A. B. M. A., & Biswas, T. K. (2017). Fish biodiversity and their present conservation status in the Meghna River of Bangladesh. International Journal of Fisheries and Aquatic Studies, 5(1), 446-455.

Rana, M. M., Chakraborty, S. C., & Saeid, A. (2020). Comparative studies of nutritional, microbial and organoleptic properties of different indigenous dried fish from local market in Bangladesh. Advanced Journal of Chemistry-Section A, 3(3), 318-327.

Indexed at, Google Scholar, Cross Ref

Rasul, M. G., Yuan, C., & Shah, A. A. (2020). Chemical and microbiological hazards of dried fishes in Bangladesh: A food safety concern. Food and Nutrition Sciences, 11(6), 523-539.

Indexed at, Google Scholar, Cross Ref

Sarkis, J. (2020). Supply chain sustainability: learning from the COVID-19 pandemic. International Journal of Operations & Production Management, 41(1), 63-73.

Indexed at, Google Scholar, Cross Ref

Shamsuzzaman, M. M., Mozumder, M. M. H., Mitu, S. J., Ahamad, A. F., & Bhyuian, M. S. (2020). The economic contribution of fish and fish trade in Bangladesh. Aquaculture and Fisheries, 5(4), 174-181.

Indexed at, Google Scholar, Cross Ref

Sunny, A. R., Masum, K. M., Islam, N., Rahman, M., Rahman, A., Islam, J., ... & Prodhan, S. H. (2020). Analyzing livelihood sustainability of climate vulnerable fishers: Insight from Bangladesh. Journal of Aquaculture Research and Development, 11(6), 593.

Indexed at, Google Scholar, Cross Ref

Received: 30-Nov-2025, Manuscript No. ASMJ-24-14285; Editor assigned: 03-Dec-2025, PreQC No. ASMJ-24-14285 (PQ); Reviewed: 18-Dec- 2025, QC No. ASMJ-24-14285; Revised: 21-Dec-2025, Manuscript No. ASMJ-24-14285 (R); Published: 28-Dec-2025