Research Article: 2024 Vol: 27 Issue: 6

EFFECTS OF EMERGING TECHNOLOGIES ON COMPUTER-BASED PROJECT MANAGEMENT

Gregory Chimere Enyinna, Federal University of Technology Owerri

Joy Okwuchi Chizitere Oguzie, Federal University of Technology Owerri

Uchenna U Moneke, Federal University of Technology Owerri

Chidiebere Cyprian Ekennia, Federal University of Technology Owerri

Ogbonnaya Blessing Nmesoma, Federal University of Technology Owerri

Stanley Okangba, University of Witwaterstrand

Columbus Ikechukwu Anyanwu, Federal University of Technology Owerri

Ulari Sylvia Onwuka, Federal University of Technology Owerri

Chidozie Bruno Okonkwo, Federal University of Technology Owerri Ihuoma Deborah Okwara, University Morrow

Citation Information: Enyinna G.C., Chizitere Oguzie O.J., U Moneke U., Cyprian Ekennia C., Blessing Nmesoma O., Okangba S., Ikechukwu Anyanwu C., Sylvia Onwuka U., Bruno Okonkwo C., & Deborah Okwara

(2024). Effects of emerging technologies on computer-based project management. Journal of Management Information and Decision Sciences, 27(6), 1-17.

Abstract

The main challenge for organizations to meet client requirements is finding ways to enhance computer-based project performance and make management knowledge more efficient. The solution is to apply key emerging technologies that have recently entered the market, including artificial intelligence (AI), 3D printing (3DP), augmented reality (AR) and mixed reality (MR), building information modeling (BIM), drones, and mobile technology (VP). The study used a well-structured questionnaire to collect data from the four randomly chosen construction companies, from which a sample size of 100 was acquired. This study used a descriptive survey research design. The study employed simple percentages, mean, standard deviation, Rank, and tables for a better interpretation. At the same time, the multiple rationalization analysis was used to determine the link between the study's variables and derive conclusions and suggestions from them. Findings reveal that the 7 identified ETs significantly influenced computer-based project management, having ascertained that the participants possess sufficient knowledge regarding emerging technologies and their impact on computer-based project management. Therefore, the study recommended adopting and implementing emerging technologies for managing computer-based projects, speedy automation, swift project delivery, and customer satisfaction

Keywords

Emerging Technologies, Computer-based projects,Managements, 3DP, AI, MT, BIM, AR, MR, Robotics and Drones.

Introduction

A variety of innovative computer-based tools are being produced as a result of current advances in information and communication technology (ICT) for the building, architectural, engineering, and facilities management industries. These tools offer improvements in the efficacy and efficiency of designing and managing computer-based building projects, especially those linked to Building Information Models (BIMs) for project modeling and integration. However, finding solutions to improve computer-based project performance and make the management knowledge more effective, is the main challenge for organizations to reach their client requirements (Alaloul et al. 2020). One of these solutions is to apply emerging technologies and implement adequate information and communication technology (ICT) applications in construction projects (Harris et al., 2021).

There are numerous emerging technologies (ETs) on the market that can be used to manage computer-based projects in the construction sector to hasten automation and boost productivity, some are famous, while others are not. Emerging technology has since introduced new approaches to completing jobs, beginning with the introduction of computer-aided design. This is important because the efficiency of traditional construction methods has reached it's peak, leaving enough time to improve. The main emerging technologies that have entered the industry in recent years include artificial intelligence (AI), 3D printing (3DP), augmented reality (AR) and mixed reality (MR), building information modelling (BIM), drones, mobile technology (MT), robotics and virtual prototyping (VP) (Saccardo, 2020).

Additive manufacturing, often known as 3DP, has been proposed to offer creative ideas in the building sector. It is a construction technique that uses successive layers of materials, commonly metallics, concrete, or plastics, to make individual geometric elements or full structures. Prototypes can also be made with it. 3DP can only function when it is powered by a data source. Computer-based design is frequently used in building projects to produce a 3 dimensional digital model. It carries 3DP and lets the printer to read the instructions thereby creating the output of the successive layers that are put together to create the physical model (Saccardo, 2020).

Artificial Intelligence (AI) refers to a computer's capacity to carry out activities with a level of intellect comparable to that of humans. This necessitates using prior data to inform future decisions. There are no AI systems that can compete with human performance. An AI system can acquire intelligence in two ways: top-down and bottom-up. As it attempts to recreate intelligence independently of brain structure, the top-down approach's goal is more symbolic. The bottom-up strategy aims to develop artificial neural networks that mimic the brain's structure by focusing more on connections.. These ways can be used to learn from historical construction data to identify efficiencies that can assist withdecreasing time and cost (Saccardo, 2020).

Augmented Reality (AR), which is an aspect of MR, offers a different way to experience computer-based projects management. In order to create an engaging experience, AR software generates real coordinates. Additionally, it has the capability to spot design collisions, which facilitates the selection or modification of design elements. It is for all types of projects, big or small, so even the smallest of projects can use the power of AR (Autodesk, Inc., 2020).

Building Information Modelling (BIM) is a method built on a clever three-dimensional model. When designing, carrying out, controlling, and managing structures, including buildings and infrastructure, it gives construction (and architecture and engineering) professionals the tools and insights they need to be more productive. Over the past five years, BIM in construction has gained momentum. Collaboration through each stage of the construction process is a key component of BIM's strength. With the assistance of the entire team as opposed to just one section, this clever technique aids in the early detection of conflicts. It enables the visualization of two-dimensional blueprints. In general, it has the power to change the Construction, Architecture and the Engineering industry by improving communication and estimation, clash identification, risk and cost reduction and smoother handovers (Autodesk, Inc., 2020).

Drones, also called Unmanned Aerial Vehicles (UAVs), directly affect construction workers. Drones gather information from the air in real-time, which is particularly helpful for site management and tracking development. For example, calculating precise placement using GPS ground markers can assist in identifying difficulties before they grow into larger ones. Drones are also helpful in computer-based construction projects in other capacities, including surveying, managing safety, and providing measurements. For instance, drones can measure the volume of materials, such as dirt, in real time. Generally, drones can help save resources and time on construction projects (DroneDeploy2020).

Mobile Technology (MT) is a collaborative program used everywhere in computer-based construction projects. The capability to send information back to a central database from any location highlights this. The capacity for several people to converse and work together at once across mobile devices is another feature highlighted by MT. Executives at the organization have been looking for ways to increase team productivity due to the construction industry's increasingly mobile workforce. To accomplish project management objectives, MT helps teams become more engaging, effective, conversational, and collaborative. The best takeaway here, is that MT can provide real-time project information to project managers who can make faster decisions as a result (eSUB, Inc. 2020).

The automated world centered on robotics presents a significant opportunity for the construction sector. Robots can automate numerous roles that workers traditionally perform. In 3DP, robots are particularly prevalent, making it easier to create homes, structures, and even bridges. Demolition robots can even improve the efficiency of gathering waste and crushing concrete, among other tasks. Nowadays, complete homes are built using robotic bricklaying, which can be done in a few days. Robotics are one sure-fire way for project managers to enable lean construction practices on projects, given the high-quality output of results that robots produce (Construction World, 2020).

Construction teams can improve design communication through Virtual Prototyping (VP), a computer-aided design technique, without having to create a material sample. VP can be used during the project's information gathering, three-dimensional model construction, and process simulation phases. It is accomplished by including various design software at each level, allowing for the early identification of design flaws. Teams can see and model sites using VP at each stage, which can also improve construction safety by anticipating accident-causing elements so that they can be planned for or prevented by redoing the whole design.

Additionally, VP makes it easy to comprehend the life cycle information for buildings, which also benefits design (Saccardo, 2020).

Under the background of modernized computer-based projects, the construction engineering business has also marked a new era of development. As a result, there are substantial modifications in the organizational structure and project management implications, as well as new obstacles in the construction organization and management model. Based on this situation, emerging technology is used to organize and manage the construction process, and the state and relevant sectors both support this (Lijian, 2020). On the one hand, new technology can offer the most precise and complete organizational structure for the project's development process because it can fully integrate resources and evaluate data. At this point, it serves as a crucial link in the use of construction organization in engineering projects. The project management system, on the other hand, maybe optimized, and the refined management system can be improved under its use. This study therefore, ventures into assessing the impact of the identified emerging technologies as revealed by Saccardo (2020), for a computer-based project management.

Phases of Project Management

To investigate how developing technologies affect computer-based project management, the study grouped the identified areas by project phase (initiation, executing, planning, controlling and closing/handover) and knowledge areas (integration, schedule, scope, cost, quality, risk, resource, communications, procurement, and stakeholder management), as put forward by Project Management Institute (PMI, 2017), these are discussed extensively below:

Project Initiating Phase

This phase is involves identifying stakeholders and developing a project charter

Project Planning Phase

This is defined as creating and maintaining a workable plan to accomplish the purpose of the project. It involves developing a project management plan which encompasses all of the project knowledge areas.

Project Scope Management

An important area of knowledge for ET at the planning stage has been recognized as project scope management. VP is an experienced ET who supports design management, in particular, the creation of intelligent building envelopes. A software experiment was conducted to better understand how different types of VP can help. This offered the capability to modify the prototype model subtly using parametric approaches to generate relevant design choices. They were also being able to assess the physical impact of building envelope performance on a model, gotten from the VP (Kim & Kim, 2017).

Another ET that has been shown to help with design management is AR. This has been tested by superimposing BIM data over a panoramic image of a renovated construction site. Then, individuals with construction experience who had never used this kind of technology before successfully audited the design in a semi-AR experience. The semi-AR settings received a favorable response, according to the quantitative results given to the experiment moderator.

AR is also helpful in transitioning decision-making from two-dimensional paper plans to a more automated task system. According to an experiment's findings, those who used augmented reality (AR) could do jobs 60% faster than those who used paper plan documentation, all while expending less mental effort. A challenge is that accuracy is significantly lower in the AR experience, because it has a much smaller detail than the paper plan documentation (Chalhoub & Ayer, 2019).

Besides, an evaluation of the BIM procedure utilized by construction teams in China revealed that design management was the primary use for most use cases. The three main BIM approach categories of integration, decentralization, and supplement were examined. They comprise a transition phase, which is quite typical of Chinese projects. An entire model is used as the basis for creating the three-dimensional models. The collaborative nature of BIM allows for multiple consultants (designers), contractors, and project managers to access an up-to-date design simultaneously so that it can be effectively carried out (Li et al., 2018).

Lastly, drones are an essential technology in this field of study. They can impact the scope by surveying properties to determine site limits. In addition, this technology eliminates the requirement for extensive tools and equipment customarily required to do the activity. This opens up the possibility of speedier services at a lesser cost. The impact of drones in construction is expected to increase moving forward (Li & Liu, 2019).

Project Schedule Management

In the planning stage, the knowledge domain of project schedule management has also been recognized as having significant effects on ET. Using 3DP, you can shorten the project's turnaround time. For example, a typical wall might be produced in less time overall when using 3DP metal structural components—specifically, 35% less time. The problem is that fabrication quality typically suffers as construction speed increases. To date, this technology is far more common for off-site manufacturing to ensure high-quality production (Buchanan & Gardner, 2019).

Project Cost Management

Another vital topic for ET at the planning stage has been highlighted as Project Cost Management knowledge. It has been demonstrated in this instance that BIM can help with the analysis of cash flows and the selection of financing solutions based on a variety of design options. Comparisons between timetables and cost plans were labor-intensive operations requiring manual involvement. A large portion of the analysis of cash flows can be automated since BIM enables the integration of several detailed levels (or dimensions) of project information. Due to contract-specific criteria that the BIM system couldn't comprehend, some payment-related details had to be manually recorded.

Another ET that has been shown to help with cost management is AI. With the aid of AI, datasets from 68 concrete bridge projects were trained and tested using the feed-forward artificial neural networks technique (FFANNs). These findings allowed them to estimate a bill of quantities (BoQ) for a similar project using just a few known factors during the planning stage. It was found that using AI methods resulted in an improved level of accuracy in the resulting BoQ (Dimitriou et al., 2018).

To ensure they would be in a solid financial position if they win the bid, contractors must submit accurate project bid pricing for requests for tenders (RFT) on bridge construction projects. In addition, AI has been shown to accurately forecast project award prices when used to test models against data only available during the project's planning phase. Contractors may then more properly estimate projects thanks to this. Lastly, 3DP provides the chance to reduce project costs, partly because of its effect on time reduction. This is because less labor is needed due to improved production automation. This also impacts reduction in re-work, which would generally add to project costs (Buchanan & Gardner, 2019).

Project Risk Management

The project risk management knowledge area is also seen as an impactful area for ET in the planning phase. BIM can be used to produce project teams with an early-warning system for cost and schedule overruns. In this case, a prototype was created combining BIM with earned-value analysis to help in this area using a real-life project as a model. However, it needs to be studied further for practical application (i.e.: an actual construction project) to comprehend how well it provides risk management support (Li et al., 2018).

Project Quality Management

The Project Quality Management knowledge area is an important aspect for ET in the planning phase. AI,here, can be used to ensure structural steel stick to guidelines given by Standards, Australia and the Australian Building Codes Board for fire resistance and safety. it is carried out by using Artificial Neural Networks and Genetic Algorithms – using a trained dataset – which

provide improved results over general mathematics, providing more accuracy of the performance on steel structures against fire (Naser, 2018). Additionally, AI can be used to understand what will happen to different types of materials such as concrete, masonry, steel, and timber under extreme temperature conditions. This is critical to understand during the project planning phase (Nazer, 2019). VP is another ET proven to assist with quality management, specifically with continuous process improvement. VP has been proven to assist to power a physical 3 dimensional model of a city which can be created in seconds. This model can be tested against various city scenarios such as population, traffic, and temperature which gauges quality standards of the model (and even compare new alternatives). Models have limitations around the size and shape type of buildings created in three dimensions.

Project Resource Management

The knowledge domain of project resource management has also been recognized as impacting ET during the planning stage. By simulating labor-based scenarios for emergency evacuation that could occur under various conditions during the project executing phase, BIM and computer-based simulation software can be utilized to effectively plan for workers' occupational health and safety (OHS) on construction sites. In addition, these simulations can be developed to depict various construction techniques. The result provided is the approximately the total evacuation number for each floor, for all workers and brings forth areas of congestion (Marzouk & Al Daour,2018).

BIM also assists OHS in other ways. For example, with four-dimensional BIM models, which combine a three-dimensional model with schedule information, it is possible to visualize the construction site before the project's execution phase starts. BIM can plan for future potential hazards. The opportunities go higher when combining BIM with other ETs, such as AR (Martinez-Aires et al., 2018).

Project Procurement Management

The knowledge area of project procurement management has also been recognized as impacting ET during the planning stage. It has been found that BIM can assist project teams in developing sustainable procurement processes but must make adjustments before that can happen. The BIM system's assessment of sustainability criteria needs to be modified, and an innovative procurement mechanism will need to be developed to support these modifications. Generally, the opportunity is available, however a unified approach needed to be taken to see it through to fruition (Chong et al., 2017).

Project Executing Phase

This is defined as carrying out project plan which involves managing and directing projects, with a aim on quality, communications, risk, procurement and stakeholder engagement (PMI, 2017).

Project Quality Management

Another important area of knowledge for ET in the executing phase has been highlighted as project quality management. MT's huge array of mobile applications (apps) available to construction teams has been created to simplify processes. These programs impact safety, project management, cost management, site operations, computer-aided design, BIM, and estimates. Top and medium construction managers in New Zealand emphasized the benefits of overall productivity and profit margin improvement for the project when asked about the advantages of mobile apps. Difficulty to learn and cost prohibition, limited time to learn were seen as reasons for hindrance for mobile app adoption (Liu et al., 2019).

In addition, An airport building project was used to study a mobile BIM app, showing the effects on ongoing process improvement. In this instance, workers received BIM project information via tablets in an effort to implement lean construction principles through digital transformation. This was accomplished by sending BIM to the construction site rather than an office setting. Benefits are also emphasized during the project controlling phase. However, because of the project's scale and complexity, there were difficulties with implementation. (Koseoglu & NurtanGunes, 2018).

Finally, AR has also been studied on its positive effect in this phase, specifically with reducing process complexity. An experiment was conducted with sixty-one people professionals, and students – who were asked to assemble a complex piping using AR technologies. It was discovered that, regardless of the type of person undertaking the task, the process saved time compared with previous methods. Nevertheless, more experiments would need to be completed to understand the impact across the entire construction industry (Kwiatek et al., 2019).

Project Resource Management

The project resource management knowledge area is also an important aspect for ET in the executing phase. Drones and other related technologies are known for adding to the occupational health area and safety (OHS) in construction. This is done through collecting drones and relaying on real-time videos to construction managers, for the site safety inspection. Drones were tasked with collecting data to know whether workers were wearing hard hats or not, and the results came out positive (Li & Liu, 2019).

Besides, AR is as useful in OHS scenarios, specifically in hazard identification and avoidance. By using a wearable device, workers can get information on dangerous situations without needing to analyse the data they receive from their devices. There were good results with the on-site hazard identification system, which uses camera-likea tool for taking photos of the work site. The wearable device receives this information and alerts the worker. There were some problems, though. For instance, workers occasionally prevent other workers from accessing photographs on the site, which can produce inaccurate statistics (Kim et al., 2017).

The effects of AR have also been examined with regard to other OHS domains, in particular safety training, site safety inspection, and instruction. Although solid research has been done to demonstrate that these impact areas have use cases, technological development will take a long time before it can produce scenarios that closely resemble human-based situations. (Li et al., 2018).

AI has a divergent way of making an impact to OHS, specifically using a Tunnel Boring Machine (TBM). AI plays a major role here. This is accomplished by employing artificial neural networks to assess the quality of the rock mass and machine learning to mine the large amount of data that the TBM has acquired in order to develop new models for predicting rock mass. These advancements can potentially save lives by preventing catastrophic events that could cause real-time alterations to the rock mass being drilled. (Li et al., 2019).

VP has also demonstrated success in the execution of bridge maintenance projects. It does away with the requirement for fall protection supplementary devices (FPSD) to undergo manual compatibility testing, which is often done by trial and error. Before arriving on site, the VP finds conflicts and verifies the accuracy of the FPSD systems, eliminating problems like productivity losses and safety risk exposure. In this instance, the use of VP allows for more productive work, cost savings, and reduced hazards. (Zuluaga & Albert, 2018).

Finally, MT also affects OHS, particularly by forecasting worker movement on the job site. In one instance, employees wear portable sensors that track their posture in order to spot problems, such as postures that lead to work-related accidents. It's aim of actively collecting and monitoring this data is to enhance safety by preventing work-related injuries (Nath et al., 2017).

Project Communications Management

The Project Communications Management knowledge area is also impactful for ET in this phase. VP can be used as a part of the project management information system. In this case, the VP model can be used to provide documentation to the labourer. Using the model to create pictographic instructions, the labourer can work toward a prefigured goal, without verbal communication (instruction), while reducing error, which without instructions, leads to inefficiencies and could create issues of delivering scope.

Project Procurement Management

The Project Procurement Management knowledge area is identified as the final impactful area for ET within the executing phase.On building sites, drones help manage the supply chain. They assist in managing this by moving items about the construction site. After being dropped off at the location, the supplies are located, recognized, and tracked using GPS. They are then immediately relocated to the proper location (Li & Liu, 2019). The management of the supply chain also makes use of MT. Mobile internet has been investigated in this case as an ET that can help cover the gaps required to give real-time, current information on the building supply chain. In this illustration, the mobile internet is a group of online-capable connected gadgets that are all linked to a single system for total visibility. Security concerns do exist, though, and they must be handled properly.

3DP has also demonstrated its effectiveness in this regard, particularly with regard to material deliveries. In this instance, the initial phase in the concrete construction process requires the use of a particle-bed as a base on the ground. Particles of various sizes, materials, and overall designs can be manufactured using 3DP technology for a variety of circumstances, opening up new possibilities for structural design and construction (Lowke et al., 2018). The advantages of printing cementitious materials are low cost, design flexibility, high efficiency, and environmental friendliness. Implementing this technology would have the side effect of reducing labor (GuoWei et al., 2018). Similar to that, walls have been built using this method. A concrete wall is 3D-printed with a foam formwork wall surrounding it to provide thermal insulation. This technology has been tested to work in fifty-centimeter increments (Furet et al., 2019). 3DP structures that require steel reinforcement prove to be challenging because these structures would require hollow voids to insert the steel bars manually which limits the architectural design freedom (Tay et al., 2017).

Robotics has also been demonstrated to be crucial to the execution phase of building project procurement. This type of technology is just beginning to infiltrate the construction sector, with examples like robots autonomously coating and painting the entire façade of a high-rise structure and industrially personalizing buildings produced on an assembly line. Setting up robotic factories on-site for prefabrication purposes is a sensible step forward for the industry when the application makes sense. There are currently machines on the market for automating tasks like bricklaying, where a robotic system can lay 1,000 bricks per hour, and glazing, where robots install windows and glass panels weighing more than 1,000 kg. Robotic 3DP has also been happening for years; however, it is still a novel concept in the industry. However, single-storey, detached homes have been 3D-printed with concrete since 2003 in China (Bogue, 2018).

Additionally, robots are enhancing construction techniques by providing the ability to automatically assemble parts of a modular structure by providing specific markers on site. Robots can also undertake the construction of walls and even high-rise buildings. For wall construction, a scaffolding rail system is set up on-site, and a mobile robot is attached to it, moving along the scaffolding while it injects concrete to create a composite wall (Więckowski, 2017). For high-rise building construction, a robotic assembly system (RAS) has been developed, which involves three sub-systems – a robotic bolting device, a control system, and a robotic transport system. These sub-systems together help perform tasks such as steel beam erection, placement, alignment and bolting in place (Casi et al. 2019).

Cable-driven robots are known in the industry for their ability to move hazardous materials throughout construction sites, which benefits supply chain management. In this case, they are also able to construct architectural systems, such as a three-dimensional model. The use a claw to drop material in place to build the model, which it does so base on a computer model (i.e. created in computer-aided design). It provides collision-free path planning in which they can identify obstacles and theinteraction of the cables used to ensure this happens without error (Pinto et al., 2017).

Moreover, these high-tech developments in robotics do offer their share of adoption challenges in the procurement area. Contractor-side challenges include these technologies being too risky to implement. Client-side challenges include lack of effectiveness and disruption to teams. Work culture challenges including issues regarding human-robot interaction. Regarding cost benefit, there are no significant cost-benefit studies that show labour cost or time saved, among many other variables that should be considered (Delgado et al., 2019).

Drones, like robotics, can make an impact in this area as well. Drones weighing just twelve kilograms can lift concrete blocks, and lay them down in place, with no human interaction, using a laser-based positioning system. This technology shows promise of building walls without the use of scaffolding, however further research is required to learn more about similar, more advanced applications (Goessens et al., 2018).

Lastly, AI is known to assist with contract management in construction, particularly with managing disputes. Using historical data as a study, AI was used to understand the data and predict conflicts. The results were successful; results show that AI can be successful in data mining historical projects to locate related projects and understand what types of conflicts may arise. This information will better prepare contract managers in project execution, as they can prepare their expectations accordingly, minimising risk.

Project Controlling Phase

Monitoring development and, when necessary, corrective measures are described as the project controlling phase. With an emphasis on scope, timeline, quality, and resources, this entails monitoring communications, risks, and stakeholder participation while managing change and controlling procurements. (PMI, 2017).

Project Schedule Management

The Project Schedule Management is an impactful area for ET in the controlling phase. AR is renowned for giving projects a sense of realism. In this instance, a user-friendly experience is produced in which four-dimensional scheduling data is tied to AR objects and shown to them. This aids in controlling the timetable in a simulation of actual life.

Long-distance managers who require timeline updates may find this to be of special use. This is a step forward from carrying out similar operations through manual fieldwork. (Kim et al., 2018).

Project Quality Management

The knowledge domain of project quality management has also been noted as having an effect on ET throughout the controlling phase. Through an interactive, intuitive method, AR has been studied and found to be useful for site and construction inspections. Data may be gathered instantaneously, which will ultimately shorten the amount of time needed to respond to inspection issues that need to be resolved right away. Due to a platform interaction between BIM and AR, this is achievable. However, the productivity benefits that can be obtained from this kind of technology are still unknown. (Machado & Vilela, 2020).

Site inspectors can also utilize augmented reality to check tunnel construction projects. This method can give details on actual displacement against designed displacement, which is a crucial area that is tracked throughout inspections. To do this, a quality-assured baseline virtual model of the tunnel is created. The virtual model and the actual view of the tunnel are actively contrasted. Real-time detection of discrepancies results in cost savings along the route. (Zhou et al., 2017).

Another area of ET that affects quality control is robotics, particularly in the area of structural inspection. Robotics offers efficiencies in these areas because construction inspections need a lot of time and resources. Given that this activity necessitates a high degree of accuracy, the key use case is inspecting difficult-to-reach places to find flaws. MT also has an impact in this area, continuing the practice of quality control checks. In this instance, interview and field measurement data are collected using a device called HeadLight in American public transportation. It was discovered that the project inspectors who used this technology saw an overall 25% increase in productivity in terms of data volume, completeness, diversity and saves time.

Last but not least, drones have an impact on quality control; this time, bridge inspection is the main objective. Due to an increase in bridges that are beginning to decay globally, drones were sought after as a more economical, effective method of bridge inspection. Drones are able to detect a wide range of damages on a number of bridge materials. (Seo et al., 2018). It is paramount to make sure you do not get "visual overload" meaning too many photos and videos in your drone. This is a very major issue in the visual monitoring of computer-based projects projects. A new methodology has been created to fight this issue, where a high accuracy of photos and video selection is given to teams (Ham & Kamari, 2019).

Project Communications Management

Ithas been determined that the knowledge domain of Project Communications Management has an impact on ET during the controlling phase. Mobile AR helps with progress reporting in this instance. The program builds on BIM to provide users a real-time, up-close look at the project. Then, teams may use AR on-site in real-time to manage the project and offer reports on actual versus projected development. This system gives a more efficient way to control projects (Zaher et al., 2018).

Project Closing (and Handover) Phase

This is defined as bringing the project and paperwork to one hundred percent completion and entering the history in a database (PMI, 2017). The operations management team will then receive a handover after this has happened.

Project Communications Management

The knowledge domain of project communications management is also recognized as impacting ET throughout the close and handover phase. BIM has been proven to improve facilities management by offering documentation control and exchanging data with the maintenance and operations phase of projects. For massive projects in the mechanical, electrical, and plumbing fields, this is very helpful. The applications were visualised not only for the construction team but for the operations team moving forward into the building's life cycle (Saccardo, 2020).

Materials and Methods

This paper employed a descriptive survey research design.This is because of the absence of archival data in most Nigerian construction organizations. Also, survey is empirical and obtains what exists (Facts and Figures) and useful because of the relatively large population from which information was collected.

Instrument

Well-designed questionnaires and in-depth personal interviews served as the primary data collection tools. Responses to the questionnaire are elicited regarding awareness of and effects on computer-based project management of some new technologies. There are two parts to this document: Sections A and B. The personal data of the respondents are covered in Section A, while the research questions in Section B are crucial to the success of the paper's objectives. Each respondent is presented a list of choices or possibilities, and they are asked to select or mark one. A demographic portion with only two items and an assessment section with nine items each comprised the survey's two divisions.

Setting

The study was carried out in Independence Layout and Emene, Enugu State. The choice of this area was purposive, because of the predominance of construction industries in the area.

Population and Sample

At the first stage, four industries in Enugu State were purposively selected, this formed the population of the study. To collect the sample for the investigation, a multi-stage sampling approach was adopted. From the sampling frame, twenty-five (25) samples were simple randomly obtained comprising project manager, QA/QC engineer, architect, and project engineer in each of the construction industries and engineering firms. Therefore, the sample size for the study was one hundred (100) respondents (Table 1).

| Table 1 Construction Firms, Locations and Sample Size Drawn | |||

| Company | Location | Coordinates (Long, Lat) | Sample size |

| Jerac Construction Company of Nigeria | Emene, Enugu State | (6.47589, 7.584) | 25 |

| Pawid Constructs Limited | Independence Layout, Enugu | (6.437976, 7.532573) | 25 |

| Akiota Limited Works | Independence Layout Enugu | (6.457252, 7.558796) | 25 |

| Sylvac Construction Company | Independence Layout Enugu | (6.439852, 7.531103) | 25 |

Data Collection Procedures

The data for this study was gotten from a primary method of data collection obtained from the four major construction companies in Enugu State. It took three weeks to get the questionnaires distributed and collated. The difficulty of meeting the construction workers at their various offices prolonged the period of the study.

Data Analysis

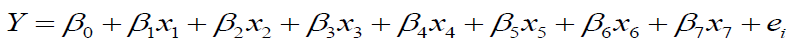

The data was analyzed by the use of descriptive and inferential statistical tools. The descriptive approach utilized the frequency, mean, standard deviation, Rank and tables for a better interpretation. The inferential tool adopted the multiple regression analysis to establish the relationship between the variables of the study and to draw conclusions and recommendations thereof. On time delivery served as a proxy for Project management against the 7 identified emerging technologies (the independent variables). The equation of the regression model is indicated below:

Where: Y = Ontime delivery, x1 = MT, x2 =BIM, x3 =VP, x4 =Drones, x5 =Robotics x6 =MR/AR, x7 =Innovation β0 =constant , ei =random error

Ethics

The aim of this study, the intended use of the data obtained from them, and the repercussions of involvement in the research were all well explained to the respondents, who voluntarily provided informed permission in an explicit way. They were informed that they could withdraw from participation at any point they choose. The respondents' personal data were de-identified as their identities were not disclosed to anyone at any time. The data gotten was utilized for the purpose of research only, making use of them in a confidential manner.

Results

This section makes a comparison and contrast between all the data received from the respondents. The outcomes of this study were based on the responses of 100 construction workers from various firms based in Enugu.

Demographics

One hundred personnel participated in the survey (n = 100), comprising of project managers (25%), QA/QC engineers (8%), architects (8%), and project engineers (59%), as shown in Figure 2. About 8% of the participants have spent close to 5years in the profession, 10% (close to 10 years), 22% (close to 15 years), 42% (close to 20 years), and 18 % have spent more than 20 years in the profession, as shown in Figure 3.

Level of Awareness on Emerging Technologies for a Computer-Based Project Management

The level of awareness of emerging technology amongst construction professionals was ascertained. Result indicates that, 86% positive response was accorded mobile technology, with mean M=3.8 and standard deviation SD=0.3. BIM also received 83% positive response, implying a high awareness level, with mean M=3.8 and standard deviation SD=0.4. Visual Prototyping received 78% response from the participants, indicating a high-level awareness level, with mean M=3.7 and standard deviation SD=0.4. Drones received a response of 97%, implying a very high awareness level amongst the participants, with mean M=3.9 and standard deviation SD=0.17. Robotics received 91% positive response, indicating a very sufficient level of awareness concerning emerging technology, with mean M=3.8 and standard deviation SD=0.4. Mixed and Augmented Reality received 50% of positive response, implying a moderate level of awareness, with mean M=3.3 and standard deviation SD=0.7. Lastly, Innovation received a positive response of 59%, implying a sufficient awareness level regarding emerging technologies, with mean M=3.4 and standard deviation SD=0.6. Drone was ranked 1st implying its most common compared to the other emerging technologies, followed by robotics (ranked 2nd), mobile technology (ranked 3rd), BIM (ranked 4th), visual prototyping (ranked 5th), innovation (ranked 6th), and lastly, mixed and augmented reality (ranked 7th). In conclusion, the participants possess the sufficient knowledge regarding emerging technologies and their impact to computer-based project management (Table 2).

| Table 2 Level of Awareness Amongst Construction Professionals | ||||

| Emerging Technology (ET) | Percent (%) | Mean | S. D | Rank |

| Mobile Technology (MT) | 86 | 3.85 | 0.385 | 3 |

| BIM (Building Information Modelling) | 83 | 3.82 | 0.411 | 4 |

| Visual Prototyping (VP) | 78 | 3.78 | 0.416 | 5 |

| Drones | 97 | 3.97 | 0.171 | 1 |

| Robotics | 91 | 3.88 | 0.432 | 2 |

| Mixed and Augmented Reality (MR/AR) | 50 | 3.37 | 0.719 | 7 |

| Innovation | 59 | 3.48 | 0.688 | 6 |

Impact of the Emerging Technologies on Computer-based Project Management ‘

From table 3, it was apparent that emerging technologies, each make a significant contribution or impact to managing computer-based projects, as mobile technology (p=0.007), BIM (p=0.034), visual prototyping (p=0.017), drones (p=0.002), robotics (p=0.004), mixed augmented reality (p=0.042), and innovation (p=0.000), all have p-values less than 0.05 (Table 3).

| Table 3 Multiple Regression of ETS on Project Management | ||

| Emerging Technologies | Standard Beta | Significance (p) |

| Mobile Technology (MT) | 0.082 | 0.007 |

| BIM | 0.039 | 0.034 |

| Visual Prototyping (VP) | 0.045 | 0.017 |

| Drones | 0.119 | 0.002 |

| Robotics | 0.014 | 0.004 |

| Mixed and Augmented Reality (MR/AR) | 0.06 | 0.042 |

| Innovation | 0.645 | 0 |

Discussion

This study was carried out within the metropolis of Enugu State, and data was collected through the use of structured questionnaires. It was noted that the participants of the study were very much aware of the 7 emerging technologies and their impact for computer-based project management.

The study further shows that the 7 ETs significantly influenced the delivery of project, as a measure to project management. This is consistent with the research of Saccardo (2020), who opined that the variety of the emerging technologies (ETs) available in the market are capable of speeding up automation and thereby increasing project performance when deployed for specific computer-based projects tasks and management in the construction industry.

Limitations

The study faced some form of impedance while data collection phase lasted, from the various respondents, due to their busy schedule. The study took about two weeks of revisiting the sites to retrieve the questionnaires from the participants.

It is therefore possible that some invalid responses were obtained due to limited knowledge regarding the topic of interest on the part of the participants, or probably lack of proper understanding of the whole context of this research and the meaning of some terms used in the questionnaire.

Conclusion

From the literature reviewed and the facts from our results, it is evident that emerging technologies greatly have a measure of contribution or impact to managing computer-based projects, especially in the construction industries. The paper therefore, infers that, the integration of emerging technologies to a managing a computer-based projects will not only speed up the automation processes, but also increase project performance, in form of on-time and quality delivery, reducing project costs, and averting project overrun, due to its less likelihood to encounter error. These technologies were outlined by the participants according to their level of awareness and usage in the construction industry as: drone, robotics, mobile technology, BIM, visual prototyping, innovation, and lastly, mixed and augmented reality.

References

Alaloul, W. S., Liew, M. S., Zawawi, N. A. W. A., & Kennedy, I. B. (2020). Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain shams engineering journal, 11(1), 225-230.

Indexed at, Google Scholar, Cross Ref

Bogue, R. (2018). What are the prospects for robots in the construction industry?. Industrial Robot: An International Journal, 45(1), 1-6.

Indexed at, Google Scholar, Cross Ref

Buchanan, C., & Gardner, L. (2019). Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Engineering Structures, 180, 332-348.

Indexed at, Google Scholar, Cross Ref

Cai, S., Ma, Z., Skibniewski, M. J., & Bao, S. (2019). Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Advanced Engineering Informatics, 42, 100989.

Indexed at, Google Scholar, Cross Ref

Chalhoub, J., & Ayer, S. K. (2019). Exploring the performance of an augmented reality application for construction layout tasks. Multimedia tools and applications, 78(24), 35075-35098.

Indexed at, Google Scholar, Cross Ref

Chong, H. Y., Lee, C. Y., & Wang, X. (2017). A mixed review of the adoption of Building Information Modelling (BIM) for sustainability. Journal of cleaner production, 142, 4114-4126.

Indexed at, Google Scholar, Cross Ref

Delgado, J. M. D., Oyedele, L., Ajayi, A., Akanbi, L., Akinade, O., Bilal, M., & Owolabi, H. (2019). Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. Journal of building engineering, 26, 100868.

Indexed at, Google Scholar, Cross Ref

Dimitriou, L., Marinelli, M., & Fragkakis, N. (2018). Early bill-of-quantities estimation of concrete road bridges: an artificial intelligence-based application. Public Works Management & Policy, 23(2), 127-149.

Indexed at, Google Scholar, Cross Ref

ESUB, Inc. (2020). What is Mobile Technology and What Does it Mean for the Construction Industry? Retrieved from eSUB Construction Software:

Furet, B., Poullain, P., & Garnier, S. (2019). 3D printing for construction based on a complex wall of polymer-foam and concrete. Additive Manufacturing, 28, 58-64.

Indexed at, Google Scholar, Cross Ref

Goessens, S., Mueller, C., & Latteur, P. (2018). Feasibility study for drone-based masonry construction of real-scalestructures. AutomationinConstruction, 94,458-480.

Indexed at, Google Scholar, Cross Ref

Ham, Y., & Kamari, M. (2019). Automated content-based filtering for enhanced vision-based documentation in construction toward exploiting big visual data from drones. Automation in Construction, 105, 102831.

Indexed at, Google Scholar, Cross Ref

Harris, F., McCaffer, R., Baldwin, A., & Edum-Fotwe, F. (2020). Modern construction management. John Wiley & Sons.

Kim, D. Y., & Kim, S. A. (2017). An exploratory model on the usability of a prototyping-process for designing of Smart Building Envelopes. Automation in Construction, 81, 389-400.

Indexed at, Google Scholar, Cross Ref

Kim, H. S., Kim, S. K., Borrmann, A., & Kang, L. S. (2018). Improvement of realism of 4D objects using augmented reality objects and actual images of a construction site. KSCE Journal of Civil Engineering, 22, 2735-2746.

Indexed at, Google Scholar, Cross Ref

Koseoglu, O., & Nurtan-Gunes, E. T. (2018). Mobile BIM implementation and lean interaction on construction site: A case study of a complex airport project. Engineering, Construction and Architectural Management, 25(10), 1298-1321.

Indexed at, Google Scholar, Cross Ref

Kwiatek, C., Sharif, M., Li, S., Haas, C., & Walbridge, S. (2019). Impact of augmented reality and spatial cognition on assembly in construction. Automation in construction, 108, 102935.

Indexed at, Google Scholar, Cross Ref

Li, J., Jing, L., Zheng, X., Li, P., & Yang, C. (2019). Application and outlook of information and intelligence technology for safe and efficient TBM construction. Tunnelling and Underground Space Technology, 93, 103097.

Indexed at, Google Scholar, Cross Ref

Li, J., Li, N., Peng, J., Cui, H., & Wu, Z. (2018). A review of currently applied building information modeling tools of constructions in China. Journal of Cleaner Production, 201, 358-368.

Indexed at, Google Scholar, Cross Ref

Liu, T., Mathrani, A., & Mbachu, J. (2019). Benefits and barriers in uptake of mobile apps in New Zealand construction industry: What top and middle management perceive. Facilities, 37(5/6), 254-265.

Indexed at, Google Scholar, Cross Ref

Lowke, D., Dini, E., Perrot, A., Weger, D., Gehlen, C., & Dillenburger, B. (2018). Particle-bed 3D printing in concrete construction–possibilities and challenges. Cement and concrete research, 112, 50-65.

Indexed at, Google Scholar, Cross Ref

Ma, G., Wang, L., & Ju, Y. (2018). State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Science China Technological Sciences, 61, 475-495.

Indexed at, Google Scholar, Cross Ref

Machado, R. L., & Vilela, C. (2020). Conceptual framework for integrating BIM and augmented reality in construction management. Journal of civil engineering and management, 26(1), 83-94.

Indexed at, Google Scholar, Cross Ref

Marzouk, M., & Al Daour, I. (2018). Planning labor evacuation for construction sites using BIM and agent-based simulation. Safety science, 109, 174-185.

Indexed at, Google Scholar, Cross Ref

Naser, M. Z. (2018). Deriving temperature-dependent material models for structural steel through artificial intelligence. Construction and Building Materials, 191, 56-68.

Indexed at, Google Scholar, Cross Ref

Nath, N. D., Akhavian, R., & Behzadan, A. H. (2017). Ergonomic analysis of construction worker's body postures using wearable mobile sensors. Applied ergonomics, 62, 107-117.

Indexed at, Google Scholar, Cross Ref

Naser, M. Z. (2019). Properties and material models for modern construction materials at elevated temperatures. Computational materials science, 160, 16-29.

Indexed at, Google Scholar, Cross Ref

Pei, L. (2020, August). Application of Big Data technology in construction organization and management of engineering projects. In Journal of Physics: Conference Series (Vol. 1616, No. 1, p. 012002). IOP Publishing.

Indexed at, Google Scholar, Cross Ref

Pinto, A. M., Moreira, E., Lima, J., Sousa, J. P., & Costa, P. (2017). A cable-driven robot for architectural constructions: a visual-guided approach for motion control and path-planning. Autonomous Robots, 41, 1487-1499.

Indexed at, Google Scholar, Cross Ref

Saccardo, D., & Langston, C. (2020). The impact of emerging technology on the value of construction projects. Faculty of Society and Design, Bond University.

Seo, J., Duque, L., & Wacker, J. (2018). Drone-enabled bridge inspection methodology and application. Automation in construction, 94, 112-126.

Indexed at, Google Scholar, Cross Ref

Tay, Y. W. D., Panda, B., Paul, S. C., Noor Mohamed, N. A., Tan, M. J., & Leong, K. F. (2017). 3D printing trends in building and construction industry: a review. Virtual and physical prototyping, 12(3), 261-276.

Indexed at, Google Scholar, Cross Ref

Więckowski, A. (2017). “JA-WA”-A wall construction system using unilateral material application with a mobile robot. Automation in Construction, 83, 19-28.

Indexed at, Google Scholar, Cross Ref

Zaher, M., Greenwood, D., & Marzouk, M. (2018). Mobile augmented reality applications for construction projects. Construction Innovation, 18(2), 152-166.

Indexed at, Google Scholar, Cross Ref

Zhou, Y., Luo, H., & Yang, Y. (2017). Implementation of augmented reality for segment displacement inspection during tunneling construction. Automation in Construction, 82, 112-121.

Indexed at, Google Scholar, Cross Ref

Zuluaga, C. M., & Albert, A. (2018). Preventing falls: Choosing compatible Fall Protection Supplementary Devices (FPSD) for bridge maintenance work using virtual prototyping. Safety science, 108, 238-247.

Indexed at, Google Scholar, Cross Ref

Received: 02-Sep-2024 Manuscript No. JMIDS-24-15209; Editor assigned: 04- Sep- -2024 Pre QC No. . JMIDS-24-15209(PQ); Reviewed: 16- Sep -2024 QC No . . JMIDS-24-15209; Revised: 23- Sep--2024 Manuscript No. . JMIDS-24-15209(R); Published: 30- Sep- -2024