Research Article: 2024 Vol: 28 Issue: 4

Driving Sustainability: Unveiling Key Factors in Implementing Sustainable Supply Chain Management in the Indian Automotive Sector

Arvind Gupta, Indian Institute of Foreign Trade, Delhi

Hemant Kumar Kaushik, Indian Institute of Foreign Trade, Delhi

Sanjay Rastogi, Indian Institute of Foreign Trade, Delhi

Citation Information: Gupta, A., Kumar Kaushik, H., & Rastogi, S. (2024). Driving sustainability: unveiling key factors in implementing sustainable supply chain management in the indian automotive sector. Academy of Marketing Studies Journal, 28(4), 1-24.

Abstract

Sustainable Supply Chain Management (SSCM) has become concern for Indian organizations striving to ensure a sustainable future. Many establishments in the Indian automotive sector are actively pursuing SSCM to gain a competitive edge. The focus on implementing SSCM involves recognizing the drivers and overcoming the barriers to strategy employment—an area of significant interest for researchers. These identified factors are then organized into a conceptual framework. Utilizing metasynthesis, an extensive literature review is conducted, revealing 111 drivers and 40 barriers. The findings are further validated through a Delphi three-round study involving 30 SCM experts from automotive companies. The analysis highlights the crucial drivers and barriers that need consideration in the implementation of SSCM within the Indian automotive supply chain.

Keywords

Enablers, Drivers, Sustainable Supply Chain, Management, Barrier.

Introduction

Organizations today face new challenges driven by global competition, governmental policies, and increasing customer demands for sustainability (Paul S.K. et al., 2023). To gain a competitive edge, businesses are integrating sustainability strategies into their supply chains (Rodríguez-González R.M. et al., 2022). The goal is to create and deliver products and services while minimizing adverse effects on the environment, addressing social concerns, and ensuring continued profitability.

SSCM is centered on three dimensional aspects, creating meaningful and sustainable impacts for all stakeholders (Diabat et al., 2014). Touboulic et al., (2015) attribute the genesis of SSCM to evolving professional competences, while Luthra S. et al. (2015) highlights its alignment with corporate responsibility.

The significance in fostering a sustainable economy has gained prominence, particularly in the context of the UN SDGs for 2030. The incorporation of SSC practices is increasingly recognized as a crucial component of business strategies aimed at contributing to sustainable development. This paradigm shift is particularly evident in industries pivotal to societal sustainability, such as the automotive sector.

Ivascu (2020) emphasize that by embracing sustainability transformations, automotive companies can address fundamental causes of sustainability challenges encountered on a global scale. The automotive industry's impact on environmental, economic, and social dimensions necessitates a comprehensive approach, with SSCM practices playing a pivotal part in enhancing organizational performance across these domains (Wang & Gunasekaran, 2015).

In the contemporary landscape, sustainable supply chains are recognized as a key avenue for businesses to align with broader sustainability objectives. This paradigm shift is encapsulated in the UN SDGs for 2030, which underscore the critical part of supply chains. The integration of SSC practices has become critical for businesses to contribute proactively to sustainable development.

Cee et al. (2016) argue that by initiating sustainability transformations, automotive companies can play role in mitigating the root causes of global sustainability challenges. This assertion aligns with the broader understanding that the extractive industries, including automotive, have a significant impact on ecological systems and must evolve toward sustainable practices to mitigate environmental degradation and societal concerns.

The multifaceted impact of the automotive industry necessitates a holistic approach to sustainability, encompassing environmental stewardship, economic viability, and social responsibility. Wang and Gunasekaran (2015) emphasize that SSCM practices are instrumental in simultaneously advancing environmental and socio-economic aspects, thereby contributing to the overarching goal of sustainable development.

The integration of sustainable supply chain practices is a pivotal aspect of contemporary business strategies, particularly in industries with far-reaching implications for global sustainability, such as the automotive sector. The transformation of the automotive industry towards sustainability is not merely a regulatory compliance issue but a proactive step towards addressing root causes of sustainability challenges worldwide.

Several companies have initiated the integration of SSCM practices into their operations, reflecting a growing responsiveness. However, research by Kurnia et al. (2014) highlights the pace of adopting SSCM practices. Research conducted by Beske et al.,2014 suggests that the implementation of SSCM is not as effective as desired, with limited number of supply chains meeting sustainability.

This challenge is not unique to specific regions or industries. Even in Indian industries, particularly within the automotive sector, the adoption of SSCM faces similar hurdles. Few automotive companies have embraced SSCM practices. The slow adoption in the automotive sector is a noteworthy concern, given its significant environmental and societal impact.

While academic research has delved into the analysis of SSCM implementation, a substantial portion of studies has concentrated on industries such as food, textiles, and electronic manufacturing. SSCM in the automotive sector has garnered increasing attention due to its unique challenges and implications for sustainable practices.

The research by Kurnia et al. (2014) and Beske et al. (2014) underscores the complexity of SSCM adoption and its varied effectiveness across different industries. These findings emphasize the need for a nuanced understanding of issues linked with sustainability practices in SCM. In the context of the automotive industry, where environmental concerns are particularly salient, the slow adoption of SSCM highlights the necessity for targeted interventions to enhance awareness and encourage sustainable practices.

The scarcity of automotive companies incorporating SSCM practices can be attributed, in part, to a lack of public awareness regarding sustainability initiatives. This underscores the importance of educational and awareness campaigns to promote the benefits of SSCM within the automotive sector and foster a broader understanding of sustainability issues.

While the significance of SSCM is increasingly acknowledged, its implementation across diverse industries, including the automotive sector, encounters certain challenges. The limited effectiveness of current SSCM implementations and the slow pace of adoption highlight the need for targeted efforts to address barriers and enhance awareness.

Organizations must conduct a comprehensive assessment of drivers and barriers. This allows evaluation of opportunities and challenges associated with SSCM, facilitating the anticipation of challenges and mitigating the risk of implementation failure. The analysis of such drivers/barriers serves in gauging SSCM performance within organizations, aiding in the pursuit of new business opportunities (Wissuwa F. et al., 2023). These factors play a crucial role in steering organizations toward new opportunities, enhancing SSCM performance, and promoting innovation for sustainable business practices. By recognizing and understanding these drivers and barriers, organizations can strategically position themselves.

The literature was scrutinized to identify key aspects and components of sustainability, highlighting areas of consensus and potential conflicts Beske et al. (2008). This groundwork provides a foundational understanding of sustainability elements, informing the current study's exploration of drivers/barriers influencing SSCM of automotive companies.

In today's dynamic business environment, where sustainability is a key consideration, understanding the interplay of internal and external factors is crucial for organizations aspiring to implement effective SSCM. The ability to anticipate potential challenges and leverage opportunities can significantly impact the success of SSCM initiatives. Yadav et al. (2020) insights underscore supply chains with sustainability goals to foster innovation and improve overall SSCM performance. By recognizing and understanding these factors, organizations can proactively address challenges, capitalize on opportunities. The collaborative effort of past research laid the groundwork for this study, establishing a solid understanding of sustainability components. The primary focus of this study is on explaining the significance of sustainable supply chain models. The reinforcement of incentives and mitigation of barriers emerge as pivotal factors for successful deployment and promotion of sustainability practices.

It becomes crucial to understand the unique drivers and barriers influencing the adoption of SSCM practices. This research contributes novelty by delving into the intricacies of sustainability within the automotive industry, offering a comprehensive examination of the subject matter. The research methodology employs metasynthesis and Delphi techniques, providing a robust and comprehensive analysis of the multifaceted factors influencing sustainability within the automotive sectors in India.

Section 1 underscores importance of the research. Section 2 conducts a thorough review of available literature on SSCM implementation, specific emphasis on drivers and barriers. Section 3 elucidates the methodology employed, highlighting the utilization of metasynthesis and Delphi techniques in understanding the complex landscape of sustainability within the Indian automotive industries. Section 4 presents the results and ensuing discussion, offering insights into the identified drivers/barriers. The final section encapsulates conclusions, outlining its contributions and proposing recommendations for future endeavors in this domain.

As illustrated in Figure 1, this study focuses on identifying factors. The research treats these factors as inputs, subsequently selecting the critical drivers/barriers. The study culminates in reporting the status of sustainability improvement as an output, providing valuable insights for practitioners, policymakers, and stakeholders involved in shaping sustainable supply chains.

Literature Review

A thorough review of existing studies concerning the drivers and barriers linked with SSCM implementation is carried out. The aim is to assess this area, identify gaps, and address any inconsistencies within the literature. By synthesizing findings from these studies, we aim to uncover key insights that can guide the identification and evaluation of crucial drivers and barriers for SSCM implementation, with a specific focus on the automotive sector in India.

The review encompasses a wide range of literature that has explored SSCM implementation, highlighting factors that facilitate or hinder supply chains. Understanding these drivers and barriers is fundamental for devising effective strategies tailored to the unique challenges and opportunities present in the Indian business landscape, particularly within the automotive industry.

Notably, this review builds on the evolving body of knowledge concerning SSCM implementation, incorporating the latest research findings and insights. This is especially relevant in the Indian context, where industries, including the automotive sector, are grappling with the need to align with sustainable business practices.

The results derived from this comprehensive review contribute to key drivers/barriers influencing SSCM implementation in Indian automotive companies. By systematically analyzing the existing literature, we can discern patterns, common themes, and specific challenges relevant to the Indian business environment. This knowledge serves as a foundation for the subsequent evaluation of critical drivers within the Indian automotive sector.

The review extends beyond a mere compilation of prior research. It provide knowledge of SSCM in India, shedding light on emerging trends, innovative approaches, and potential areas for improvement. This nuanced perspective is vital for crafting effective and context-specific strategies that resonate with the unique intricacies of the Indian market and the automotive industry.

This section serves as a gateway to a deeper exploration of SSCM implementation in the Indian automotive sector. By synthesizing insights from previous studies and addressing knowledge gaps, we lay the groundwork for a comprehensive analysis of the most influential drivers and barriers. The ensuing evaluation will contribute valuable insights for stakeholders involved in shaping the trajectory of SSC practices within the Indian automotive industry.

SSCM Implementation

Sustainable Supply Chain Management (SSCM) entails coordinating essential elements within the supply chain, emphasizing sustainability across socio-economic and environmental dimensions (Seuring & Müller, 2008). Unlike conventional SCM, the objective of SSCM is not merely to optimize organizational processes but to ensure that these processes do not harm the natural and social systems. Instead, SSCM aims for organizations to derive ongoing benefits from these systems, expanding their customer base and business operations sustainably in the long run (Pagell & Shevchenko, 2014). The strategic alignment with sustainability principles in SSCM is designed to harmonize economic profitability, stakeholder satisfaction, competitive positioning, and organizational flexibility, tailored to achieve these multifaceted goals (Ahi & Searcy, 2013).

Building upon the foundations of traditional SCM, SSCM introduces a comprehensive paradigm shift by integrating socio-economic and environmental aspects. This holistic method acknowledges that environmental, social, and economic objectives are interconnected and must be addressed collectively to achieve sustainable results.

In the Indian context, where sustainability considerations are gaining increasing prominence, the adoption of SSCM becomes especially relevant. India, as a rapidly developing economy, faces unique challenges and opportunities. The principles of SSCM provide a framework for Indian organizations, particularly within the dynamic landscape of the automotive sector, to align their supply chain activities with sustainability goals.

Seuring and Müller's (2008) seminal work on SSCM emphasizes the need to consider sustainability dimensions in supply chain arrangements. Pagell and Shevchenko's (2014) insights further underscore the long-term vision of SSCM, emphasizing the importance of organizations deriving benefits from natural and social systems while expanding their market presence sustainably.

In the specific domain, where the need for sustainable practices is accentuated by environmental concerns and societal expectations, SSCM offers a strategic avenue for organizations to navigate challenges. The multifaceted nature of SSCM, incorporating socio-economic and environmental considerations, positions it as a comprehensive framework for fostering sustainability.

SSCM represents a paradigm shift in SCM by integrating socio-economic and environmental aspects. Organizations, particularly in the Indian automotive sector, can derive value from this approach by aligning their supply chain activities with sustainability goals. Seuring and Müller's (2008) foundational insights, coupled with Pagell and Shevchenko's (2014) emphasis on long-term benefits, provide a robust foundation for understanding and implementing SSCM principles in the context of India's evolving business landscape. As organizations in India strive to balance economic growth with sustainability imperatives, SSCM emerges as a strategic imperative for navigating the complex dynamics of the automotive industry.

The implementation of SSCM has garnered significant attention from scholars, leading to diverse research streams. A seminal work by Seuring et al. (2005) conducted an analysis in SSCM. Their research culminated in the development of a framework that encapsulates two key focal points in SSCM: risk and performance, along with sustainable product strategies. The study not only contributed valuable insights to the conceptualization of SSCM but also identified knowledge gaps within the field, stimulating further inquiry and exploration.

Miranda et al. (2020) researched resources impact and competences on SSCM performance, shedding light on the crucial internal factors that shape sustainability outcomes. Beske (2012) explored the dynamic capabilities concept. The framework integrates dynamic capabilities into SSCM practices, providing a strategic lens to enhance organizational sustainability efforts. These studies collectively underscore the significance of internal organizational dynamics in shaping and implementing effective SSCM strategies.

In an empirical exploration, Wolf (2013) explored the intricate interplay between SSCM, stakeholders, and organizational sustainability. The study uncovered meaningful relationships, between stakeholder and SSCM practices significantly contribute to enhancing organizational sustainability performance. This empirical evidence reinforces the real-world impact of SSCM in fostering sustainability within organizations, aligning with the broader goals.

The dynamic nature of the Indian business landscape, particularly within industries like automotive, demands a nuanced understanding of SSCM's applicability and effectiveness. The insights from these studies provide a foundation for exploring and tailoring SSCM strategies within the Indian context.

As the research in SSCM continues to evolve, recent studies have delved into specific industries, offering contextualized perspectives. For instance, research within the Indian automotive sector has explored the challenges and opportunities of implementing SSCM practices (Isasi-Sanchez et al.2020). This recent work provides insights into the industry-specific nuances of SSCM within automotive sector.

The research landscape in SSCM implementation has witnessed significant contributions across various dimensions. From conceptual frameworks to empirical investigations, scholars have deepened our understanding of the intricacies involved in implementing sustainable practices within supply chains. The relevance of these studies is particularly pronounced in the Indian context, where sustainable development is a pressing concern. As the field progresses, ongoing research, especially within specific industries like the Indian automotive sector, continues to shed light on tailored strategies and challenges, enriching the broader discourse on SSCM.

In recent years, the trajectory of SSCM research has witnessed a notable shift towards an integration-centric approach. Scholars have increasingly focused on developing models that seamlessly incorporate sustainability measures (Fahimnia et al., 2015). This integration approach reflects an acknowledgment of the interconnectedness of sustainability and supply chain dynamics, aiming to optimize organizational performance while addressing environmental and social concerns.

One noteworthy exploration in this integrated vein comes from Genovese et al. (2015). This novel approach emphasizes systems, aligning with the broader goal of minimizing waste and maximizing resource efficiency. Zeng et al. (2016) further contributed to the integration discourse by proposing a conceptual model. This model aims to achieve sustainability benefits for organizations, signaling a holistic approach to addressing socio-environmental challenges within the supply chain.

The evolving landscape of SSCM is summarized in Table 1, categorizing studies based on their research focus. Notably, there has been a proliferation of efforts to analyze various facets of SSCM implementation. However, a critical observation reveals a predominant emphasis on research direction, frameworks, and empirical analyses. Limited attention has been directed towards strategic aspects.

Acknowledging the existing gap in the literature, this study aims to explore the strategic dimensions of SSCM implementation. This study seeks to address the dearth of literature in this specific area, offering valuable insights into the strategic considerations that organizations must navigate in their pursuit of sustainable supply chains.

In the Indian context, where sustainability imperatives are increasingly shaping business strategies, a nuanced examination of SSCM implementation drivers and barriers becomes particularly relevant. India, with its diverse economic landscape and environmental challenges, necessitates a tailored understanding of the strategic issues surrounding SSCM. Recent research within the Indian context has explored industry-specific challenges and opportunities for SSCM implementation, shedding light on the unique dynamics at play in the Indian business environment (Isasi-Sanchez L. et al., 2020).

The current research trend in SSCM places a pronounced emphasis on integration, aligning with the interconnected nature of sustainability and practices. The integration of circular economy principles and the consideration of institutional pressures underscore the holistic approach taken by recent studies. However, the strategic dimensions of SSCM implementation, including drivers, barriers, and success factors, require further exploration. This study seeks to fill this gap, offering a nuanced understanding of the strategic considerations crucial for successful SSCM implementation in the evolving landscape of sustainable business practices.

SSCM Implementation Challenges

While some companies have incorporated SSCM practices into their strategic plans, the effective implementation of these systems remains a challenge (Ghadimi, Farzipoor Saen, & Rashidi, 2017). Acknowledging the crucial role of SSCM in attaining sustainability goals, the objective is to obtain a comprehensive understanding of the drivers and barriers associated with its implementation.

Recognizing the significance of identifying internal and external challenges and opportunities, it is widely acknowledged as critical to the successful implementation of SSCM (Nasrollahi M. et al., 2021). Scholars emphasize the significance of this step, as it sets the stage for a strategic and informed approach to incorporating sustainable practices.

Recent research highlights the importance of overcoming challenges and leveraging drivers to enhance the effectiveness of SSCM implementation. In a global context, companies are increasingly acknowledging the need to align supply chain activities with sustainability goals. A study by Sarkis, Zhu, and Lai (2011) emphasized the role of drivers such as environmental concerns, regulatory pressures, and corporate social responsibility in motivating organizations to adopt SSCM practices. Understanding these drivers is essential not only for meeting regulatory requirements but also for gaining a competitive edge and fostering positive stakeholder relationships.

On the global stage, companies are grappling with the complexities of SSCM implementation. An analysis by Zhou, Y et al. (2023) underscores the role of barriers such as resource constraints, lack of awareness, and resistance to change in hindering effective SSCM implementation. Overcoming these barriers necessitates a proactive approach, emphasizing the need for organizations to develop the knowledge, capabilities, and strategic vision required for successful integration.

In the Indian perspective, where sustainable development is a growing priority, SSCM practices gain additional relevance. India's unique economic landscape and environmental challenges demand a tailored implementation. Recent studies within India's business context highlight the need for increased awareness, stakeholder collaboration, and government support to overcome barriers and drive successful SSCM adoption (Gupta, Jain, & Jain, 2021).

While some companies have recognized the importance of SSCM practices in their strategic plans, the effective implementation of these strategies remains a challenge. Understanding the drivers and barriers associated with SSCM is a crucial initial step for organizations globally. Insights from global and Indian perspectives underscore the need for organizations to proactively address challenges, leverage motivating factors, and align their supply chain activities with sustainable practices for long-term success in an increasingly sustainability-driven business landscape.

Exploring the crucial facets of SSCM implementation, Ansari and Kant (2017) underscored the significance of early-stage deliberation on drivers and barriers. Recognizing these elements as strategic components, the authors highlighted their pivotal role in shaping adoption of SSCM practices. In a parallel vein, Abdul-Rashid et al. (2017) characterized drivers as influential agents compelling companies to embrace sustainable production actions.

A global perspective on the analysis of drivers and barriers is evident in the work of Walker et al. (2012), who delved into the intricacies of SSCM adoption within the British multisector industry. They categorized numerous factors as drivers and barriers, providing a holistic view of the complexities associated with SSCM adoption. This study contributes valuable insights into the diverse factors influencing the uptake of sustainable practices across sectors.

Shifting focus to the Indian context, Diabat et al. (2014) conducted a detailed analysis of drivers for SSCM implementation within the textile industry. This research, grounded in the industrial landscape of the country, identified key drivers drawn from insights gathered from previous studies. The Indian textile industry serves as a pertinent case study, shedding light on region-specific factors.

Taking a broader view of global SSCM implementation, studies have consistently emphasized the need to address both internal and external drivers and barriers. For instance, Mehdikhani R.; Valmohammadi C. (2019) conducted a meta-analysis of 75 empirical studies, confirming the multifaceted nature of SSCM adoption. Their findings highlighted the intricate interplay between internal organizational factors, such as leadership commitment and organizational culture, and external factors like regulatory pressures and customer expectations. This global meta-analysis adds a nuanced layer to our understanding of the diverse forces influencing SSCM practices across industries and geographies.

In their exploration Mangla et al. (2017) shed light on pertinent barriers within this domain. This underscores the evolving nature of research into sustainable practices within supply chains. Drawing on a broader perspective, Govindan and Hasanagic (2017) extended their investigation to encompass drivers/barriers. Their contribution takes a multiperspective approach, linking stakeholders' viewpoints with key elements such as drivers, barriers, and practices. This framework enhances our understanding of the complex interplay of factors influencing circular economy practices in global supply chains.

Turning our attention to Green Supply Chain Management (GSCM), Kaur et al. (2018) conducted a focused study on barriers encountered in GSCM implementation within Canadian electronic manufacturing companies. While the study's focus is on the Canadian context, the insights derived can be extrapolated to inform global practices in electronic manufacturing supply chains. This underscores the importance of contextualizing research findings while recognizing the potential applicability of insights across diverse geographical settings.

Table 2 provides a comprehensive overview of studies focusing on the drivers and barriers associated with SSCM. It is crucial to emphasize the necessity for continuous research to address emerging challenges and opportunities. Global perspectives on sustainable supply chains are well-represented in the literature. For instance, Pagell and Wu (2009) conducted a meta-analysis of studies on environmental practices in supply chains, offering insights. They contribute to describe diverse factors that organizations navigate when incorporating sustainability.

| Table 2 Factors Influencing SSCM Implementation | |||||

| Reference | Research focus | Methodology | Drivers | Barriers | Drivers and barriers |

| Faisal (2010) | Manufacturing | ISM | Yes | ||

| Wolf (2011) | Manufacturing | Framework | Yes | ||

| Gopalakrishnan et al. (2012) | Aerospace | Case study | Yes | ||

| Walker et al. (2012) | Manufacturing | Case study | Yes | ||

| Al Zaabi, Al Dhaheri, and Diabat (2013) | Manufacturing | Fuzzy | Yes | ||

| Rossi, Colicchia, Cozzolino, and Christopher (2013) | Coordination Industry | Data analysis | Yes | ||

| Beske et al. (2014) | Food Industry | Conceptual research | Yes | ||

| Diabat et al. (2014) | Textile | I S M | Yes | ||

| Brandenburg et al. (2014) | Manufacturing | Fuzzy | Yes | ||

| Grimm, Hofstetter, and Sarkis (2014) | Food industry | field study | Yes | ||

| Chkanikova (2015) | Retailing | Interviews | Yes | ||

| Dubey, Gunasekaran, and Childe (2015) | Manufacturing | Qualitative study | Yes | ||

| Wang and Gunasekaran (2015) | Packaging | Decision making | Yes | ||

| Ansari and Kant (2017) | Manufacturing | Case study | Yes | ||

| Mangla et al. (2017) | Manufacturing | Fuzzy | Yes | ||

| Biswal and Muduli (2017) | Manufacturing | Descriptive | Yes | ||

| Abdul‐rashid et al. (2017) | Manufacturing | Structure Eq. Modelling | Yes | ||

| Dubey et al. (2017) | Framework | MCDM | Yes | ||

| Govindan (2017) | Circular economy | Review | Yes | ||

| Kaur et al. (2018) | GSCM | Fuzzy | Yes | ||

| Govindan and Hasanagic (2018) | Framework | Review | Yes | ||

| Jia, Zuluaga, Bailey, and Rueda (2018) | Adoption | Review | Yes | ||

In a more recent global examination, Jamwal A. et al. (2022) investigated the drivers and barriers in the automotive industry. By focusing on a specific sector with complex and extensive supply chains, the study provides nuanced insights into the challenges and motivators that companies face on a global scale. The findings contribute valuable knowledge that can inform strategies not only in the automotive sector but also across industries with similar supply chain complexities.

Table 2 illustrates a discernible trend in previous research, which predominantly concentrates on the food, textile, and electronics industries when examining SSCM implementation. This oversight suggests a need for more comprehensive investigations into the unique challenges and opportunities associated with SSCM within the automotive industry, given its strategic importance in global and regional economies.

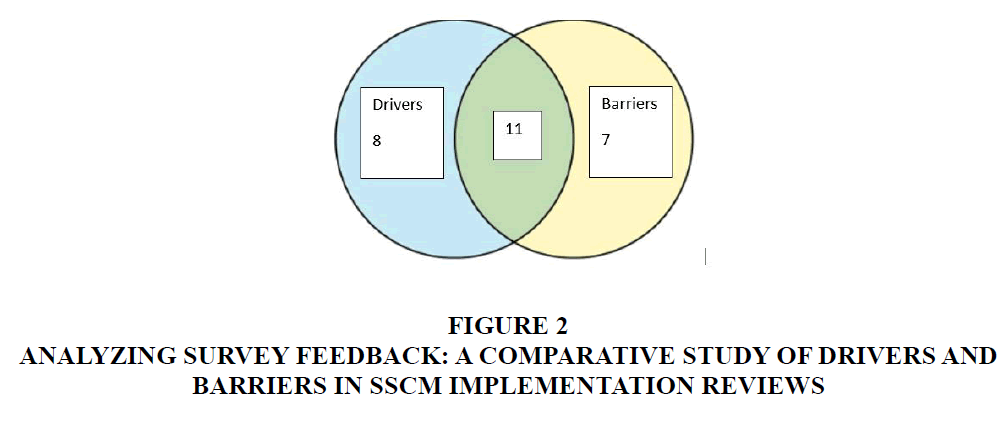

A comparative analysis depicted in Figure 2 further highlights this gap in research focus. The visual representation underscores the disproportionate attention given to certain industries, particularly food, textile, and electronics, in contrast to the limited emphasis on the automotive sector in surveys and reviews examining SSCM drivers and barriers. This discrepancy calls for a recalibration of research priorities to encompass a broader spectrum of industries, acknowledging the distinct characteristics and challenges inherent in each sector.

Figure 2 Analyzing Survey Feedback: a Comparative Study of Drivers and Barriers in SSCM Implementation Reviews

Expanding the geographical scope to the Indian perspective, it is crucial to contextualize the findings within the country's burgeoning industrial landscape. In India, where the automotive sector plays a pivotal role in meeting energy demands, understanding the unique dynamics of SSCM implementation in this industry becomes imperative. Recent research within the Indian context, such as studies by Isasi-Sanchez L. et al. (2021), underscores the significance of sector-specific investigations, emphasizing the need for tailored strategies to enhance sustainability practices within the automotive industry. This aligns with global imperatives for sustainable energy practices and further emphasizes the need for a more inclusive approach to SSCM research encompassing diverse sectors.

On a global scale, literature examining SSCM in the automotive sector has made strides in recent years. A study by Wu L. & Subramanian N. (2021) conducted a review of sustainable practices within the automotive industry, offering insights into barriers and opportunities specific to this sector. This global perspective contributes valuable knowledge that can inform strategies not only in India but also in other regions where the automotive industry is a critical component of the economy.

Moreover, research by Mathivathanan D. & Haq A.N. (2017) delves into sustainable practices in the automotive sector, recognizing the need for sector-specific considerations. Their study provides a broader global context, emphasizing the importance of aligning sustainability practices. These global perspectives enrich our understanding of the intricacies associated with SSCM in the automotive sector and provide insights that can be applied to diverse regional contexts.

Research Methodology

In this study, we initially framed a pivotal question:

What are the Key Drivers to Sustainable Supply Chain within India's Automotive Industry?

To comprehensively address this question, we conducted a systematic review, utilizing targeted keywords related to SSC, and its drivers and barriers. This review spanned databases such as “Wiley, Springer, Elsevier, Scopus, Science Direct, Emerald, and ”, ensuring a robust collection of contemporary research resources aligned with the Indian context.

The initial stage, titled "search and select the right articles," involved the scrutiny of titles, leading to the identification of 154 articles published between 2008 and 2023. Subsequent evaluation of abstracts and content facilitated a refined selection, narrowing down to 33 papers initially and eventually culminating in a focused set of 24 papers that were deemed pertinent to the subject matter and aligned with our research question.

Advancing into the "analyze and integrate the qualitative findings" stage, we systematically coded and categorized important concepts derived from the selected articles. This rigorous coding process enabled a comprehensive content analysis, shedding light on recurring themes and insights embedded in the literature.

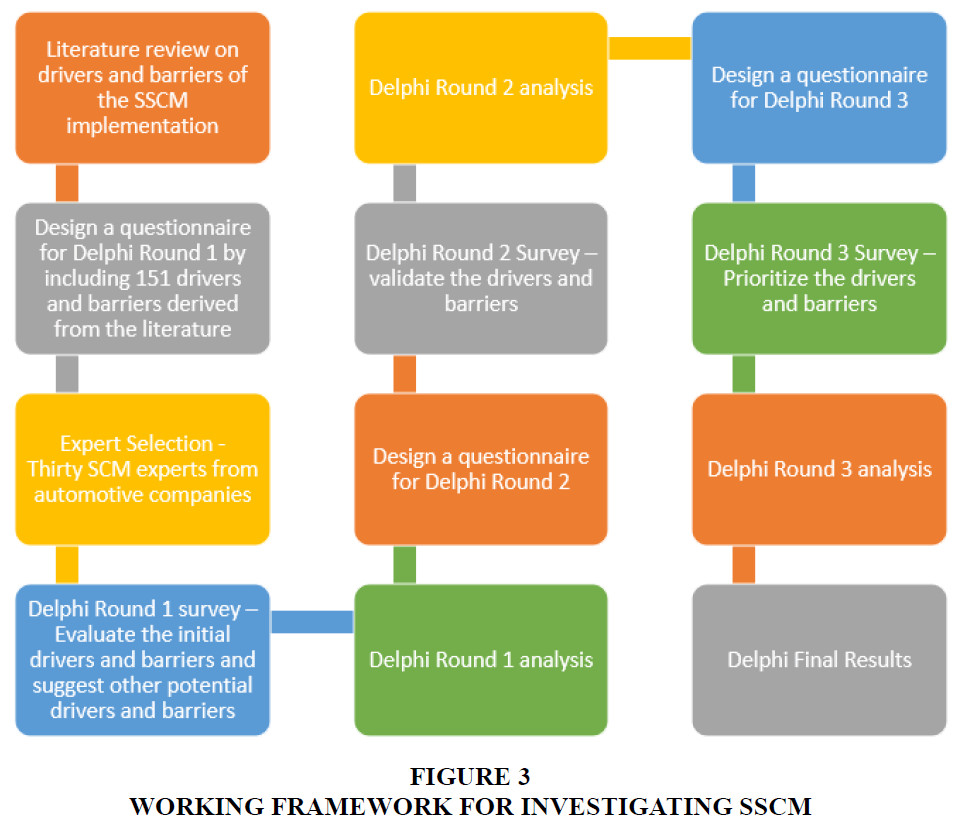

Throughout this journey, a total of 113 drivers and 42 barriers were distilled from the literature and presented to experts. The ensuing Delphi stages involved engagement with these experts, who not only validated the identified factors but also proposed 11 new drivers and 15 additional barriers. Through 3 iterative Delphi rounds, 11 drivers and 9 preeminent barriers to a SSC garnered the consensus. Notably, the insights derived from this collaborative process emanated from the collective wisdom of 30 experts deeply embedded in the operational dynamics of Indian automotive companies.

The research framework also encompassed a parallel evaluation, where an examination of literature and subsequent evaluation and prioritization were conducted by experts from automotive companies using the Delphi study. This multifaceted approach ensured a convergence of theoretical insights and practical industry perspectives, offering a comprehensive understanding to SSCM implementation within the Indian automotive industry.

Figure 3 visually represents the fluid trajectory of the study, encapsulating the stages of literature review, metasynthesis, Delphi consultations, and expert validation. This methodological transparency provides a clear roadmap for navigating the intricacies of the research process.

By synthesizing insights from literature and expert viewpoints, the study provides to a understanding of the unique challenges and opportunities present in the Indian context. The methodology outlined herein underscores the importance of a multifaceted approach, integrating theoretical foundations with practical industry insights for a holistic comprehension of SSCM dynamics in the Indian automotive sector.

Delphi Technique

The Delphi technique, initially introduced by Dalkey and Helmer in 1963, serves as a systematic approach for the attainment of collective consensus. In the context of this study, 30 esteemed experts specializing in supply chain management within India's automotive sector were engaged. The selection criteria for these experts, encompassed individuals with over a decade of industry experience and possessing post-graduation in supply chain management.

To ensure a rigorous exploration of the subject matter, a questionnaire, employing a ninepoint Likert scale, was distributed among participants within the Indian automotive network. This approach aimed to capture opinions, refining, and tailoring the initial questionnaire for the Delphi study. The questionnaire, meticulously crafted by the researcher, encapsulated insights garnered from the preceding stage and featured 152 drivers and barriers associated with the SSCM in the automotive industry.

A notable aspect of the questionnaire design is its openness, affording experts the opportunity to contribute additional drivers/barriers to SSCM practices within the automotive sector. This approach aligns with the dynamic and evolving nature of the automotive industry, acknowledging the need for continual adaptation and consideration of emergent factors influencing sustainable supply chain practices.

The inclusion of experts and academic qualifications in SCM strengthens the reliability and relevance of the insights derived through the Delphi technique. Drawing on the expertise of professionals with a substantial industry background ensures a practical and informed exploration of the challenges and opportunities associated with SSCM in the Indian automotive landscape.

In parallel, a wide-ranging assessment of global literature on SSCM drivers and barriers within the automotive sector enriches the contextual understanding of the Indian scenario. These global perspectives, combined with the specific insights collected from the Indian experts, provide holistic understanding of the factors influencing SSCM implementation.

The utilization of the Delphi technique, aligned with rigorous selection criteria for experts, forms a robust methodological approach in this study focused on the Indian automotive industry's perspective on SSCM. The openness of the questionnaire design, coupled with insights from global literature, ensures the dynamic landscape of SSCM drivers and barriers. The convergence of expert perspectives and global insights positions this study to make valuable contributions.

Data Collection

After meticulously take out 151 drivers and barriers from a synthesis of literature research and qualitative studies, a comprehensive reevaluation of these factors unfolded in 3 stages of the Delphi study. To ensure a robust exploration of these drivers and barriers, the Delphi study enlisted the insights of 30 experts specializing in SCM.

I stage of the Delphi study involved the development of an initial questionnaire. This questionnaire, derived from the 151 drivers and barriers identified in the literature review (comprising 111 drivers and 40 barriers), served as a foundational tool for engaging the experts. Respondents, contributing to the study's depth, introduced 12 novel drivers, 14 additional barriers, and amalgamation of certain pre-existing drivers and barriers in two rounds of the Delphi study. This iterative process ensured a dynamic and evolving understanding of the landscape, allowing for the incorporation of emergent perspectives.

Throughout the three Delphi rounds, experts actively engaged in the refinement and prioritization of the identified drivers and barriers. The culmination of these iterative rounds resulted in the selection of final drivers and barriers that garnered consensus among the expert cohort. The assessment of consensus was established through the application of the Kendall correlation coefficient (W), a statistical measure extensively employed for gauging consensus in Delphi studies (Schmidt, 1997). As defined by Narimissa et al.,(2019), the Kendall's concordance coefficient W ranges from 0 to 1, with interpretations as follows:

W > .7 -a robust agreement.

W = .5 -a moderate agreement.

W < .3 -a weak agreement

The conclusive results after 3rd step unequivocally indicate that a substantial agreement has been achieved among the experts. This consensus signifies a convergence of expert opinions, affirming the reliability and validity of the identified drivers and barriers. Accordingly, the Delphi process was deemed conclusive, attesting to the coherence and concordance achieved throughout the iterative rounds.

In essence, the Delphi study, informed by global insights and expert perspectives, serves as a robust methodological approach to separate and rank drivers and barriers for SSCM within the Indian automotive sector. The amalgamation of qualitative research, iterative expert engagement, and global contextualization positions this study to make meaningful contributions to the discourse on SSCM practices in the rapidly evolving landscape of the Indian automotive industry.

Result and Discussions

A comprehensive discussion of the results, is aiming to draw comparisons with previous related studies and underscore novel findings, specifically tailored to the Indian automotive industry perspective. The Delphi study unfolded across 3 iterative rounds, each playing a distinct role in exploring SSCM within the Indian automotive sector.

Commencing with the initial round of the Delphi study, experts rigorously evaluated 151 drivers/barriers to implementation. Importantly, this stage served as an open forum for experts to contribute additional insights, suggesting potential drivers and barriers that may have been overlooked. This inclusive approach is especially relevant in the dynamic and evolving context of the automotive industry, where emerging factors require ongoing adaptation and consideration.

The transition to the second round marked a crucial phase in the Delphi study, focusing on the validation of the identified drivers and barriers. This stage sought to refine and authenticate the relevance of each factor, ensuring a robust foundation for subsequent prioritization. By subjecting these elements to a rigorous validation process, the study aimed to distill the multitude of identified factors to those most pertinent to the nuanced context of the Indian automotive sector.

The third and final round of the Delphi study concentrated on prioritization, a pivotal step in discerning the drivers and barriers that wield the most substantial impact on SSCM implementation within Indian automotive companies. The culmination of these iterative rounds yielded a nuanced understanding of the distinctive factors influencing sustainability practices within the specific contours of the Indian automotive industry.

The results are summarized in Table 3, providing a comprehensive overview of the evolving insights gathered from expert consultations. To achieve a comprehensive understanding, Tables 4 and 5 meticulously catalog the ultimate drivers and barriers specific to SSCM implementation in Indian automotive companies.

| Table 3 Delphi Study Findings | ||||||

| Delphi study N | Number of experts | Cronbach's α | Responses | Average | Standard deviation | Kendal (W) |

| First Round | 30 | 0.97 | 30 | 6.99 | 0.98 | 0.72 |

| Second Round | 30 | 0.96 | 30 | 7 | 0.96 | 0.65 |

| Third Round | 30 | 0.95 | 30 | 7.05 | 0.7 | 0.69 |

| Table 4 Key Drivers for SSCM Implementation in Automotive Industries | |||

| Total from 269 | Mean | Standard Deviation | |

| Implementation of sustainability in three dimensions, encompassing economic, environmental, and social aspects | 254 | 8.45 | 0.54 |

| Endorsement and support from top management and leadership | 255 | 8.54 | 0.52 |

| The significance of meritocracy in the employment context | 254 | 8.55 | 0.54 |

| Finance | 255 | 8.57 | 0.54 |

| Customer satisfaction | 256 | 8.6 | 0.52 |

| Warehousing | 257 | 8.57 | 0.53 |

| Waste hazards | 258 | 8.58 | 0.54 |

| Product life cycle management | 256 | 8.59 | 0.54 |

| Risk management | 257 | 8.56 | 0.57 |

| Local manufacturing | 258 | 8.57 | 0.49 |

| Table 5 Barriers | |||

| Total from 269 | Mean | Standard Deviation | |

| High expenses linked to the implementation | 257 | 8.6 | 0.49 |

| Difficulties in banking and constraints due to limited financial resources | 258 | 8.57 | 0.49 |

| Challenges related to administrative hurdles, intricate rules, and work methods. | 254 | 8.55 | 0.48 |

| Constraints and integrity | 254 | 8.54 | 0.49 |

| Measurement system | 257 | 8.59 | 0.49 |

| Education and training | 256 | 8.58 | 0.47 |

| Inadequate governmental promotion of sustainability leadership. | 254 | 8.54 | 0.48 |

| Lack of transparency in the actual pricing of goods. | 255 | 8.57 | 0.48 |

| Deterioration of equipment and machinery due to aging | 260 | 8.56 | 0.45 |

| Warehouses | 254 | 8.57 | 0.49 |

A noteworthy revelation from the analysis is the pivotal role accorded to top leadership. The support and unwavering commitment of leadership emerge as integral drivers for successful implementation of SSCM. This finding resonates with corroborative evidence from prior studies, such as the work by José, Jabbour, Beatriz, and Sousa (2015), affirming that management support form linchpin factors for attaining enduring sustainability values.

Expanding the discussion globally, Sarkis et al. (2019) and Jamwal et al. (2022) further enrich the understanding of leadership's crucial role in SSCM within the automotive sector. These global perspectives contribute to a broader comprehension of the overarching trends and challenges characterizing SSC practices in the automotive industry, providing a valuable backdrop against which the Indian findings can be juxtaposed.

The Delphi study, grounded in a global and Indian context, serves as a valuable instrument to interpret, and rank drivers and barriers for SSCM within the Indian automotive sector. By engaging experts and leveraging insights from the literature, this study provides nuanced and actionable findings that can inform strategies in the dynamic landscape of the Indian automotive industry.

The discoveries of this research underscore the formidable challenge of supply chain risk management as a paramount concern for companies within the Indian automotive sector, aligning with observations made in studies (Nasrollahi M. et al., 2021). To navigate this challenge successfully, supply chain managers must formulate strategic approaches that effectively address risks throughout the implementation of SSCM. This is crucial not only to curtail costs but also to ensure the seamless continuity of the SSCM system.

A novel contribution of this study lies in the recognition of the imperative to fortify local production and manufacturing facilities. This arises from a nuanced understanding of the influence of political conditions and embargoes, a dimension not extensively explored in previous studies. The implications for supply chain managers are clear—there is a pressing need to mitigate risks by reducing reliance on overseas equipment procurement. Shifting focus towards local products not only serves to minimize operational costs but also acts as a strategic response to geopolitical uncertainties.

Beyond the immediate concerns of the automotive sector, there is a noteworthy recommendation i.e. the government should encourage sustainable energy sources, particularly renewable energy. This strategic shift aligns with the global push for enhanced energy efficiency and addresses the broader socio-environmental dimensions of SSCM adoption. Recognizing the interconnectedness of sectors, this holistic approach fosters a more comprehensive and resilient sustainability strategy for the nation.

In the pursuit of SSCM adoption, it is imperative for experts to embrace a tri-dimensional perspective encompassing economic, environmental, and social considerations. Embedding these dimensions across all aspects of the value chain is crucial for realizing the full potential of SSCM within an organization. Notably, this multifaceted approach aligns with the evolving discourse on sustainability, where a balance between economic prosperity, environmental stewardship, and social responsibility is deemed essential for long-term viability.

Crucially, the study underscores the need for strategic alignment between the sustainability policy and the overall corporate plan of a company. This amalgamation ensures that sustainability initiatives permeate all facets of the value chain, including the intricacies of the supply chain. The efficacy of SSCM implementation is contingent upon this synergy, emphasizing the interconnectedness of sustainability goals with the overarching business objectives of the organization.

Drawing on global insights, studies by Carter and Rogers (2008) and Seuring and Müller (2008) corroborate the emphasis on supply chain risk management and the imperative for strategic alignment. These perspectives contribute a broader context to the Indian automotive sector's challenges and offer global benchmarks for addressing complexities in SSCM adoption.

The identification of supply chain risk management as a pivotal challenge, coupled with novel insights into fortifying local production and navigating geopolitical uncertainties, enriches the discourse on sustainable practices in the automotive industry. The global citations provide a broader lens through which to interpret these findings, fostering a more nuanced understanding of the intricate dynamics at play in SSCM implementation within the Indian automotive sector.

This study underscores the pivotal role of meritocracy in several key domains. Specifically, meritocracy is identified as a driver influencing employment practices, resource allocation, customer satisfaction, the adoption of new warehousing systems, and control mechanisms. These considerations are paramount for companies aiming to establish an effective SSCM strategy, aligning with the principles of sustainability and corporate responsibility.

For companies at the nascent stages of SSCM implementation, the study recommends a strategic approach where investments in sustainability should be economically validated. The linkage between such investments and financial benefits must be transparently articulated, ensuring a judicious allocation of resources. Furthermore, the study identifies the high cost of sustainability implementation, banking challenges, and limited financial resources as formidable barriers that need to be addressed proactively to facilitate smoother SSCM adoption.

The mapping process employed in the study illuminates the intricate connections between identified drivers and barriers and their impact on SSCM implementation. This analysis serves as a valuable tool for top-level managers and decision-makers, offering insights into the nuanced dynamics that influence the organizational supply chain. This aligns with contemporary literature emphasizing the significance of mapping and understanding supply chain dynamics for effective sustainability management (Wu & Pagell, 2011; Srivastava, 2007).

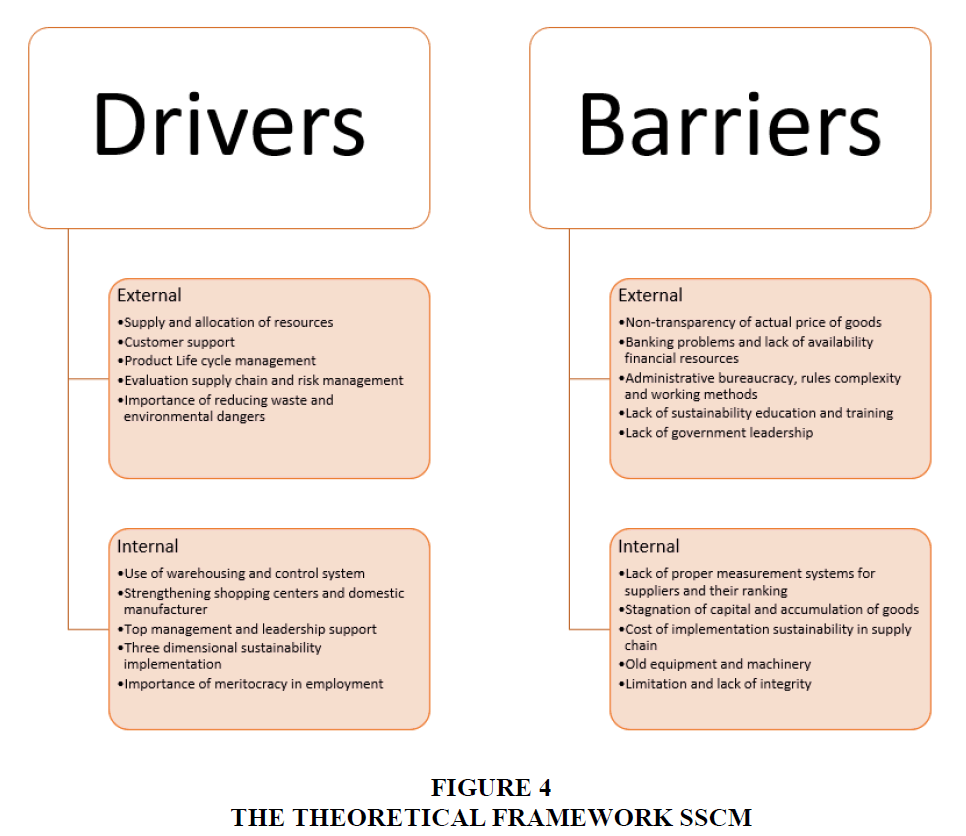

An interesting aspect brought to the forefront by experts is the differentiation of drivers and barriers into internal and external sources. 5 drivers and 5 barriers are categorized as internal, implying that organizations have direct control over these aspects. Conversely, five drivers and barriers are considered external, requiring collaboration with external entities for effective deployment or improvement. This nuanced categorization provides actionable insights for companies seeking to strengthen their SSCM strategies.

In summary, the study summarizes the comprehensive findings through a conceptual framework illustrated in Figure 4.This framework categorizes the identified drivers and barriers into internal and external supply chain sources, offering a visual representation of their interplay. This conceptual framework aligns with contemporary literature that advocates for visual aids in conveying complex information and facilitating better understanding.

A global perspective enriches the study's insights. The works of Pagell and Wu (2009) and Seuring and Müller (2008) contribute to the understanding of drivers and barriers in SSCM, offering benchmarks. Additionally, insights from best practices in global supply chain sustainability management inform the recommendations for addressing barriers and leveraging drivers (Sarkis, Zhu, & Lai, 2011).

The outcomes of this research serve as a compelling incentive for automotive supply chain managers to discern and adopt effective strategies for advancing Sustainable Supply Chain Management (SSCM) within their organizations. The study's significant contributions extend beyond immediate managerial implications, encompassing valuable impacts in the realms of education planning and corporate responsibility.

One notable contribution lies in the realm of educational planning. The findings underscore the importance of educational initiatives, such as training programs, aimed at enhancing the knowledge base of employees within automotive companies. These programs can specifically focus on sustainability principles and the nuanced implementation of SSCM.

Another noteworthy impact centers around the improved capability of managing equipment and machinery in a manner that reduces energy consumption and minimizes pollution. The study advocates for enhanced competencies in handling exhausted equipment, promoting energy efficiency, and mitigating environmental impact. This aligns with global efforts to transition towards cleaner, greener business practices, and corresponds with literature emphasizing the importance of resource efficiency. Furthermore, the study advocates for supporting indigenous manufacturing. This involves sourcing products from local suppliers, thereby contributing to the economic well-being of the community. Such practices align with the principles of social responsibility and sustainable business models, promoting economic development at the local level. The encouragement of local manufacturing not only bolsters economic sustainability but also fosters a positive social impact, aligning with broader societal goals.

The study's results provide actionable insights for automotive supply chain managers, urging them to formulate and implement effective strategies for SSCM. Beyond managerial implications, the study emphasizes the importance of educational planning, enhanced capabilities in equipment management for sustainability, and support for local manufacturers.

Conclusion

The primary objective was to identify the key drivers and barriers associated with the adoption of SSCM within the automotive sector. Employing a combination of review and the Delphi study, the research aimed to provide valuable insights into the factors influencing SSCM adoption in the context of the automotive industry. The outcomes revealed ten critical drivers/ barriers that necessitate consideration both before and during the SSCM implementation.

Among the identified drivers, certain factors were highlighted for implementation. Enablers encompass customer satisfaction, warehouse adoption & control system, product life, evaluation, risk management practices, and the reinforcement collaboration with local manufacturers. These aspects were recognized as pivotal contributors to the effectiveness of SSCM adoption within the automotive sector, aligning with the broader literature emphasizing the importance of customer satisfaction, technological integration, and strategic collaborations in sustainable supply chain practices.

On the flip side, the study identified several barriers that pose challenges to SSCM implementation. Notable barriers included implementation cost, the absence of measurement on product needs, equipment and machinery exhaustion, capital stagnation, and the accumulation of goods in warehouses. Additionally, a significant barrier highlighted was the education on sustainability and training. These findings underscore the multifaceted nature of challenges faced by organizations in their pursuit of sustainable supply chain practices.

The study's practical implications are substantial, providing managers and decision-makers with a roadmap to gauge potential opportunities and threats associated with SSCM implementation. By focusing efforts on the identified drivers and addressing the barriers, organizations in the automotive sector can enhance their likelihood of successful and sustainable supply chain practices. By concentrating on the identified drivers and addressing the barriers, automotive companies, and potentially others, can pave the way for a more effective and resilient sustainable supply chain.

The findings of this study serve as a valuable resource for practitioners in the automotive industry, offering insights that allow them to anticipate potential Sustainable Supply Chain Management (SSCM) implementation challenges and steer clear of failure. The strategic aspects of SSCM implementation present promising avenues for future research. These endeavors would provide practitioners with a comprehensive understanding of SSCM implementation, fostering successful and sustainable practices in automotive companies.

Future studies could explore the applicability of the model in other industries to enhance its generalizability. The reliance on expert opinions for data collection also poses a limitation, and alternative methodologies or data sources could be explored to complement and validate the findings. Additionally, the potential lack of familiarity with sustainability concepts among experts might impact the depth of insights gathered.

To expand the applicability of the present research, future investigations could consider implementing the proposed model for automotive industry or other comparable sectors. Comparing the outcomes with alternative techniques, such as interpretive structural modeling, could provide a more comprehensive understanding of SSCM implementation dynamics. Furthermore, exploring MCDM techniques like the AHP and the TOPSIS for prioritizing or allocating weights to barriers would contribute to a more nuanced understanding of the challenges faced in SSCM implementation.

In conclusion, while this study has laid a foundation for understanding SSCM implementation in the automotive industry, future research endeavors should aim to address the identified limitations, explore broader industry applications, and leverage alternative methodologies to enhance the robustness and applicability of the findings. This iterative process of research and refinement will contribute to advancing sustainable practices and strategies within the dynamic landscape of supply chain management.

References

Abdul‐Rashid, S. H., Sakundarini, N., Ariffin, R., & Ramayah, T. (2017). Drivers for the adoption of sustainable manufacturing practices: A Malaysia perspective. International Journal of Precision Engineering and Manufacturing, 18(11), 1619–1631.

Adhi Santharm, B., & Ramanathan, U. (2022). Supply chain transparency for sustainability – an intervention-based research approach. International Journal of Operations and Production Management, 42(7), 995-1021.

Ahi, P., & Searcy, C. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. Journal of Cleaner Production.

Al Zaabi, S., Al Dhaheri, N., & Diabat, A. (2013). Analysis of interaction between the barriers for the implementation of sustainable supply chain management. Spring, 895–905.

Alexandra Pinto, L. (2017). Social sustainable supply chain practices and impacts on companies' performance: An exploratory study on Portuguese manufacturing industries. In Proceedings of the 30th International Business Information Management Association Conference, IBIMA 2017 - Vision 2020: Sustainable Economic Development, Innovation Management, and Global Growth, 3677-3696.

Ansari, Z. N., & Kant, R. (2017). A state‐of‐art literature review reflecting 15 years of focus on sustainable supply chain management. Journal of Cleaner Production, 142, 2524–2543.

Baddaoui, J., Ech-Charrat, M. R., Nassimi, A., & Zouadi, T. (2020). The Impact of National Investment in Sustainable Development on the Performance of SSCM: Case of Moroccan Automotive Sector. In Advanced Intelligent Systems for Sustainable Development (AI2SD’2019) Volume 3-Advanced Intelligent Systems for Sustainable Development Applied to Environment, Industry and Economy (pp. 763-776). Springer International Publishing.

Baddaoui, J., Nassimi, A., & Zouadi, T. (2017). Sustainable Supply Chain and reverse logistics management: An empirical study in the Moroccan automotive sector. In Proceedings of the International Conference on Industrial Engineering and Operations Management (pp. 1071-1079).

Baig, S. A., Abrar, M., Batool, A., Hashim, M., & Shabbir, R. (2020). Barriers to the adoption of sustainable supply chain management practices: Moderating role of firm size. Cogent Business & Management, 7(1), 1841525.

Bartos, K. E., Schwarzkopf, J., & Mueller, M. (2024). The role of trainings in improving supplier sustainability performance. World Development, 175, 106482.

Bartos, K. E., Schwarzkopf, J., Mueller, M., & Hofmann-Stoelting, C. (2022). Explanatory factors for variation in supplier sustainability performance in the automotive sector – A quantitative analysis. Cleaner Logistics and Supply Chain, 5, 100068.

Beske, P. (2012). Dynamic capabilities and sustainable supply chain management. International Journal of Physical Distribution and Logistics Management, 42(4), 372–387.

Beske, P., Koplin, J., & Seuring, S. (2008). The use of environmental and social standards by German first-tier suppliers of the Volkswagen AG. Corporate Social Responsibility and Environmental Management, 15(2), 63-75.

Beske, P., Land, A., & Seuring, S. (2014). Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. International Journal of Production Economics, 152, 131–143.

Biswal, J. N., & Muduli, K. (2017). Critical analysis of drivers and barriers of sustainable supply chain management in Indian thermal sector. International Journal of Procurement Management, 10(4).

Brandenburg, M., Govindan, K., Sarkis, J., & Seuring, S. (2014). Quantitative models for sustainable supply chain management: Developments and directions. European Journal of Operational Research, 233(2), 299–312.

Campos, J. K., & Rebs, T. (2018). Opportunities of Combining Sustainable Supply Chain Management Practices for Performance Improvement. In Greening of Industry Networks Studies, 5 (pp. 13-34).

Cee, J., Dieiev, O., Holman, D., Lenort, R., Stas, D., & Wicher, P. (2016). System-oriented Sustainable Supply Chain Management innovations in the automotive industry - SKODA auto case study. Communications - Scientific Letters of the University of Žilina, 18(3), 54-59.

Chkanikova, O. (2016). Sustainable purchasing in food retailing: interorganizational relationship management to green product supply. Business Strategy and the Environment, 25(7), 478-494.

de Góes, B. B., Kotabe, M., & Geleilate, J. M. G. (2021). The diffusion of corporate sustainability in global supply networks: An empirical examination of the global automotive industry. In The multiple dimensions of institutional complexity in international business research (Vol. 15, pp. 435-458). Emerald Publishing Limited.

Diabat, A., Kannan, D., & Mathiyazhagan, K. (2014). Analysis of enablers for implementation of sustainable supply chain management–A textile case. Journal of cleaner production, 83, 391-403.

Dubey, R., Gunasekaran, A., & Childe, S. J. (2015). The design of a responsive sustainable supply chain network under uncertainty. The International Journal of Advanced Manufacturing Technology, 80, 427-445.

Dubey, R., Gunasekaran, A., Papadopoulos, T., Childe, S. J., Shibin, K. T., & Fosso, S. (2017). Sustainable supply chain management: Framework and further research directions. Journal of Cleaner Production, 142, 1119–1130.

Dumitrascu, O., Dumitrascu, M., & Dobrotǎ, D. (2020). Performance evaluation for a sustainable supply chain management system in the automotive industry using artificial intelligence. Processes, 8(11), 1384.

Erol, I., & Velioglu, M. N. (2019). An investigation into sustainable supply chain management practices in a developing country. International Journal of eBusiness and eGovernment Studies, 11(2), 104-118.

Fahimnia, B., Bell, M., Hensher, D. A., & Sarkis, J. (2015). Green logistics and transportation. Cham: Springer International Publishing, 2-197.

Faisal, M. N. (2010). Sustainable supply chains: A study of interaction among the enablers. Business Process Management Journal, 16(3), 508–529.

Finger, G. S. W., & Lima-Junior, F. R. (2022). A hesitant fuzzy linguistic QFD approach for formulating sustainable supplier development programs. International Journal of Production Economics, 247, 108428.

Fraser, I. J., Müller, M., & Schwarzkopf, J. (2020). Transparency for multi-tier sustainable supply chain management: A case study of a multi-tier transparency approach for SSCM in the automotive industry. Sustainability (Switzerland), 12(5), 1814.

Genovese, A., Acquaye, A. A., Figueroa, A., & Koh, S. L. (2017). Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega, 66, 344-357.

Ghadimi, P., Dargi, A., & Heavey, C. (2017). Sustainable supplier performance scoring using audition check-list based fuzzy inference system: A case application in the automotive spare part industry. Computers and Industrial Engineering, 105, 12-27.

Gopalakrishnan, K., Yusuf, Y. Y., Musa, A., Abubakar, T., & Ambursa, H. M. (2012). Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics, 140, 193–203.

Govindan, K., & Hasanagic, M. (2018). A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective. International Journal of Production Research, 56(1-2), 278-311.

Grimm, J. H., Hofstetter, J. S., & Sarkis, J. (2014). Critical factors for subsupplier management: A sustainable food supply chains perspective. International Journal of Production Economics, 152, 159–173.

Hofman, P. S., Blome, C., Schleper, M. C., & Subramanian, N. (2020). Supply chain collaboration and eco-innovations: An institutional perspective from China. Business Strategy and the Environment, 29(6), 2734-2754.

Hunke, K., & Prause, G. (2014). Sustainable supply chain management in the German automotive industry: Experiences and success factors. Journal of Security and Sustainability Issues, 3(3), 15-22.

Isasi-Sanchez, L., Morcillo-Bellido, J., Ortiz-Gonzalez, J. I., & Duran-Heras, A. (2020). Synergic sustainability implications of additive manufacturing in automotive spare parts: A case analysis. Sustainability (Switzerland), 12(20), 8461.

Ivascu, L. (2020). Measuring the implications of sustainable manufacturing in the context of Industry 4.0. Processes, 8(5), 585. Google Scholar, Cross Ref

Jamwal, A., Patidar, A., Agrawal, R., Sharma, M., & Manupati, V. K. (2022). Analysis of barriers in sustainable supply chain management for Indian automobile industries. In Recent Advances in Industrial Production: Select Proceedings of ICEM 2020 (pp. 79-89). Springer Singapore.

Jauhar, S. K., & Pant, M. (2016). Using differential evolution to develop a carbon-integrated model for performance evaluation and selection of sustainable suppliers in Indian automobile supply chain. In Proceedings of Fifth International Conference on Soft Computing for Problem Solving: SocProS 2015, Volume 2 (pp. 515-528). Springer Singapore.

Jayant, A., Singh, S., & Walke, T. (2021). A robust hybrid multi-criteria decision-making approach for selection of third-party reverse logistics service provider. In Advances in Production and Industrial Engineering: Select Proceedings of ICETMIE 2019 (pp. 423-443). Springer Singapore.

Jia, F., Zuluaga-Cardona, L., Bailey, A., & Rueda, X. (2018). Sustainable supply chain management in developing countries: An analysis of the literature. Journal of cleaner production, 189, 263-278.

Kalverkamp, M., & Young, S. B. (2019). In support of open-loop supply chains: Expanding the scope of environmental sustainability in reverse supply chains. Journal of Cleaner Production, 214, 573-582.

Kaur, J., Sidhu, R., Awasthi, A., Chauhan, S., & Goyal, S. (2018). A DEMATEL based approach for investigating barriers in green supply chain management in Canadian manufacturing firms. International Journal of Production Research, 56(1–2), 312–332.

Khatri, J. B., & Srivastava, M. (2015). Sustainable supplier selection: a case of Indian SME. In Managing in Recovering Markets (pp. 441-452). Springer India.

Khera, N., & Mudgal, R. K. (2023). Competitive advantage through sustainable supply chain management: an insight into the Indian automotive sector. International Journal of Public Sector Performance Management, 11(4), 467-480.

Kumar, S., Chattopadhyaya, S., & Sharma, V. (2012). Sustainable Supply Chain Management: A Case Study From Indian Automotive Industry. Advanced Materials Research, 472–475, 3359–3370. https://doi.org/10.4028/www.scientific.net/amr.472-475.3359.

Kurnia, S., Mahbubur, R., Samson, D., & Singh, P. (2014). Exploring the adoption of sustainable supply chain practices in Australia: Current practices and adoption motivations. Retrieved from.

Laari, S., Wetzel, P., Töyli, J., & Solakivi, T. (2022). Leveraging supply chain networks for sustainability beyond corporate boundaries: Explorative structural network analysis. Journal of Cleaner Production, 377, 134475.

Luthra, S., & Mangla, S. K. (2018). When strategies matter: Adoption of sustainable supply chain management practices in an emerging economy's context. Resources, Conservation and Recycling, 138, 194-206.

Luthra, S., Garg, D., & Haleem, A. (2015). Critical success factors of green supply chain management for achieving sustainability in the Indian automobile industry. Production Planning and Control, 26(5), 339-362.

Mangla, S. K., Govindan, K., & Luthra, S. (2017). Prioritizing the barriers to achieve sustainable consumption and production trends in supply chains using fuzzy Analytical Hierarchy Process. Journal of cleaner production, 151, 509-525.

Masoumi, S. M., Kazemi, N., & Abdul-Rashid, S. H. (2019). Sustainable supply chain management in the automotive industry: A process-oriented review. Sustainability, 11(14), 3945.

Mathivathanan, D., & Haq, A. N. (2017). Comparisons of sustainable supply chain management practices in the automotive sector. International Journal of Business Performance and Supply Chain Modelling, 9(1), 18-27.

Mathivathanan, D., Agarwal, V., Mathiyazhagan, K., Saikouk, T., & Appolloni, A. (2022). Modeling the pressures for sustainability adoption in the Indian automotive context. Journal of Cleaner Production, 342, 130972.

Mathivathanan, D., Kannan, D., & Haq, A. N. (2018). Sustainable supply chain management practices in the Indian automotive industry: A multi-stakeholder view. Resources, Conservation and Recycling, 128, 284-305.

Mehdikhani, R., & Valmohammadi, C. (2019). Strategic collaboration and sustainable supply chain management: The mediating role of internal and external knowledge sharing. Journal of Enterprise Information Management, 32(5), 778-806.

Meutcheho, J. P. (2017). A mixed-methods analysis of the effect of global sustainable supply chain management on firm performance. In Implementing triple bottom line sustainability into global supply chains (pp. 58-80). Routledge.

Miranda, M. A., Alvarez, M. J., Briand, C., Urenda Moris, M., & Rodríguez, V. (2021). Eco-efficient management of a feeding system in an automobile assembly-line. Journal of Modelling in Management, 16(2), 464-485.

Muangpan, T., & Neamvonk, J. (2018). Green Supply Chain Management in the Thai Automotive Industry: Confirmed Factor Analysis. International Journal of Business & Management Science, 8(3).

Munir, M. A., Habib, M. S., Hussain, A., Shahbaz, M. A., Qamar, A., Masood, T., Sultan, M., Mujtaba, M. A., Imran, S., Hasan, M., Akhtar, M. S., Uzair Ayub, H. M., & Salman, C. A. (2022). Blockchain Adoption for Sustainable Supply Chain Management: Economic, Environmental, and Social Perspectives. Frontiers in Energy Research, 10, 899632.

Nasrollahi, M., Fathi, M. R., Sanouni, H. R., Sobhani, S. M., & Behrooz, A. (2021). Impact of coercive and non-coercive environmental supply chain sustainability drivers on supply chain performance: Mediation role of monitoring and collaboration. International Journal of Sustainable Engineering, 14(2), 98-106.

Neumüller, C., Lasch, R., & Kellner, F. (2016). Integrating sustainability into strategic supplier portfolio selection. Management Decision, 54(1), 194-221.

Oelze, N., Brandenburg, M., Jansen, C., & Warasthe, R. (2018). Applying Sustainable Supply Chain Management Frameworks to Two German Case Studies. IFAC-PapersOnLine, 51(30), 293-296.

Pagell, M., & Shevchenko, A. (2014). Why research in sustainable supply chain management should have no future. Journal of Supply Chain Management, 50(1), 44–55.

Pagell, M., & Wu, Z. (2009). Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of Ten Exemplars. Journal of Supply Chain Management, 45(2), 37–56.

Patel, P. H., Angrish, A. K., & Nadda, V. (2023). A cross-sector comparison of industry 5.0: Digital technologies in supply chain management of FMCG and the automotive sector. In Opportunities and Challenges of Business 5.0 in Emerging Markets (pp. 99-123). IGI Global.

Paul, S. K., Karuppiah, K., Sankaranarayanan, B., & Ali, S. M. (2023). Barriers for Sustainable Supply Chain Management and Their Overcoming Strategies in Context of the Indian Automobile Industry. In Data Analytics for Supply Chain Networks (pp. 129-165). Cham: Springer International Publishing.

Prashar, A. (2022). Supply chain sustainability drivers for fast-moving consumer goods (FMCG) sector: an Indian perspective. International Journal of Productivity and Performance Management, (ahead-of-print).

Rodríguez-González, R. M., Maldonado-Guzmán, G., Madrid-Guijarro, A., & Garza-Reyes, J. A. (2022). Does circular economy affect financial performance? The mediating role of sustainable supply chain management in the automotive industry. Journal of Cleaner Production, 379, 134670.

Rossi, S., Colicchia, C., Cozzolino, A., & Christopher, M. (2013). The logistics service providers in eco‐efficiency innovation: An empirical study. Supply Chain Management: An International Journal, 18(6), 583–603.

Saji, S. S., Ramasamy, N., & Chandramana, S. B. (2020). Sustainable supply chain management: A hybrid method to assess the drivers. International Journal of Advanced Science and Technology, 29(8 Special Issue), 2165-2182.

Sarkis, J., Zhu, Q., & Lai, K. H. (2011). An organizational theoretic review of green supply chain management literature. International Journal of Production Economics, 130(1), 1-15.

Schöggl, J.-P., Fritz, M. M. C., & Baumgartner, R. J. (2016). Toward supply chain-wide sustainability assessment: A conceptual framework and an aggregation method to assess supply chain performance. Journal of Cleaner Production, 131, 822-835.

Seuring, S., & Müller, M. (2008). Core issues in sustainable supply chain management–a Delphi study. Business strategy and the environment, 17(8), 455-466.

Seuring, S., & Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16, 1699–1710.

Siems, E., Land, A., & Seuring, S. (2021). Dynamic capabilities in sustainable supply chain management: An inter-temporal comparison of the food and automotive industries. International Journal of Production Economics, 236, 108128.

Sonar, H., Mukherjee, A., Gunasekaran, A., & Singh, R. K. (2022). Sustainable supply chain management of the automotive sector in the context of the circular economy: A strategic framework. Business Strategy and the Environment, 31(7), 3635-3648.

Swami, S., Ghosh, D., & Swami, C. (2020). Sustainability Indicators in Supply Chains. Encyclopedia of Renewable and Sustainable Materials: Volume 1-5, 503-511.

Touboulic, A., & Walker, H. (2015). Theories in sustainable supply chain management: a structured literature review. International Journal of Physical Distribution & Logistics Management, 45(1/2), 16-42.

Walker, H., & Jones, N. (2012). Sustainable supply chain management across the UK private sector. Supply Chain Management: An International Journal, 17(1), 15-28.

Wang, G., & Gunasekaran, A. (2017). Modeling and analysis of sustainable supply chain dynamics. Annals of Operations Research, 250, 521-536.

Wissuwa, F., & Durach, C. F. (2023). Turning German automotive supply chains into sponsors for sustainability. Production Planning and Control, 34(2), 159-172.

Wolf, J. (2011). Sustainable supply chain management integration: A qualitative analysis of the German manufacturing industry. Journal of Business Ethics, 102(2), 221–235.

Wolf, J. (2013). The relationship between sustainable supply chain management, stakeholder pressure and corporate sustainability performance. Spring.

Wu, L., & Subramanian, N. (2021). Sustainable Supply Chain Management: Research Pathways Based on Empirical Evidence from Chinese Automotive Companies. International Series in Operations Research and Management Science, 301, 171-197.