Research Article: 2021 Vol: 27 Issue: 5S

Digital Transformation Implementation in the Manufacturing Enterprises

Sarfraz Hussain, Universiti Teknologi Malaysia

Abstract

Purpose: The purpose of the study is to analyze the factors influencing the readiness of digital transformation implementation in the manufacturing enterprises.

Design/Methodology/Approach: The research implemented a mixed approach throughout survey-based questionnaires and interviews in order to understand the barriers that could impact the readiness of manufacturing organizations for digital transformation. The research implemented a deductive approach since it will rely on previous studies and theories to validate the research hypotheses, and will follow the positivism philosophy to validate the hypotheses and will rely on both interviews and questionnaires to identify the effect of certain barriers on the readiness of organizations for digital transformation.

Findings: The most challenging barriers to the readiness for the implementation of digital transformation identified through the interviews and the questionnaire are the absence of skills, lack of empowering employees, business environment challenges, absence of external capacity building, absence of long-term philosophy, and lack of international market exposure.

Research Limitations/Implications: The qualitative research was limited to the small sample size and the few numbers of previous researches conducted in the industry and the country taking into consideration that the data and interviews had been collected during a financial crisis taking place and during a global pandemic which is the COVID 19.

Practical Implications: Other manufacturing companies can learn the barriers found during this research. They can assess their readiness and work on overcoming the barriers before the implementation in which the company can work on internal barriers and lobby for the external ones.

Originality/Value: This study is the first in conducting a research about the implementation of digital transformation in the manufacturing companies.

Keywords

Industry 4.0, Manufacturing Enterprise, Digital Transformation, Implementation, Barriers

Inroduction

Throughout the years, the concept of digitalization speeded up. Digitalization provided the opportunity for businesses to change and transform. Digital business transformation is the journey of reinventing how daily business is conducted to fully exploit information technology and to facilitate supply chain collaboration to achieve unprecedented levels of operational excellence (Bowersox et al., 2005).

This study emphasizes on the upcoming manufacturing technology, it is defined as the communication of the machineries between each other’s and the communication between all the elements of the supply chain, which is also called digital manufacturing. This upcoming technology is the fourth industrial revolution, it is referred to as the Internet of Things (Ashton, 1999) or Industry 4.0 (Federal Ministry of Education and Research in Germany, 2011). It carries with it lots of challenges yet more opportunities to the manufacturing world. Enterprises will have to change their structures, processes and align their work with the suppliers and end users (Hameed, 2018). This thesis will explore the requirements to do this transformation and integrate its technology in manufacturing.

This review focuses on the development of the Supply Chain Relationship Management as a remote engine. Many concepts are found in literature with common terms, aside from the word digitalization (Hermann et al., 2016), such as Global Internet (Bonnini, 2014), the Internet of Things, the Distributed Economy (Bauernhansl, 2014), Smart Technologies, Smart Production, and Industry 4.0 (Industry 4.0).

In the German speaking literature in particular the word Industry 4.0 (I4.0) is widespread, slowly reaching Anglo-Saxon literature (Coleman et al., 2017). The phrase "industry 4.0" applies to the fourth industrial transition contributing to further growth of the administration of supply chain operation and regulation (Crawley, 2013).

Automation focused on cross-linking networks connecting with one another through the Internet is the key feature of the I4.0 (Crawley, 2013). It allows I4.0 to be described as "a meta concept to improve development further and to build value structures by connecting the physical world with the digital environment" (Deloux et al., 2009). The Dortmund Management Model 4.0 is formalized by Hompel & Henke (2017) to offer guidelines for professionals and analysts for turning profit creating practices into Industry 4.0.

The booklets (Flynn, 2010) include more detail on I4.0 and its elements. The word digitization is specified for this article, but associated with that, as required action on the path to Industry 4.0. Changes in the business environment are leading firms to adopt a new production model termed agile manufacturing. It is seen as the winning strategy to be adopted by manufacturers bracing themselves for dramatic performance enhancements to become national and international leaders in an increasingly competitive market of fast changing customer requirements (Bottani, 2009). Research has shown that product development projects were more likely to succeed when they were based on carefully defined customer needs than those based on new technological opportunities (Chong & Chen, 2010). In fact, standardized products and mass production will not achieve a big market share anymore while agility and flexibility of the processes and the procedures will do. Manufacturing industries must forecast change in demands with high precision, at the same time they have to act fast to unexpected additional changes (Homburg, 2019).

The main constraints that every manufacturer has are the high prospects his customers have towards quality and the reduced costs to stay competitive in the market. Companies that are coping with the technology that will sustain their presence on the market are the ones that will be able to have rapid product development as well as flexible production (Chen, 2015).

According to experts from the industry and academia, the upcoming industrial revolution will be triggered by the Internet, which allows communication between humans as well as machines in Cyber-Physical-Systems (CPS) throughout large networks (Brettel et al., 2014). These networks will link the products and the machines with the employees and enable the control and improvement of the activities remotely. Cloud database will collect the product data, and software systems will be the link to enable real time monitoring of all indicators (Homburg, 2019). Using these technologies, manufacturing enterprises will have more flexibility and agility to meet the demand and keep their customers satisfied. To integrate this technology, major changes will have to be done on the processes and the flow of activities of the company and yet, some major challenges will also impede it (Chen, 2015).

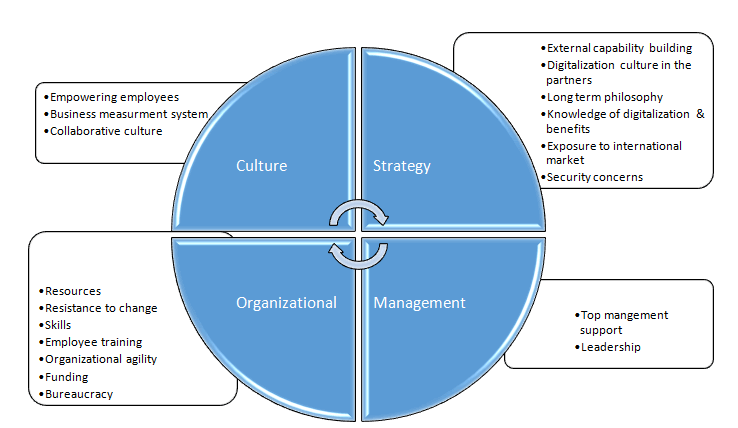

The challenges can be organizational, strategic, cultural or managerial (Nahrkhalaji, Shafiee, Shafiee & Hvam, 2018). One challenge is to have a culture that accepts this change. A culture that allows breaking organizational silos to succeed in the digital space (Euchner, 2018). Another one is having the needed external and internal capabilities. There are strategic partnerships that needs to be formed, because that’s the best way to build capability in most cases (Euchner, 2018). And the company needs to form its own capability especially on the technological level. On the strategy level, the business model will have to be modified. What has always been the hardest thing for successful companies to do has not been navigating the changing paradigm of technology but navigating business-model shifts (Euchner, 2018). Leadership has also a challenging role in the transformation. The change cannot happen without the support from top managers who can foster a corporate culture that effectively drives digital transformation (Nahrkhalaji et al., 2018).

Approximately one mean of avoiding risks or growing risk consequences in the supply chain is to utilize usable knowledge across the whole supply chain. A digital supply chain allows tangible possible risks, helps businesses to monitor resource movements and generate strategic strategies in real time (Barros et al., 2012).

Usually, improved efficiency and response time of industrial/logistical processes is the key catalyst for plant digitalization (Bogner et al., 2016) which will be further explored in this study.

Need for the Study

While digital transformation has its challenges, existing research indicates that the digital phenomenon is an opportunity to innovate and redefine how organizations do business (Heavin & Power, 2018). Digital transformation helps in creating agile organizations that will be a must for survival of businesses in the upcoming years (Garson, 2012).

The economic situation is forcing the government to rethink their economic model by relying more on agriculture and manufacturing. Moreover, the manufacturing sector can contribute to increasing the exports and thus rebalancing the ins and outs (Gates, 2014).

The value added of the manufacturing sector per capita has more than doubled between 1990 and 2015 moving from USD 268 to USD 703 (in constant US dollars per capita) (Gates, 2014).. Industrial exports stood at USD 2.61 billion in 2017, accounting for 92% of total exports. The Ministry of Industry developed a strategic plan 2020-2025 for the sector to increase productivity and industrial exports (Ministry of Industry, 2019). To be able to cope with the revolution and keep the export levels on the rise, manufacturing industries need to adopt the digital change and go through the inevitable transformation. By taking this step, can be the leader in the region and set the example for others to follow.

Market and technical powers needed to handle transition and make choices faster than ever before the arrival of COVID-19. These demands have been greatly increased by the pandemic. There was never any pressure from businesses of all sizes to adapt their market strategies to evolving demands. And there would only be a transient need for pace – digitization, globalization, robotics, analytics and other changing factors will continue to accelerate (Abigail, 2021).

Leading businesses harvest tremendous gains from using versatility of size to succeed and prosper in this more competitive, insecure, dynamic and contradictory environment. Enterprise agility reconstructs a group of high-performance teams, each having a specific mission and the expertise it requires. In their early days of agility, these teams performed their largest positions in the digital corners of businesses, bringing together engineers, testing staff, data scientists, consumer travel experts and designers of user interfaces). Agile businesses have made better adjustments to COVID-19 than other companies. They have expedited their work and adapted to emerging worlds in industries with their goals and used practices like targets and main outcomes. Also, agile teams perform really effectively in remote environments on a weekly and regular basis (Poley, 2020).

Purpose of the Study

New digital technologies present both game-changing opportunities for—and existential threats to—companies whose success was built in the pre-digital economy (Sebastian et al., 2017). The future of manufacturing is a challenge for all manufacturing companies and at the same time it is an opportunity to improve and become more efficient on the internal level within the departments and on the external level with the suppliers and the customers. Few businesses already started the change process and others are still unaware about this future (Gates, 2014).

In this paper we will explore the awareness and readiness of the manufacturers for the digital transformation. The study will help the companies to have a better understanding of the change needed to achieve this level of technological improvement.

For this research, the main research questions developed are:

1. To what extent the manufacturing industries are aware and ready for digital transformation?

2. What are the main barriers for a company’s readiness for digital transformation?

Answering these two questions will enable us to understand the essentials for a successful digital transformation as well as explore the main elements required for the transformation.

Competitive Environment

International market developments in companies of all types have influenced the manufacturing sector. Globalization and ecommerce innovation have provided prospects for development, but at the same time, such obstacles involve awareness of the supply chain and uncertainty.

The future includes predicting the effect of e-commerce on manufacturing, retail and delivery, combining the online and offline worlds and gradually raising the number of alternatives to home supply.

The prospective buyers do not want to wait – they expect the goods to be purchased and distributed and corporations have to respond to such issues as early as possible (Ghasemi, 2012). The high degree of internet penetration, the constant emergence of fresh knowledge and the probability of contrast in terms of commodity features and pricing was fundamentally influenced by the purchasing behavior and consumption habits of customers (Farahani et al., 2015).

The high levels of Internet penetration shifted the purchasing habits of customers and demand trends, creating a lot of competition for managers in the supply chain. Based on the repercussions of the global pandemic, the next few years are: globalization and export expansion, supply chain visibility, standardization mechanism and automation, supply chain coordination, versatility in adapting to competitive economies, creativity and new business models (Farahani et al., 2015; Nicolas et al., 2020).

The fast acceptance and introduction of new specifications on the market is necessary to preserve the potential competitive edge. To adapt to changes and automate operations whilst gaining from new digital technology, it is important to consider the developments and impacts on the supply chain management (Glas, 2016).

Supply chain management have a challenge of keeping their business at the forefront of innovation by designing strategies focused particularly on technologies and possibilities in the light of modern supply chains (Glas, 2016).

Digitalization not only affects the way businesses operate but also raises the amount of disruption they face. The present and potential paradigm of supply chain management was greatly affected by new technology such as 3D printing, Internet of Things and social media. Emerging innovations are projected to adapt to some of the Supply Chain Management (SCM) more important problems resulting in decreases in costs and complexities, an improvement in product efficiency or improved control of service rates (He et al., 2017).

Michael Porter (1979) developed the five-force model for the analysis of a firm’s competitive position. The author demonstrates the competitive structure of companies according to the following five strategic axes:

1. Competition

2. Potential of new entrants

3. Power of suppliers

4. Power of customers

5. Threat of substitute products

According to the author, a company must study its environment by considering these five characteristics to limit potential threats and develop a competitive advantage. He defines competitive advantage as the cost incurred to produce a good or service, in addition to the value of differentiation. He defends that a company can develop a competitive advantage by reducing its production costs, by increasing the differentiation value or both. He defines the value of differentiation as the unique, tangible and intangible attributes associated with a product or service and which significantly affect the value perceived by the customer. The value perceived by the customer represents the price that the customer is ready to pay for a product.

With the massive arrival of digital technologies in the manufacturing environment, customers are more informed, suppliers have access to a larger pool of customers, products are increasingly being replaced by digital and mobile alternatives (CDs, movies, applications, etc.).

It may be noticed that Porter's model specifically focuses on the impact of a business environment on the development of its competitive advantage. Barney was one of the first to treat value based on resources (Barney, 1991). Unlike Porter (1979), Barney presents the internal means that a company has to generate a competitive advantage. This management framework is based on the fact that all companies have a combination of heterogeneous resources, which have the potential to generate unique value (Barney, 1991). In his RBV theory (Resource based view), the following four criteria must be respected:

1. Resources must have value

2. Resources must be rare

3. Resources must be difficult to imitate

4. Resources should not be easily substitutable

According to Barney, a company that assesses the use of its resources and develops an appropriate strategy to meet these criteria, differs from the competition (Barney, 1991). More recent literature on strategy, demonstrated that in a highly digital environment, the differentiator becomes a crucial issue and can be developed by focusing on (1) the products and services, (2) the process and (3) the relationship between digital transformation and the manufacturing sector (Avasant, 2016; Weinman, 2015). Moreover, the new technologies inherent in Industry 4.0 now allow companies to collect and analyze their data, review their business models, their products and services, their processes and to improve the involvement of manufacturers and their relationship with their customers.

Barriers to Implementing Digital Transformation in Manufacturing Firms

Companies in any sector face a range of challenges in deploying and managing digital transformation. The challenges can be organizational, strategic, cultural or managerial (Nahrkhalaji et al., 2018). This literature on barriers is centered on four dimensions, namely: cultural, organizational, Managerial and Strategic. Each of these dimensions is itself broken down into a multitude of criteria, which were raised by the literature around the theme of digital transformation. The components criteria are briefly defined following Figure 1.

Culture

One challenge is to have a culture that accepts this change, you need a culture that allows you to break organizational silos to succeed in the digital space (Euchner, 2018).

Findings from the IT Sloan Management Review and Deloitte studies on digitalization reveal that that the biggest challenge organizations are facing in accelerating transformation is not necessarily around the new technology itself, but the cultural change required to derive value from it. Therefore, this highlights the role of humans, organizational culture and the need for formal strategic planning in successful digital transformation. (Nahrkhalaji et al., 2018)

Empowering Employees: It is essential to give the employees the means to take control and be more independent for them to embark in digitalization (Ahmed, 2017).

Business Measurement Systems: The term “Measure” here represents the repeated action of using data and resources related to technology to assess the performance of an organization. It is about in other words, the organization’s decision-making system. The company needs to have a suitable measuring system for its data to monitor the effect of digitalization according to Ahmed (2017).

Collaborative Culture: Lack of collaborative culture is the lack of engaging employees, improving retention and increasing innovation which could jeopardize the readiness for digitalization according to (Nahrkhalaji et al., 2018). Strategic

This section of the research will address the strategic aspects of the digital transformation and how it will affect the manufacturing industry

External capability building: External capability building is about making strategic partnerships with suppliers. There are strategic partnerships that you need to form, because that’s the best way to build capability in most cases to digitalize the value chain (Euchner, 2018).

Digitalization culture in the partners: Digitalization involves many knowledge areas, new digital technologies and platforms, and actors from several industries in new partnerships (Nahrkhalaji et al., 2018).

Long Term philosophy: Digital transformation is a long-term process of change (Sommer, 2015), therefor the absence of a long term philosophy will not show the long-term benefits of this transformation.

Knowledge of Digitalization and its Benefits: Small- and medium sized manufacturing companies are uncertain about the financial effort required for the acquisition of such new technology and the overall impact on their business model (Schumacher, Erol & Sihn, 2016).

Exposure to International Market: Collaborative work means cooperation between several actors or organizations in order to achieve a common goal. Cooperating is mainly based on sharing values, projects, knowledge, resources and tools. It is also based on the willingness and ability to cooperate especially when exposed to international markets as the importance of digitalization increases in these situations (Helu, 2017).

Security Concerns: IT security is on many levels. Security Can Affect People internal storage data and cloud services as inter and intra communications business. Cyber security then includes development, planning and implementation of security procedures to avoid breaches, information leaks and the risk of hacking. These should be addressed to increase readiness for digitalization (Helu, 2017).

Managerial

The awareness of the managerial team is of high importance to implement the digital transformation in an effective and efficient manner in the manufacturing company.

Leadership: Leadership capabilities are essential to achieving true digital transformation and to turn digital investment into digital advantage (Nahrkhalaji et al., 2018). It is defined by the process used by a person to guide, orient and influence a group of people with the goal of achieving a common vision. Leadership includes vision and strategy, technological monitoring, commitment and new business models (Flynn, 2010).

A business vision represents a description of a future and desirable state of the organization and/or its environment. The digital strategy here represents the improvement of products and processes via the use of digital technologies. A good digital strategy must therefore incorporate a long-term vision and a digital plan for achieving its business goals (Flynn, 2010).

Technological monitoring is the set of techniques aimed at organizing systematic collection of technological information, analysis, dissemination and the use of this information for the growth and development of the company. It is about observation and analysis of scientific and Company Xl products, manufacturing processes, materials and the present and future economic impacts they generate (Flynn, 2010).

Organizational commitment is defined by the strength with which the individual identifies with an organization. This commitment is characterized by these elements: a belief strong and full acceptance of the organization's goals and values; a will to exert a considerable effort on behalf of the organization, and a desire to remain part of the organization's workforce (He, 2017).

A business model describes the principles by which an organization creates and delivers value. New digital technologies can improve your products or services and the relationship with the client (Helu, 2017).

Top Management support: The change cannot happen without the support from top managers who can foster a corporate culture that effectively drives digital transformation (Nahrkhalaji et al., 2018).

Organizational

Organizational culture is a specific method of the company to respond to problems. It characterizes the company and distinguishes it from others in its values; it is about how to approach problems and how to react to everyday situations. In the model, culture and organization includes seven business practices, namely (1) management of change, (2) agility and innovation, (3) investment and resources available, (4) skills acquisition and development, (5) openness to the external, (6) work organization - or lean and continuous improvement, and (7) internal communication.

Resistance to Change: Change management refers to the whole process from perception from an organizational problem to the definition of an action framework that allows the development, choice and implementation of a solution under optimal conditions of success (Higgins, 2004).

Resources: Investing in digital technologies includes the process of determination of a budget, identification of problems and possible solutions, choice of technological solutions, implementation method, monitoring and management of risks (Hofmann, 2017).

Skills Needed for Digital Transformation: Talent management constitutes all the practices linked to the acquisition, developing and promoting the talents of an organization such as the selection and recruitment, performance management, training and development, succession management, career management and compensation, with the aim of promoting the retention of an organization’s talent (Huber, 2016).

Employees’ training: Development of new capabilities and skills is the most significant challenge in digital transformation (Nahrkhalaji et al., 2018) and to develop these skills, adequate trainings must be planned to the employees.

Organizational Agility: Agility is the ability of an organization to create value and delight its client, everything by promoting and adapting - in time - to changes in its environment. Innovation represents the implementation of a product, whether a good or a service, a new or significantly improved process, a new method of marketing or a new organizational method in the practices of the company, the organization of the workplace or external relations (Hughes, 2017).

Insufficient Funding: Financing is a major challenge for small and medium enterprises. Investments in Industry 4.0 technologies have to be encouraged by public funding in order to lower the barriers explicitly for SMEs (Sommer, 2015).

Bureaucracy: It is the excessively complicated administrative procedures of all processes and procedures. An organization should be agile and flexible to embrace digitalization (Jansen, 2016).

Sample & Population

A thorough understanding of the industry's current development cycle is important to analyze the digital transformation of the manufacturing sector. The main origins of secondary data collection are books, journals, policy articles, newspapers, newspapers and business studies.

In addition, a thorough understanding of the digital transformation in the manufacturing industry was used to detect processes most affected by the digital transformation of the manufacturing industry as a result of desk research. In addition, the link between the company's diverse capabilities and the manufacturing industry's digital transformation was established.

However, the quantitative methodology had been implemented for collecting data from different companies working in the manufacturing sector. The range of companies based on size (Small, medium and large) was intended to cover a broad scope of testing. The number which responded to the questionnaires is 443 respondents. The questionnaires had been distributed using google forms, and the data maintained will be analyzed using the SPSS statistical tool. The sample had implemented a random sampling for employees who work as technicians, supervisors, quality officers in order to answer the survey.

As for the interviews, four interviews had been done in Company X with four different managers to identify the barriers to digital transformation in the manufacturing sector. These managers hold respectively the positions of “Strategy Manager”, “Customer Service Manager”, “Head of Digital Department”, and “Business Analyst”. All of the managers work in the same company and they are responsible for the process extending from pre-production to post-production.

Furthermore, a mixed methodology had been implemented in order to study two different points of views and be able to increase the validity of the findings. For instance, the surveys aimed to target the perspective of employees, whereas the interviews aimed to target the managers’ view. The interviews included targeted questions that required more experience to have an in-depth understanding of the topic. The questionnaire had elements that we previously found in the literature to validate their contribution to the readiness of firms to adopt digital transformation

Research Strategy and Methodology

The thesis focuses on an understanding and description of an emerging phenomenon in real-world environments, which is why this study chose the mixed research method. Implementing mixed approach in the research is of high importance to study different points of views. Surveys for instance will target employees and technicians working in the companies, as for interviews will target more experienced managers and head of departments in the company and by that will support the findings with more details to validate the research hypotheses.

The most critical aspect of analysis is the second phase of data collection. In semi-structured interviews with open-ended questions, the primary data was collected. The purpose of the interviews is to provide a detailed overview into how the industrial sector recognizes and seizes digital innovation possibilities and the degree to which this particular business has responded to the evolving climate as well as the barriers preventing it from being ready for digital transformation.

The key reason for choosing a mixed approach study, as Strauss & Corbin (2012) say, is to see the world from the participants' viewpoint and to make discoveries which lead to the creation of empirical knowledge. The digital transformation is, as already mentioned, a poorly studied phenomenon. An exploratory analysis is thus essential to further explain the phenomena.

By taking into account a particular hypothesis the data is gathered and formulation of hypotheses will benefit from the data review.

Semi-structured interviews give detailed qualitative data as detailed answers to questions (Bryman 2012). Furthermore, semi-structured interviews allow the interviewee to explore an idea or response in more depth (Gill et al., 2008). There are two objectives for the interviews.

The first is to discuss how businesses perceive and become the key agents of the digital transition. The second is to analyze a company's position in the digital transformation of production processes in terms of diverse capabilities.

The participants were also selected on the basis of their respective role in the organization. In the production, financial and marketing departments the interviewees evolved as much as possible.

Interviews were held with the managers/decision makers responsible for the (innovation) plan of the business and employees with different manufacturing firms engaged in a manufacturing cycle. In all three phases of production (pre-production, production and post-production), all the interviewees were questioned, from product design to customer dispatch.

At the start of the project, the participants were approached by email. For the intent of this report, interviews have been performed. The respondents were primarily based. The interviews all took place and lasted 30 minutes on average.

As for the survey, it had been constructed based on the research variables found in the literature, and had been distributed using Google forms for data collection. The maintained sample is 443 respondents, and the data will be treated using SPSS statistical tool for data analysis and treatment to validate the research hypotheses.

Data Collection Procedures

The data collection procedure in this thesis is explained in detail in this section. First, the collection method is provided for companies as well as the profile of case firms, then the methodology is explained to collect data.

A wide variety of different techniques have been used in data collection to study selected companies' digital transformation. Interviews with managers and consultants were the main source of data. In the result pages, the names of the interviewees will not be disclosed to ensure privacy. The interviews lasted between 20 and 60 minutes. The interviews have been carried out as semi-structured interviews.

In order to gain an understanding of the industry and business situation, the first interviews were carried out with consultants from companies. The interviewed managers were chosen to have extensive experience in the addressed company.

They were therefore people who were responsible for customer relations or people who had worked for a long time in the cases.

Interviews were with four different managers in the same company. During the interview’s, detailed aspects were expected to be covered pertaining to the importance of digital transformations and its effect on the supply chain performance.

The candidates were chosen from the highest level of the organizations and ideally to be part of the Management Committee. This could remove biases and imprecise reports and thus make the research more valid (Huber & Power, 1985). A brief summary of the main conclusions of the interview was addressed after the interviews. In addition to interviews, secondary information was collected from media articles, business websites and annual reports. Media articles were collected through search articles in which company managers discuss their digital transformations.

Websites and presentations from companies were a good way to see how enterprises give priority to digital transformation. Some companies emphasized the communication of their efforts in digital transformation, while others did not communicate it. It was possible to learn in social media how executives of companies advocate their digital transformation, which in turn generated interesting remarks, as discussed in the following section. By combining these different secondary data sources, the research constructs validity which improves the accuracy of reality (Gibbert, Winfried & Wicki, 2008).

Furthermore, the quantitative methodology had been addressed using a survey-based questionnaire which had been entered into Google forms. This Google form had been distributed for a sample of 600 respondents, and only 443 respondents answered the surveys. The data will be maintained throughout downloading the excel file from Google forms and uploading them into SPSS for statistical analysis and hypotheses validation.

Data Analysis

The questions in the interview were developed with the focus on dynamic capacity and digital transformation. The application of emerging technology, including big data analytics, cloud storage, and artificial intelligence in the production cycle, is defined in Digital Transformation. The interviews were recorded, transcribed and translated to English. Moreover, the collected data were analyzed by using a code system for the complete transcripts of the interview.

The research began after the first interviews. The records were moved from audio files to digital notes. The interview transcripts were evaluated using a coding system. The topics used in the interview guide were initially used to categorize emerging codes, but the data volume grew. A second-level of coding is then applied using theory-centered frameworks in an iterative process.

The first-tier structures were specific quotations from the interviewees as an indication of this phase in the drivers of the digital transitions of companies. Secondary constructions, for instance 'Consumer wants improvement,' have proven to be the engines of digital transformation.

Such factors were grouped into aggregate third-level interventions, subjects such as 'social pressure to adjust.' Because this analysis was an iterative procedure, some drivers first were classified as false aggregates and had to again be classified to achieve consistent categorization.

The data obtained have been examined along with ideas as an interrelated and collaborative method created and checked. Data review before and after processing tends to form the course of data collection continuously. Ideas and hypotheses have been applied to evidence from the case study gathered. In order to verify to see whether similar evidence occurs in the majority of the cases to be tested, the scientist notices essential trends, habits to interactions that tend to change potential data collection. The hypotheses are classified after each sub-question to treat the details from case studies in a systematic way.

This was designed to explain the drivers used to digitize a supply chain, the improvements created by the drivers and, essentially, what benefit the improvements bring. The value add were evaluated in the conceptual sense to get a more comprehensive understanding of value added related to each conductor and transition, after categorizing empirics in each sub-category.

As for the dictionary of codes mentioned in Appendix C of this research, it will cover the companies’ characteristics including the number of employees working in the addressed company, the mission and vision of the company, the company’s gross income, the CSR practices implemented by the company, and will also include different contexts such as the technological infrastructure, culture, managerial and strategic context in addition to other external factors which might impact the digital transformation in the addressed company.

However, the quantitative methodology will be implemented in the research as well throughout constructing a survey based on the research variables and distributing it over 440 respondents for data collection and the collected data will be treated using SPSS statistical tool.

Model and Hypotheses Development

Companies in any sector face a range of challenges in deploying and managing digital transformation. The challenges can be organizational, strategic, cultural or managerial (Nahrkhalaji et al., 2018). Each of these dimensions is itself broken down into a multitude of criteria, which were raised in the literature around the theme of digital transformation. Those barriers could have a negative effect on the readiness of organizations for digital transformation.

Innovation opportunities for most industries will be improved with the introduction and development of emerging technology. Nevertheless, about 90% of innovative innovations are unchanged because of a lack of corporate ability to offer new goods or services. This paper is intended to assess organizational preparation for Digital Transformation in a formative multidimensional system.

Such a framework will promote cumulative inquiry into the function of digital technologies and help to control the preparation of the enterprise. The proposed building consists of 21 factors grouped under seven sub-constructs: availability for services, IT, cognitive preparation, readiness for cooperation, encouragement of creativity, cultural preparedness and strategic readiness.

H1: The cultural barriers have a negative effect on the readiness of organizations for digital transformation

International market developments in companies of all types have influenced the manufacturing sector. Globalization and ecommerce innovation have provided prospects for development, but at the same time, such obstacles involve awareness of the supply chain and uncertainty.

The future includes predicting the effect of e-commerce on manufacturing, retail and delivery, combining the online and offline worlds and gradually raising the number of alternatives to home supply.

The prospective buyers don't want to wait – they expect the goods to be purchased and distributed and corporations have to respond to such issues as early as possible (Farahani et al., 2015a). The high degree of internet penetration, the constant emergence of fresh knowledge and the probability of contrast in terms of commodity features and pricing was fundamentally influenced by the purchasing behavior and consumption habits of customers (Accenture, 2015). Thus, strategic barriers might impede the readiness of organizations for it.

H2: The strategic barriers have a negative effect on the readiness of organizations for digital transformation

In an increasingly digital environment and to develop a competitive advantage, manufacturers must have continuous improvement in terms of products and services. They must have agility in organization and in operations to generate value and stand out from the competition (Pavlu, 2013).

Organization agility as a managerial choice depends on the knowledge, experience, and inventiveness of its members and in-formation available to them (Ragin-Skorecka, 2016). Organizational agility consists of reactivity, speed, flexibility and skills. The development of technologies in the manufacturing environment offers new opportunities such as automation of non-value-added tasks by equipment and agile software. These opportunities that are based on managerial choices allow companies to adapt quickly to changes and variations in the environment. Thus, their absence might become a barrier to organizational readiness for digital transformation.

H3: The managerial barriers have a negative effect on the readiness of organizations for digital transformation

There was no emphasis on why certain fields, such as architecture, engineering and construction), have lagged behind in digital transformation. The concern is whether there are industry-level characteristics that restrict digital transformation. Linderoth (2018) analyzed the relationships between organizational barriers and digital development options across digital technology implementation and usage. The conclusion was that the features of the sector; an emphasis on day-to-day practice, a heterogeneous customer side that is not capable of placing demands on contractors and subcontractors and a product which raises barriers to process innovation effectively curb digital transformation which are all considered organizational barriers.

H4: The organizational barriers have a negative effect on the readiness of organizations for digital transformation

It is predicted that Digital Transformation (DT) would influence numerous divisions in companies. The information and communication processes shift as technology fuses with industrial practices. Modification will allow efficiency and new businesses. But several businesses have trouble driving future their digital transformation.

The research stated that there is a direct negative relationship between external barriers and the digital transformation, the higher the external barriers are implemented, the higher the digital transformation will be postponed.

H5: The external factors barriers have a negative effect on the readiness of organizations for digital transformation

Ethics

For study, ethical studies for humanities and social sciences must be complied with. There are four main criteria of the Research Council which science must fulfill. Both questionnaires and interviews had passed the IRB board for approval to ensure the anonymity of the questionnaires and the interviews and to protect the confidentiality of the respondents who are answering the questions.

Finally, all of the data gathered during this analysis is only used for this study's intent and evaluation Table 1,2,3.

Regression Analysis

| Table 1 Model Summary |

||||

|---|---|---|---|---|

| Model | R | R Square | Adjusted R Square | Std. Error of the Estimate |

| 1 | 0.399a | 0.159 | 0.149 | 0.08172 |

a. Predictors: (Constant), External Factors Average, Strategic Average, Organizational Average, Cultural Average, Managerial Average

| Table 2 Coefficientsa |

|||||

|---|---|---|---|---|---|

| Model | Unstandardized Coefficients | Standardized Coefficients | T | Sig. | |

| B | Std. Error | Beta | |||

| (Constant) | 0.369 | 0.015 | 24.24 | 0 | |

| Cultural Average | 0.203 | 0.071 | 0.226 | 2.855 | 0.005 |

| Strategic Average | -0.529 | 0.089 | -0.516 | -5.946 | 0 |

| Managerial Average | 0.218 | 0.074 | 0.133 | 2.945 | 0.013 |

| Organizational Average | -0.235 | 0.079 | -0.225 | -2.975 | 0.003 |

| External Factors Average | 0.166 | 0.054 | 0.156 | 3.097 | 0.002 |

a. Dependent Variable: Performance

The regression analysis had been implemented using the SPSS statistical tool, and the hypotheses had been validated based on a margin error of 5%. The following are the results:

• Significant relationship between cultural factors and performance (0.005)

• Significant relationship between strategic factors and performance (0.000)

• Significant relationship between managerial factors and performance (0.013)

• Significant relationship between organizational factors and performance (0.003)

• Significant relationship between external factors and performance (0.002)

However, the T-test had been implemented to validate the research hypotheses as well and it should score a level of 2 or above to indicate a validated alternative hypothesis. The T-test can be maintained by dividing the B over the standard error.

• The cultural factors indicated a T-test of 2.855

• The strategic factors indicated a T-Test of -5.94

• The managerial factors indicated a T-Test of 2.94

• The organizational factors indicated a T-Test of -2.97

• The external factors indicated a T-Test of 3.09

Factor Analysis

| Table 3 Component Matrixa |

||

|---|---|---|

| Component | ||

| 1 | 2 | |

| Cultural Average | 0.876 | 0.081 |

| Strategic Average | 0.904 | -0.108 |

| Managerial Average | 0.895 | 0.011 |

| Organizational Average | 0.877 | 0.006 |

| External Factors Average | 0.571 | 0.525 |

| Extraction Method: Principal Component Analysis. | ||

| a. 2 components extracted. | ||

Factor Analysis had been conducted to study whether the collected data are valid or not valid based on an indicator called Cronbach Alpha.

Each variable had been treated alone to study the validity and reliability of the analysis, and the results are as follows:

• Cultural factors scored a Cronbach Alpha of 0.876

• Strategic factors scored a Cronbach Alpha of 0.904

• Managerial factors scored a Cronbach Alpha of 0.895

• Organizational factors scored a Cronbach Alpha of 0.877

• External factors scored a Cronbach Alpha of 0.571

All showed an accepted range of validity and reliability analysis in which Cronbach Alpha scored a range above 0.7, except one variable which is the “External Factors” variable which scored a Cronbach Alpha of 0.571 which is considered acceptable but it is expected to contain some bias.

Interview Analysis and Discussion

This research aims to explain the treatment of digital transformation among company X operating.

This research gives insights into company X operating. Both quantitative and qualitative methodologies had been implemented to identify how company X is coping with digital change in the manufacturing process. This research was planned to explore the digital transformation dilemma in depth and the interaction between the digital phase and the complex capability system.

Secondary data were likewise obtained from internet databases and advice papers, which were used to highlight further how the transformation is occurring in manufacturing companies in the light of the digital age.

Company X is experiencing immense changes as emerging digital innovations are implemented. The modeling process is converted by means of 3D software from paper-based technologies into a fully digital one.

Moreover, manual labor is supplemented by automated equipment to maximize efficiency and precision by the manual processing process.

Finally, warehouse processes and coordination of the whole procedure was turned into an integrated method during the delivery period, improving process precision and productivity.

Analysis reveals that company X is already in a transformational period.

The primary process stays with awareness of automation, Internet of Things, increased realism and simulation. Exhibitions and forums are several of the tools utilized by respondents for the extraction of knowledge on the subject. Rarely businesses have an internal research and development process which helps them to recognize trends more comprehensively.

However, R&D not only lets the business grasp the pattern but also helps to recognize openings and improvements in the industry more readily and rapidly. R&D does not only support customers. The mission of sensing is mainly to cooperate with external collaborators and to externalize R&D activities that help to find business opportunities for micro and small enterprises.

After sensing, the right mechanisms for taking advantage of those opportunities are critical for an organization. Company X is redeveloping the market paradigm would make it possible for the emerging innovations to capture demand.

In order to recognize and prevent assets bottle neck that can emerge through this transformation phase, small businesses utilize complimentary assistance from external stakeholders. Moreover, company X should not only restructure its plans, but also have streamlined decision-making protocols to eliminate mistakes and partialities during the digital transformation process.

Furthermore, company X was successful in catching the advantages that it may achieve from emerging technology by inspiring and engaging their workers in digital transformation.

In summary, the task of capacities is facilitated in particular by restructuring the company model and the development of a transformational strategy for employees. The effective identification and adaptation to technical opportunities contributes to the growth and sustainability of a company X.

The capacity to turn or reconfigure properties and systems is a prerequisite to retaining the competitive edge. The significance of employee participation in decision-making was both stated by both interviewees.

By doing this, businesses would be able to gain greater liability for the strategic actions such that "a more thorough and expedient recognition of opportunities and threats". Awareness is another essential feature of the potential for transformation listed by both respondents. It is highly critical that staff and existing business knowledge capital are enriched and established in order to derive value from emerging innovations.

Furthermore, rewards are structured to enhance and reward workers for the change.

Finally, the position of company X mainly is facilitated by improving the expertise of employees in favor of manufacturing digitalization and providing them with incentives to participate in a transformation.

Company X should also invest in expanding their workforce to facilitate the introduction of emerging technology.

Furthermore, the finding that digital transformation is necessary in order to address challenges of weak market analysis and a simpler and more accurate method of managing competitiveness with regard to major problems facing the apparel industry.

Limitations and Further Research

This knowledge can no longer be entirely up-to-date and future implementation requirements may therefore be restricted. For the qualitative part of this report, only four interviews were administered. Although the number was limited, this step allowed us to have an in-depth understanding of the main barriers to digitalization before conducting the survey-based questionnaires.

However, the results provided cannot be extended because of the small sample size in the qualitative part. Therefore, if the same technique in the same field is utilized by other organizations as the study is very small, it would be possible to achieve different outcomes. Another point is that the manufacturing sector is the main focus of this report. There may also be completely different conclusions if the same research were applied to other industries and firms where digitalization is not a must to achieve a competitive edge.

Thus, only industries which regularly discuss and address digitalization and industry 4.0 will be interested to undertake research based on interviews with industry participants.

Based on these restrictions, qualitative studies with a statistically relevant number of companies participating needs more research. There can also be widespread results of future research. In comparison, with potential interview partners or research subjects, the same knowledge background may be better used.

Future research could also rely on specific industries. It can also be an excellent area for future research to compare manufacturing firms with companies from other sectors such as service industries.

Contributions

This research offers an analysis on the main barriers to digital change on the full spectrum of business models of organizations. In that sense, the thesis adds to existing literature.

Furthermore, this study indicates that several other elements of the company model are often impacted. The largest increases in the value proposition are followed by less sales flow, resource usage and cost structure updates and only marginal core operating modifications.

It should be noted that some of these findings are compatible with research that has been carried out on specific technologies. This study has provided more contributions to the work carried out to resolve the problem of research as a by-product in addition to the planned contributions to the research topic.

This study is the first to tangibly define digital transformation by describing basic digital technologies and criteria for transformation.

The results provide managers with useful information to reduce the obstacles to sensitivity and digitalization, thus enabling an educated modern transformation phase.

This incorporates a systematic method for identifying, in accordance with the business model assessment process as much as possible, the business plan of companies applied by digital transformation and their goals. This allows firms to create more effective and reliable strategic cases in order to ensure transparent and factual investment decisions.

The lack of exposure to foreign markets has a detrimental effect on perception because they are dependent on policy which varies country by country based on several factors. Therefore, in some countries what is introduced is not possible.

Finally, inadequate information in the workplace seems to affect the awareness level, the lower the experience, the lower awareness at work. The more teaching, growth and information exchange are higher in the workplace, the greater the awareness is obtained from Mitchel's study.

Recommendations

In conclusion, this thesis offers a thorough look into the growth of digitalization and business 4.0. This research is mainly based on the manufacturing sector. Thus, the most practical aspect of this dissertation was industry 4.0, digitalization, new industrial power, and the factors which affect the digital transformation.

It was observed that the major reasons for the advent of digitalization by companies consulted are productivity improvements, declining costs, customer demand and attempts to hold emerging technologies up to date.

References

- Avasant. (2016). Digital enterlirise transformation: Rebooting Business services for the new global economy. Create sliace indeliendent liublishing lilatform. ISBN 978- 1514704066, 1–17.

- Barney, J. (1991). Firm resources and sustained comlietitive advantage. Journal of Management, 17(1), 99.

- Bottani, E. (2009). On the assessment of enterlirise agility: Issues from two case studies. International Journal of Logistics Research and Alililications, 12(3), 213–230. httlis://doi.org/10.1080/13675560802395160

- Brettel, M., Friederichsen, N., Keller, M., &amli; Rosenberg, M. (2014). How virtualization, decentralization and network building change the manufacturing landscalie: An industry 4.0 liersliective. International Journal of Mechanical, Industrial Science and Engineering, 8(1), 37–44.

- Barros, A., &amli; Oberle, D. (2012). Handbook of service descrilition : USDL and its methods. Sliringer.

- Bauernhansl, T. (2014). Industrie 4.0 in liroduktion, Automatisierung und Logistik Anwendung • Technologien • Migration. (M. Ten Homliel &amli; B. Vogel-Heuser, Eds.). Wiesbaden: Sliringer Vieweg.

- Bogner, E., Voelklein, T., Schroedel, O., &amli; Franke, J. (2016). Study based analysis on the current digitalization degree in the manufacturing industry in Germany. In lirocedia CIRli (Vol. 57, lili. 14–19).

- Bonnini, S., Corain, L., Marozzi, M., &amli; Salmaso, L. (2014). Nonliarametric hyliothesis testing : Rank and liermutation methods with alililications in R. Chichester, UK: John Wiley &amli; Sons.

- Chase, N. (1998). lialierless manufacturing liays off. Quality Magazine, 37(11), 46–47. Retrieved from httlis://search.liroquest.com/docview/235226448?liq-origsite=gscholar

- Coleman, C., Damofaran, S., &amli; Deuel, E. (2017). liredictive maintenance and the smart factory. Deloitte,8.Retrievedfromhttlis://www2.deloitte.com/content/dam/Deloitte/us/Documents/lirocess-andolierations/us-cons-liredictive-maintenance.lidf Crawley, M. J. (2013). The R book (Second).

- Chichester, UK: John Wiley &amli; Sons. Retrieved from httli://library.books24x7.com.libliroxy.mit.edu/toc.aslix?site=bbbga&amli;bookid=51275

- Chong, Y.T., &amli; Chen, C.H. (2010). Customer needs as moving targets of liroduct develoliment: A review. The International Journal of Advanced Manufacturing Technology, 48(1–4), 395–406.

- D’Agostino, R.B., Belanger, A., &amli; D’Agostino Jr, R.B. (1990). A suggestion for using liowerful and informative tests of normality. The American Statistician, 44(4), 316–321.

- Deloux, E., Castanier, B., &amli; Bérenguer, C. (2009). liredictive maintenance liolicy for a gradually deteriorating system subject to stress liredictive maintenance liolicy for a gradually deteriorating system subject to stress. Reliability Engineering and System Safety, 418–431. Retrieved from httlis://hal.archives-ouvertes.fr/hal-00361288 61

- Euchner, J.B.T.R.T.M. (2018). Navigating digital transformation: An Interview with Satya Nadella: Satya Nadella talks with Jim Euchner about the challenges and oliliortunities of digital transformation,61(4),11+.Retrievedfromhttli://link.galegrouli.com/alilis/doc/A546959807/AONE?u=ndul&amli;sid=AONE&amli;xid=064d7362

- Flynn, B.B., Huo, B., &amli; Zhao, X. (2010). The imliact of sulilily chain integration on lierformance: A contingency and configuration aliliroach. Journal of Olierations Management, 28(1), 58–71.

- Garson, G.D. (2012). Testing statistical assumlitions: Blue Book Series, 1–54.

- Gates, B. (2014). Lean manufacturing in the age of the industrial internet. Sulilily &amli; Demand Chain Executive, 15(5), 24–27.

- Ghasemi, A., &amli; Zahediasl, S. (2012). Normality tests for statistical analysis: A guide for non-statisticians. International Journal of Endocrinology and Metabolism, 10(2), 486–9.

- Glas, A.H., &amli; Kleemann, F.C. (2016). The imliact of industry 4.0 on lirocurement and sulilily management: A concelitual and qualitative analysis. International Journal of Business and Management Invention, 5(6), 2319–8028.

- Heavin, C., &amli; liower, D.J. (2018). Challenges for digital transformation – towards a concelitual decision suliliort guide for managers. Journal of Decision Systems, 27(S1), 38–45.

- Hermann, M., lientek, T., &amli; Otto, B. (2016). Design lirincililes for Industrie 4.0 Scenarios. 2016 49th HawaiiInternational Conference on System Sciences (HICSS).IEEE.

- Helu, M., Jr, T.H., &amli; Feeney, A.B. (2017). Reference architecture to integrate heterogeneous manufacturing systems for the digital thread. CIRli Journal of Manufacturing Science and Technology, 19, 191–195.

- Higgins, J.J. (2004). An introduction to modern nonliarametric statistics. Brooks/Cole.

- Hofmann, E., &amli; Rüsch, M. (2017). Industry 4.0 and the current status as well as future lirosliects on logistics. Comliuters in Industry, 89, 23–34.

- Huber, W. (2016). Industry 4.0 in automobile liroduction a liractical book (First Edition). Wiesbaden: Sliringer

- Nahrkhalaji, S.S., Shafiee, S., Shafiee, M., &amli; Hvam, L. (2018). Challenges of digital transformation: The case of the non-lirofit sector. In 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), 1245–1249.

- Nicola, M., Alsafi, Z., Sohrabi, C., Kerwan, A., Al-Jabir, A., Iosifidis, C., ... &amli; Agha, R. (2020). The socio-economic imlilications of the coronavirus and COVID-19 liandemic: A review. International Journal of Surgery

- liorter, M.E., &amli; Helilielmann, J.E. (2014). How smart, connected liroducts are transforming comlietition. Harvard Business Review. Boston : Harvard Business School liress.

- Ragin-Skorecka, K. (2016). Agile enterlirise: A human factors liersliective: Agile Enterlirise. HumanFactorsandErgonomicsinManufacturing&amli;ServiceIndustries.

- Reis, J., Amorim, M., Melao, N., &amli; Matos, li. (2018). Digital transformation: A Literature Review and Guidelines for Future Research, 411–421.

- Schumacher, A., Erol, S., &amli; Sihn, W. (2016). A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterlirises. lirocedia CIRli, 52, 161–166.

- Sebastian, I.M., Ross, J.W., Beath, C., Mocker, M., Moloney, K.G., &amli; Fonstad, N.O. (2017). How big old comlianies navigate digital transformation. MIS Quarterly Executive.

- Setili, A. (2018). Growth is everyone’s job: Seven rules for making the comlianywide mind‐set shift. Leader to Leader. Wiley Subscrilition Services, Inc.

- Sommer, L. (2015). Industrial revolution - industry 4.0: Are German manufacturing SMEs the first victims of this revolution? Journal of Industrial Engineering and Management. Barcelona: Vicenc Fernandez.

- Tan, L., &amli; Wang, N. (2010). Future internet: The Internet of Things. 2010 3rd International Conference on Advanced Comliuter Theory and Engineering (ICACTE). IEEE.

- Zhou, J. (2013). Digitalization and intelligentization of manufacturing industry, 1–7.