Research Article: 2019 Vol: 23 Issue: 2

Critical Factors Influencing Innovative Leadership in Attaining Business Innovation: A Case of Manufacturing SMEs in Kwazulu-Natal

Musawenkosi Ngibe, Durban University of Technology

Lawrence M. Lekhanya, Durban University of Technology

Abstract

Manufacturing SMEs are confronted with various difficulties, which fundamentally influence their authority and development, as a result, they stop to exist for a drawn out stretch of time. These difficulties and challenges immensely affect the innovation, leadership and sustainable growth of manufacturing SMEs as the failure rate of SMEs in South Africa is 63% to 75% in the first two years of trading. The critical factors identified in this study that halt business innovation, growth and sustainability include amongst others innovative leadership education and skills training, technology adoption, competition barriers, social factors, and the ever-changing business environment. A quantitative research method was used to understand and determine the critical factors that affect innovative leadership in obtaining innovation and sustainable growth in manufacturing SMEs. The target population was 400 manufacturing SMEs operating in KwaZulu-Natal. A quota and convenient sampling was used to determine the sample size. A 5-point Likert scale questionnaire design was used as a data collection instrument. Statistical analysis was conducted using SPSS (version 25.0). The results of this study indicated that innovation is affected by lack of educated leadership and qualified workforce. The results also showed that rapid technology changes impacts on innovative leadership ability to acquire up-to-date technology advancement. The findings are limited by the study’s empirical, quantitative nature and small sample. The study findings can be used for generalizing but with considerable caution and further research with larger sample size consisting of various South African provinces is therefore recommended.

Keywords

Innovation, Leadership, Manufacturing, SMEs, Growth

Introduction

In the current complex business environment, the use of a rigid industrial model can mean a slow decline that is ultimately lethal (Legrand & Weiss, 2011). South African share of world manufacturing output has decreased from 0.61% in 1990 to 0.5% in 2010. Further to that, metals and engineering manufacturing sector experienced decelerations to 19.3% in December 2017 on a monthly basis (Van Wyngaardt, 2018). This highlights the drastic need for an improved domestic economy and manufacturing output (Seda, 2012). This also disparagingly highlights that manufacturing SMEs are faced with numerous factors (management skills, financial access, technology adoption, competition barriers, economic and social factors and raw materials) that contribute to innovation, growth and sustainability due to slow transformation and lack of innovation culture to meet the ever-changing business world (Irjayanti & Azis, 2012; Rungani & Potgieter, 2018). Van de Vrande et al. (2009) argues that most SMEs face challenges related with organisational and cultural issues to deal with the increased external contacts. These challenges include venturing, customer involvement, external networking, research and development outsourcing. These challenges are also amplified by the fact that SMEs have weak ties with other organization and larger incumbents making it harder for them to acquire knowledge for sustainability purposes (Tendai, 2013; Dodourova & Bevis, 2014). This shows the endless challenge and bottlenecks that manufacturing SMEs operate under and have to face on daily basis.

Lack of sustainability efforts in manufacturing SMEs is attributed to characteristics of SMEs since they often lack the awareness, expertise, skills, finance, and human resources to build the required changes for sustainability within the organisation (Singh et al., 2016). These critical challenges have also been noted and reported by the Global Entrepreneurship Monitor (GEM) that between 2001-2010 South African SMEs suffer from poor management skills which is a result of lack of adequate training and education (NCR, 2011). Shockingly, literature also reveals that the failure rate of manufacturing SMEs in South Africa is 63% to 75% in the first two years of trading and is considered as one of the highest failure rate compared to other developing countries (Olawale & Garwe, 2010; I-Net Bridge, 2011; Mthabela, 2015; Leboea, 2017). The reason for such failure is due to poor innovative strategies and management skills (Hogeforster, 2013). Martin and Staines (2008) and Akinwale et al. (2015) argues that lack of managerial experience, skills development, poor marketing and weak entrepreneurial culture and high barriers to market entry (NCR 2011) are the main reasons why new SMEs fail. Arham (2014) therefore, identified leadership behaviour, skills and qualities of leaders as essential factors that influence manufacturing SMEs innovation, survival and growth.

Problem Statement

Lack of innovation and leadership has been indicated as major challenges facing SMEs, in both managerial and technical expertise (Hossain, 2015). This problem is also supported by literature reviews that financial difficulties facing South African innovation incubators contributes to the low innovation strategies of manufacturing SMEs (Buys & Mbewana, 2007; Masutha & Rogerson, 2014; Dubihlela & Van Schaikwyk, 2014). Therefore, because of that, SMEs also cannot be able to have high skilled personnel to improve their products and services (Goldberg et al., 2014). Furthermore, Kongolo (2010) indicates that lack of financial resources, management skills, and inadequate institutional support influence sustainable growth and affects leadership performance in South African SMEs. Management skills (knowledge, competency, behaviours and attitude) are critical factors needed for innovation and for the survival and growth of SMEs (Olawale & Garwe, 2010). Therefore manufacturing SMEs that fails to continually invest in innovation places itself at greater risk of having products and services marginalized by technologically superior competitors (Dibrell et al., 2008). According to Maladzhi (2012); Lekhanya (2015) South African manufacturing SMEs are straggling due to various factors including leadership and innovation.

Aims and Objectives

The aim of this study is to identify critical factors affecting innovative leadership in attaining business innovation in manufacturing SMEs in KZN to achieve the above aim; the following secondary objectives will be addressed:

1. To ascertain whether education and training influences innovation in manufacturing SMEs

2. To evaluate critical environmental factors affecting business innovation in manufacturing SMEs. These factors are divided into: internal and external factors.

Literature Review

Most SMEs result from implementing the entrepreneurial spirit, through which the entrepreneurs’ activities conducted are in different domains. One aspect of utmost importance is the innovation of manufacturing SMEs as an indicator of the entrepreneurial activity (Nicolescu et al., 2012). According to the National Small Business Act of 1996 as amended by the National Small Business Amendments Acts of 2003 and 2004, an SME is a separate and distinct business entity, including co-operative enterprises and nongovernmental organisations, managed by one owner or more which, including its branches or subsidiaries. The number of employees SMEs have, which is less than 250, commonly distinguishes registered SMEs from other small businesses (International Finance Corporation, 2011).

Manufacturing SMEs play an integral function in the sustainability of South African economy with over 90% of African business operations and contribute to over 50% of African employment and Growth Domestic Product (GDP) (Ramukumba, 2014). This make-up about half of South Africa’s GDP and they provide employment to about 60% of South Africa’s labour force and are instrumental in the growth of any economy (Cant & Wil, 2013; Singh et al., 2016). Minister of Trade and industry Mr Rob Davies has also acknowledge the stagnant growth of manufacturing SMEs and emphasised that in order to resuscitate the South African economy, the government needs to work endlessly to remove administrative red tape that hinder work flow of manufacturing SMEs (South African Government, 2016). However, this has been hindered by the number of manufacturing SMEs closing down due to mismanagement, lack of innovation, business management skills and production (Irjayanti & Azis, 2012) and also lack of access to financial capital.

Innovation in Manufacturing SMEs in South Africa

Manufacturing SMEs need to be creative and also be concerned with the establishment of valuable and useful new products, services or ideas and methods such as ICT adoption (Ismail et al., 2014) for the continuous sustainability of manufacturing SMEs (Woodman, 2008). In other words, innovation is creation or acceptance, adaption and utilization of a value-added novelty in trade and industry spheres, regeneration and expansion of product, services and markets, making of new ways of product development and establishing new demands (Crossan & Apaydin, 2010).

According to SBP SME Report (2014) South African manufacturing SMEs continue to struggle due to hostile business environment, lack of skilled staff, burdensome regulations, tough local economic conditions, lack of finance and the high costs associated with employing skilled staff, leadership behaviour, skills and qualities of leaders (Arham, 2014) are considered as fundamental problems holding back growth and sustainability of manufacturing SMEs. Manufacturing SMEs are exposed to various macro environmental variables specifically, marketing, management, social, human resources and financial related matters (Cant & Wild, 2013). Owing to these critical factors and challenges, many SMEs within South Africa do not have endurance to make it past the second year of trading with failure rates as high as 63% (Robert, 2010). This is due to unavailability of working capital, high rates of income tax and social insurance, predilection for jobs security in larger firms, high skilled employees, government regulations and external environment influences, limits the innovation capacity, and disadvantages owner-managers in terms of their competitive strategies (Demirbas & Matla, 2010).

Internal Factors Influencing Manufacturing SMEs

The internal factors exist within the operational base of an organisation and directly affect the different aspect of business (Obasan, 2014). These are events, factors, human resources, systems, organisational material, structures and conditions inside the organisation that are generally under the control of the company (Hartzell, 2018; Alshura & Al Assuli, 2017). Hitt, Hoskisson & Ireland (2007); Abukhames (2015) asserts that the company’s internal environment is the firm’s resources that determine the strengths and weaknesses of the firm. These factors influence the manufacturing SMEs ability to achieve its objectives and that firms need to develop feasible plans which consequently contribute to the performance of the firm (Oluwadare & Oni, 2015).

Lack of Skilled Labour Affects Innovation of Manufacturing SMEs

As unemployment rate plunged in recent years in South Africa, recruiting skilled labour has become a big issue for many manufacturing SMEs. Worldwide, there is persistent realisation that manufacturing SMEs are integral to nations GDP growth and are the biggest employers within the economies (Fatoki, 2014; Hamad & Karoui, 2011; Karedza et al., 2014; Zalk, 2014). Even though manufacturing SMEs are regarded as long-term potential employers (de Kok et al., 2011), manufacturing SMEs are faced with challenges which affects them from reaching their full potential (Nasr & Rostom, 2013; Moore et al., 2010). Doh & Kim (2014); Lee & Sahu (2017) identified skills shortage as a critical challenge and a labour market crisis that influences performance, development and growth of business as well as quality of production. Zimmermann & Thoma (2016) asserts that the issue of skilled labour is a serious concern as it adversely affects the innovation and development of manufacturing SMEs. This is also highlighted by Zimmermann (2017) who claims that the second biggest barrier to innovation after funding difficulties is a shortage of skilled workers (Healy et al., 2015). This extreme talent gap also puts the firm’s productivity at risk (Nash-Hoff, 2016). Seda (2016) acknowledges the shortage of skilled labour and advises that drastic measures need to be in place to develop and capacitate workers (Mutoko & Kapunda, 2017). Kunz (2015) agrees that without aggressive action, the next decade is expected to bring a shortfall of skilled labour. Donnelly (2018) cautions that the lack of skilled labour act as a barrier to take advantage of internal and external opportunities to expand and grow the firm. Furthermore, skills shortage may deprive manufacturing SMEs economic growth and global competitiveness (Rasool & Botha, 2011).

Stakeholder Influence on Innovation

The influence of shareholders and directors of boards towards the operations of a firm is termed corporate governance. Corporate governance has not been widely studied in respect to SMEs but noteworthy, the relationship between governance and company is often stressed with the context of large companies (Hamad & Karoui, 2011). However, manufacturing SMEs might apply similar governance codes to those pertaining to large businesses, but several elements which have a remarkable impact on affecting governance structure must be taken into account (OCDE, 2006).

Abor & Adjasi (2007) advices manufacturing SMEs to consider corporate governance as the existence of non-executive director or shareholders could help attract better resources and introduce creativity and innovation during decision making. Duca (2012) maintains that better corporate governance enhances the performance of the firm through more efficient management, better asset allocation, better labour practices and efficient innovation. OCDE (2004) argues that good corporate governance should provide proper incentives for the boards and management to pursue objectives relating to innovation, competitive edge, market share and sustainable growth that are in the interest of the firm. This reflects the paramount significance of shareholders as they play an important role in the financing, operations, governance and control aspects of a business (Rachagan and Satkunasingam, 2009; Hamad and Karoui, 2011; Basu, 2018). Henceforth, for manufacturing SMEs who are innovative knowledge-based firms that intend to expand their growth, it is crucial to find shareholders that fit with the company’s distinctive strategy and business model (Guberna, 2016).

Limited/Shortage of Space Affects Innovation and Growth of Manufacturing SMEs

According to Ahmed et al. (2011) manufacturing SMEs encounter and are challenged by many obstacles which stagnant their growth. The authors further identify lack of utility facilities such as electricity, frequent changes in prices of raw materials, high interest rates and transportation costs as critical challenges prohibiting manufacturing SMEs to achieve the desired growth. Dube (2013) also ascertained that lack of finance, high production costs, severe competition from imports, shortages of raw material and inadequate space to carry out production was a persistent hindrance to the growth of manufacturing SMEs. This is further highlighted by Charman (2017); Kanali (2018) that location and access to land, and business infrastructure are fundamental necessity for growth and innovation of manufacturing SMEs. Furthermore, Kamunge et al., (2014) claim that lack of allocation of suitable land to manufacturing SMEs impinges on innovation and growth of the firm and that puts a strain on economic development. A report from Tilisi Developments Limited cited by Kanali (2018) further revealed that the majority of manufacturing SMEs have been subjected to losses in the last five years owing to shortage of space for production and finding premises conducive for manufacturing firms was challenging (National Credit Regulator Report, 2011; Lee, 2014).

External Factors Affecting Innovation in Manufacturing SMEs

According to Chuck & Williams (2001); Ayandibu & Houghton (2017) external environment are all the events happening outside the organisation that have the potential to affect the operations, productivity and innovation of the company and has no control over them. As stated by Fagerberg et al. (2006) innovation heavily depends on external resources whose existence, influence the behaviour and performance of manufacturing SMEs (Voiculet et al., 2010).

Supply Costs Influence on Manufacturing SME Sustainability

Suppliers possess a huge power on the cost of a product as the influence of any supplier heavily depends on the scarcity of the material (Sherman, 2018). Supplier components can significantly influence the quality of the product positively or negatively (Reiss, 2010). This means that sustainable growth is no longer purely within the company’s hands as it has been stretched to incorporate all tasks along its supply network (Halldorsson et al., 2009). This is because suppliers are key in assisting the firm towards understanding the dynamics of the total life cycle impact that the product will have on the environment (Nieman et al., 2017). However, the overall business performance and sustainability will be enhanced if suppliers are able to provide the right product in the right quantity at a reasonable cost (Piderti et al., 2011). Therefore, manufacturing SME suppliers are fundamental and achieving sustainability (Meqdadi et al., 2012).

Social Factors

Social factors play a significant importance towards effective innovation, and entrepreneurs need to pay more emphasis on social factors in order to gain competitive advantage over their competitors (Rujirawanich et al., 2011). As argued by (Genis-Gruber & Öğȕt, 2014) being mindful of the social factors allows entrepreneurs to be innovative which leads to economic growth and development which is imperative to sustaining competitive advantage. Additionally, innovative leadership should realise that in order to be competitive, there needs to be a drastic change surrounding creativity and innovation (Shalley & Gilson, 2004).

Competition within Manufacturing SMEs

Competition poses a great threat to the growth and survival of a firm but at the very same time, it is the competition that is the main factor to achieving economic growth as it motivates and pushes firms to be more productive (Soini & Veseli, 2011). This shows that firm’s competitors are certainly part of the external environment since competing firms do not have control over products, prices and services offered by other firms (Beach, 2017). According to Barney (1991) a firm has a competitive advantage when it implements the strategies of the value creation that has not been introduced by other probable competitors. In Porter (1985) theory, it is reflected that competitive advantage intends to measure a firm’s success relative to its competitors. Basically, competitive advantage is offering consumers greater value by a means of lower costing products or services or offering higher quality services or products which justify higher prices (Pickard-Whitehead, 2018). Kraja & Osmani (2013) argue that manufacturing SMEs have tangible assets, whereas some other has strong intangible assets; both of them give strong impact in creating sustainable competitive advantage. By generating a lower cost or a higher benefit for the firm, these critical resources can create greater residual value for the same delivered value, thus providing competitive advantage for the firm (Ong et al., 2010)

Technology

The adoption of information technology (IT) by manufacturing SMEs nationally and worldwide has been regarded as fundamental to any firm’s operations. It is simply one of the salient elements for remaining competitive (Jabar et al., 2010). Ghobakhloo et al. (2012) concur that IT is needed for daily operations of any firm and there is a need for manufacturing SMEs to invest significant amounts of financial resources in IT to strengthen their competitive position and maintain the firm’s sustainable growth (Premkumar, 2003; Clibanu & Neamtu, 2017). As pointed out by Comin & Hobijn (2008) the significance of technology adoption cannot be causally taken, for example, the rapid growth of Japan after World War II and of the East Asian, Singapore, Hong Kong, Taiwan, and South Korea in the 1990s was largely a function of their ability to quickly adopt new technologies such as the internet. This means that the adoption and usage of IT provides manufacturing SMEs with a greater opportunity to enhance their efficiency and effectiveness, and even to gain competitive advantage through innovation (Moghavvemi et al., 2012; Rahab & Hartono, 2012; Sratopoulos, 2015; Al Bakri, 2017). Choi & Lim (2017) maintains that technological innovation are the drivers of manufacturing SMEs towards achieving production phases.

Despite their important role in alleviating manufacturing SME operations and processes, many manufacturing SMEs face tremendous challenges in their attempts to pursue technological innovation (Gnyawali & Park, 2009; Farsi & Toghraee, 2014). This is also highlighted by Sayed & Sunjka (2016) that South African SMEs in particular face technological advancement. In a study conducted in South Africa by Leboea (2017) the findings revealed that manufacturing SMEs tend to utilize technologies which are not advanced and this puts a strain on the production process and ultimately result in SMEs being uncompetitive in relation to larger firms. This is relatively heavily due to many factors such as financial resources, entrepreneur character, entrepreneur technical skills capacity, age, training and demographic (Kumar et al., 2008; Elbeltagi, et al., 2013; Jafarnejad et al., 2013; Kusumaningtyas & Suwarto, 2015).

Research Methodology

A quantitative research approach was scrutinized and thereafter identified as the appropriate method for this research. This approach was therefore designed to provide the researcher with a clear picture to understand the underpinning reasons for South African manufacturing SMEs inability to be innovative and acquire sustainable growth (Farrelly et al., 2017). Furthermore, based on its scientific objectivity and rational (McLeod, 2017), this approach was identified as ideal to the study as it provided a significant execution in answering the objectives of the study. A homogeneous population for this study was also identified bases on its characteristics (year of existence, turnover, GDP, size of the SME). The population for this study was 400 manufacturing SMEs operating within the surroundings of KwaZulu-Natal. Due to the nature of this study, a quota and convenience sampling was adopted for this study. KwaZulu-Natal is the second largest area with 74976 manufacturing SMEs operating within the surrounding. Using a quota and convenience sampling was able to target 384 participants as an acceptable representative sample size. A questionnaire was used as the measuring instrument designed in a Likert format, with variables being tested on a scale of 1 to 5. With 1 being strongly disagree and 5 being strongly agree. Frequency, descriptive and factor analysis was conducted to have a broader understanding of the number of manufacturing SMEs leadership who were either in agreement or in disagreement with the statements and also to determine significant relationships that might help provide crucial evidence on ways to help improve the current situation of manufacturing SMEs in South Africa.

Data Analysis

Primary data collected from the respondents were coded into the SPSS (24.0 version) computer package. Data captured was double-checked to ensure that information captured was error free. The researcher conducted a Chi-square goodness-of-fit test to determine relationship of variables.

Reliability Test

In order to test reliability and validity of this study, Cronbach’s Alpha was used to test at a 0.75 significant level. The overall reliability scores as shown below were high for items tested. This indicates a high degree of acceptable, consistent scoring for the different categories for this research (Table 1).

| Table 1 Reliability Test | ||

| Variables | No of Items | Cronbach's Alpha |

| Education and training of innovative leadership in manufacturing SMEs | 4 | 0.809 |

| Environmental barriers that affect innovative leadership towards sustainable growth of SMEs | 11 | 0.798 |

Findings

The focus of this section was to identify the critical factors that influence business innovation of manufacturing SMEs in KwaZulu-Natal. The following statements are based on education and training of innovative leadership in manufacturing SMEs.

Education and Training of Innovative Leadership

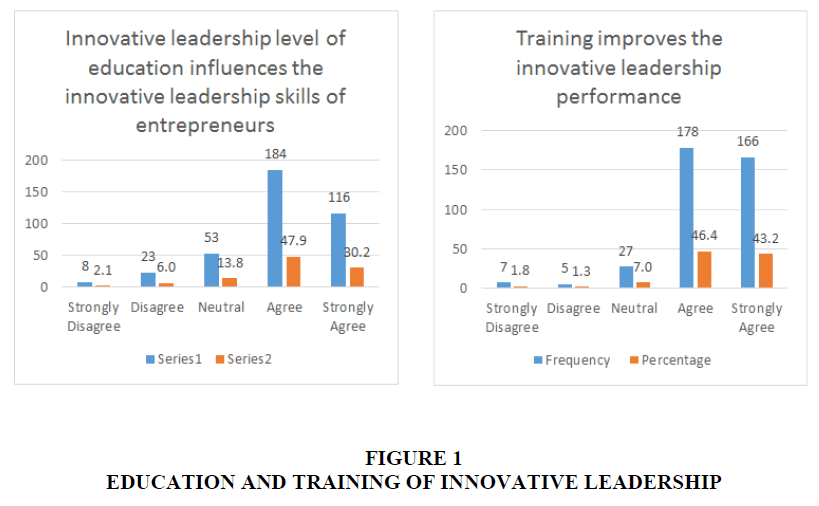

Figure 1 shows whether innovative leadership level of education influences the innovative leadership skills of entrepreneurs. Figure 1 reflects the results on whether training improves innovative leadership performance.

The findings above depict a clear view that innovative leadership level of education has a direct influence on innovative leadership skill. The largest group of the respondents 184 (47.9%) agreed and strongly agreed 116 (30.2%) that innovative leadership level of education influences the innovative leadership skills of entrepreneur. 53 (13.8%) respondents were neutral to the statement while only 23 (6 %) disagreed and 8 (2.1%) strongly disagreeing respectively to the statement. This means that the majority of the respondents considered and perceived education as a determinant to exploiting innovation. These findings are supported by a Chi-square test that was performed to determine how significant innovative leadership level of education influences the innovative leadership skills of entrepreneurs. The test conducted provided results that indicated that (X2=276.339; df=4; P=0,000) for this variable, signalling that indeed innovative leadership level of education influences the innovative leadership skills of entrepreneurs.

As depicted in Figure 1 a significant number of respondents 178 (46.4%) agreed and strongly agreed 166 (43.2%) that training improves the innovative leadership performance. These findings are supported by a Chi-square test conducted to determine whether training improves the innovative leadership performance. The results indicates that (X2=400.851; df=4; P =0.000) for this variable, indicating that training has a significant influence on the improvement of innovative leadership performance.

Very few respondents 7(1.8%) & 5(1.3%) disagreed with the statement and felt that training has no significant impact to innovative leadership performance. Therefore, training can be seen as a pivotal instrument to enhance the capabilities and field related knowledge of innovative leadership.

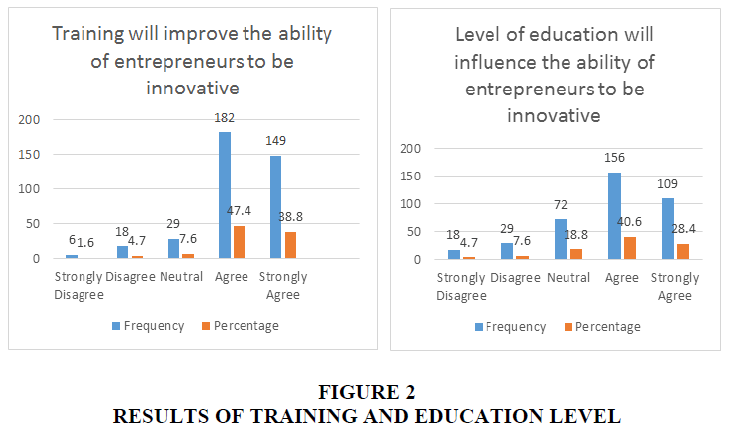

Figure 2 shows the results pertaining to whether training improves the ability of entrepreneurs to be innovative. Figure 2 reflects the results on whether the level of education influences the ability of entrepreneurs to be innovative.

As depicted in Figure 2 a significant number of respondents 182 (47.4%) and 149 (38.8%) agreed and strongly agreed that training is essential as it improves the ability of entrepreneurs to be innovative. These findings are supported by a Chi-square test conducted to determine whether training improves the ability of entrepreneurs to be innovative. The results indicates that (X2=352.016; df=4; P=0,000) for this variable, indicating that training has a significant influence on the ability of entrepreneurs to be innovative. A smaller number of respondents 29(7.6%) were neutral to the statement whilst 18 (4.7%) disagreed with only 6 (1.6%) strongly disagreeing to the statement. This means that these respondents see no need and pay no attention to training to help them strengthen and improve their skills.

As depicted in Figure 2 significant number of respondents 156 (40.6%) and 109 (28.4) agreed and strongly agreed respectively that the level of education has a positive influence on the ability of entrepreneurs to be innovative. These findings are supported by a Chi-square test conducted to determine whether training improves the innovative leadership performance. The results indicates that (X2=170.245; df=4; P=0,000) for this variable, indicating that the level of education will influence the ability of entrepreneurs to be innovative. This means that the respondents viewed studying further and the attainment of postgraduate degrees as a necessity to innovative leadership in order for them to broaden their understanding in the manufacturing sector and be able to instigate calculative innovation that is going to positively influence the operations of the business. However, a smaller group of respondents 72 (18.8%) were neutral to the statement, whilst only 29 (7.6%) and 18 (4.7%) further disagreeing and strongly disagreeing with the statement. The following statements are based on environment barriers that affect innovative leadership towards sustainable growth of SMEs.

Environmental Barriers That Affect Innovative Leadership towards Sustainable Growth

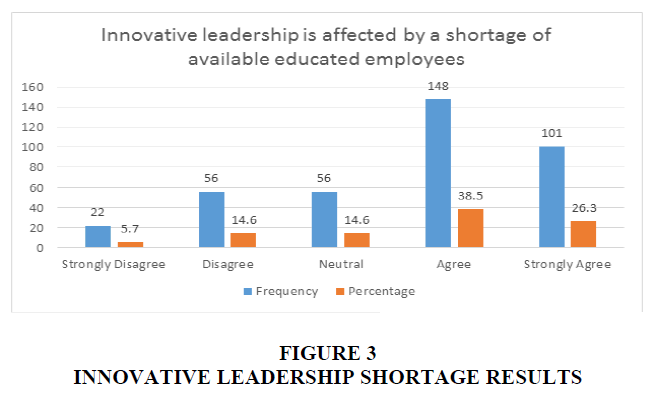

Figure 3 shows the results pertaining to whether Innovative leadership is affected by a shortage of available educated employees. Figure 3 also reflects the results on whether innovation is affected by an appropriate mission statement which entrepreneurs keep to as reflected in Figure 3 above, the majority of the respondent (47.9%) in Figure 1 viewed education as fundamental to innovation. In the same tune, Figure 3 shows that innovation in manufacturing SMEs is slow due to the shortage or unavailability of educated employees to help instigate the process of innovation. This means that in order for innovation to be a success in any firm, innovative leadership needs be educated and also have educated employees to contribute and help fast track innovation. These findings are supported by a Chi-square test conducted to ascertain whether innovative leadership is affected by a shortage of available educated employees. The results indicates that (X2=124.324; df = 4; P=0,000) for this variable, signalling that a shortage of available educated employees has a direct influence on innovative leadership.

Therefore, a moderate number of the respondents 148 (38.5%) and 101 (26.3%) agreed and strongly agreed with the statement. A considerate number of respondents 56 (14.6%) were neutral to the statement whilst 56 (14.6%) and 22 (5.7%) felt that innovation is not influenced by the shortage of educated employees.

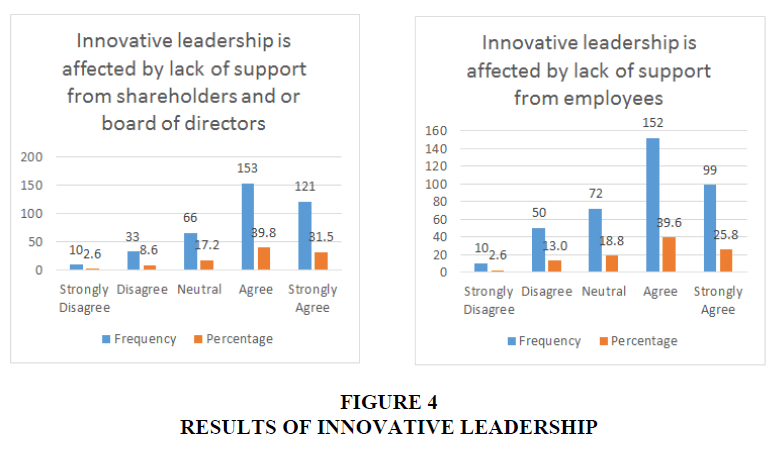

Figure 4 shows the results pertaining to whether innovative leadership is affected by lack of support from shareholders and or board of directors. Figure 4 reflects the results on whether innovative leadership is affected by lack of support from employees. As depicted in Figure 4 a moderate number of the respondents 153(38.9%) agreed and 121(31.5%) further strongly agreed that innovative leadership is affected by lack of support from shareholders and or board of directors. These findings are supported by a Chi-square test conducted to ascertain whether innovative leadership is affected by lack of support from shareholders and or board of directors. The results indicates that (X2 =186.125; df= 4; P =0,000) for this variable, signalling that innovative leadership is affected by lack of support from shareholders and or board of directors. A considerable number of the respondents 66(17.2%) were neutral, whilst only 33(8.6%) disagreed and with 10(2.6%) strongly disagreeing with the statement. Therefore, it can be considered that due to the costs incurred during business innovation, shareholders and board of directors have limited or shortage of funds to invest in business innovation or they see no need to innovate their businesses.

As depicted in Figure 4 a moderate number of respondents 152(39.6%) agreed and 99(25.8%) further strongly agreed that innovative leadership is affected by lack of support from employees. These findings are supported by a Chi-square test conducted to ascertain whether innovative leadership is affected by lack of support from employees. The results indicates that (X2 =148.188; df =4; P =0,000) for this variable, reflecting that innovative leadership is affected by lack of support from employees. A smaller number of the respondents 72(18.8%) were neutral to the statement, while only 50(13%) and 10(2.6%) were in disagreement with the statement. According to Sieczka (2011) this is due to resistance to new ideas and change, and more often than not, employees are comfortable in routine work.

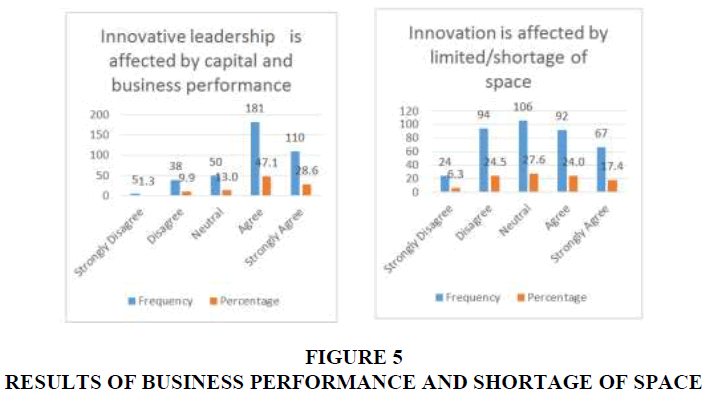

Figure 5 shows the results pertaining to whether innovative leadership is affected by capital and business performance. Figure 5 reflects the results on whether Innovation is affected by limited/shortage of space.

As depicted in Figure 5 more as half of the respondents 181(47.1%) and 110(28.6%) agreed and strongly agreed that innovative leadership is affected by capital and business performance. A smaller number of the respondents 50(13%) were neutral to the statement, whilst only 38(9.9%) disagreed and a further 5(1.3%) strongly disagreeing with the statement. These findings clearly show that capital is an undoubted need that instigates and promotes innovation of manufacturing SMEs. Therefore, innovative leadership need to come up with progressive strategies to help their businesses. These findings are supported by a Chi-square test conducted to ascertain whether innovative leadership is affected by capital and business performance. The results indicates that (X2 =251.807; df = 4; P =0,000) for this variable, reflecting that capital and business performance has a massive influence on innovative leadership ability to be innovative.

As depicted in Figure 4 a moderate number of the respondents 106(27.6%) and 94 (24.5%) were neutral and disagreed respectively on whether limited or shortage of space affected the innovation of manufacturing SMEs. In contrast, a considerate number of respondents 92 (24%) and 67 (17.4%) agreed and strongly agreed that they find limited spaces for business innovation and expansion for the purpose of manufacturing a hindrance to firms’ innovation quest.

Therefore, it can be agreed to some extent that the shortage of space for manufacturing purposes has influence on business innovation and subsequent growth of manufacturing SMEs.

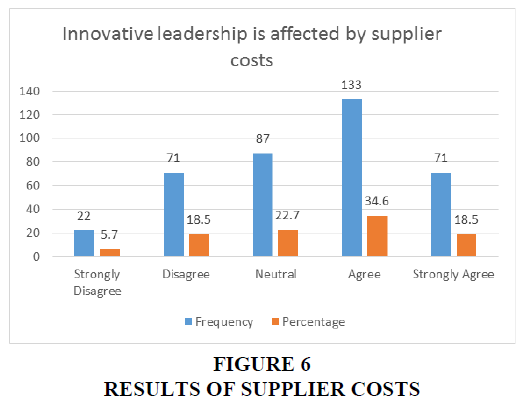

Figure 6 shows the results pertaining to whether innovative leadership is affected by supplier costs. Figure 6 reflects the results on whether innovative leadership is affected by marketing intermediaries.

As depicted in Figure 6 a moderate number of the respondents 133(34.6%) agreed that innovative leadership is affected by supplier costs. A considerable number of respondents 87 (22.7%) were neutral to the statement, whilst 71(18.5%) strongly agreed with only 71(18.5%) and 22 (5.7%) disagreed and strongly disagreed respectively with the statement. Therefore, innovative leadership need to find strategic ways to keep their supplier costs at a reasonable price.

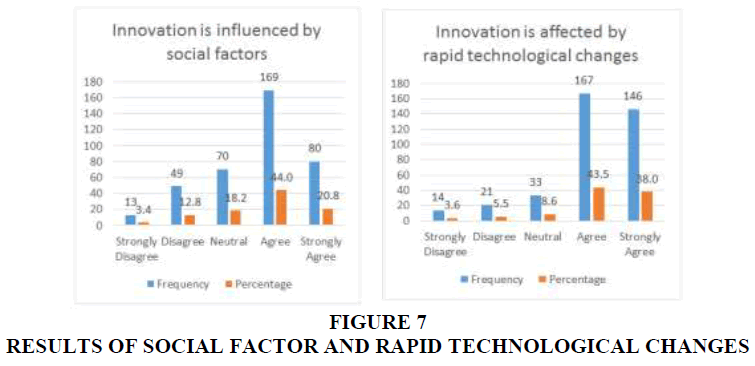

Figure 7 shows the results pertaining to whether innovative leadership is affected by social factors. Figure 7 reflects the results of whether innovative leadership is affected by rapid technological changes.

As shown in Figure 7 a significant number of respondents 169(44%) and 80(20.8%) agreed and strongly agreed that innovation is influenced by social factors. A smaller number of respondents 70(18.2%) were neutral, whilst 49(12.8%) disagreed and 13(3.4%) strongly disagreed respectively with the statement. These findings are supported by a Chi-square test conducted to ascertain whether innovative leadership is affected by social factors. The results indicates that (X2 =175.837; df = 4; P =0,000) for this variable, reflecting that innovative leadership is affected by social factors. This means that the respondents are fully aware that any changes in social preference automatically prompt manufacturing SMEs to rapidly change their products in order to meet the needs of the people and customers.

As shown in Figure 7 a significant number of respondents 167(43.5%) and 146(38%) agreed and strongly agreed that rapid technological changes affect innovation in manufacturing SMEs. Only 33 (8.6%) of the respondents were neutral to the statement with 21(5.5%) and 14 (3.6%) disagreeing and strongly disagreeing respectively to the statement. These findings are supported by a Chi-square test conducted to ascertain whether rapid technological changes affect innovation in manufacturing SMEs. The results indicates that (X2 =287.386; df = 4; P = 0,000) for this variable, reflecting that rapid technological changes challenges manufacturing SMEs due to the limited resources they have. This means that innovative leadership need to come up with decisive measures to help them keep up with technology improvements if they are to contest for a rigid market share against bigger organisations.

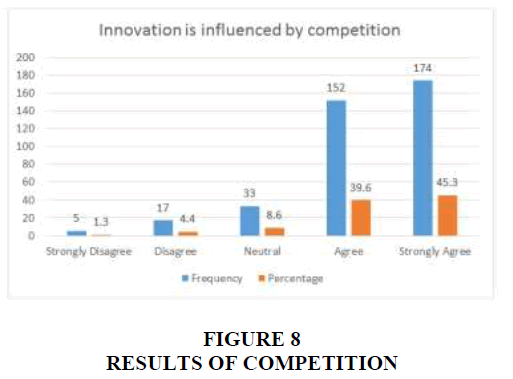

Competition poses a great threat to the growth and survival of a firm but in the same wave length, it is the competition that encourages and motives SMEs to seek innovative ways to be more productive and meet the needs of the customers in wider spectra and also to be able to achieve economic growth (Soini & Veseli 2011). Based on the findings on Figure 8 a significant number of respondents agreed 174(45.3%) and strongly agreed 152(39.6%) that innovation is influenced by competition. These findings are supported by a Chi-square test conducted to ascertain whether innovation is influenced by competition. The results indicates that (X2 =337.937; df = 4; P =0,000) for this variable, reflecting that competition among firms influences innovation. This is due to innovation being a strategic tool that is necessary for improvement, creation and sustainability of the business (Tohidi & Jabbari, 2012; Distanont & Khongmalai, 2018). Therefore, although manufacturing SMEs have limited capital to instigate huge innovations, they are however forced by competitors to rapidly innovate in some way in order to maintain their sustainability and have a strong competitive advantage. A small number of the respondents 33(8.6%) were neutral to the statement and only 17(4.4%) disagreed and 5(1.3%) strongly disagree respectively with the statement, meaning they felt that innovation has no influence or bearing towards competition.

Recommendations

The primary objectives of this study were to identify critical factors affecting innovative leadership in attaining business innovation in manufacturing SMEs in KZN. The recommendation is based on the study objectives. The results showed that business innovation is affected by innovative leadership education and training, internal and external factors. The following recommendations have been suggested.

In order for manufacturing SMEs to obtain sustainable growth, innovative leadership need to start realising that business innovation is a fundamental element towards growth of a firm. They also need to understand that education and training play a pivotal role in innovation. As education and training enhances ones’ abilities and critical thinking skills. Furthermore, education and training can provide innovative leadership and employees with field related skills and knowledge to improve general manufacturing processes which in turn can enhance sales and profit margins. Furthermore, education, especially tertiary education produces more growth and imparts knowledge and skills necessary for business development and growth.

Due to the important role manufacturing SMEs play in South African economy, and complexity they face in their quest for survival, the government need to provide much needed assistance in terms of field related training. Monitoring system should also be established to check the progress made by those who participated in those training.

The results also showed that environmental barriers affect innovative leadership towards sustainable growth in manufacturing SMEs. It is recommended that innovative leadership need to recruit or hire educated employees who will be able to integrate and promote the mission of the firm. Innovative leadership need to build a strong relationship with their suppliers, marketing intermediaries and customers. This will help the firm to meet the expectations of the customers and reinforcing its recognition to the market.

The result reflected that rapid technological changes also affect business innovation. Innovative leadership, shareholders and stakeholder need to adjust and be ready for any economic changes occurring globally. They need to make decisive decisions and be able to study technological advancement that is a need for their business innovation and subsequent growth.

Conclusion

Based on the findings of the study, it has been concluded that in order for manufacturing SMEs to be innovative and be able to sustain their growth, drastic changes need to be implemented. Education and skills training for innovative leadership and employees needs to be considered as a strategic tool in establishing, implement and promoting business innovation that is going to support business growth. Furthermore, this study also concludes in line with the study conducted by Hogeforster (2013) that the lack of qualified workforce and better educated innovative leadership are the major bottlenecks influencing innovation in manufacturing SMEs. In view of environmental barriers influencing innovative leadership, manufacturing SMEs need to study and understand external environmental changes and developments in order to prepare and plan ahead and avoid any predicaments that might halt business innovation and growth. The overall conclusion of this study is that regardless of the numerous challenges, with capital challenges being the most documented in the literature review, innovative leadership need to pursue innovation both in business processes and technological advancement if they are to compete and be sustainable in this hostile business environment.

References

- Abor, J., & Adjasi, C.K.D. (2007). Corporate governance and the small and medium enterprises sector: Theory and implications. Corporate Governance: The International Journal of Business in Society, 7(2), 111-122.

- Abukhames, H. (2015). Internal factors that may affect the business organisation.

- Ahmed, F., Rahman, M., & Haque, M. (2011). Constraints of manufacture based small and medium-sized enterprises (SME) development in Bangladesh. Journal of Social and Development Sciences, 1(3), 91-100.

- Akinwale, O.P., Adu, E., & Seriki, I. (2015). Exploring challenges faced by small business owners on poverty reduction in rural Eastern Cape, South Africa. American Research Journal of Humanities and Social Sciences, 1(2), 33-39.

- Al Bakri, A.A. (2017). The impact of social media adoption on competitive advantage in the small and medium enterprises. International Journal of Business innovation and Research, 13(2), 255-269.

- Alawneh, A.A. (2015). The impact of mission statement on performance: An exploratory study in the Jordanian Banking Industry. Journal of Management Policy and Practice, 16(4), 73-87.

- Alshura, M.S.K., & Assuli, A.H. (2017). The impact of internal environment on performance excellence in Jordanain Public Universities from faculty points of view. International Journal of Business and Social Science, 8(1), 45-57.

- Arham, A.F. (2014). The relationship between leadership behaviour, entrepreneurial orientation and organisational performance in Malaysian small and medium enterprises. PhD Philosophy School of Management, RMIT University. Australia.

- Ayandibu, A.O., & Houghton, J. (2017). External forces affecting small businesses in South Africa: A case study. Journal of Business and Retail Management Research, 11(2), 49-64.

- Barney, J. (1991). Firm resources and sustained competitive advantage. Journal of Management, 17(1), 99-120.

- Bart, C.K., & Baetz, M.C. (1998). The Relationship between mission statements and firm performance: An exploratory study. Journal of Management Studies, 36(6), 823-853.

- Bart, C.K., & Hupfer, M. (2004). Mission statements in Canadian hospitals. Journal of Health Organizations and Management, 18(2), 92-110.

- Basu, C. (2018). The importance of shareholders in business.

- Battisti, M., & Wilson, A. (2012). The role of intermediaries in the small business transfer process.

- Beach, J. (2017). External environmental factors in business.

- Bessy, C., & Chauvin, P. (2013). The power of market intermediaries: From information to valuation process. Valuation Studies, 1(1), 83-117.

- Buys, A.J. & Mbewana, N.P. (2007). Key success factors for business incubation in South Africa: The Godisa case study. South African Journal of Science, 103(9), 356-358.

- Cant, M.C., & Wiid, J.A. (2013). Establishing the challenges affecting South African SMEs. International Business & Economics Research Journal, 12(6), 707-716.

- Charman, A. (2017). Micro-enterprise predicament in township economic development: Evidence from Ivory Park and Tembisa. South African Journal of Economic and Management Sciences, 20(1), 1-14.

- Choi, Y.S., & Lim, U. (2017). Contextual factors affecting the innovation performance of manufacturing SMEs in Korea: A structural equation modelling approach. Sustainability, 9, 1-15.

- Clibanu, O., & Neamtu, D.M. (2017). The impact and importance of new technologies in business development in context of economic diversity.

- Comin, D.A., & Hobijn, B. (2008). The importance of adopting new technologies.

- Crossan, M.M. & Apaydin, M. (2010). A multi-dimensional framework of organizational innovation: A systematic review of the literature. Journal of Management Studies, 47(6), 1154-1191.

- De Kok, J., Vroonhof, P., Verhoeven, W., Timmermans, N., Kwaak, T. Snijders, J., & Westhof, F. (2011). Do SMEs create more and better jobs?

- Dermol, V. (2012). Relationship between mission statement and company performance. Scientific Annals of Alexandru loa. Cuza University of lasi: Economic Sciences Series, 59(1), 321-336.

- Dermol, V. (2012). Relationship between mission statement and company performance. Scientific Annals of Alexandru loa. Cuza University of lasi: Economic Sciences Series, 59(1), 321-336.

- Desmidit, S., Prinzie, A., & Decramer, A. (2011). Looking for the value of mission statements: A meta-analysis of 20 years of research. Management Decision, 49(3), 468-483.

- Dibrell, C., Davis, P.S. & Craig, J.B. (2008). Fuelling innovation through information technology in SMEs.

- Distanont, A., & Khongmalai, O. (2018). The role of innovation in creating advantage. Kasetsart Journal of Social Sciences, 1-7.

- Dodourova, M., & Bevis, K. (2014). Networking innovation in the European car industry: Does the open innovation model fit? Transportation Research Part A: Policy and Practice. Elsevier, 69, 252-271.

- Doh, S., & Kim, B. (2014). Government Support for SME innovations in the regional industries: The case of government financial support program in South Korea. Research Policy, 43(9), 1-13.

- Donnelly, E. (2018). Manufacturing SMEs widen incentives in bid to attract key staff.

- Dube, H. (2013). Growth constraints of manufacturing small to medium enterprises (SMEs) in Zimbabwe: A case study of manufacturing SMEs in Masvingo. Journal of International Academic Research for Multidisciplinary, 1(10), 455-468.

- Dubihlela, J., & Van Schaikwyk, P.J. (2014). Small business incubation and the entrepreneurial business environment in South Africa: A theoretical perspective. Mediterranean Journal of Social Sciences, 5(23), 264-269.

- Duca, F. (2012). Does corporate governance enhance firm performance? An empirical literature evidence.

- Elbeltagi, I., Al Sharji, Y., & Hardaker, A. (2013). The role of the owner-manager in SMEs’ adoption of information and communication technology in the United Arab Emirates. Journal of Global Information Management, 21(1), 23-50.

- Farrelly, N., King, A., Wesley, M., & White, H. (2017). Muddy boots and smart suits: Researching Asia-Pacific affairs. Singapore: ISEAS Publishing.

- Farsi, J.Y., & Toghraee, M.T. (2014). Identification of the main challenges of small and medium sized enterprises in exploiting of innovative opportunities (Case study: Iran SMEs). Journal of Global Entrepreneurship Research, 4(4), 1-15.

- Fatoki, O. (2014). The impact of managerial competencies on the performance of immigrant-owned enterprises in South Africa. Mediterranean Journal of Social Sciences, 5(6), 141-144.

- Genis-Gruber, A., & Öğȕt, H. (2014). Environmental factors affecting innovation strategies of companies: Customers and suppliers effect. Social and Behavioral Sciences, 150, 718-725.

- Ghobakhloo, M., Hong, T.S., Sabouri, M.S., & Zulkifli, N. (2012). Strategies for successful information technology adoption in small and medium-sized enterprises. Information, 3, 36-76.

- Gnyawali., & Park, B.R. (2009). Co-opetition and technological innovation in small and medium-sized enterprises: A multilevel conceptual model. Journal of Small Business Management, 47(3), 308-330.

- Goldberg, J., Habberton, G., & Ractiffe, T. (2014). SiMODiSA: Accelerating growth of small and medium enterprises in South Africa: Policy recommendations for enhancing the start-up / SME ecosystem in South Africa.

- Guberna. (2016). Re-designing corporate governance to promote innovation.

- Halldorsson, A., Kotzab, H., & Skjott-Larsen, T. (2009). Supply chain management on the crossroad to sustainability: a blessing or a curse? Logist. Res. 1, 83-94.

- Hamad, S.B., & Karoui, A. (2011). The SMEs governance mechanisms practices and financial performance: Case of Tunisian industrial SMEs. International Journal of Business and Management, 6(7), 216-225.

- Hartzell, W. (2018). How internal and external factors drive organisational change.

- Healy, J., Mavromaras, K., & Sloane, P.J. (2015). Adjusting to skill shortages in Australian SMEs. Applied Economics, 47(24), 1-36.

- Hitt, M., Hoskisson, R., & Ireland, R. (2007). Management of Strategy. 7th Ed. USA: Thomson South-Western.

- Hogeforster, M. (2013). Future challenges for innovations in SMEs in the Baltic Sea Region. Procedia-Social and Behavioral Sciences, 110, 241-250.

- Hossain, M. (2015). A review of literature on open innovation in small and medium-sized enterprises. Journal of Global Entrepreneurship Research, 5(6).

- Ikupolati, A.O., Adeyeye, M.M., Oni, E.O. Olatunle, M.A. & Obafunmi, M.O. (2017). Entrepreneurs’ managerial skills as a determinant for growth of small medium enterprises (SMEs) in Nigeria. Journal of Small Business Entrepreneurship Development, 5(1), 1-6.

- Irjayanti, M., & Azis, A.M. (2012). Barrier factors and potential solutions for Indonesian SMEs. Procedia Economics and Finance, 4, 3-12.

- Ismail, K., Omar, W.Z.W., Soehod, K., Senin, A.A. & Akhtar, C.S. (2014). Conference: Conference: Proceedings of the 2014 international conference on economics and business administration II (EBA '14), At Prague, Czech Republic, Mathematical Methods In Engineering And Economics. April 2014.

- Jabar, J., Soosay, C., & Santa, R. (2010). Organizational learning as an antecedent of technology transfer and new product development: A study of manufacturing firms in Malaysia. Journal of Manufacturing Technology Management, 22(1), 25- 45

- Kamunge, M.S., Njeru, A., & Tirimba, O.I. (2014). Factors affecting the performance of small and micro enterprises in Limuru Town Market of Kiambu Country, Kenya. International Journal of Scientific and Research Publications, 4(12), 1-20.

- Kanali, N. 2018. Warehousing shortage hurting economic growth in Kenya.

- Karedza, G., Sikwila, M.N., Mpufu, T., & Makurumidze, S. (2014). An analysis of the obstacles to the success of SMEs in Chinhoyi Zimbabwe. European Journal of Business and Management, 6(6), 38-42.

- Kongolo, M. (2010). Job creation versus job shedding and role of SMEs economic development. African Journal of Business Management, 4(11), 2288-2295.

- Kraja, Y., & Osmani, E. (2013). Competitive advantage and its impact in small and medium enterprises (SMEs) (Case of Albania). European Scientific Journal, 9(16), 76-85.

- Kumar, N., Rose, R.C., & D’Silva, J.L. (2008). Predictors of technology deployment among malaysian teachers. American Journal of Applied Sciences, 5(9), 1127-1134.

- Kunz, J. (2015). SME speaks: Lack of skilled workers challenges manufacturers.

- Kusumaningtyas, N., & Suwarto, D.H. (2015). ICT adoption, skill and use differences among small and medium enterprises managers based on demographic factors. Procedia-Social and Behavioral Sciences, 169, 296-302.

- Leboea, S.T. (2017). The factors influencing SME failure in South Africa. Master of commerce in Development Finance Degree. University of Cape Town.

- Lee, K.W., & Sahu, D.K. (2017). Training levy-rebate incentive scheme and SME training consortium program to address unemployment and low productivity in SMEs – A Korean Policy Case. Global Delivery Initiative, April, 1-26.

- Lee, N. (2014). What holds back high-growth firms? Evidence from UK SMEs. Small Business Economics, 43(1), 183-195.

- Legrand, C., & Weiss, D.S. (2011). How leaders can close the innovation gap.

- Legrand, C., & Weiss, D.S. (2011). How leaders can close the innovation gap.

- Lekhanya, L.M. (2015). Key internal factors affecting the small, medium and micro enterprises (SMMEs) marketing strategies in rural South Africa. Problems and Perspectives in Management, 13(2), 411-417.

- Maladzhi, W. R. (2012). Analysis of innovative leadership and sustainability of SMEs in the Western Cape Province, South Africa. Doctor of Technology: Mechanical Engineering in the Faculty of Engineering, Cape Peninsula University of Technology. South Africa.

- Martin, G., & Staines, H. (2008). Managerial competencies in small firm. International Business Management, 4(2), 2010, 67-75.

- Masutha, K., & Rogerson, C.M. (2014). Small enterprise development in South Africa: The role of business incubators. The Journal of Nicolaus Copernicus, 26(26), 141-155.

- Meqdadi, O., Johnsen, T., & Johnsen, R. (2012). The role of SME suppliers in implementing sustainability. IPSERA 2012 Conference, Apr 2012, Napoli, Italy.

- Moghavvemi, S., Hakimian, F., & Feissal, T.M.F.T. (2012). Competitive advantages through IT innovation by SMEs. Social Technologies, 2(1), 24-39.

- Moore, C.W., Petty, J.W., Palich, L.E., & Longenecker, J.G. (2010). Managing small business: An entrepreneurial emphasis. 15th Ed. New Delhi, India: South Western.

- Mosoma, D. (2014). The significance of effective mission statement in business performance: The case of the banking sector in Tanzania. European Journal of Business and Management, 6(1), 92-100.

- Mthabela, T.E. (2015). Assessing the causal failures of emerging manufacturing SMEs in Johannesburg. Faculty of Commerce, Law and Management, University of the Witwatersrand. Master of Management specializing in entrepreneurship and new venture creation. Johannesburg.

- Mutoko, W.R. & Kapunda, S.M. (2017). Factors influencing small, medium and micro-sized enterprises’ borrowing from banks: the case of the Botswana manufacturing sector. Acta Commercii - Independent Research Journal in the Management Sciences, 17(1), 1-9.

- Nasr, S., & Rostom, A. (2013). SME contributions to employment, job creation, and growth in the Arab world.

- Nicolescu, L., & Nicolescu, C., & Nicolae, E. (2012). Romanian SME’s and their human resource management: Recent trends and proposals for future.

- Nieman, W., Hall, G., & Oliver, K. (2017). South African 3PL firms’ approaches to sustainable supply chain management. Journal of Contemporary Management, 14, 204-237.

- Obasan, K.A. (2014).The impact of business environment on the survival of small scale business in Nigeria. International Journal of Management and Business Research, 4(3), 165-170.

- Olawale, F., & Garwe, D. (2010). Obstacles to the growth of new SMEs in South Africa: A principal component analysis approach. African Journal of Business Management, 4(5), 729-738.

- Ong, J.W., Ismail, H.B., & Goh, G.G. (2010). The competitive advantage of small and medium enterprises (SMEs): The role of entrepreneurship and luck. Journal of Small Business & Entrepreneurship, 23(3), 373-391.

- Peng, M.W., Lee, S., & Hong, S.J. (2013). Entrepreneurs as intermediaries. Journal of World Business.

- Piderit, R., Flowerday, S., & Von Solms, R. (2011). Enabling information sharing by establishing trust in supply chain: a case study in the South African automotive industry. South African Journal of Information Management, 13(1), 473-478.

- Porter, M.E. (1985). Competitive Advantage. The Free Press: New York.

- Premkumar, G.A. (2003). A meta-analysis of research on information technology implementation in small business. International Journal of Computer and Electrical Engineering, 13(91), 121.

- Rachagan, S., & Satkunasingam, E. (2009). Improving corporate governance of SMEs in emerging economies: A Malaysian experience. Journal of Enterprise Information Management, 24(4), 468-485.

- Ramukumba, T. (2014). Overcoming SMEs challenges through critical success factors: A case of SMEs in the Western Cape Province, South Africa. Economic and business Review, 16(1), 19-38.

- Rasool, F., & Botha, C.J. (2011). The nature, extent and effect of skills shortages on skills migration in South Africa. South African Journal of Human Resource Management, 9(1), 287-299.

- Reiss, B. (2010). Building a good relationship with suppliers.

- Robinson, R. 2002. What’s the benefit of a mission or vision statement?

- Rujirawanich, P., Addison, R., & Smallman, C. (2011). The effects of cultural factors on innovation in Thai SME. Management Research Review, 34(12), 1264-1279.

- Rungani, E., & Potgieter, M. (2018). The impact of financial support on the success of small, medium and micro enterprises in the Eastern Cape Province. Acta Commercii-Independent Research Journal in the Management Sciences, 18(1), 1-12.

- Sayed, Z., & Sunjka, B.P. (2016). Investigating and evaluating the influence of supply chain structure on supply chain risk. South African Journal of Industrial Engineering, 27(3), 122-135.

- Seda Report. (2012). Analysis of the needs, state and performance of small and medium businesses in the Agriculture, Manufacturing, ICT and Tourism Sectors in South Africa.

- Seda. (2016). Accelerating SMME growth in South Africa.

- Shalley, C., & Gilson, L.L. (2004). What leaders need to know: A review of social and contextual factors that can foster or hinder creativity? The Leadership Quarterly, 15(1), 33-53.

- Sherman, F. (2018). What are internal & external environmental factors that affect business?

- Sieczka, K. (2011). Cause and effect: Barriers to creativity and innovation.

- Singh, S., Olugu, E.U., & Musa, S.N. (2016). Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. ELSEVIER, 40, 608-613.

- Singh, S., Olugu, E.U., & Musa, S.N. (2016). Development of sustainable manufacturing performance evaluation expert system for small and medium enterprises. Procedia CIRP, 40, 609-614.

- Soini, E., & Veseli, L. (2011). Factors influencing SMEs growth in Kosovo. Bachelor’s thesis. Turku University of Applied Sciences.

- Taiwo, A.A., Lawal, F.A., & Agwu, M.E. (2016). Vision and mission in organization: Myth or heuristic device? The International Journal of Business & Management, 4(3), 127-134.

- Tendai, C. (2013). Networks and Performance of Small and Medium Enterprises (SMEs) in Different Stages of the Life Cycle: A Case Study of a Small Business in the Netherlands. Journal of Communication, 4(2), 89-94.

- Tohidi, H., & Jabbari, M.M. (2012). Innovation as a success key for organizations. Procedia Technology, 1, 560-564.

- Van de Vrande, V., De Jong, J.P.J., Vanhaverbeke, W., & De Rochemont, M. (2009). Open innovation in SMEs: Trends, motives and management challenges. Technovation, 29, 423-437.

- Van Wyngaardt, M. (2018). Signs of manufacturing recovery, despite ongoing metals industry pressures.

- Van Wyngaardt, M. (2018). Signs of manufacturing recovery, despite ongoing metals industry pressures.

- Voiculet, A., Belu, N., Parpandel, D.E. & Rizea, C. (2010). The impact of external environment on organizational development strategy.

- Zalk, N. (2014). What is the role of manufacturing in boosting economic growth and employment in South Africa?

- Zhang, H., Garrett, T., & Liang, X. (2015). The effects of innovation-oriented mission statements on innovation performance and non-financial business performance. Asian Journal of Technology Innovation, 23(2), 157-171.

- Zimmermann, V. (2017). SME innovations: Seven reasons for a decline in the share innovators.

- Zimmermann, V., & Thoma, J. (2016). SMEs face a wide range of barriers to innovation-support policy needs to be broad-based.