Research Article: 2023 Vol: 29 Issue: 6S

Competences for Industry 4.0 in Innovation Environments: A Field Study at Technology Parks in Rio Grande Do Sul, Brazil

Sandra Iepsen, University in Santa Cruz do Sul

Dantom Guilherme Helfer, University in Santa Cruz do Sul

Rejane Frozza, University in Santa Cruz do Sul

Daniel Pacheco Lacerda, University of Vale do Rio dos Sinos

Ana Julia Dal Forno, Santa Catarina Federal University

Liane Mahlmann Kipper, University in Santa Cruz do Sul

Citation Information: Kipper, L.M., Dal Forno. A.J., Lacerda. P.D., et al. (2023). Competences for industry 4.0 in innovation environments: A field study at technology parks in rio grande do sul, Brazil. Academy of Entrepreneurship Journal, 29(S6), 1-17.

Abstract

Purpose: Learning environments that allow the development of the skills needed for professional training, whether linked to education, research or industry, are vital in the context of the fourth industrial revolution. The objective of this study was to identify the skills needed for professionals to remain in markets in constant digital transformation, according to the perception of university representatives, in this case managers of Technology Parks (TPs) associated with the Rede Gaucha de Ambientes de Inovacao (Reginp; 2019); and other representatives of government and industry.

Design/Methodology: A review of the literature provided knowledge about this topic, which helped in the elaboration of a questionnaire and subsequent field study, in which fourteen (14) managers of TPs in Rio Grande do Sul, Brazil participated. For data analysis, the multicriteria method MOORA (Multi-Objective Optimization on the basis of Ratio Analysis) was used.

Research Results: The analysis identified that it is important for professionals to develop soft skills, and that they display creativity, and the ability to work in teams and solve problems, which are all essential to work in industry 4.0 environments. Among hard skills considered necessary, data analysis stood out. A contrast in understanding between representatives of industry and government about which skills should be developed was identified by a questionnaire, which may show a misalignment between these parties.

Originality/Value: The research also identified the technologies most used by companies associated with TPs, namely Information and Communication Technology, cloud computing, integrated systems, sensors, and Internet Services (IoS). These results indicate that even in the Innovation Environment the effective adoption of industry 4.0 is still underway

Keywords

Industry 4.0, Learning Factories, Technology Parks, Competencies, Innovation, Education, Skills.

Introduction

Over the years, industry has undergone various moments of rupture that are known as Industrial Revolutions. The first Industrial Revolution in the nineteenth century was marked by the emergence of the steam engine and the transition from manual labor to mass production. In this period, workers needed little qualification and few skills were required for factory work. The second Industrial Revolution in the twentieth century was highlighted by the use of electric energy and production lines. In this context, workers sought qualification in specific functions and to develop technical skills. Based on information technology (IT), the digital revolution or the third Industrial Revolution emerged in the late twentieth century requiring workers to undertake complex activities and to be trained in theoretical and practical terms (Jacques & Langmann, 2016; Dalenogare et al., 2018). For Jacques and Langmann (2016), educational programs developed by Germany develop not only scientific and professional skills to meet future demands.

The current stage of industrial development requires workers and information and communication systems to work seamlessly and intelligently (Dalenogare et al., 2018). The fourth industrial revolution, which is now well underway, involves a series of changes sparked by the intensive use of technologies, such as the internet of things (IoT), cyber physical systems (CPS), big data and the digitization of corporate operations to generate intelligence about decision making. This movement aims to increase the productivity and efficiency of companies through the use of information and communication technologies (ICT) in a decentralized and autonomous model (Baena et al., 2017).

In this context, the need arises to restructure the organization of work since routine activities may be absorbed by autonomous systems such as equipment and software (Wahl 2015; Motyl et al., 2017) reducing demand for workers' skills. Schwab (2017) comments, for example, that lawyers, financial analysts, journalists, accountants, insurance brokers, librarians and even doctors may have their activities automated to some degree. According to Schwab, the ten professions likely to be automated are: telemarketing, tax calculation, insurance and auto damage assessment, referees and other sports professions, and others. On the one hand, new technologies imply the elimination and reconfiguration of jobs and the skills needed for their execution. On the other hand, it is necessary to train professionals for the purposes of Industry 4.0.

The emergence of different forms of working, such as, digitized environments, virtual spaces, network and hybrid teams (human-robot), require professionals to develop new skills (Richert et al., 2016). This requires the strengthening of soft skills, hard skills and digital skills, which are increasingly important, since they have a direct impact on the changes caused by Industry 4.0 (Richert et al., 2016; Motyl et al., 2017).

To help develop these competencies, the concept of Learning Factories has been disseminated in Latin America to refer to complex learning environments that allow the development of skills needed by professionals, whether they work in education, research or industry. Learning Factories are replicas of part of a manufacturing value chain that are designed to create a formal learning environment (Baena et al., 2017). For Leydesdorff (2012) these innovation environments help to implement Industry 4.0. Concomitantly, there is a need to strengthen the relationships between university, industry and government, known as the “triple helix”. This helps to establish a technologically integrated innovation ecosystem (Etzkowitz & Zhou, 2017). This integration fosters the creation of innovation environments at universities, through Technology Parks, enabling the strengthening and growth of companies and, consequently, the increase and development of regional economies.

In this context, the objective of this study was to identify, in the perception of representatives of universities, Technology Park managers, and representatives of government and industry, the skills needed by Industry 4.0 professionals to remain in the constantly changing market.

The document was structured as follows: this first section has presented an introduction. Section 2 is composed of the theoretical foundation of the study, and reviews concepts about Industry 4.0, and competencies needed in innovation environments and Technology Parks (TP). The methodology is described in section 3. Sections 4 and 5 present, respectively, the analysis of the results and their discussions, and the conclusion of this research. Finally, the references used and appendices are listed.

Literature Review

This section explores the themes Industry 4.0, competence for innovation environments and Technology Parks. The constructs and hypotheses to be investigated are also presented, which support the data collection instrument presented later.

Industry 4.0

Industry 4.0 emerged in 2011 with a strategy to increase the competitiveness of German industry, seeking to develop advanced production systems based on the integration between emerging technologies (Frank et al., 2019). The goal is to provide companies greater autonomy and flexibility throughout their industrial processes, with a focus on mass production, in small batches and customized products (Tortorella et al., 2019). Motyl et al. (2017) considers that Industry 4.0 is based on the widespread use of intelligent networked systems and the Internet of Things (IoT), and the development of intelligent actions, products and processes. From intelligent connections between systems (machines, sensors, work areas, information systems) and the use of the internet, it is possible to analyze data generated to predict failures, self-configure and adapt to changes. For Zhong et al. (2017) Industry 4.0, allows better decision making by establishing real-time communication and cooperative work between humans and machines.

Although the Reference Architecture Model Industry 4.0 (RAMI 4.0) exists, the literature on Industry 4.0 are not consensual and there is no standard for the application and use of technologies (Yli-Ojanpera et al., 2019). Kipper et al. (2020) show that the most representative technologies for Industry 4.0 are CPS, IoT and big data. The integration of technologies will help resolve problems, facilitate the flexibility of production and increase efficiency at companies. Motyl et al. (2017) consider that nine pillars support Industry 4.0, that is, nine emerging high-level technologies, namely: Big data, autonomous robots, simulation, integrated systems, IoT, cybersecurity, cloud computing, additive manufacturing and augmented reality. Zhong et al. (2017) identify five key technologies for intelligent manufacturing, namely: IoT, CPS, cloud computing, big data analytics and information and communication technology (ICT).

In summary, the purpose of Industry 4.0 is to analyze large amounts of data to assist decision making, and obtain quick responses, making production flexible and more efficient, to obtain high quality products and reduce costs, promoting the growth of productivity and the economy, and modifying the profile of the workforce (Motyl et al., 2017; Kipper et al., 2020). Therefore, it is important to rethink human factors, since professionals must develop their skills to maximize the benefits of technologies and improve their performance (Dalenogar et al., 2018).

The transformations brought about by Industry 4.0 require professionals to gain command of activities such as: constant learning, solving complex problems and adapting to changes in organizations. This occurs with the use of intelligence and skills when conducting collaborative work that is, using advanced technologies and man-machine integration, as well as adaptive automation (Mattsson et al., 2020).

Competencies for Innovation Environments

For Kipper et al., (2021) and Richert et al. (2016) the use of Industry 4.0 technologies requires that future engineers have a high degree of adaptability and flexibility since there is a strong tendency for them to be required to handle large amounts of data, solve complex and multidisciplinary problems, and be able to perform collaborative man-machine tasks. These authors also emphasize the increased importance of so-called soft skills, and meta-cognitive and interdisciplinary skills, since employees must become experts in certain subjects, think globally and have a holistic understanding of organizations. Represented by analytical thinking, problem solving skills, communication skills, teamwork and leadership, soft skills will be the last to be replaced by automated processes and, therefore, will be among the most valued (Pérez-Pérez et al., 2018) and the most requested by the fourth industrial revolution (Sobri et al., 2017). Hard skills are skills that are represented by mathematical knowledge, design and investigative and experimental skills, information processing, computer programming and software knowledge (Motyl et al., 2017).

Employees must also have digital skills, which are understood to include both basic digital skills such as the ability to conduct internet searches, as well as advanced digital skills such as specialized knowledge of information technology (IT) (Motyl et al., 2017). These skills enable professionals to explore and face new technological situations, and to analyze, select and critically evaluate data and information, in order to solve problems and build shared and collaborative knowledge (Nyikes, 2018). However Block et al., (2018) identify a gap in knowledge of digital skills among professionals, mainly in IT skills.

This demand for new professional skills requires that universities improve their educational programs, and that companies develop training plans for employees (Pinol et al., 2017). Difficulties in workforce training are evident at universities due to gaps in teaching (Cacciolatti et al., 2017). At companies, employees are often not interested in training programs since they often do not meet their real needs. Employees often lack a sense of belonging and there is poor communication between companies and employees (Pinol et al., 2017).

In the context of changes brought about by Industry 4.0, it is necessary to understand which skills are most important for allowing professionals of the future to remain in the market, connected virtually and with marked competitiveness. Thus, two constructs were established: the first related to soft skills and the second to hard skills. Then, four hypotheses were formulated to understand which skills will be most important for professional development, namely:

H1: Digital transformation establishes a greater need for soft skills than hard skills.

H2: The development of Industry 4.0 has not prioritized the use of digital technologies.

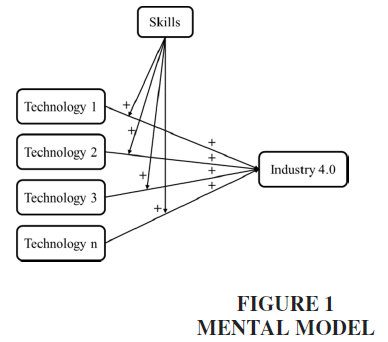

Figure 1 summarizes the mental model proposed in this research.

Technology Parks (TP)

In Brazil, TPs emerged in the 1980s with support from the National Council for Scientific and Technological Development (CNPq) (Pereira et al., 2016).

In this study, a Technology Park is understood to be: “A planned complex for business and technological development, which promotes a culture of innovation, industrial competitiveness, business training and synergies in scientific research, technological development and innovation activities, among companies and one or more Science and Technology Institutions (STI), with or without a link” (Pereira et al., 2016). In Brazil, Technology Park initiatives have multiplied, from 10 in the year 2000 to 103 in 2017, and have a greater concentration (in operation or implementation) in the country’s South and Southeast regions.

University-industry-government relationships are important in the dynamics of innovation environments, in which the interaction between the three parties, known as the triple helix, contributes to the smooth functioning of the whole. The possible benefits of this union are described in Table 1.

| Table 1 Benefits Of University-Business-Government Integration | ||

| University | Business | Government |

| Additional financial resources | Access to qualified and specialized human resources and new knowledge | Regional economic development |

| Regional economic development through the realization of its social function | Cost and risk reduction | Increase in the number of job openings for recent graduates and social development |

| Knowledge of existing real problems |

Troubleshooting specific problems | Development of information for planning and decision making |

| Access to the latest equipment | Belief in the strategic value of technological innovation in the short and long terms | Development of smart cities |

| Incorporation of new information in the teaching and research process |

Access to public resources through cooperative research work | Access to public resources through cooperative research |

| Dissemination of the university's image to the community | Agility in the development of new technologies | National and international recognition of actions for the development of the region covered |

Technology Parks are environments favorable to all types of innovation, whether related to products or services. The participation of universities facilitates the transfer of knowledge from academia to industries or corporations, enabling the rapid development of technologies directly reflected in society in products and services. In this context, public and private investments can boost the growth of a region (Anprotec, 2019).

Methodological Procedures

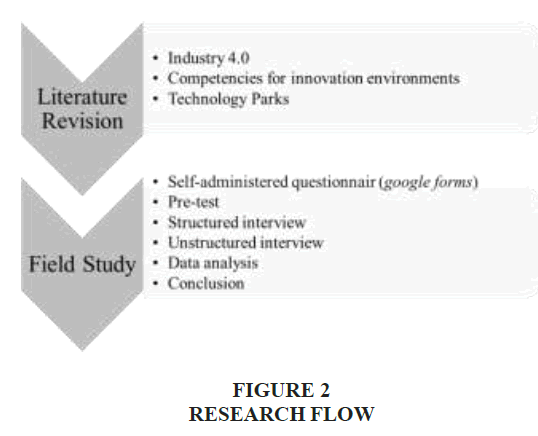

This study was developed in two stages, namely: a literature review and field study. Each step was subdivided as shown in Figure 2.

The purpose of the literature review was to expand knowledge about the topics covered, that is, Industry 4.0, skills needed in innovation environments and Technology Parks. In the second stage, a field study was conducted and composed of: an interview with two representatives, one from the government of Rio Grande do Sul, Brazil, one from the business community, and a questionnaire sent to managers of Technology Parks in the state to understand what skills they believed should be developed by professionals who wish to work in innovation fields. To do so, a non-probabilistic convenience sample was used, which, according to Babbie (1999), is suitable when precise representativeness is not required.

Also called intentional sampling, the sample was selected considering the population's knowledge and research objectives. Although it does not represent a significant population, it can be considered as a pre-test for future research (Babbie, 1999). To understand the perspective of university representatives, managers of Technology Parks associated with the Rede Gaucha de Ambientes de Inovacao (Reginp, 2019), and representatives of government and companies from Rio Grande do Sul state were intentionally sampled.

A continued focus on education can help maintain the skills needed to provide a foundation for regional growth sustained by innovation. Because we recognize the importance of universityindustry- government integration, the focus of this study is on innovation environments in Rio Grande do Sul (Brazil). The population included fourteen (14) Technology Parks, active in Rio Grande do Sul, associated with the Rede Gaucha de Ambientes de Inovacao (Reginp, 2019). To preserve the TP's identity the following nomenclature was used: TP01, TP02, TP03, TP04, TP05, TP06, TP07, TP08, TP09, TP10, TP11, TP12, TP13 and TP14 (2019, <http: // reginp.com.br/parques>).

Most of the innovation environments in Rio Grande do Sul are in the metropolitan region. For this reason, Porto Alegre is the fourth city in the national ranking in the number of startups, 552. According to the Brazilian Startup Association (Abstartups), Rio Grande do Sul has 924 startups, being the state with the third most startups in Brazil, behind only São Paulo and Minas Gerais (https://startupbase.com .br / home / stats, Startupbase. Statistics, 2019). According to the Commercial Report of Zero Hora (2019) TP4 and TP11 were repeatedly recognized as the best in Brazil, becoming international references due to the results they bring to the country's economy (2019,<http://www.cwaclipping.net/sistema/cliente/materia?security=118626dc9992.7901862.129021 60&rn=1>).

The research was structured to identify competencies, that is, the knowledge and skills professionals of the future need to remain in the market considering the possible transformations caused by Industry 4.0.

The semi-structured interviews conducted with the two representatives (one from the government of Rio Grande do Sul and one from the business community), sought to answer the following question: “Considering the current context of digital transformation and Industry 4.0, in your opinion, what are the main skills that should be developed in professionals who want to work in innovation environments or Learning Factories?”.

A questionnaire (Appendix A) was developed, with open and closed questions (multiple choice), in the Google Forms tool. It was evaluated and tested by specialists in the fields of education and innovation, and subdivided into three stages: The first stage sought to collect data related to the TP manager (Q1-Q4). The second stage was dedicated to the TP (Q5-Q8). The third stage focused on understanding the manager's perception of the use of emerging technologies (Q9) and the skills needed by professionals of the future (Q10). Two e-mails with a link to the survey were sent to the managers of the fourteen TPs in Rio Grande do Sul, in August 2019. Since this is an extremely significant sample, other contacts were made through tools such as WhatsApp and Skype. As a result, a 100% rate of return of respondents was obtained. To assist in data analysis, the five-point Likert scale was used ranging from 1 for “not at all important” to 5, “extremely important”. This scale is easy to understand and allows the survey respondents to position themselves according to their level of agreement about the importance of the item (Junior & Da Costa, 2014).

To create a ranking of the technologies most used by companies associated with TPs and to identify the skills that, in the perception of the managers of these TPs, will be paramount for professionals of the future to remain in the market, the multicriteria method Moora (Multi- Objective Optimization on the basis of Ratio Analysis) was used.

The MOORA multicriteria method is a classification tool that helps problem solving. From a decision matrix (Equation 1) a ranking is created that presents a categorization from the best to worst options (Brauers & Zavadskas, 2006; Echakraborty, 2011).

Equation 1

Where, Xij is a measure i, for each respondent j, m is the number of measures and n is the number of respondents. Then, a relationship system is developed for each answer, compared with a denominator that represents all the answers, according to Equation 2 (Karande & Chakraborty, 2012).

Equation 2

Data Analysis and Discussion

Seeking to understand the perspective of the Rio Grande do Sul state government and local businessmen, a representative from each area was sought and the following question was asked: "Considering the current context of digital transformation and Industry 4.0, in your opinion, what are the main skills that should be developed in professionals who wish to work in innovation environments or Learning Factories?" (Rubmann et al., 2015). The responses obtained by the representatives are described in Table 2:

| Table 2 Perception about Competencies | |

| Agents | Replies |

| Government | “I think the main skills in this context are: data analysis (data science, artificial intelligence, etc.); computational simulation of production and computing and automation environments”. |

| Industry | “To be successful in innovation environments, professionals first need to enjoy challenges. In Addition communication skills, strategic thinking, leadership, creativity to solve problems, self-motivation, entrepreneurship and a global mindset are essential, following global trends”. |

Analyzing the responses in Table 2, a difference in opinions is observed among the respondents, since the representative of the Rio Grande do Sul state government sees the need to develop hard skills while the representative of the companies emphasizes the need for professionals who have developed their soft skills.

A compilation and analysis of the data obtained in the field study allows us to observe that most of the managers of the TPs studied have been working for a short period of time. Most respondents (64%) had worked for up to five years as manager of a TP, while 36% had worked from six to ten years.

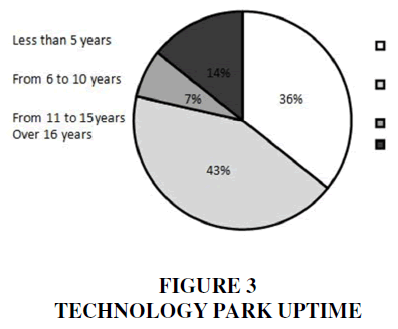

As for universities linked to TPs, ten (10) are private universities while four (4) are federal universities. It was found that the TP in Rio Grande do Sul are young, with 36% are less than 5 years old, 43% between 6 and 10 years old, 7% between 11 and 15 years old and 14% over 16 years old, as shown in Figure 3.

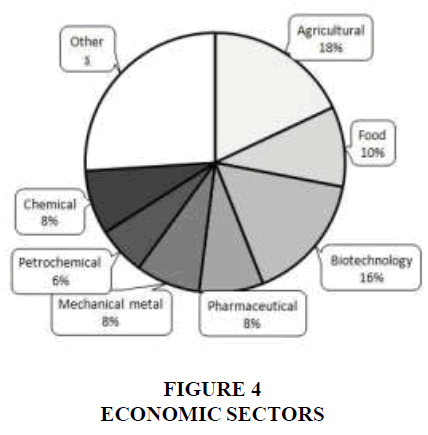

Figure 4 represents the different sectors of the economy where the companies associated with the TPs studied operate.

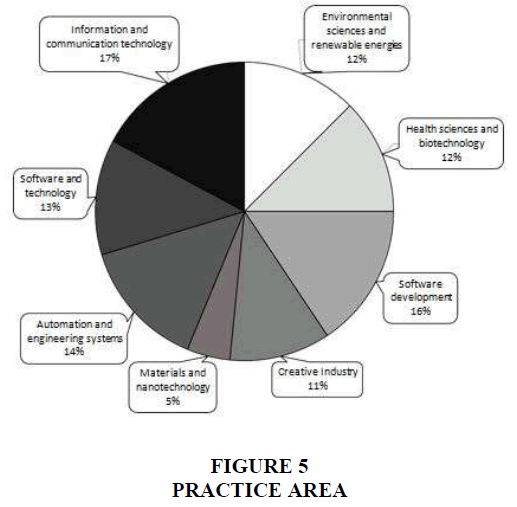

It is observed that the agricultural (18%) and biotechnology sectors (16%) are of paramount importance for the development of the Rio Grande do Sul economy. There is also a wide diversification of sectors due to the item entitled “other”, which accounted for 26% of the total. The sectors mentioned in this item are dominated by: life sciences, logistics, security, entertainment, retail, services, environment, and others. Figure 5 presents the areas of activity of the companies associated with the TP.

The Information and Communication Technology area stood out as the most explored in these companies (17%), followed by Software Development (16%). Other areas of activity were also identified, such as semiconductors and telecommunications.

Table 3 was designed to help better understand the relationship between the times a TP has been operating and the number of associated companies. The category of universities (private or public) to which the Technology Parks are linked is also highlighted.

| Table 3 Relationship between time of Activity and Associated Companies | |||

| Technology Parks |

Associated companies |

Administrative Category |

Uptime |

| TP04 | 170 | Private | over 16 years |

| TP11 | 93 | Private | over 16 years |

| TP01 | 73 | Private | from 11 to 15 years |

| TP05 | 63 | Private | less than 5 years |

| TP03 | 55 | Private | from 6 to 10 years |

| TP08 | 45 | Public | from 6 to 10 years |

| TP07 | 39 | Public | from 6 to 10 years |

| TP10 | 25 | Private | less than 5 years |

| TP09 | 16 | Private | from 6 to 10 years |

| TP06 | 15 | Private | less than 5 years |

| TP12 | 13 | Private | from 6 to 10 years |

| TP02 | 10 | Public | less than 5 years |

| TP13 | 5 | Private | less than 5 years |

| TP14 | 5 | Public | from 6 to 10 years |

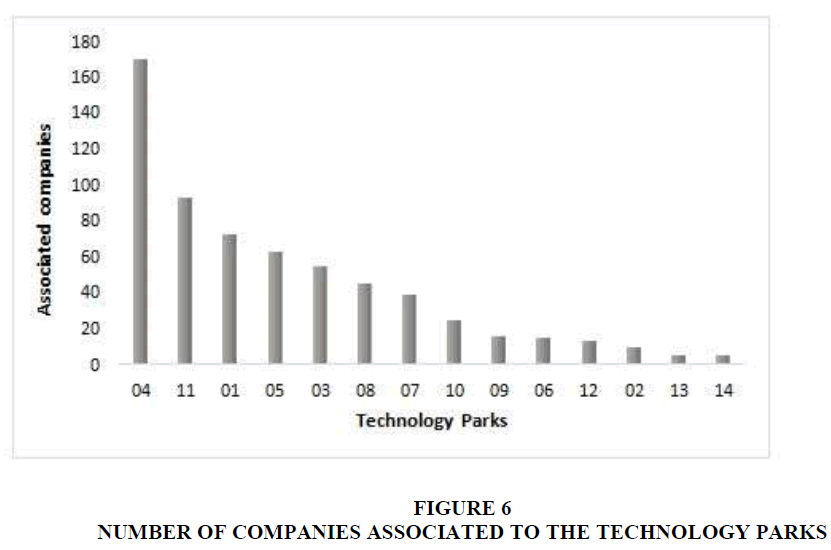

Table 3 indicates that the TPs with the largest number of associated companies are those that have been active for a longer period of time, that is, TP04 and TP11, which have been active for more than sixteen years, and TP01 which has been active for more than 10 years. The five TPs with the most associated companies are linked to private universities. Figure 6 shows the relationship between the TPs in Rio Grande do Sul and the number of associated companies.

We also sought to understand which technologies are used by the companies associated with the TPs studied. Based on the weights attributed to the managers' responses, it was possible to apply the multicriteria method MOORA to obtain a ranking by degree of use. The data obtained are presented in Table 4.

| Table 4 Relationship between Time of Activity and Associated Companies | ||

| Ranking | Technology | Result MOORA |

| 1 | Information and communication technology | 1,44 |

| 2 | Cloud Computing | 1,22 |

| 3 | Integrated systems | 1,03 |

| 4 | Sensors | 1,01 |

| 5 | Internet of Service (IoS) | 1,00 |

| 6 | Collaborative Software | 0,94 |

| 7 | Embedded systems | 0,93 |

| 8 | Big Data | 0,93 |

| 9 | Internet of Things (IoT) | 0,91 |

| 10 | Artificial intelligence | 0,89 |

| 11 | Robots | 0,85 |

| 12 | Augmented Reality | 0,78 |

| 13 | Wearable | 0,73 |

| 14 | Neural networks | 0,67 |

| 15 | Cyber-Physical- System (CPS) | 0,66 |

The technologies mentioned were reported to be used by the companies associated with the TPs in this study. It was observed that the five technologies currently most used are:

• Information and Communication Technology (ICT): developed at the end of the 20th century, the advances in these technologies (computers, mobile technologies, internet, and others) have progressed rapidly in several fields (hardware and software) becoming the basis for the new industrial revolution (Kang et al., 2016).

• Cloud Computing: is supported by a network that supports technological connectivity through cloud computing. Client-centered, it is designed to make production more flexible and allocate resources, increasing efficiency on production lines, reducing costs over a product's life cycle, responding to the variable demand generated by the client (Kang et al., 2016; Da Costa et al., 2019).

• Integrated Systems: involve the integration of advanced production systems such as Flexible Manufacturing Systems, Reconfigurable Manufacturing Systems or Integrated Computer Manufacturing Systems (Mittal et al., 2019).

• Sensors: this is technology that is considered basic that has the function of collecting data in real time through a central controller. Sensors have different applications and greater or lesser complexity according to the nature of the environment in which it is operating (Kang et al., 2016).

• Internet of Services (IoS): integrates various complex systems and technologies such as simulation, modeling, cloud computing, big Data and others (Kang et al., 2016).

Prisecaru (2016) highlights the main characteristics of industrial revolutions, and considers the main technological achievements of the Third Industrial Revolution to be the use of computers and robots, which reinforced the development of the automobile and chemical industries. In the Fourth Industrial Revolution the author highlights the use of the Internet, 3D printers and genetic engineering, which led to the use of more advanced technology in industry. Schwab (2017) cites three points that differentiate the Third from the Fourth Industrial Revolutions, the first of which is speed (which is exponential in the Fourth), resulting from a multifaceted and interconnected world, where new technologies generate other even more qualified ones. The second point is breadth and depth, which occurs through the combined use of various technologies, and the third and last point, is the systemic impact, since it generates transformations across society.

This study sought to identify competencies needed for professionals to remain prepared, according to the perception of the managers of TPs in RS, for changes caused by the use of emerging Industry 4.0 technologies. Table 5 is based on the managers' responses regarding the degree of importance of each skill. It was prepared with the multicriteria method MOORA.

| Table 5 Competencies by Degree Of Importance | ||

| Ranking | Hard and Soft Skills | Result MOORA |

| 1 | Creativity | 0,69 |

| 2 | Problem solving | 0,69 |

| 3 | Team work | 0,68 |

| 4 | Data analysis | 0,67 |

| 5 | Communication | 0,66 |

| 6 | Initiative | 0,66 |

| 7 | Proactivity | 0,65 |

| 8 | Innovation | 0,65 |

| 9 | Collaborative work | 0,63 |

| 10 | Adaptability | 0,62 |

| 11 | Give and receive feedback | 0,62 |

| 12 | Flexibility | 0,61 |

| 13 | Interdisciplinarity | 0,61 |

| 14 | Strategic vision of knowledge | 0,61 |

| 15 | Leadership | 0,59 |

| 16 | Automation | 0,58 |

| 17 | Self-management | 0,57 |

| 18 | Self-organization | 0,57 |

| 19 | Information and Communication Technology | 0,57 |

| 20 | Software Development and Security | 0,54 |

| 21 | Algorithms | 0,53 |

| 22 | Sustainable Development Techniques | 0,50 |

| 23 | General Systems Theory | 0,49 |

Based on the data obtained, the responses and perceptions of the managers of the Technology Parks of Rio Grande do Sul regarding skills professionals will need in the future to work in innovation environments emphasized: creativity, problem solving, teamwork, data analysis and communication.

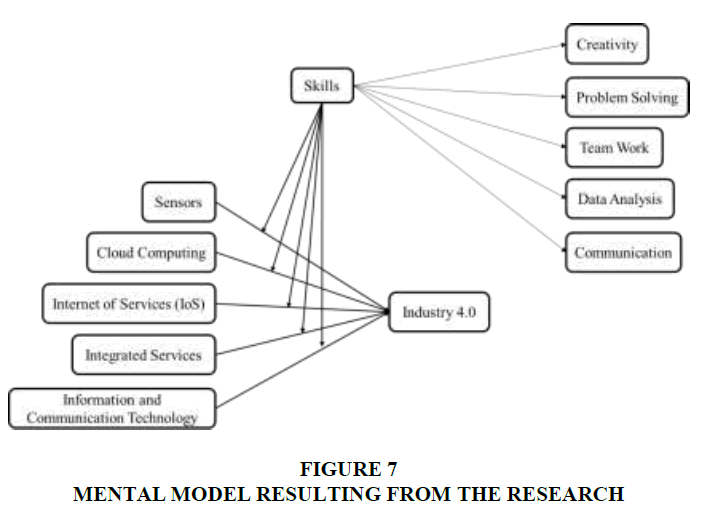

From the data obtained in this field study, it was possible to return to the model initially proposed (Figure 1), which resulted in the elaboration of Figure 7.

The new mental model (Figure 7) shows that companies associated with innovation environments, represented here by TP in Rio Grande do Sul, have mainly been using the following technologies: sensors, cloud computing, internet of services, integrated systems and information and communication technologies (ICT). Cieslik (2021) reinforces this research finding but. For professionals to accompany the evolution of the proposed technologies and remain in markets that undergo constant transformation; they must develop skills such as creativity, problem solving, teamwork, data analysis and communication. This shows that professionals must develop hard and soft skills. Professionals who develop their soft skills will have opportunities to remain in the market, which are thus the most important skills for working in innovation environments and with the as the habilitating technologies of Industry 4.0 discussed by Ahuett-Garza & Kurfess (2018).

Conclusion

The objective of this research was to identify the competences needed by professionals of Industry 4.0 to be able to remain in markets in constant transformation, according to the perceptions of representatives of universities, managers of Technology Parks associated to the Reginp, and representatives of state government and industry. The study showed that professionals must develop their behavioral skills, which are also known as soft skills.

The responses of the representatives of government and industry revealed that they have different opinions about the theme, since the government representative emphasized the development of technical skills (hard skills), while the representative the industry emphasized the importance of professionals who have a taste for challenge and who have or want to develop their behavioral skills (soft skills), and remain in constant transformation as is the market. This indicates that there is a need for alignment in communication between the components of the triple helix of university-government-industry, and that even within Innovation Environments the effective adoption of industry 4.0 is still ongoing.

The responses of the Technology Park managers gathered in the field study reveal two important points. First, that the main technologies used by companies associated with TPs in Rio Grande do Sul are information and communication technologies (ICT), cloud computing, integrated systems and sensors. Second that the skills professionals need to remain in markets undergoing digital transformation are:

• Soft skills, which involve: creativity or creative thinking, the ability to work in a team and problem solving abilities.

• Hard skills also stood out due to the importance of data analysis.

Analyzing the ranking as a whole, soft skill - those inherent to human behavior – are seen to be more important than hard skills. This reinforces affirmations of Pérez-Pérez; Gómez and Sebastián (2018) who found that these skills will be more difficult to be replaced by automated processes and will be those most requested in the future.

It was concluded that, from the research questions and the hypotheses that, in the experts' opinion, the set of soft skills seems to be more important to digital transformation than the set of hard skills and that there is no prioritization of use of digital technologies for the development of I4.0, with information and communication technologies, cloud computing, integrated systems, sensors and internet of services (IoS) being those most used in the innovation environments studied.

It should also be noted that in the perception of the Technology Park managers in Rio Grande do Sul, to keep up with digital transformations, soft skills are more important for professionals who want to remain in dynamic and increasingly competitive markets. Hard skills are also important, however, to a lesser extent according to the research results.

Regarding the TPs, it was observed that TP4 and TP11, which have more than 16 years of activity, have the largest number of associated companies and are internationally recognized.

As suggestions for future work, we can emphasize the importance of replicating the research in other innovation environments in Brazil.

Acknowledgement

This study was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior [Coordination for Improvement of Personnel in Higher Education] - Brazil (CAPES) – Financing Code 001. The authors would also like to thank CNPq and Fapergs for their financial support, UNISC and the Graduate Program in Industrial Systems and Processes.

References

ANPROTEC. (2019). Technology parks: Study, analysis and propositions. 560.

Ahuett-Garza, H., & Kurfess, T. (2018). A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manufacturing Letters, 15, 60-63.

Indexed at, Google Scholar, Cross Ref

Babbie, E. (1999). Survey research methods. Belo Horizonte: Ed. UFMG, 1.

Baena, F., Guarin, A., Mora, J., Sauza, J., & Retat, S. (2017). Learning factory: The path to industry 4.0. Procedia Manufacturing, 9, 73-80.

Indexed at, Google Scholar, Cross Ref

Block, C., Kreimeier, D., & Kuhlenkötter, B. (2018). Holistic approach for teaching IT skills in a production environment. Procedia Manufacturing, 23, 57-62.

Indexed at, Google Scholar, Cross Ref

Brauers, W. K., & Zavadskas, E. K. (2006). The MOORA method and its application to privatization in a transition economy. Control and cybernetics, 35, 445-469.

Cacciolatti, L., Lee, S. H., & Molinero, C. M. (2017). Clashing institutional interests in skills between government and industry: An analysis of demand for technical and soft skills of graduates in the UK. Technological Forecasting and Social Change, 119, 139-153.

Indexed at, Google Scholar, Cross Ref

Chakraborty, S. (2011). Applications of the MOORA method for decision making in manufacturing environment. The International Journal of Advanced Manufacturing Technology, 54(9-12), 1155-1166.

Indexed at, Google Scholar, Cross Ref

Cieślik, E. (2021). Towards the industry 4.0: Have ICT services improved the position of Central and Eastern Europe in global production linkages?. Manufacturing Letters, 28, 11-16.

Indexed at, Google Scholar, Cross Ref

Da Costa, M. B., Dos Santos, L. M. A. L., Schaefer, J. L., Baierle, I. C., & Nara, E. O. B. (2019). Industry 4.0 technologies basic network identification. Scientometrics, 121(2), 977-994.

Indexed at, Google Scholar, Cross Ref

Dalenogare, L. S., Benitez, G. B., Ayala, N. F., & Frank, A. G. (2018). The expected contribution of Industry 4.0 technologies for industrial performance. International Journal of Production Economics, 204, 383-394.

Indexed at, Google Scholar, Cross Ref

Etzkowitz, H., & Zhou, C. (2017). Triple Helix: innovation and entrepreneurship university-industry-government. Advanced studies, 31(90), 23-48.

Frank, A. G., Dalenogare, L. S., & Ayala, N. F. (2019). Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economics, 210, 15-26.

Indexed at, Google Scholar, Cross Ref

Jacques, H., & Langmann, R. (2016). Dual study: A smart merger of vocational and higher education. In 2016 IEEE Global Engineering Education Conference (EDUCON) (pp. 434-437). IEEE.

Indexed at, Google Scholar, Cross Ref

Junior, S. D. D. S., & Costa, F. J. (2014). Measurement and verification scales: a comparative analysis of Likert and Phrase Completion scales. PMKT – Brazilian Magazine of Marketing, Opinion and Media Research, 15(1-16), 61.

Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., Son, J. Y., & Do Noh, S. (2016). Smart manufacturing: Past research, present findings, and future directions. International journal of precision engineering and manufacturing-green technology, 3(1), 111-128.

Indexed at, Google Scholar, Cross Ref

Karande, P., & Chakraborty, S. (2012). Application of multi-objective optimization on the basis of ratio analysis (MOORA) method for materials selection. Materials & Design, 37, 317-324.

Indexed at, Google Scholar, Cross Ref

Kipper, L. M., Furstenau, L. B., Hoppe, D., Frozza, R., & Iepsen, S. (2020). Scopus scientific mapping production in industry 4.0 (2011–2018): a bibliometric analysis. International Journal of Production Research, 58(6), 1605-1627.

Kipper, L. M., Iepsen, S., Dal Forno, A. J., Frozza, R., Furstenau, L., Agnes, J., & Cossul, D. (2021). Scientific mapping to identify competencies required by industry 4.0. Technology in Society, 64, 101454.

Leydesdorff, L. (2012). The triple helix, quadruple heli., and an N-tuple of helices: Explanatory models for analyzing the knowledge-based economy?. Journal of the Knowledge Economy, 3(1), 25-35.

Indexed at, Google Scholar, Cross Ref

Mattsson, S., Fast-Berglund, A., Li, D., & Thorvald, P. (2020). Forming a cognitive automation strategy for Operator 4.0 in complex assembly. Computers & Industrial Engineering, 139, 105360.

Indexed at, Google Scholar, Cross Ref

Mittal, S., Khan, M. A., Romero, D., & Wuest, T. (2019). Smart manufacturing: Characteristics, technologies and enabling factors. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 233(5), 1342-1361.

Motyl, B., Baronio, G., Uberti, S., Speranza, D., & Filippi, S. (2017). How will change the future engineers’ skills in the Industry 4.0 framework? A questionnaire survey. Procedia Manufacturing, 11, 1501-1509.

Indexed at, Google Scholar, Cross Ref

Noveli, M., & Segatto, A. P. (2012). University-company cooperation process for technological innovation in a technology park: empirical evidence and proposition of a conceptual model. RAI Magazine of Administration and Innovation, 9(1), 81-105.

Nyikes, Z. (2018). Contemporary digital competency review. Interdisciplinary Description of Complex Systems: INDECS, 16(1), 124-131.

Pereira, M. J., Oliveira, E. A. D. A. Q., & de Oliveira, A. L. (2016). Origins of technology parks and contributions to Brazilian regional development. Latin American Journal of Business Management, 7(1).

Pérez-Pérez, M., Gómez, E., & Sebastián, M. A. (2018). Delphi prospection on additive manufacturing in 2030: Implications for education and employment in Spain. Materials, 11(9), 1500.

Indexed at, Google Scholar, Cross Ref

Pinol, T. C., Porta, S. A., Arévalo, M. R., & Minguella-Canela, J. (2017). Study of the training needs of industrial companies in the Barcelona Area and proposal of Training Courses and Methodologies to enhance further competitiveness. Procedia Manufacturing, 13, 1426-1431.

Indexed at, Google Scholar, Cross Ref

Prisecaru, P. (2016). Challenges of the fourth industrial revolution. Knowledge Horizons. Economics, 8(1), 57.

Rede Gaucha De Ambientes De Inovacao - Reginp. 2019. Available at: http://www. http://reginp.com.br/parques.

Richert, A., Shehadeh, M., Willicks, F., & Jeschke, S. (2016). Digital transformation of engineering education-empirical insights from virtual worlds and human-robot-collaboration. International Journal of Engineering Pedagogy, 6(4), 23-29.

Indexed at, Google Scholar, Cross Ref

Rubmann, M., Lorenz, M., Gerbert, P., Waldner, M., Justus, J., Engel, P., & Harnisch, M. (2015). Future of Productivity and Growth in Manufacturing. Boston Consulting.

Schwab, K. (2017). The fourth industrial revolution. Currency.

Sobri, K. M., Hanum, F., Zulnaidi, H., & Ahmad, A. R. (2017). A comparative study of school environment for students' skills development in Malaysia and Indonesia. Kasetsart Journal of Social Sciences, 40(1), 149-154.

Indexed at, Google Scholar, Cross Ref

Startupbase. Statistics. Top 10 States. Available at: https://startupbase.com.br/home/stats. Accessed on: December 19th. 2019.

Tortorella, G., Miorando, R., & Mac Cawley, A. F. (2019). The moderating effect of Industry 4.0 on the relationship between lean supply chain management and performance improvement. Supply Chain Management-An International Journal, 24(2), 301-314.

Wahl, M. (2015). Strategic factor analysis for industry 4.0. Journal of Security & Sustainability Issues, 5(2).

Indexed at, Google Scholar, Cross Ref

Yli-Ojanpera, M., Sierla, S., Papakonstantinou, N., & Vyatkin, V. (2019). Adapting an agile manufacturing concept to the reference architecture model industry 4.0: A survey and case study. Journal of Industrial Information Integration, 15, 147-160.

Indexed at, Google Scholar, Cross Ref

Zero Hora. Commercial Report. P6. Southern region on the global innovation map. December 19th. 2019.

Zhong, R. Y., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616-630.

Indexed at, Google Scholar, Cross Ref

Received: 15-July -2023, Manuscript No. AEJ-23-13986; Editor assigned: 18-July-2023, PreQC No. AEJ-23- 13986(PQ); Reviewed: 31-July-2023, QC No. AEJ-23-13986; Revised: 05-Aug-2023, Manuscript No. AEJ-23- 13986(R); Published: 17-August-2023